Lithium nickel cobalt aluminate composite material and preparation method and application thereof

A technology of nickel-cobalt-lithium-aluminate and composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of material performance degradation, and achieve the effect of avoiding performance degradation and facilitating application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

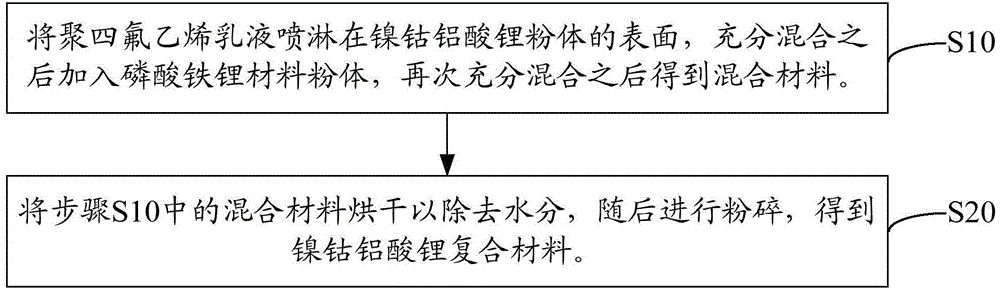

[0036] like figure 1 The preparation method of the shown nickel-cobalt-lithium-aluminate composite material comprises the steps:

[0037] S10. Spray the polytetrafluoroethylene emulsion on the surface of the lithium nickel cobalt aluminate powder, mix thoroughly, add the lithium iron phosphate material powder, and mix thoroughly again to obtain a mixed material.

[0038] The polytetrafluoroethylene emulsion includes polytetrafluoroethylene, nonionic surfactant and water. The solid content of the polytetrafluoroethylene emulsion is 20% to 60%. The mass ratio of the polytetrafluoroethylene and the nonionic surfactant is 99-99.5:0.5-1. The solid content is the mass percentage of the remaining part of the emulsion or coating after drying under specified conditions.

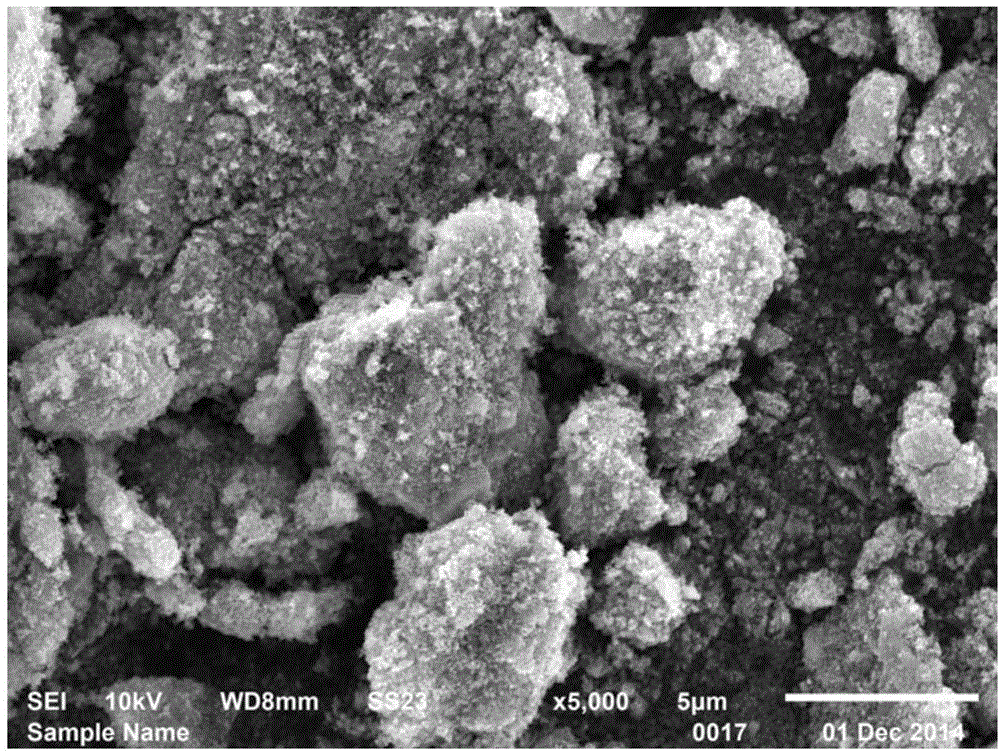

[0039] The particle size of the lithium nickel cobalt aluminate powder is 1 μm to 12 μm. The particle size of the lithium iron phosphate material powder is 50nm-200nm.

[0040] Wherein, sufficient mixing can be r...

Embodiment 1

[0058] Spray 13.75g of polytetrafluoroethylene emulsion (60% solid content) evenly on the surface of 165g of micron-sized nickel-cobalt-lithium aluminate powder, mix thoroughly after stirring with a high-speed mixer for 2 hours, and then add 135g of nano-sized ferromanganese phosphate The lithium powder was stirred by a high-speed mixer for 2 hours and then fully mixed to obtain a mixed material.

[0059] The above mixed material was moved into an oven, baked at 130° C. for 6 hours to remove moisture, and then pulverized with a high-speed pulverizer to obtain a nickel-cobalt-lithium-aluminate composite material.

Embodiment 2

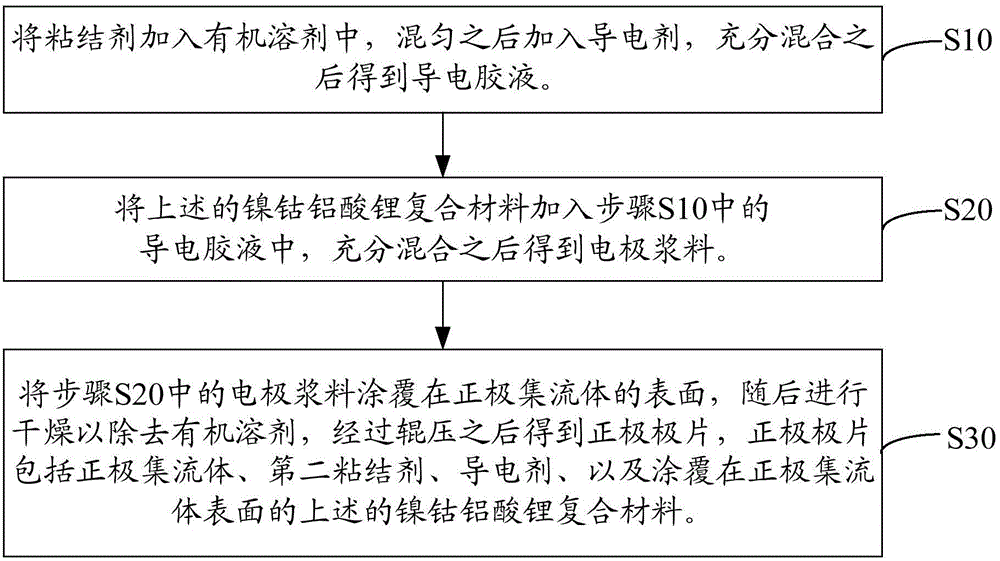

[0061] Add polyvinylidene fluoride into N-methylpyrrolidone, mix well, add superconducting carbon black, and mix thoroughly to obtain conductive glue.

[0062] Add the nickel-cobalt-lithium-aluminate composite material prepared in Example 1 into the above-mentioned conductive glue solution, wherein the mass ratio of the nickel-cobalt-lithium-aluminate composite material, superconducting carbon black, and polyvinylidene fluoride is 90:5:5. The electrode slurry is obtained after the above three are fully mixed.

[0063] The above-mentioned electrode slurry is coated on the surface of the aluminum foil, followed by drying to remove N-methylpyrrolidone, and the positive electrode sheet is obtained after rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com