Preparation method for ammonium fluoride modified nickel-cobalt-aluminum ternary positive electrode material

A cathode material, ammonium fluoride technology, which is applied in the field of preparation of ammonium fluoride modified nickel-cobalt-aluminum ternary cathode material, can solve the problems of high energy consumption, long preparation time, unfavorable for industrialized production and the like, and achieves low energy consumption , Easy to operate, significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) At room temperature, put ammonium fluoride particles and nickel-cobalt-lithium aluminate powder in an agate mortar with a mass ratio of 0.003:1, and grind for 30 minutes to make them evenly mixed;

[0033] (2) Put the ground mixture in a muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min, and keep it warm for 3 hours;

[0034] (3) After grinding the obtained product, sieve it with 400 mesh to obtain the final product, which is recorded as NCA-F-0.3%-1.

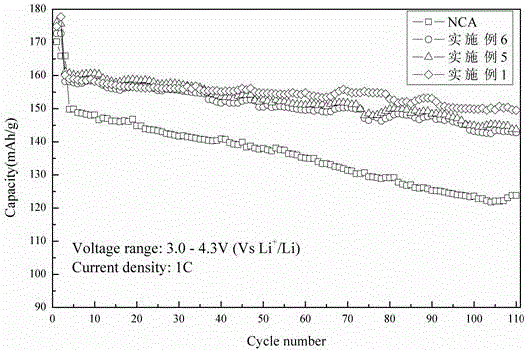

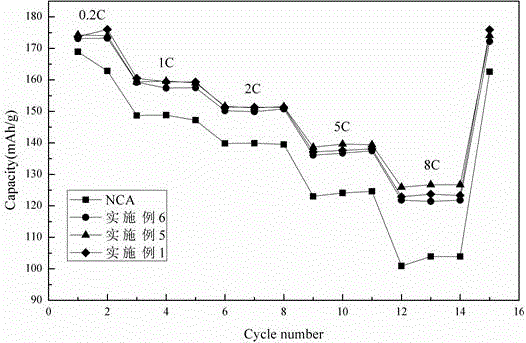

[0035] The electrochemical performance of lithium battery cathode materials was tested by constant current charge and discharge using Wuhan Landian CT2001A charge and discharge instrument. The experimental battery is carried out in a glove box filled with argon, and the electrolyte used is LiPF 6 / EC+DMC+EMC (volume ratio 1:1:1), the diaphragm is Celgard 2400 type diaphragm; the counter electrode is metal lithium sheet. The electrochemical performance of the material was investigated using...

Embodiment 2

[0041] (1) At room temperature, put ammonium fluoride particles and nickel-cobalt-lithium aluminate powder in an agate mortar with a mass ratio of 0.003:1, and grind for 20 minutes to make them evenly mixed;

[0042] (2) Put the ground mixture in a muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min, and keep it warm for 3 hours;

[0043] (3) After grinding the obtained product, sieve it with 400 mesh to obtain the final product, which is recorded as NCA-F-0.3%-2.

Embodiment 3

[0045] (1) At room temperature, put ammonium fluoride particles and nickel-cobalt-lithium aluminate powder in an agate mortar with a mass ratio of 0.003:1, and grind for 60 minutes to make them evenly mixed;

[0046] (2) Put the ground mixture in a muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min, and keep it warm for 3 hours;

[0047] (3) After grinding the obtained product, sieve it with 400 mesh to obtain the final product. Recorded as NCA-F-0.3%-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com