Positive electrode material of lithium ion battery as well as preparation method and application of positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve structural defects, cannot eliminate and improve lithium ion safety performance and electrochemical performance and other problems, so as to improve service life, improve Effects of ionic conductivity and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

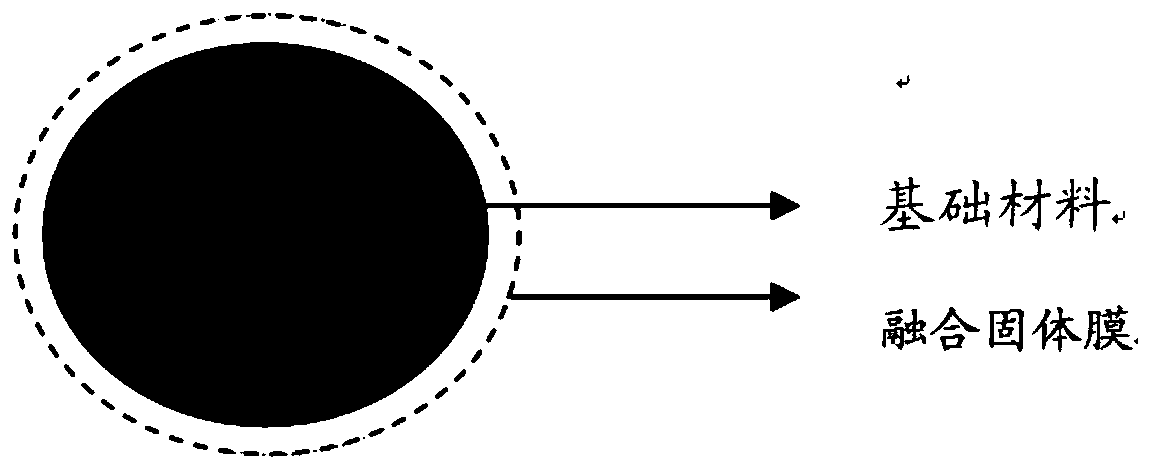

[0069] In another preferred embodiment, the present invention provides a method for preparing a positive electrode material for a lithium ion conductor battery, which is characterized in that it includes the preparation of a nano-lithium ion conductor precursor, mixing with the positive electrode body material and the lithium ion conductor crystal of the positive electrode material. Boundary sintering fusion and other processes. Its preparation method is as follows.

[0070] 1) Mix and dissolve the precursor lithium salt, fast ion conductor raw materials, and water-based polyketone resin, and then prepare a slurry after high-speed dispersion and mixing. Then selectively add or not add a small amount of lithium salt to the slurry, dry the slurry at 80-150° C. for 1-10 hours to dehydrate, keep the water content at 5-20%, and obtain the fast ion conductor precursor.

[0071] 2) Composite drying. Prepare the sol according to the weight ratio of deionized water: CMC = 100: (0.2-4),...

Embodiment 1

[0098] Weigh 23.3kg of lithium hydroxide monohydrate and add it to a 500L coulter mixer, start stirring and add 100kg of polyvinylpyrrolidone and 40kg of deionized water, and then add 91.6kg of titanium dioxide and 105.85kg of lanthanum hydroxide after stirring fully. Stir for 50 minutes and then transfer to a tray and bake in an oven at 105° C. for 2 hours to keep the moisture content of the material at about 5% to obtain a fluffy fast ion conductor solid material 1 .

[0099] Add 120kg of deionized water to the kneader, then add 1.2kg of sodium carboxymethylcellulose to dissolve completely, then add 100kg of lithium cobaltate positive electrode material and stir for 20 minutes, then add 10kg of solid material 1, after mixing for 30 minutes, pour the slurry Put it into a tray and put it in a drying oven to dry at 120°C / 10h to obtain a solid block material.

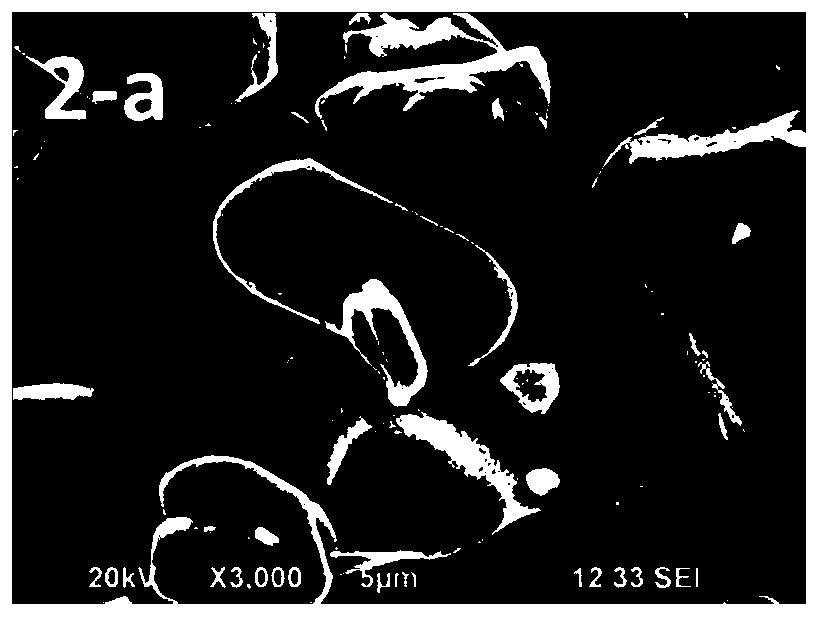

[0100] The above-mentioned dried material is packed into a ceramic bowl, and a 24m roller kiln is used to feed oxygen-e...

Embodiment 2

[0106] Weigh 42.6kg of lithium carbonate and add it to a 500L kneader, start stirring and add 30kg of polyvinylpyrrolidone and 40kg of deionized water, and then add 34.29kg of metatitanic acid and 52.61kg of lithium titanate (Li 4 Ti 5 o 12 ), and 17.94kg aluminum hydroxide. Stir the material for 50 minutes, then transfer it to a tray, put it in an oven and bake at 150° C. for 1.5 hours, and keep the moisture content of the material at about 20% to obtain block-shaped solid material 2 .

[0107] Add 120kg of deionized water to the kneader, then add 1.2kg of sodium carboxymethylcellulose to dissolve completely, then add 100kg of lithium manganate positive electrode material and stir for 20 minutes, then add 20kg of solid material 2, after mixing for 30 minutes, pour the slurry Put it into a tray and put it in a drying oven to dry at 150°C / 10h to obtain a solid block material.

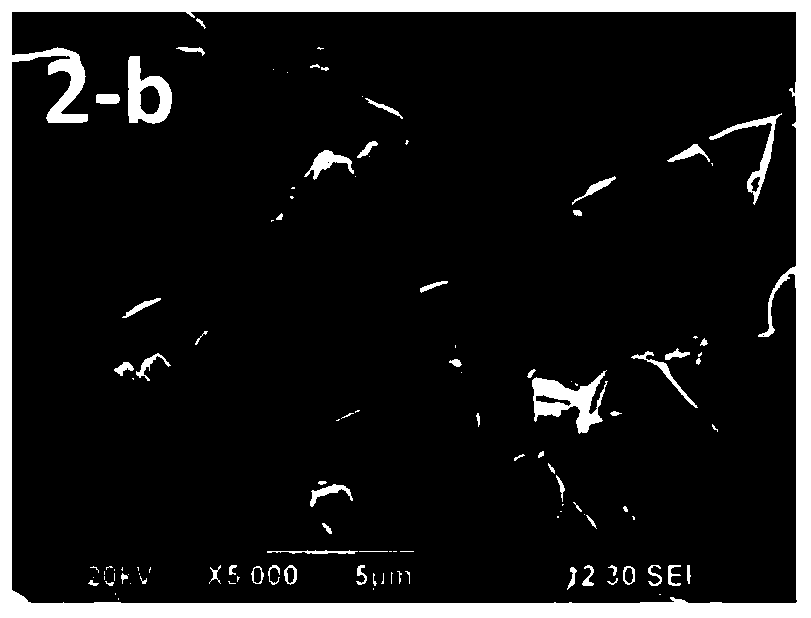

[0108] The above-mentioned dried materials are packed into a ceramic bowl, and a 24m roller kiln i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com