High-capacity monocrystal-like lithium nickel cobalt aluminate positive electrode material and preparation method thereof

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of increasing the cation mixing degree of positive electrode materials, reducing material capacity and cycle performance, and achieving the purpose of suppressing side effects. Reaction, reduce calcination temperature and time, prevent corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

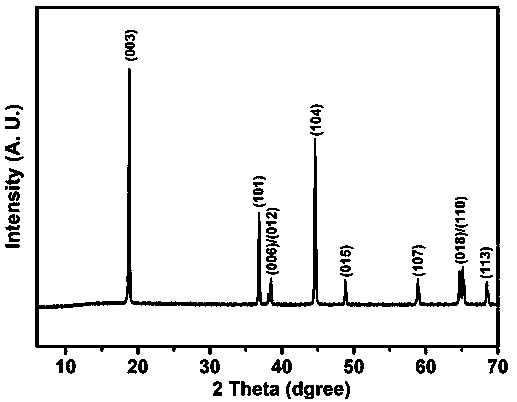

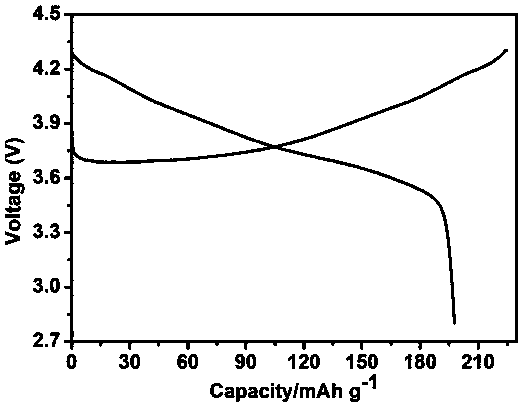

[0027] The preparation method of the high-capacity single-crystal nickel-cobalt-lithium aluminate cathode material in this example is as follows:

[0028] 1) Preparation of quasi-single-crystal nickel-cobalt lithium aluminate precursor: calcining nickel-cobalt lithium aluminate hydroxide precursor at 500°C for 4 h to obtain oxides, cooling to room temperature, crushing through a 200-mesh sieve, and then oxidizing The material was crushed by ball milling to obtain a particle size distribution of D 50 6 μm quasi-single-crystal nickel-cobalt-lithium-aluminate precursor;

[0029] 2) Preparation of single-crystal nickel-cobalt lithium aluminate cathode material: according to the mass ratio of lithium hydroxide to precursor is 46%, additive B 2 o 3 The mass ratio to the precursor is 5%. Under an oxygen atmosphere, the first-stage calcination temperature is 500°C for 5 h, the second-stage calcination temperature is 750°C for 15 h, and the heating rate from 500°C to 750°C is 5°C / m...

Embodiment 2

[0033] The preparation method of the high-capacity single-crystal nickel-cobalt-lithium aluminate cathode material in this example is as follows:

[0034] 1) Preparation of quasi-single-crystal nickel-cobalt-lithium-aluminate precursor: calcining the nickel-cobalt-lithium-aluminate hydroxide precursor at 200°C for 10 hours to obtain the oxide, cooling to room temperature, crushing through a 200-mesh sieve, and then crushing the oxide Perform ball milling to obtain a particle size distribution of D 50 4.8 μm quasi-single crystal nickel cobalt lithium aluminate precursor;

[0035] 2) Preparation of single-crystal nickel-cobalt lithium aluminate cathode material: according to the mass ratio of lithium hydroxide to the precursor is 55%, the mass ratio of additives NaCl and KCl to the precursor is 0.05%, and the mass of NaCl and KCl is 1: 1. In an oxygen atmosphere, the calcination temperature of the first stage is 400°C for 10 hours, the temperature of the second stage is 800°C f...

Embodiment 3

[0039] The preparation method of the high-capacity single-crystal nickel-cobalt-lithium aluminate cathode material in this example is as follows:

[0040] 1) Preparation of quasi-single crystal nickel cobalt lithium aluminate precursor: calcining the nickel cobalt lithium aluminate hydroxide precursor at 450°C for 2 h to obtain the oxide, which was cooled to room temperature and crushed through a 200-mesh sieve, and then oxidized The material was crushed by ball milling to obtain a particle size distribution of D 50 7.5 μm quasi-single crystal nickel cobalt lithium aluminate precursor;

[0041] 2) Preparation of single-crystal nickel-cobalt lithium aluminate cathode material: according to the mass ratio of lithium hydroxide to the precursor is 40%, the mass ratio of the additive KF to the precursor is 20%, in the oxygen atmosphere, the first stage of calcination Calcination at 550°C for 4 h, second-stage calcination at 600°C for 24 h, heating rate from 550°C to 600°C at 1°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com