Patents

Literature

97 results about "Lithium electrolyte" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte plays a key role in transporting the positive lithium ions between the cathode and anode. High purity electrolytes are a core component of li-ion batteries. The most commonly used electrolyte is comprised of lithium salt, such as LiPF6 in an organic solution.

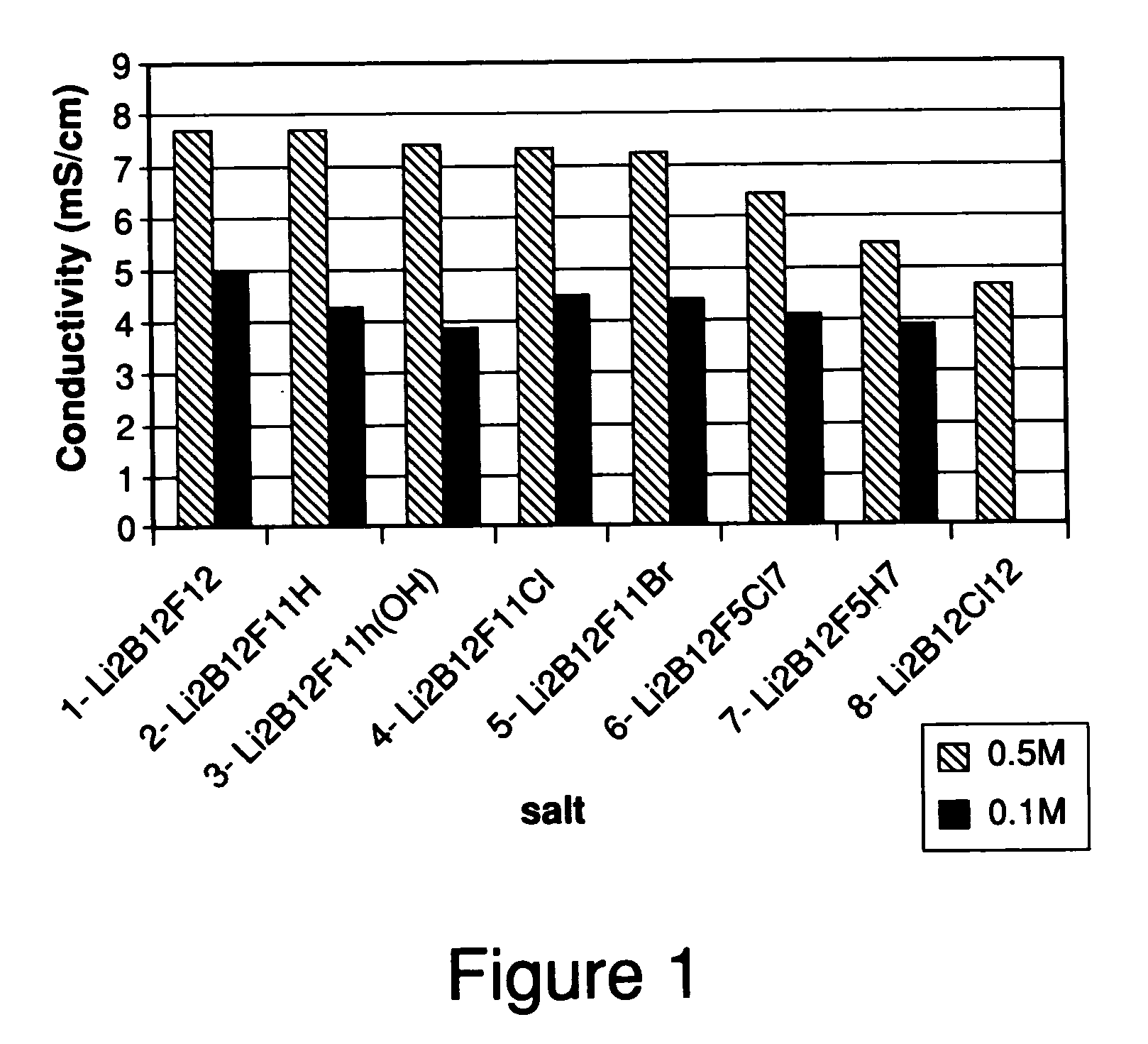

Polyfluorinated boron cluster anions for lithium electrolytes

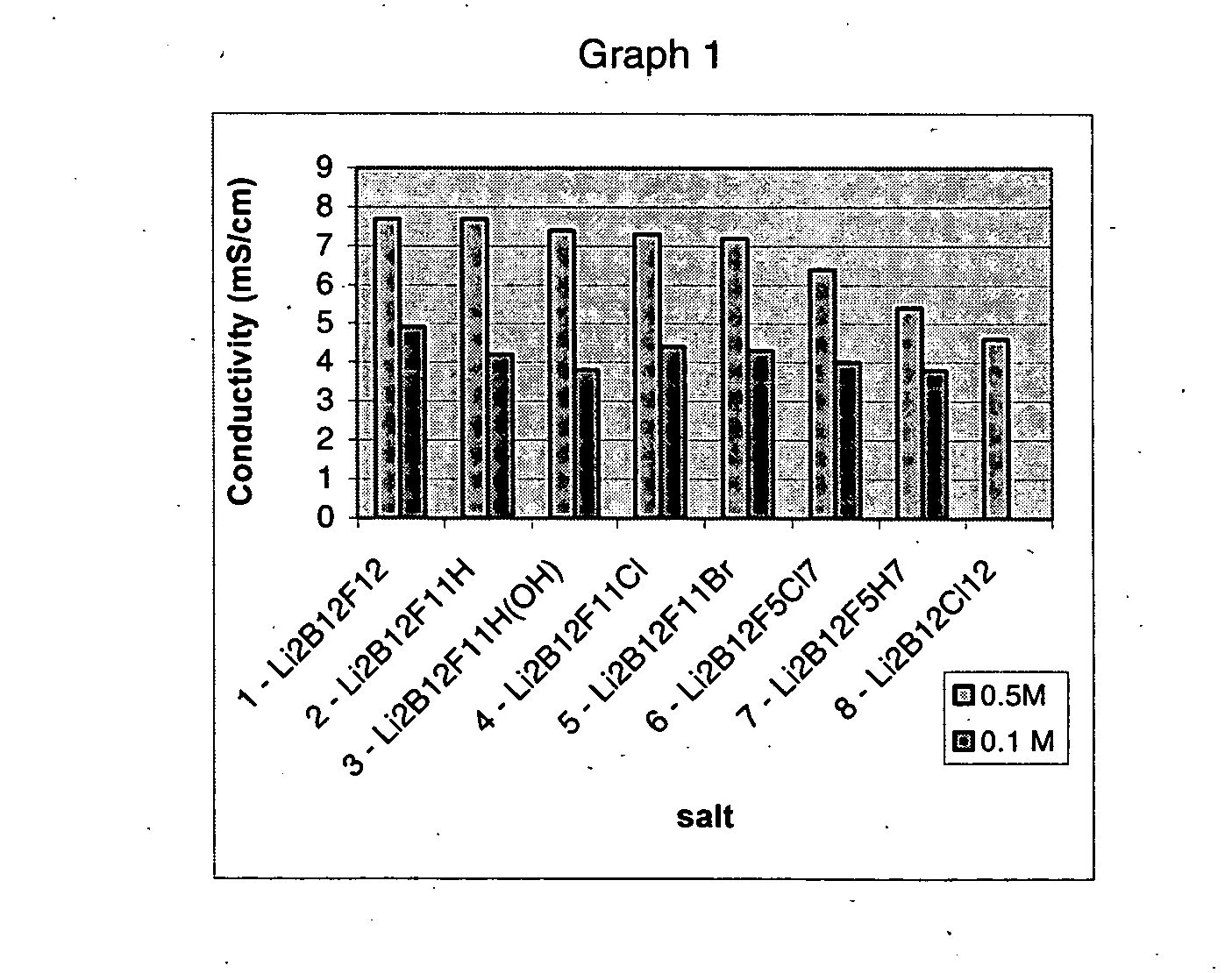

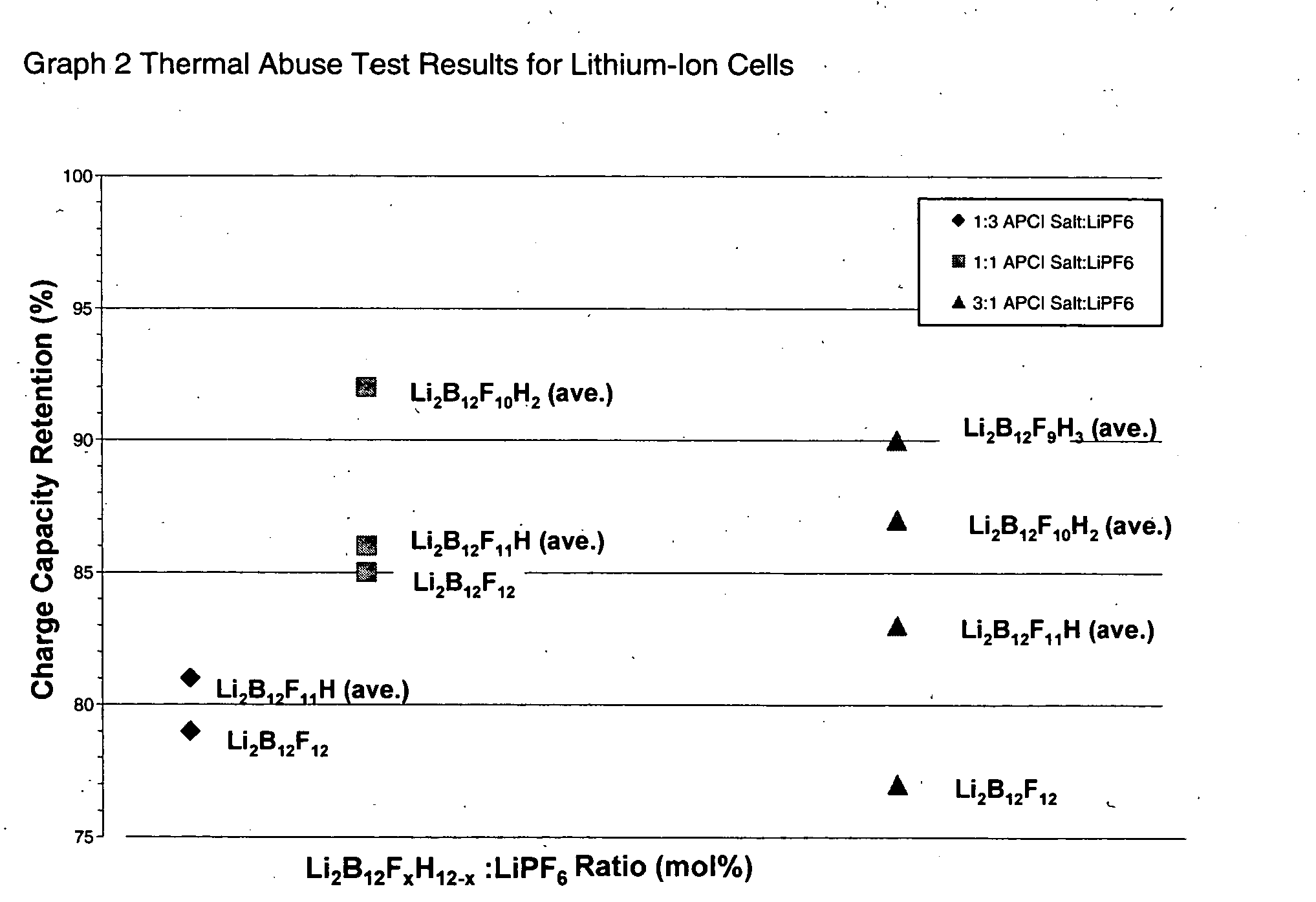

ActiveUS20050064288A1Low viscosityLower impedanceOrganic electrolyte cellsBiochemical fuel cellsBoron clustersElectrolyte composition

The present invention relates to an improvement in lithium secondary batteries comprised of a negative electrode, a positive electrode, a separator, and a lithium-based electrolyte carried in an aprotic solvent and to the electrolyte compositions. The improvement resides in the use of a lithium salt of the formula: Li2B12FxZ12-x wherein x greater than or equal to 4 and Z represents H, Cl, and Br.

Owner:AIR PROD & CHEM INC

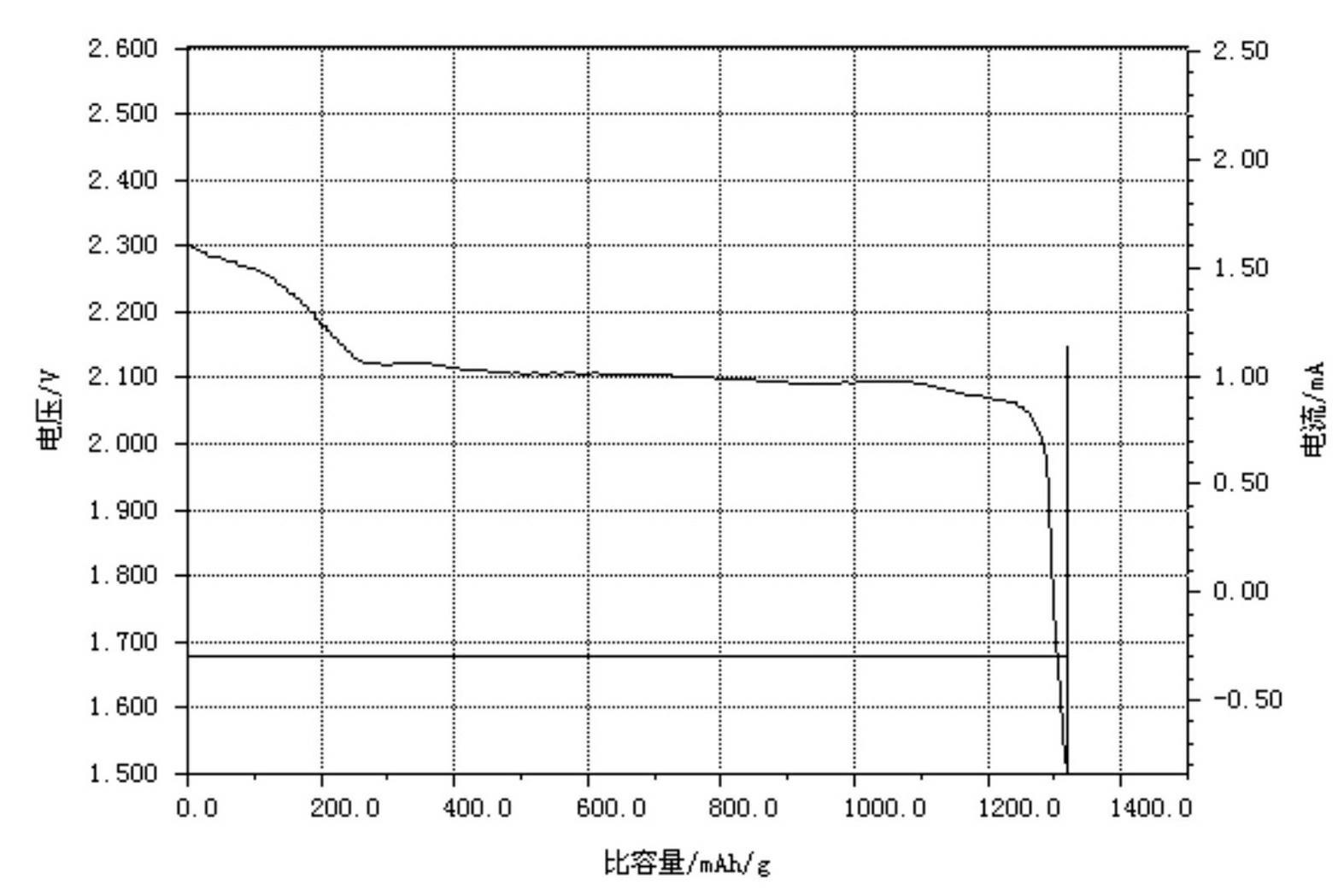

Sulfur-containing composite anode material, anode plate and Li-S (lithium-sulfur) secondary battery and preparation method thereof

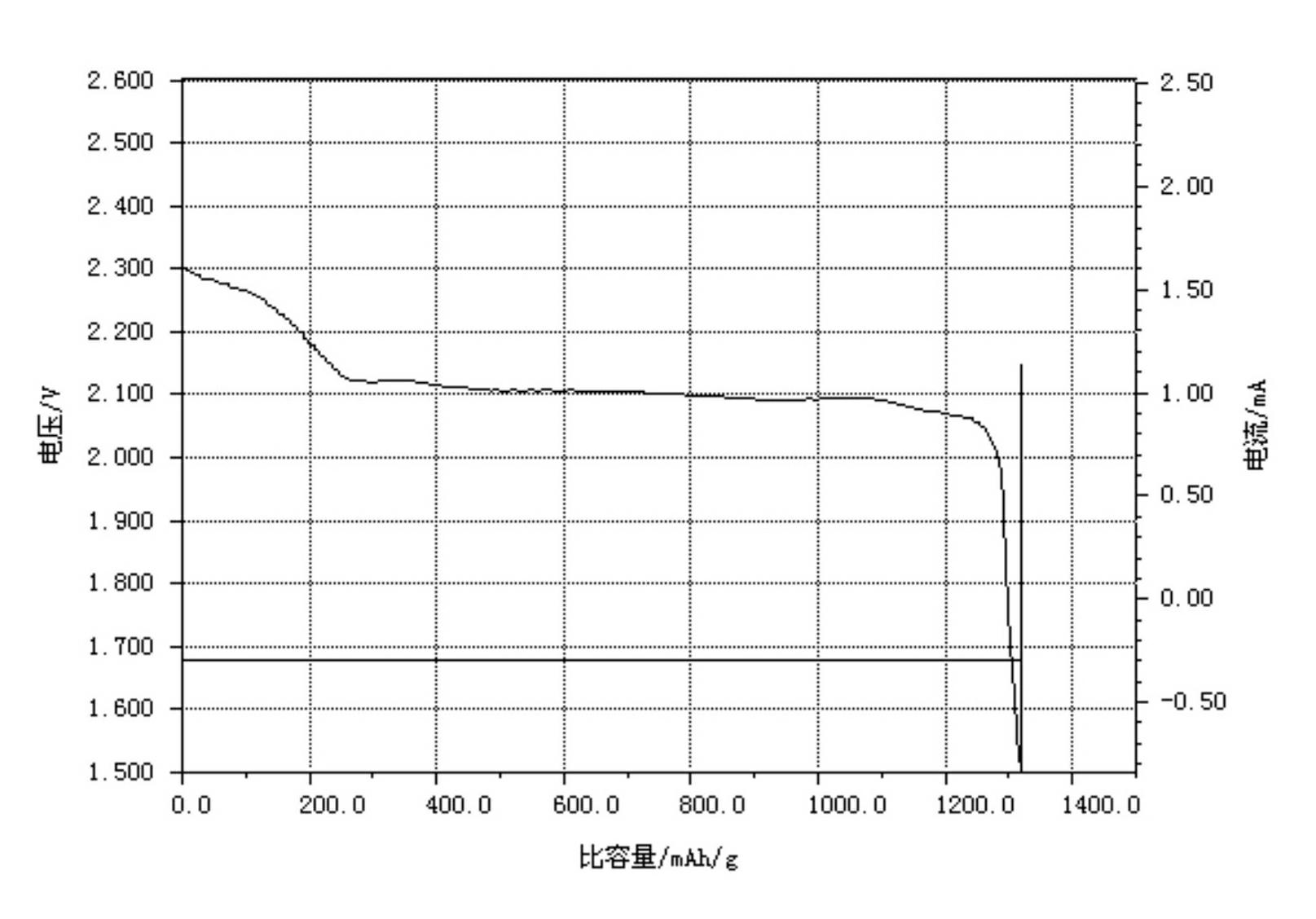

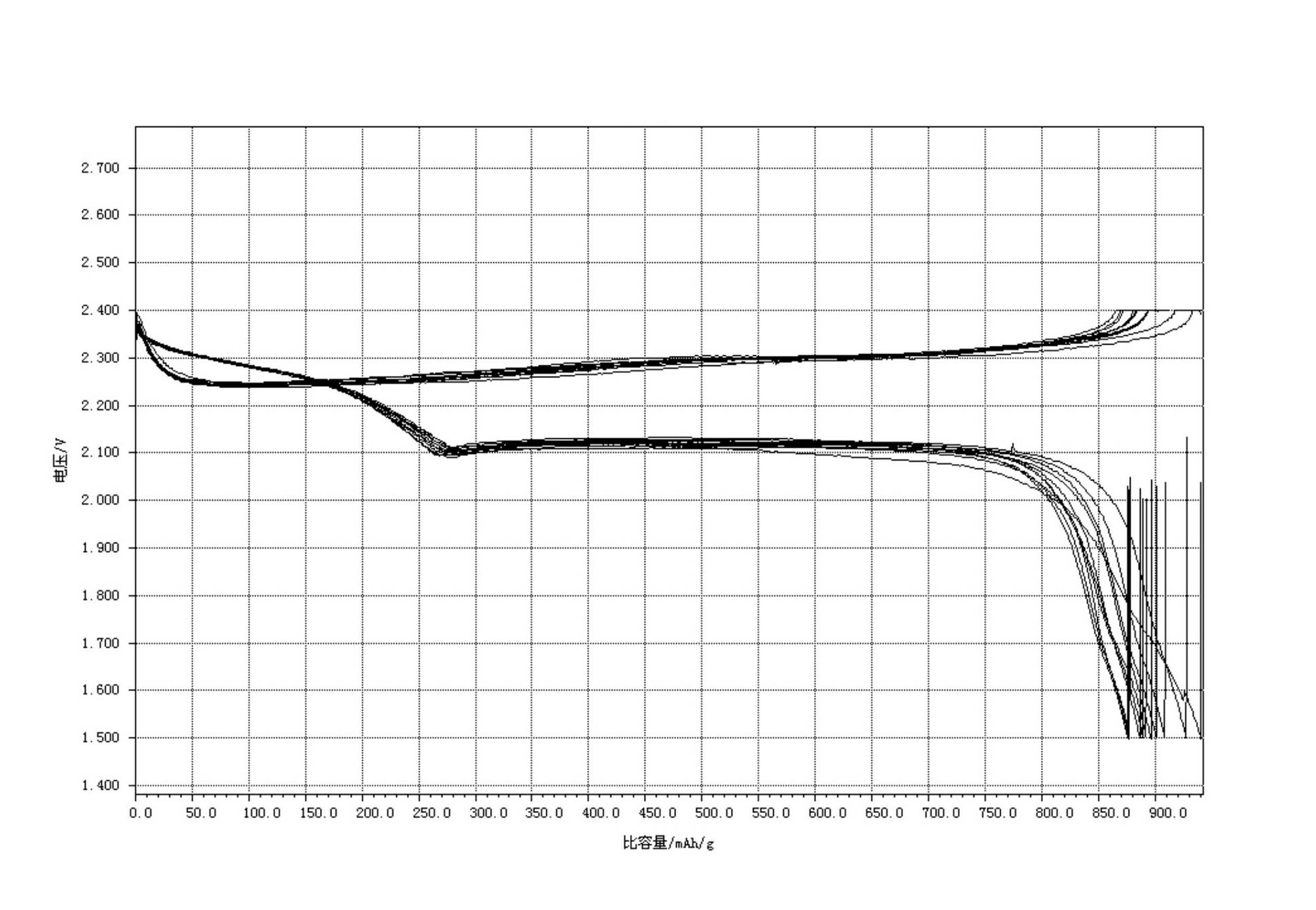

ActiveCN102097622AImprove cycle performanceIncrease energy densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesAdhesiveLithium sulfur

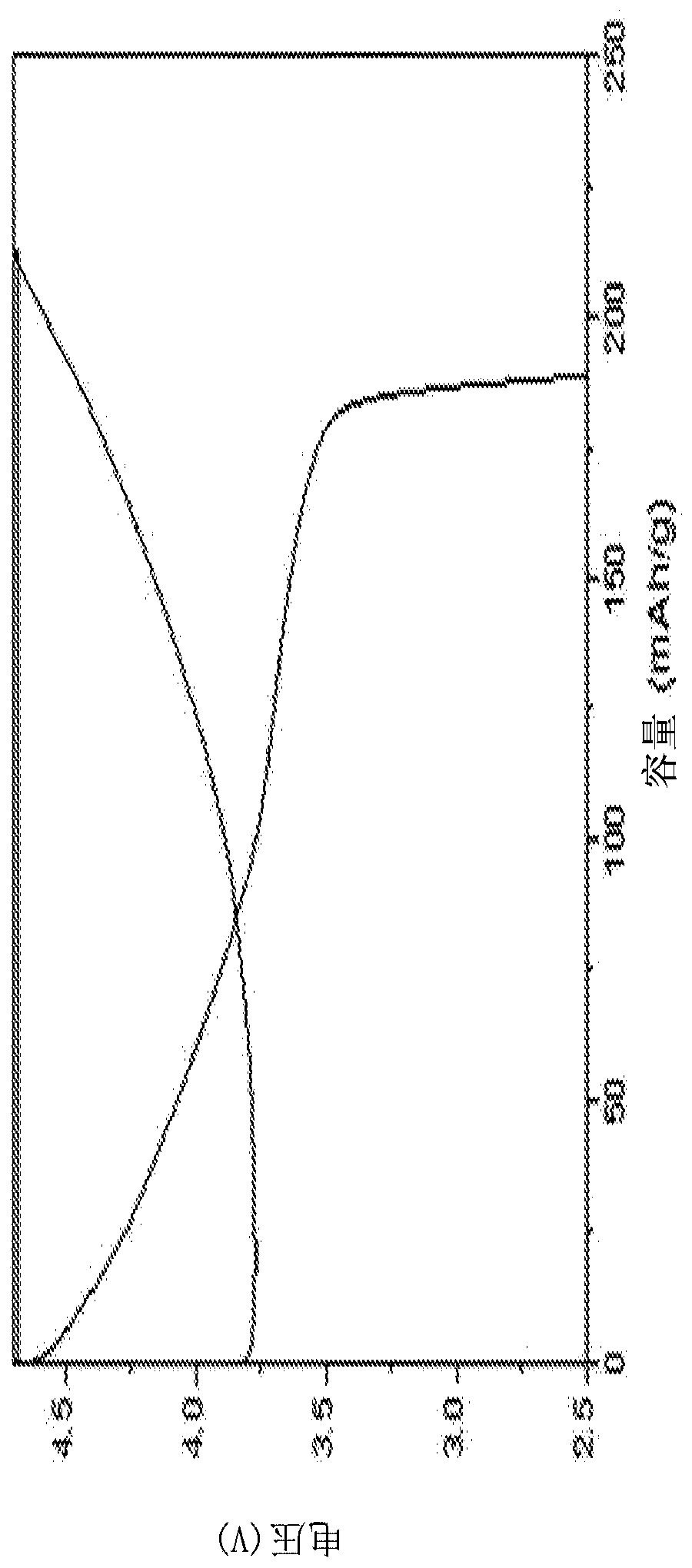

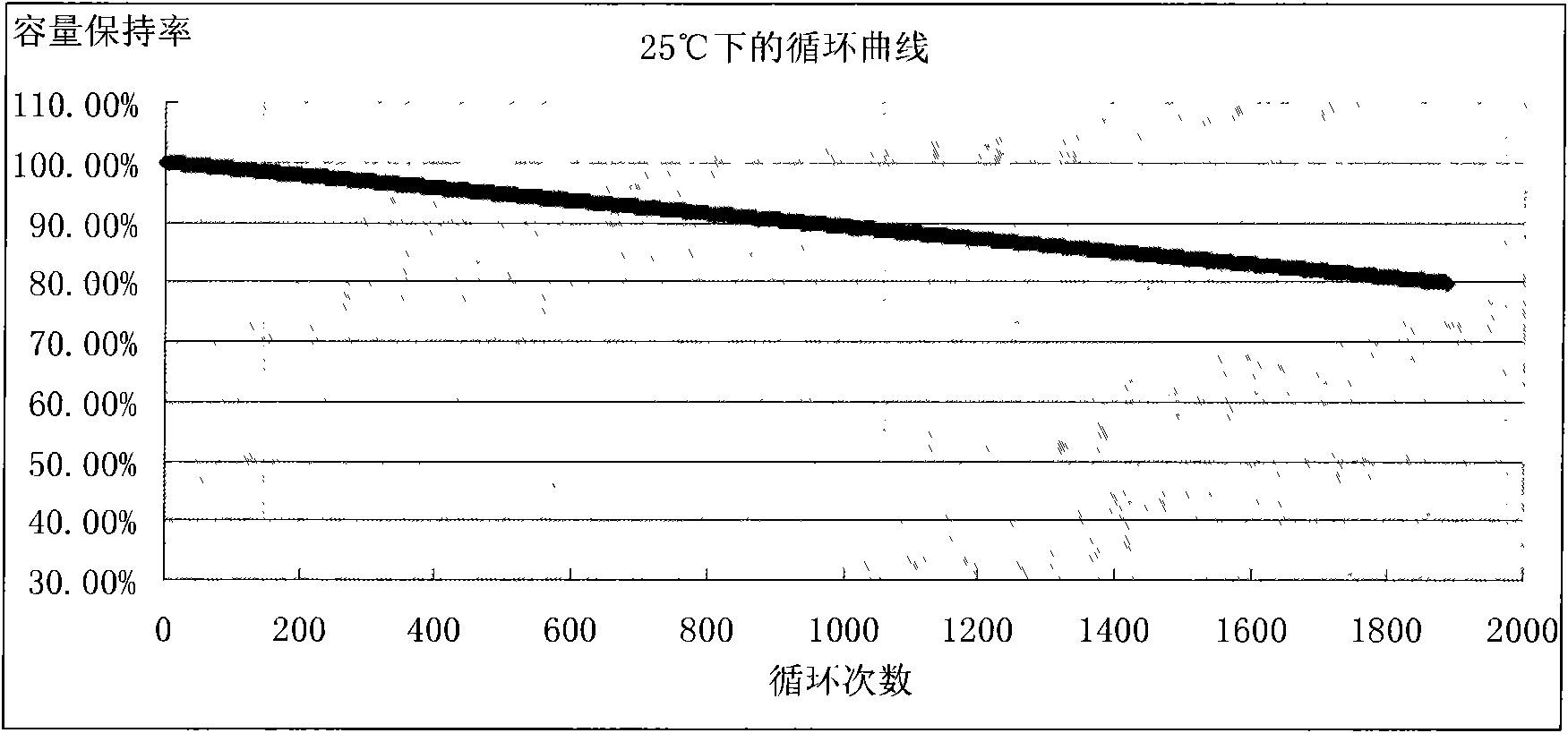

The invention discloses a sulfur-containing composite anode material which is of a core-shell structure, wherein a core is a C / S (carbon / sulfur) composite composited by utilizing elemental sulfur and nano conductive carbon black; and a shell is an organic polymer clad film layer containing a plasticizer. The preparation method comprises the following steps: mixing the sulfur and carbon and heating to obtain the C / S composite; adding an organic polymer solution; emulsifying and shearing the mixture; and finally filtering and drying. The invention further discloses an anode plate which comprises an aluminum current collector and the sulfur-containing composite anode material coated on the aluminum current collector. The anode plate is prepared by ball milling and blending the sulfur-containing composite anode material with adhesives, a solvent and process additives, and printing or coating on the aluminum current collector. The invention also discloses a Li-S (lithium-sulfur) secondary battery which is formed by packaging a battery core and an electrolyte, wherein the battery core mainly comprises a cathode component, a polymer porous diaphragm and the anode plate. The cathode component comprises a lithium foil, and the electrolyte comprises an organic solvent and lithium electrolyte salts. The secondary battery disclosed by the invention has the advantages of high specific energy and good cycle performance.

Owner:NAT UNIV OF DEFENSE TECH +1

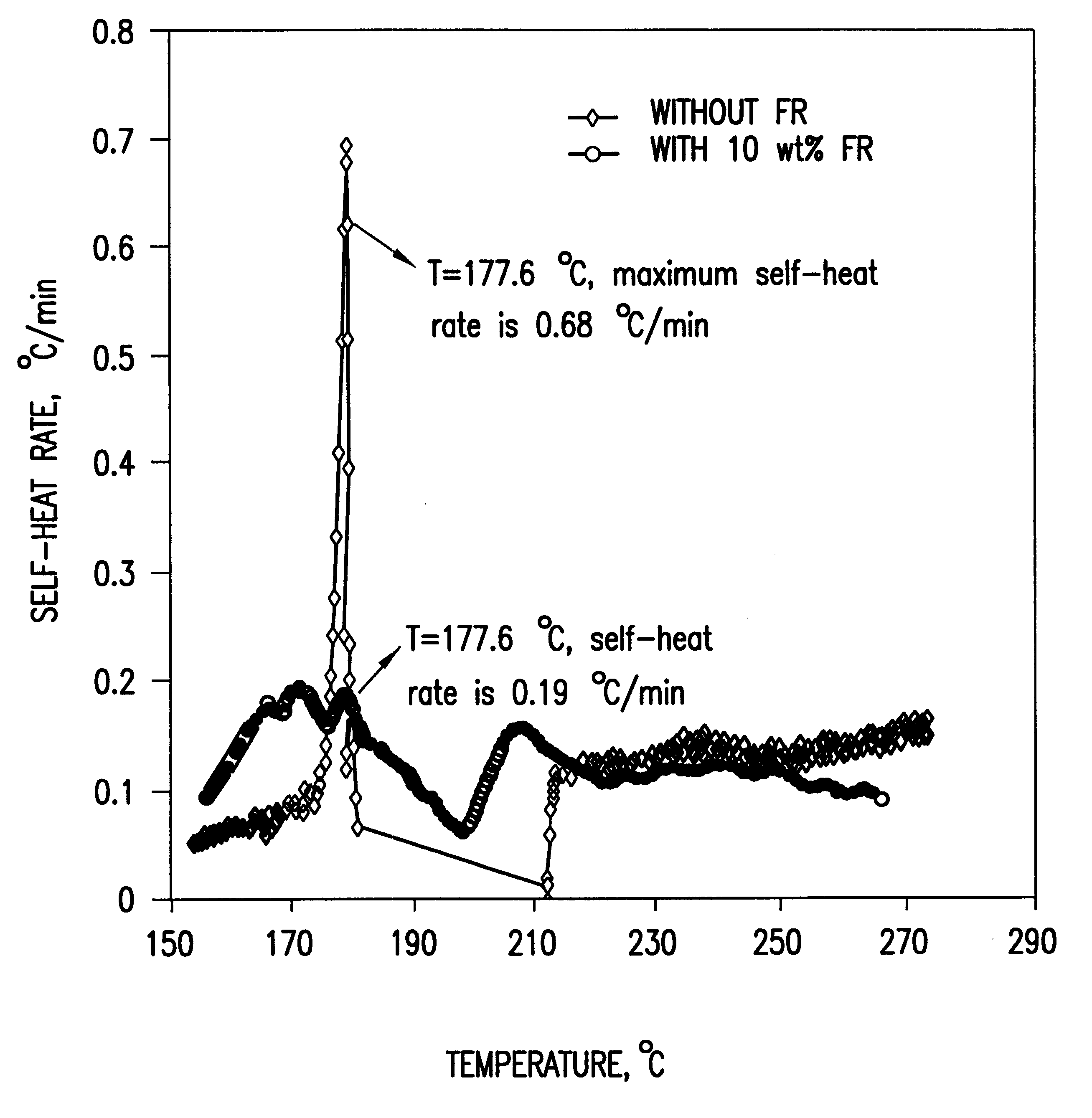

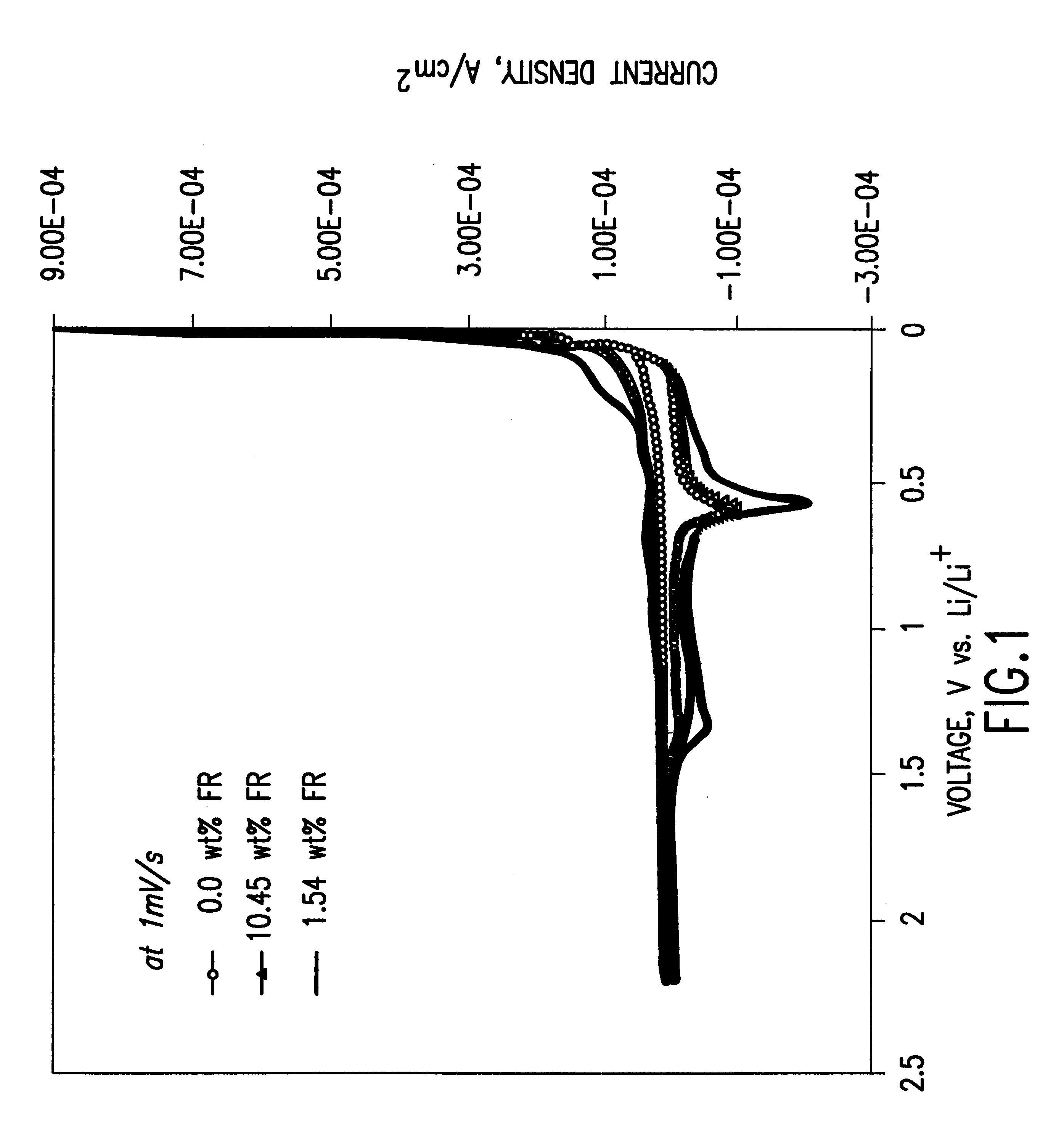

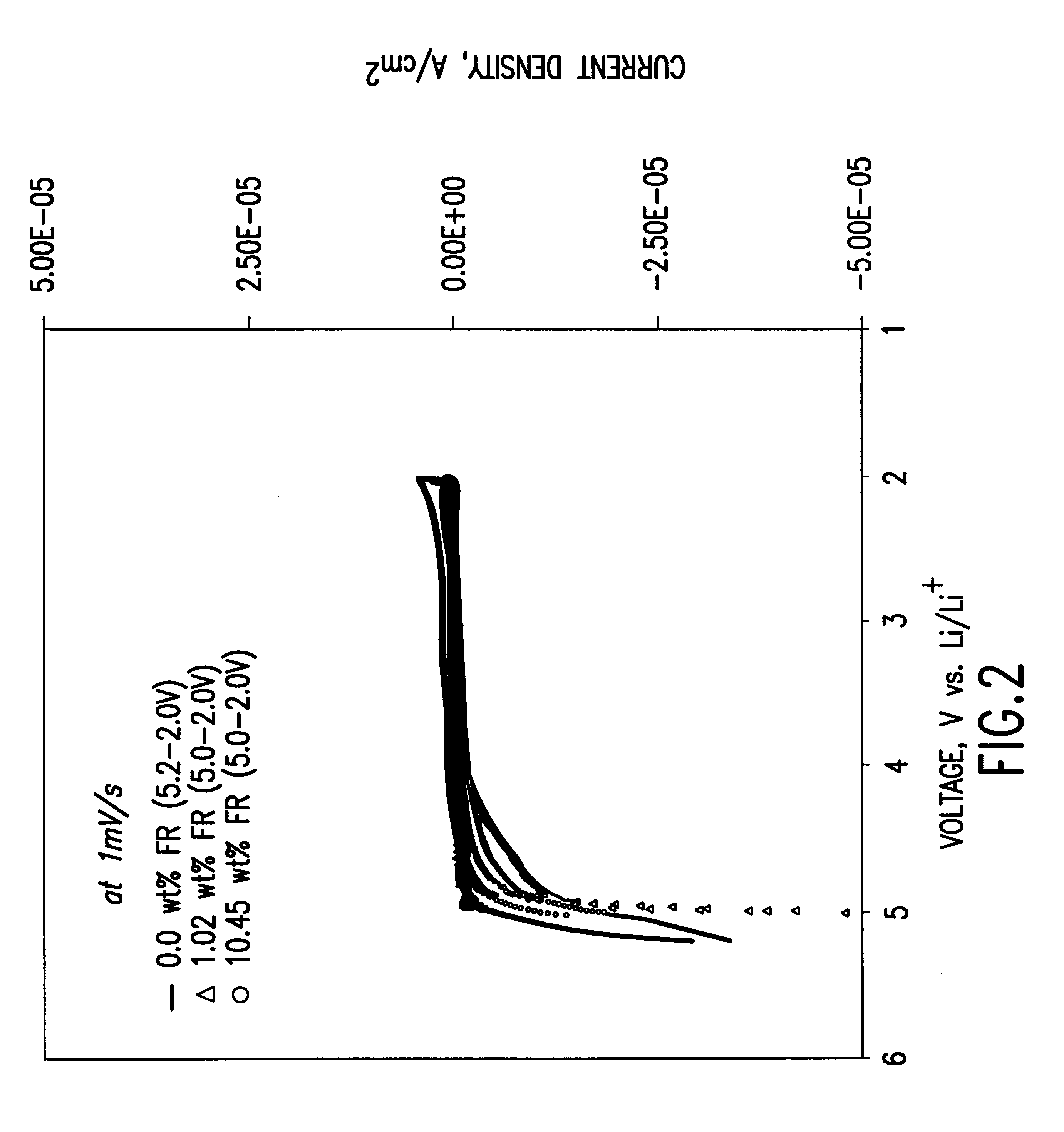

Flame-retardant additive for li-ion batteries

InactiveUS6455200B1Reduction in exothermic peakImprove thermal stabilityOrganic electrolyte cellsSolid electrolyte cellsSolventLithium-ion battery

A lithium-ion battery having an anode electrode, a cathode electrode and a non-aqueous solvent lithium electrolyte. At least one cyclophosphazene is added to the non-aqueous solvent lithium electrolyte, which cyclophosphazene acts as a flame-retardant material. The non-aqueous solvent lithium electrolyte is preferably a carbonate-based electrolyte and the preferred cyclophosphazene is hexamethoxycyclotriphosphazene.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

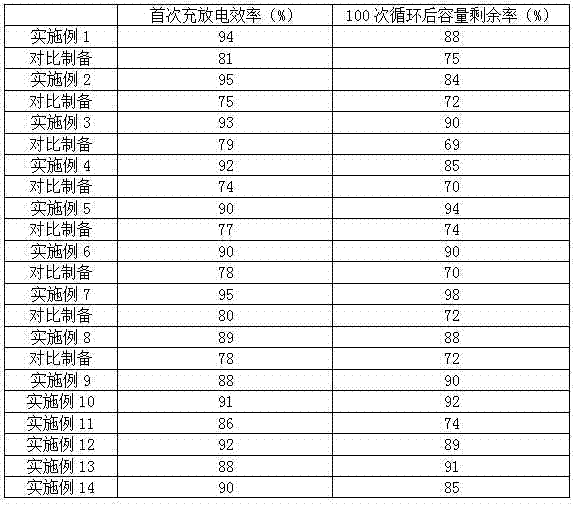

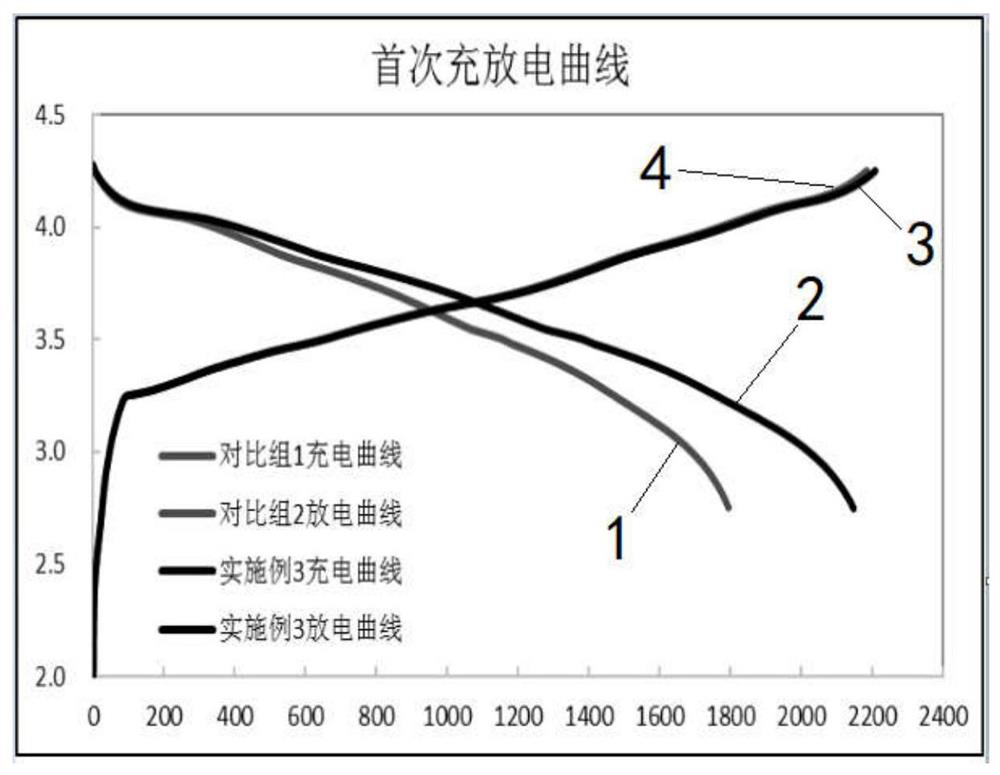

Lithium ion secondary battery and preparation method thereof

ActiveCN102522560ASlow particle pulverizationAvoid reunionCell electrodesFinal product manufactureLithium-ion batteryLithium electrolyte

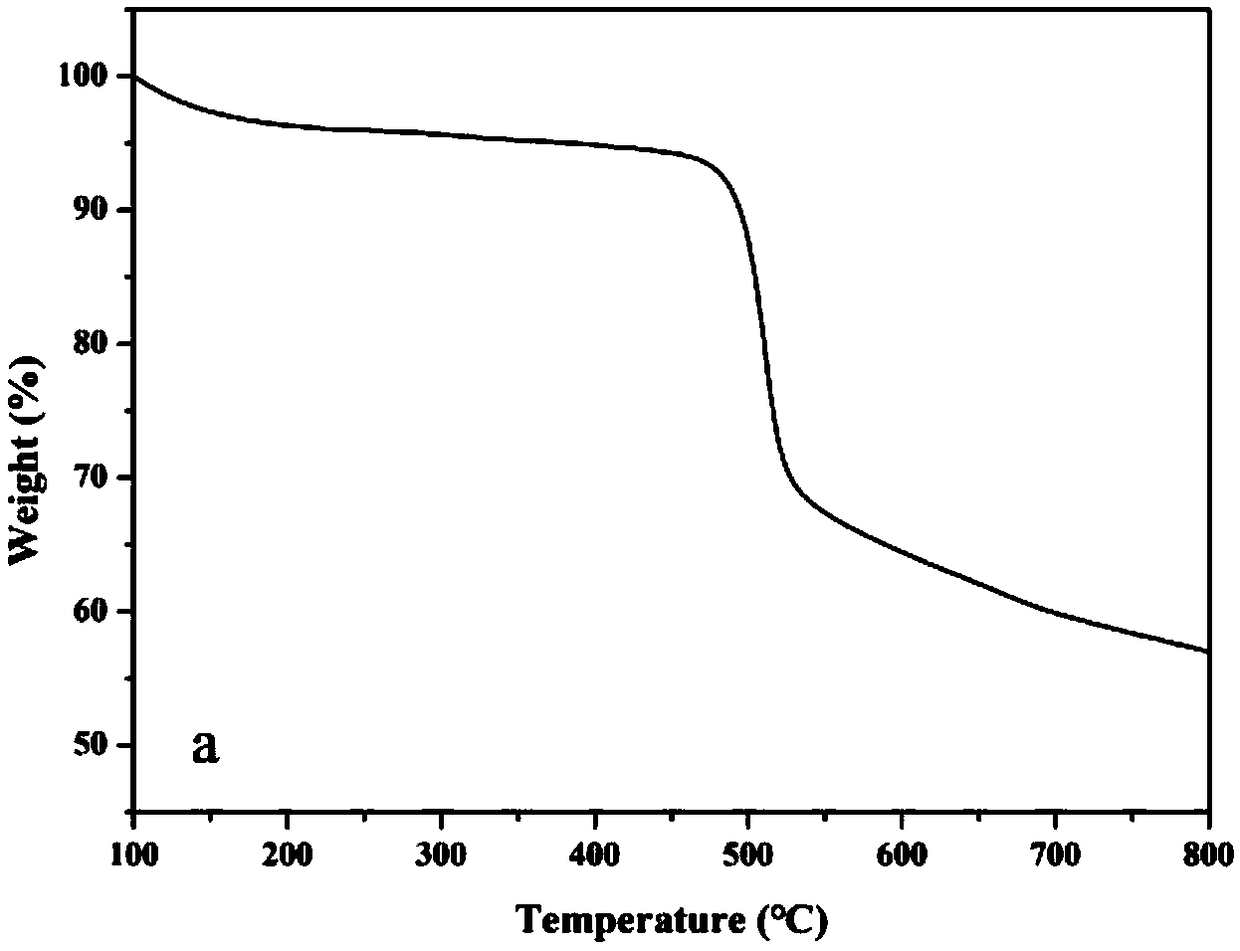

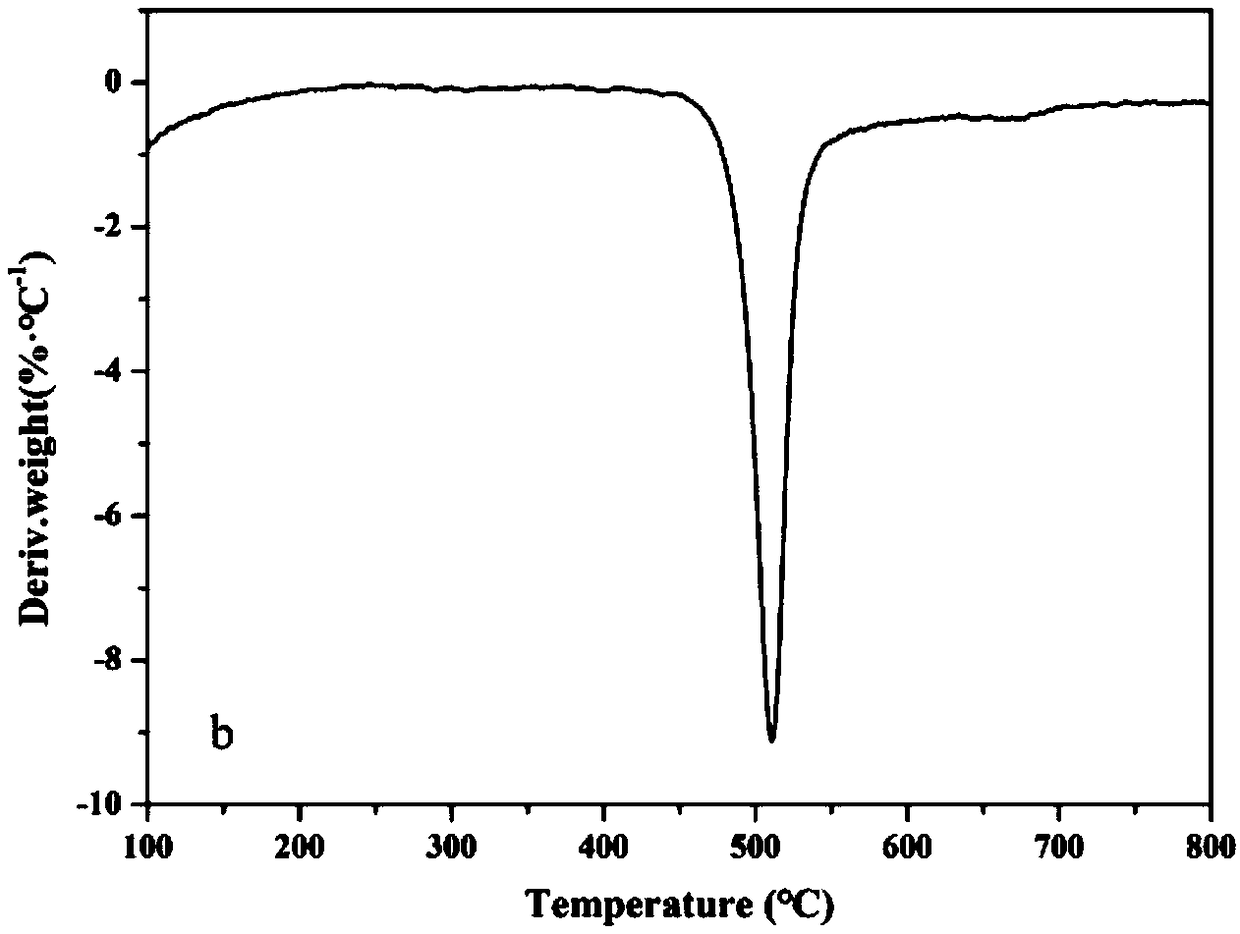

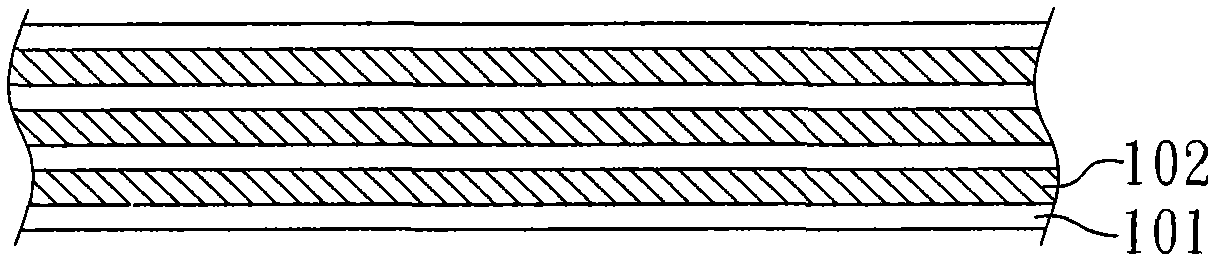

The invention relates to a lithium ion secondary battery and a preparation method thereof. The cathode of the battery is a lithium ion battery silicon-based cathode containing a gel coating and comprises a current collector, a silicon-based cathode material loaded on the current collector and the gel coating which is coated on the surface of the silicon-based cathode material through heat treatment after coating, wherein the gel coating comprises a polymer matrix material, a non-aqueous solvent, a toughening agent and a lithium electrolyte salt dissolved in the non-aqueous solvent and has a thickness of 5 to 50 mu m, preferably, 10 to 20 mu m. According to the invention, the cathode of the lithium ion secondary battery is coated with the gel coating, and the gel coating comprises a polymer matrix with high elasticity and high viscosity and electrolyte containing a lithium salt, is coated on the surface of the silicon-based cathode and forms a semi-solid gel layer on the surface of the cathode and in pores through heat treatment, thereby alleviating pulverization of particles of active substances in the silicon-based cathode during the processes of charging and discharging and avoiding re-agglomeration of the particles.

Owner:DONGFANG ELECTRIC CORP LTD

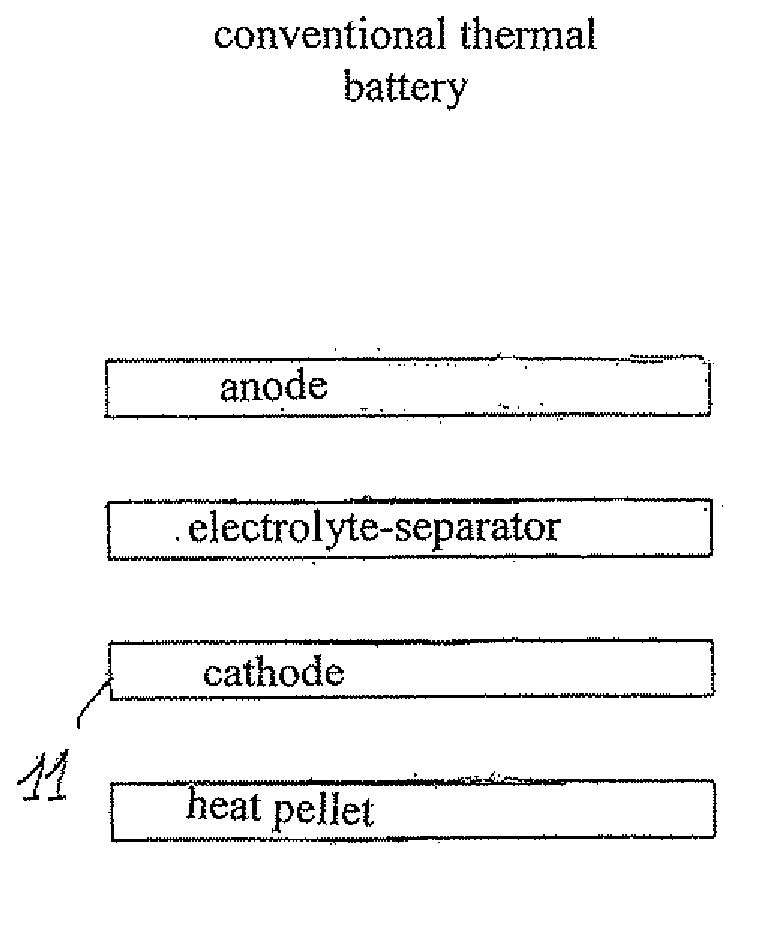

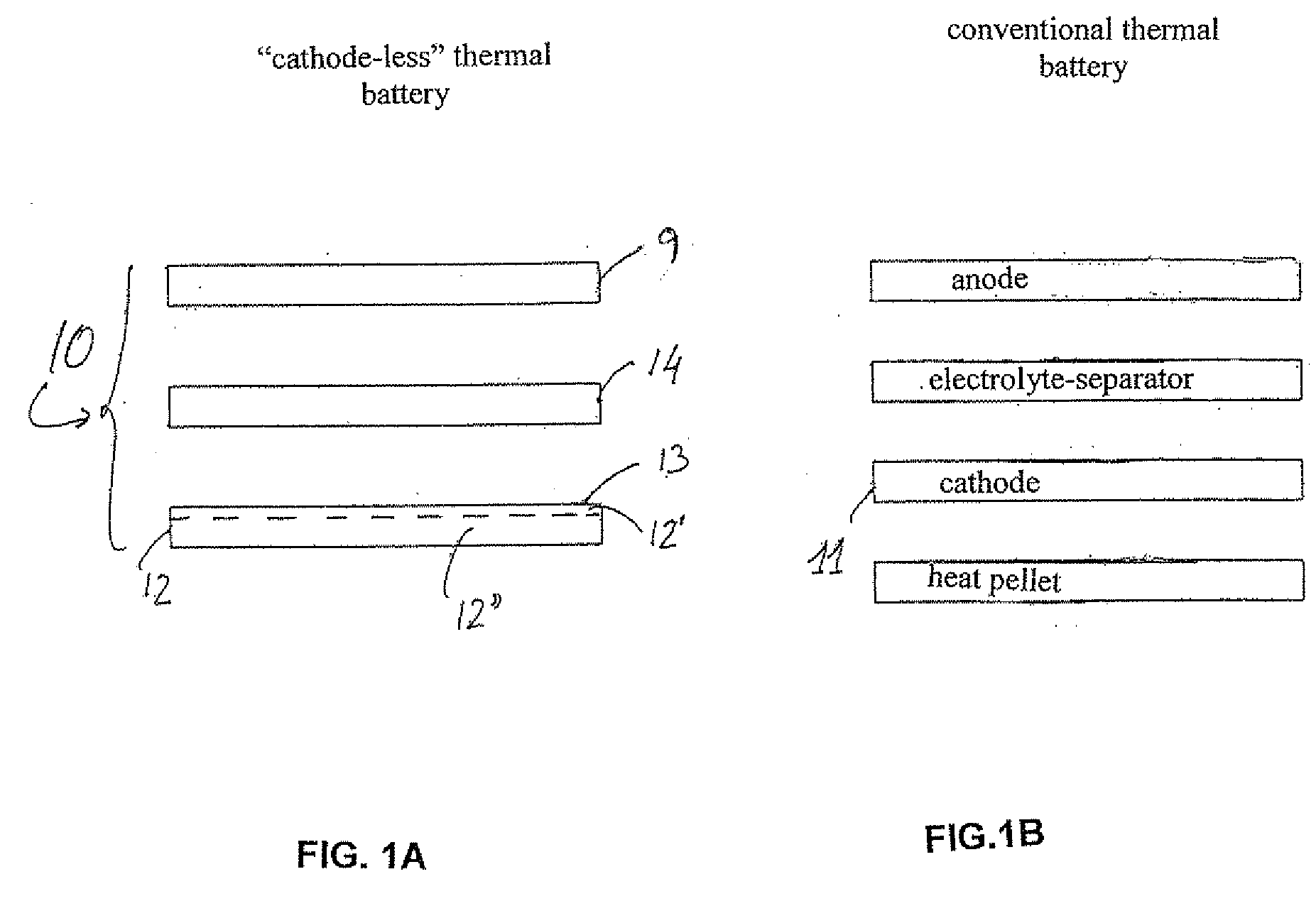

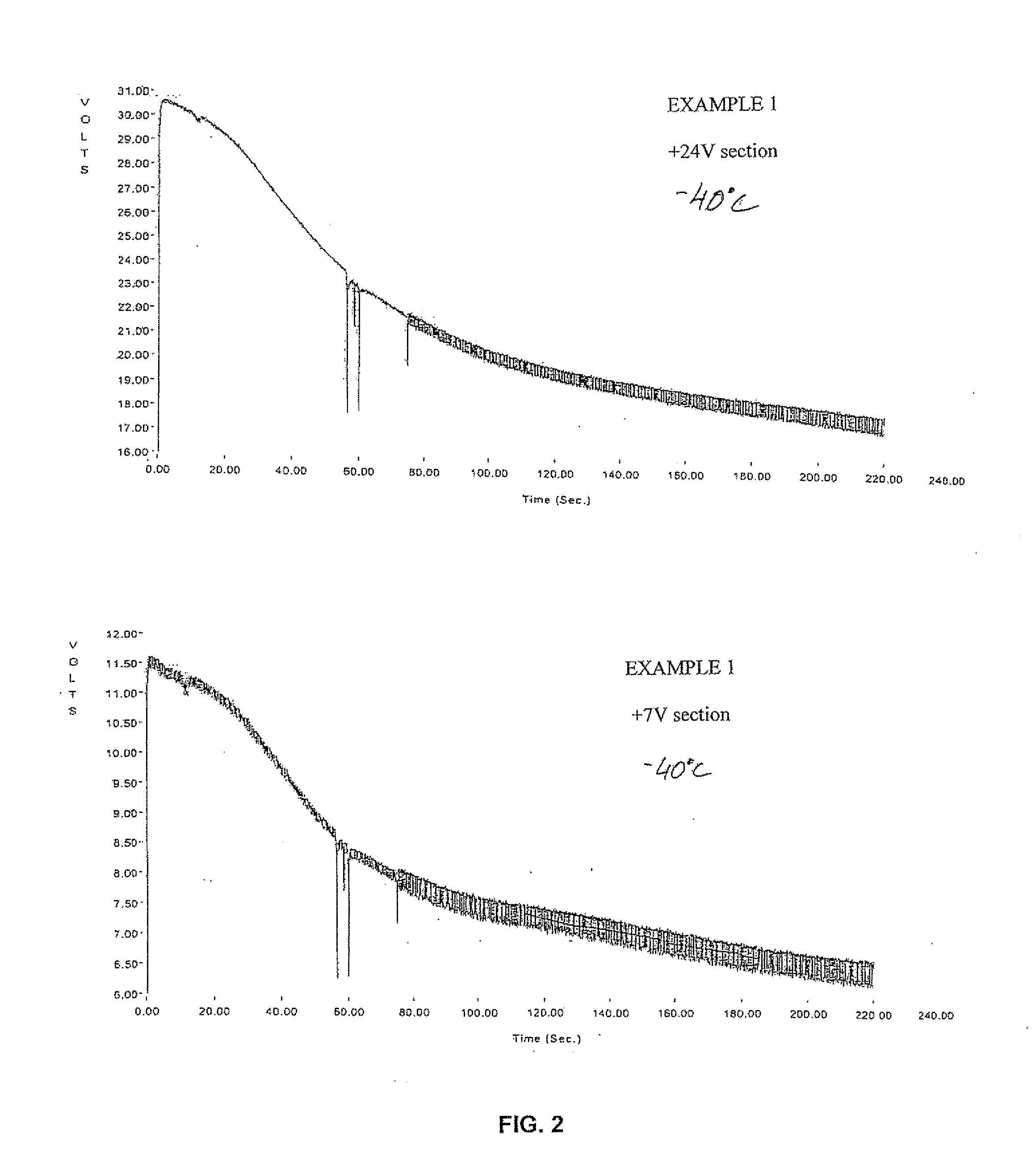

Thermal batteries using cathode-precursor pyrotechnic pellets

InactiveUS20070292748A1Extended service lifeReliable and reliableDeferred-action cellsCell electrodesPyrotechnic heat sourceLithium.free

Owner:THE STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG ARO VOLCANI CENT

Fluorinated ether as electrolyte co-solvent for lithium metal based anode

ActiveUS20180062206A1Improve cycling efficiency and durabilityIncrease capacityFinal product manufactureElectrode carriers/collectorsLithium metalEther

The performance and durability of an electrochemical cell using a lithium metal based anode and a compatible lithium-accepting cathode are improved by the use of a suitable lithium electrolyte salt and a new liquid co-solvent mixture for the electrolyte. The co-solvent mixture comprises a non-aqueous ionic liquid, conductive of lithium ions, and a liquid fluorinated organic ether.

Owner:GM GLOBAL TECH OPERATIONS LLC

High temperature-resistant electrolyte solution of lithium ion battery

ActiveCN103825049AImprove cycle stabilitySmall capacity attenuationSecondary cellsOrganic baseSolvent

The invention provides a high temperature-resistant electrolyte solution of a lithium ion battery. The high temperature-resistant electrolyte solution of the lithium ion battery comprises the raw materials of lithium electrolyte salt, an organic solvent, a high temperature-resistant additive, a film forming additive and a circulatory stability additive, wherein the concentration of the lithium electrolyte salt in the organic solvent is 0.5-2 mol / L; the organic solvent comprises the following components in parts by volume: 5-30 parts of a high-dielectric-constant organic base solvent, 40-65 parts of a high-boiling-point organic solvent, and 5-55 parts of a low-viscosity organic solvent; the high temperature-resistant additive is at least one of lithium tetrafluoroborate, lithium difluoroborate, lithium bis(malonato)borate, lithium bis(oxalate)borate and lithium malonato oxalate borate, the mass of the high temperature-resistant additive accounts for 0.1-8% of the total mass of the electrolyte solution, the mass of the film forming additive accounts for 0.2-4% of the total mass of the electrolyte solution, and the mass of the circulatory stability additive accounts for 0.5-5% of the total mass of the electrolyte solution. According to the invention, the high temperature resistance and circulatory stability of the lithium ion battery are effectively improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for preparing lithium carbonate by extracting lithium salt from aluminium electrolytic high-lithium electrolyte waste

InactiveCN108569711AReduce manufacturing costReduce dependenceLithium carbonates/bicarbonatesLithium sulphateLithium carbonate

The invention discloses a method for preparing lithium carbonate by extracting lithium salt from aluminum electrolytic high-lithium electrolyte waste, which specifically comprises the following stepsof S1, taking the aluminum electrolytic high-lithium electrolyte waste as a raw material to prepare a lithium sulfate solution; S2, filtering the lithium sulfate solution prepared in S1 to obtain filter residue and filter liquor, returning the obtained filter residue to an aluminum electrolytic cell to be used as aluminum electrolyte, and enabling the obtained filter liquor to be standby for lateruse; S3, performing impurity removal, lithium precipitation and secondary filtering to obtain crude lithium carbonate for later use; S4, washing and drying the crude lithium carbonate prepared in theS3 to obtain a lithium carbonate finished product. By taking the aluminum electrolytic high-lithium electrolyte waste as the main raw material to produce the lithium carbonate product, the more expensive and scarce lithionite is replaced, so that the dependence of the lithium-electric energy materials in China on the lithionite is reduced, and the production cost of lithium carbonate is greatly reduced; the obtained filter residue are returned to the electrolytic cell for use, the lithium concentration of the original electrolyte is reduced, the property of the electrolyte is optimized, and the energy is saved.

Owner:HENAN UNIV OF SCI & TECH

Non-aqueous electrolyte and lithium secondary battery using the same

InactiveCN106159324AImprove interface impedanceImprove low temperature performanceSecondary cells servicing/maintenanceOrganic solventLithium-ion battery

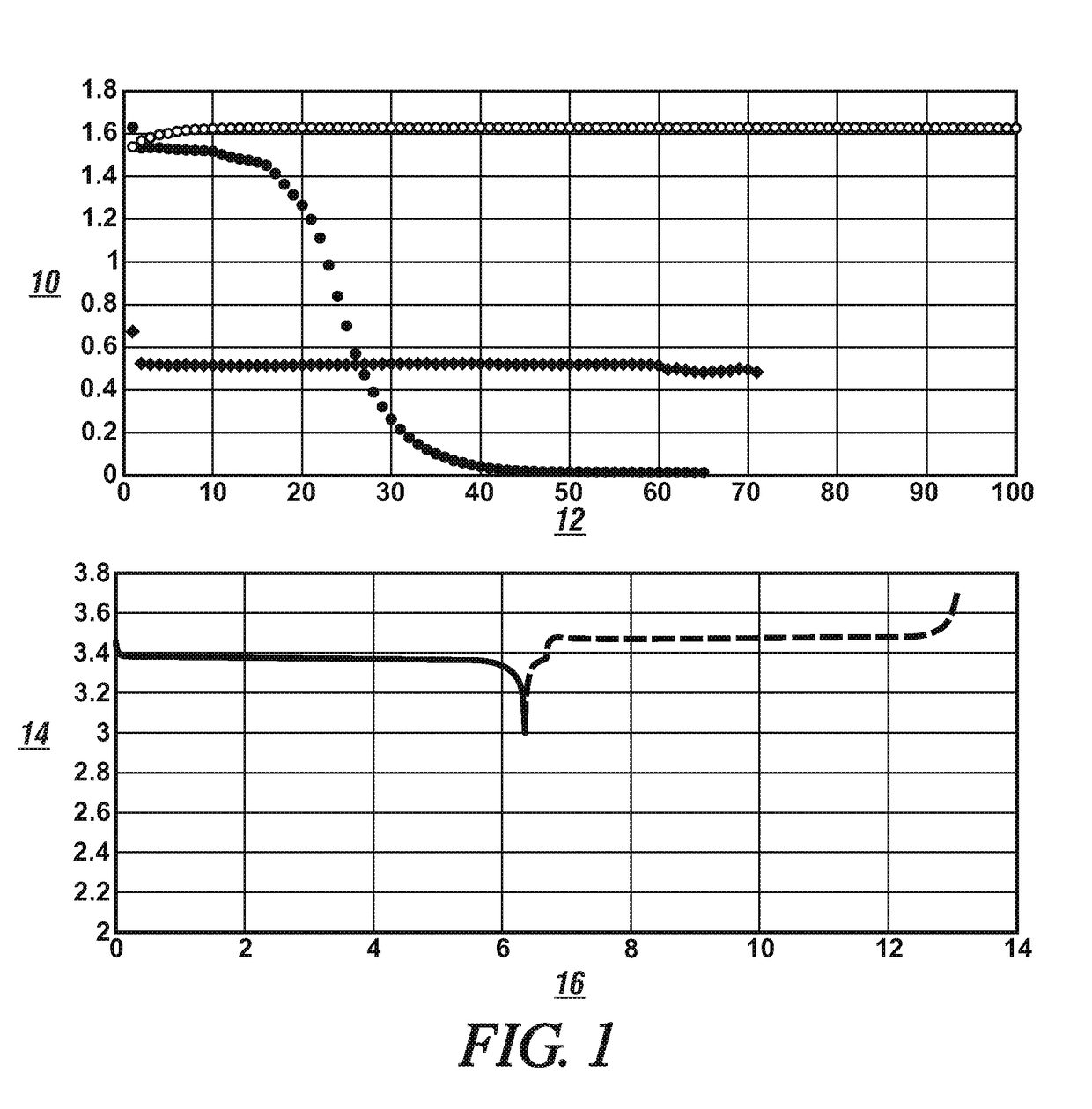

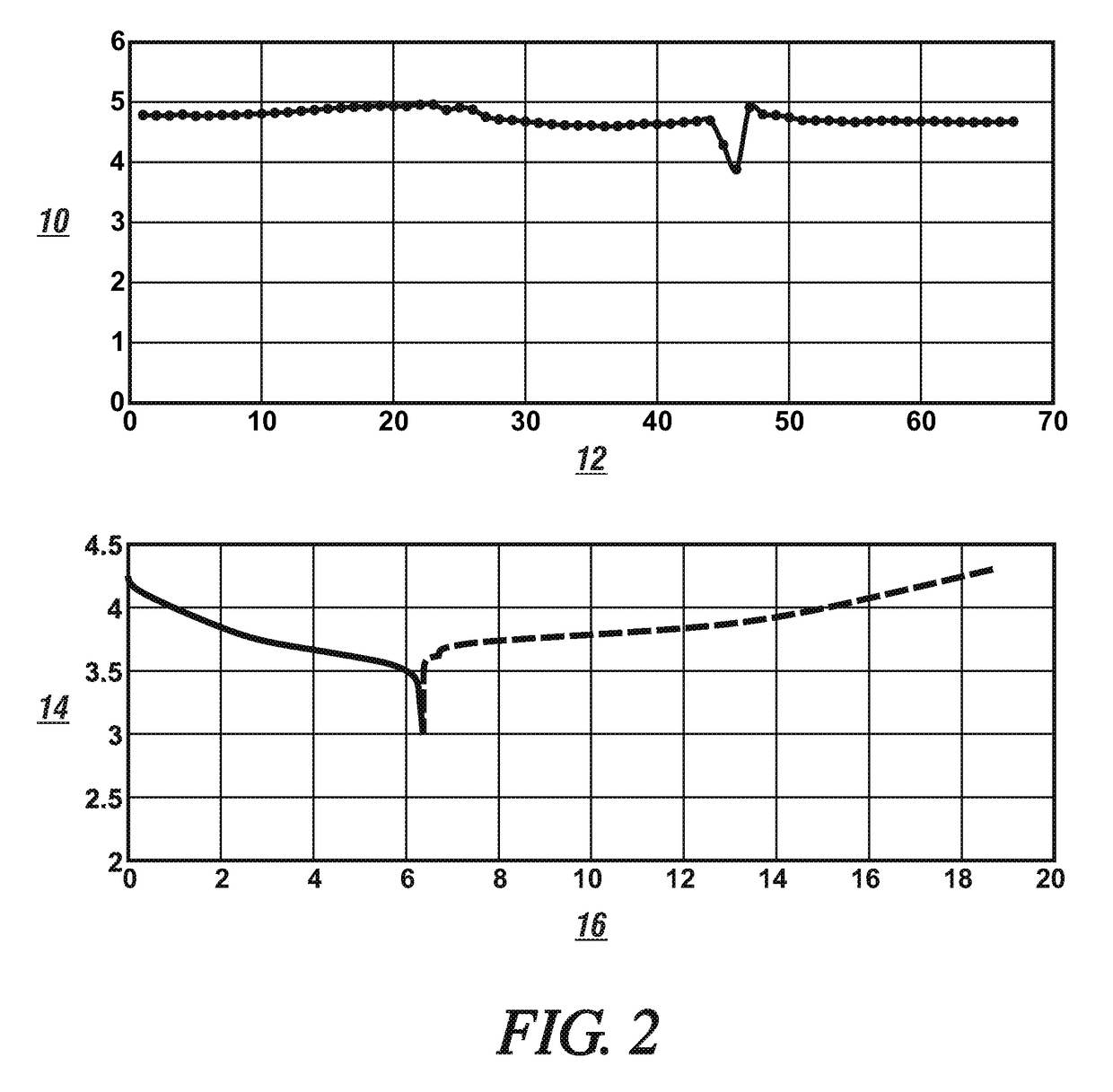

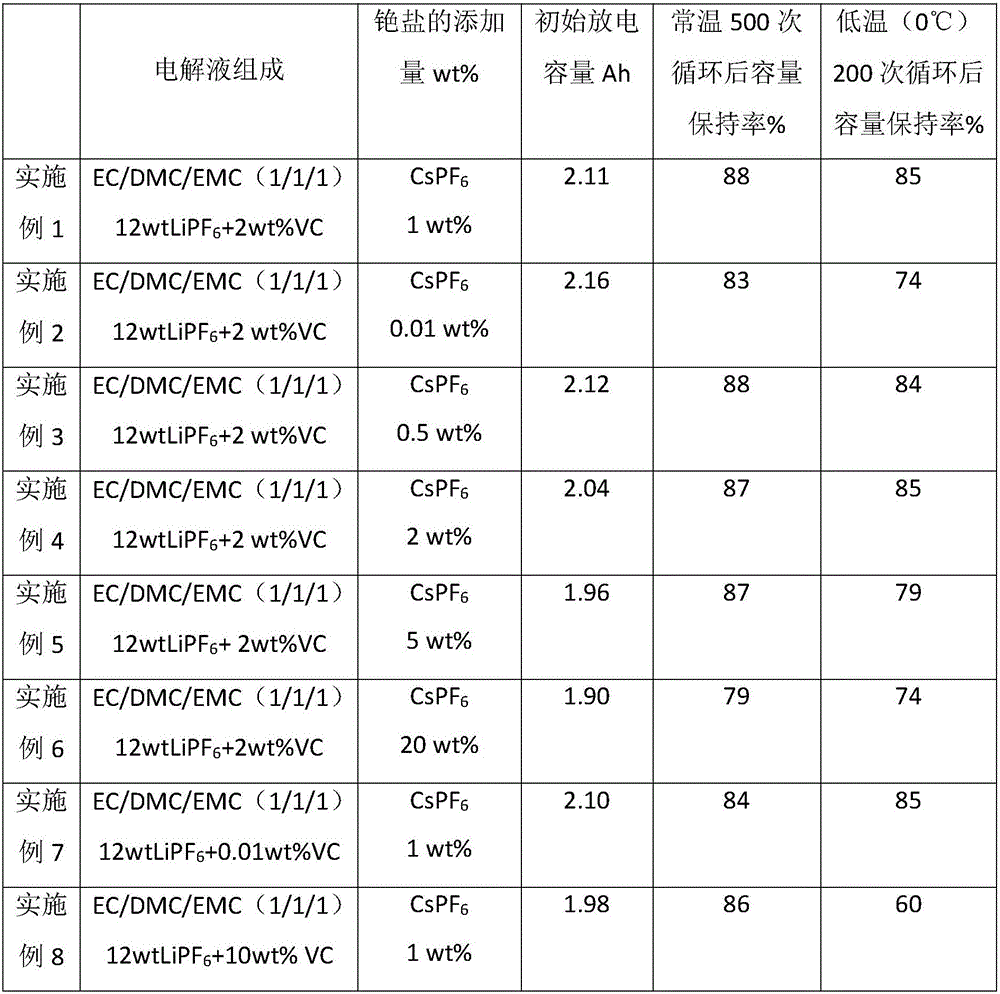

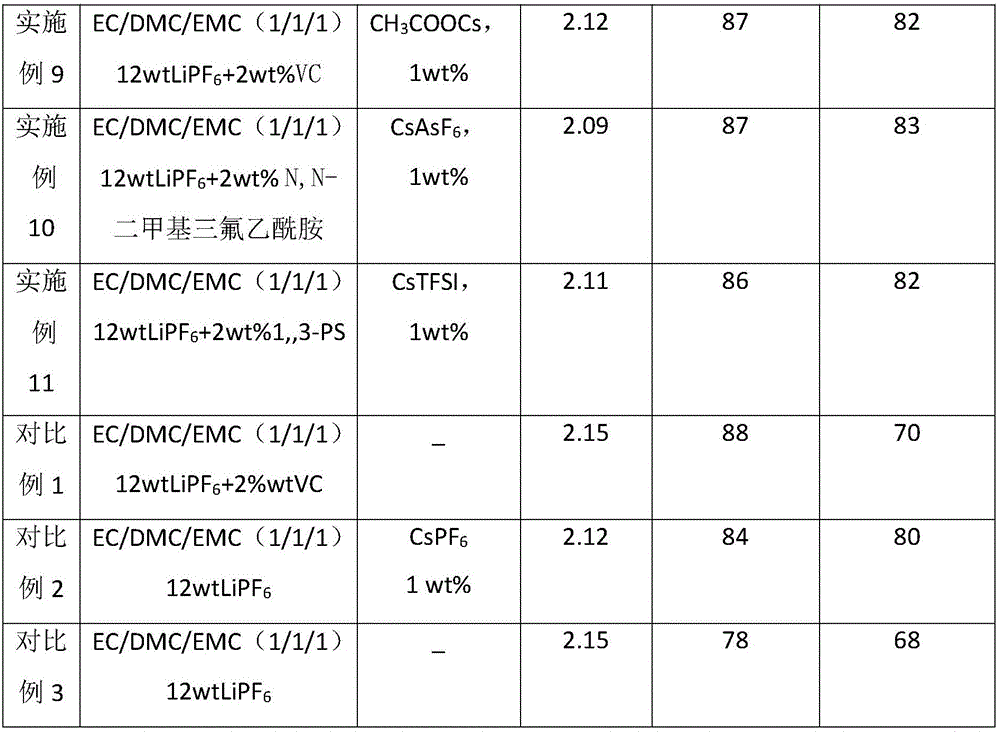

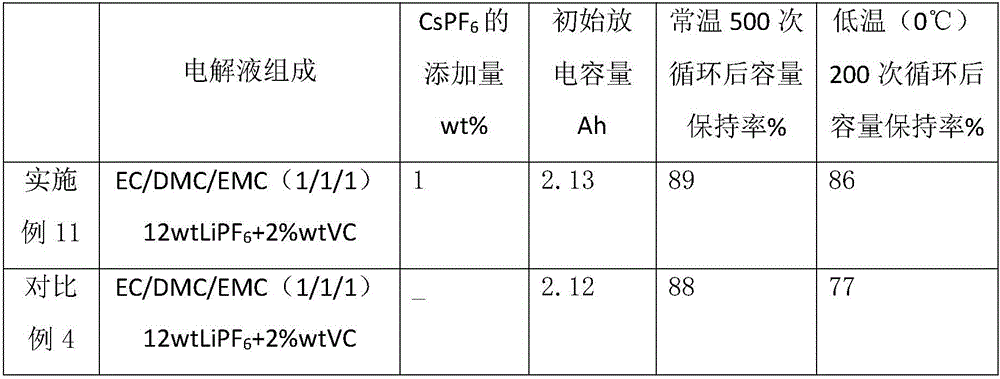

The invention discloses a non-aqueous electrolyte and a lithium secondary battery using the same. The non-aqueous electrolyte contains lithium electrolyte salt, a non-aqueous organic solvent, a cesium salt compound additive and a film forming additive; the cesium salt compound additive accounts for, by weight, 0.01%-20% of the total amount of the non-aqueous organic solvent. In the non-aqueous electrolyte, the cesium salt compound additive can increase ionic conductivity of the electrode surface during charging and discharging, impedance formed on the electrode surface to an SEI film by a conventional film-forming additive is lowered, cyclic stability of the lithium secondary battery is well maintained, and low-temperature property and rate performance are obviously improved.

Owner:SHANGHAI XIAOYUAN ENERGY TECH CO LTD

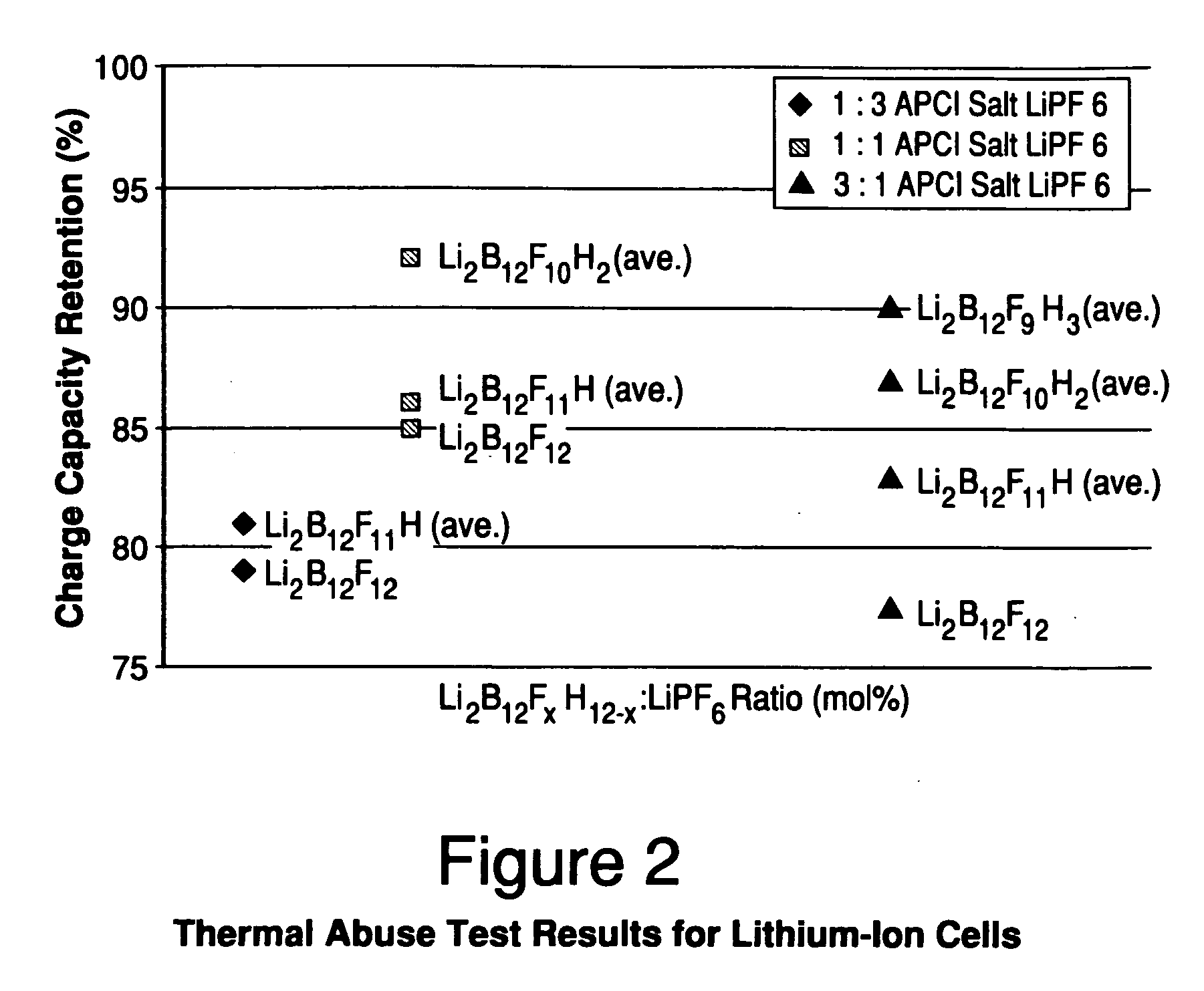

Polyfluorinated boron cluster anions for lithium electrolytes

InactiveUS20060204843A1Low viscosityLower impedanceOrganic electrolyte cellsLi-accumulatorsBoron clustersSolvent

The present invention relates a battery comprising: a lithium salt of the formula: Li2B12FxZ12-x where x averages at least 4 but not more than 12 and Z is H, Cl, or Br, and a solvent having a higher dielectric constant than a solvent consisting of a 3:7 ratio by weight of ethylene carbonate (EC) and diethyl carbonate (DEC).

Owner:AIR PROD & CHEM INC

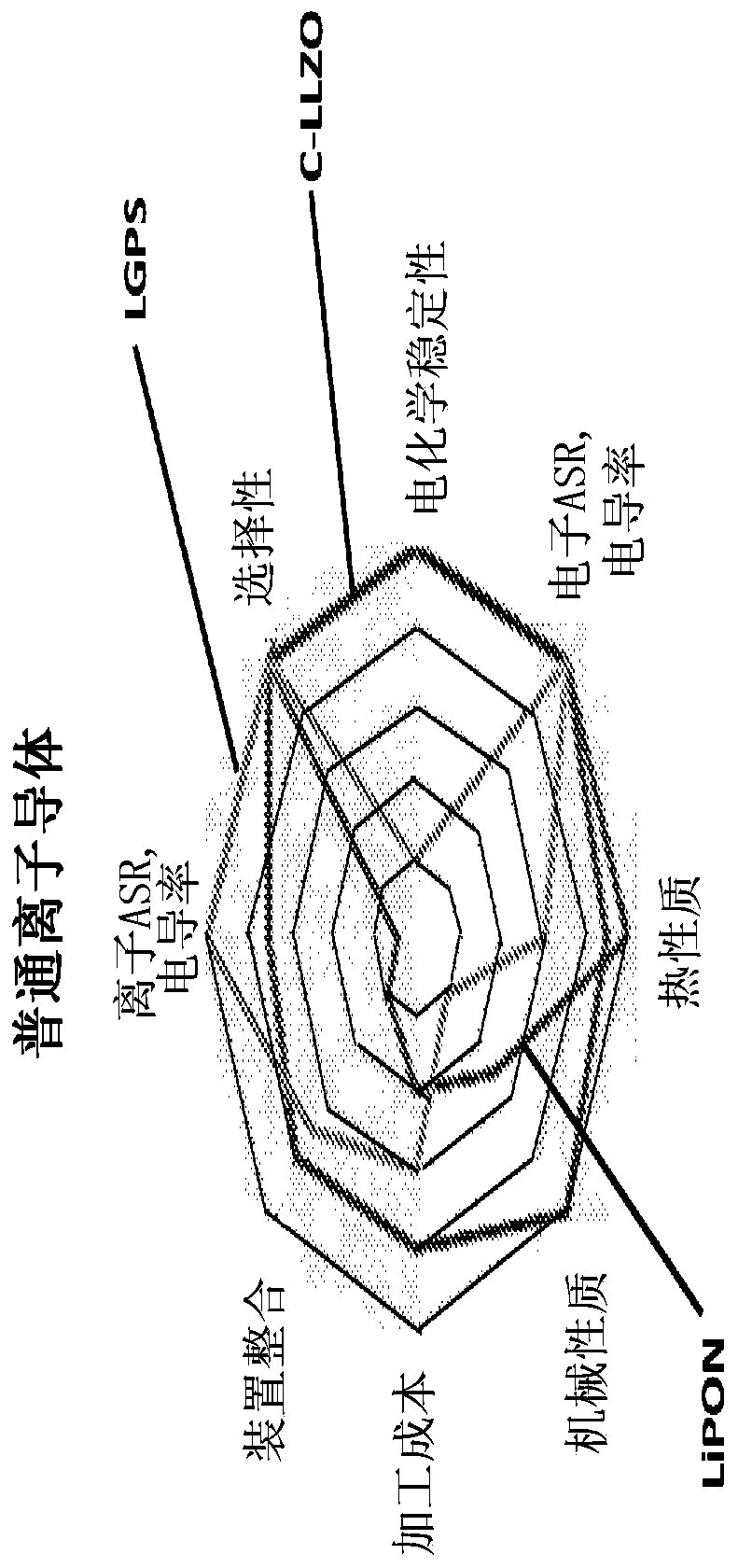

All-solid state li ion batteries comprising mechanically flexible ceramic electrolytes and manufacturing methods for the same

InactiveCN110088969ASolid electrolytesElectrode thermal treatmentSolid state electrolyteAll solid state

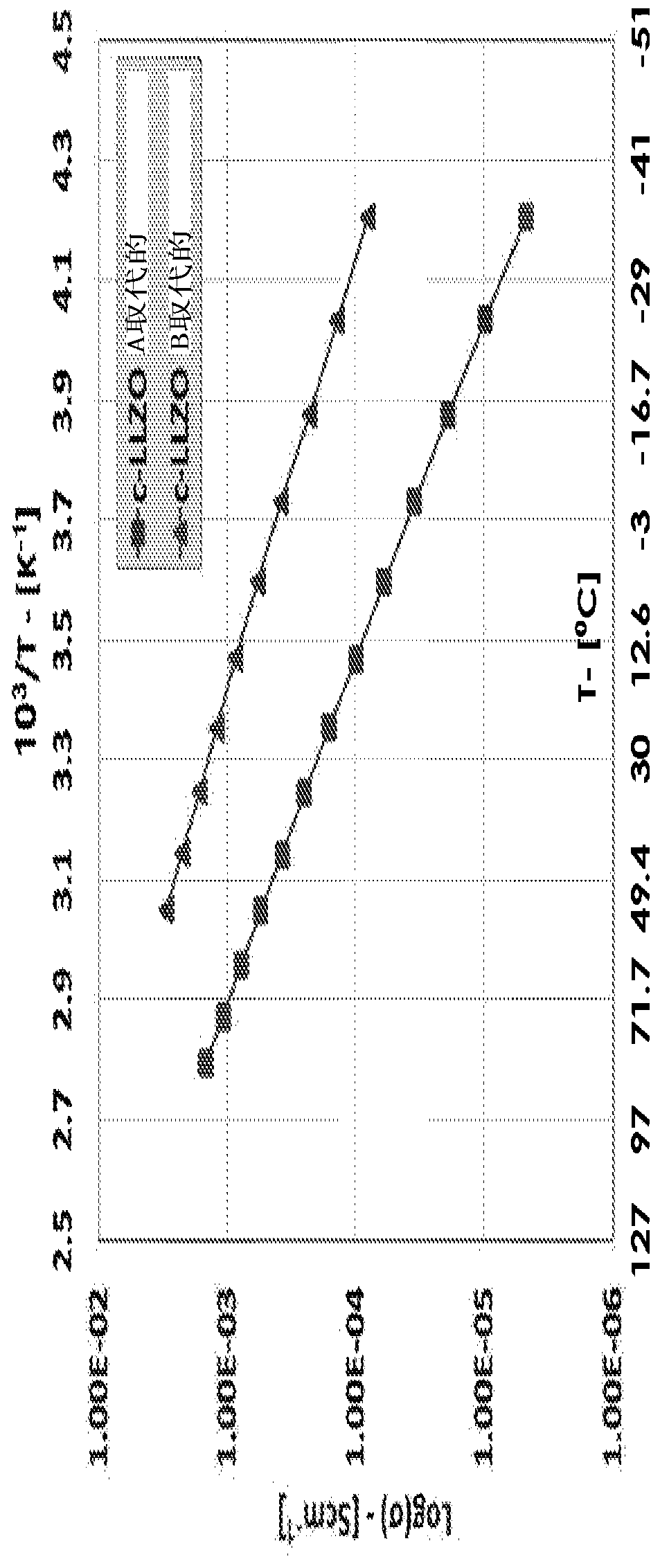

An all solid-state Li-ion battery having a mechanically flexible, ceramic, solid-state electrolyte having a lithium-conducting oxide composition selected from the group consisting of perovskite-type oxides, NASICON-structured lithium electrolytes, and garnet-type structures containing transition metal oxides. In particular, the garnet cubic lithiumlanthanium zirconium oxide (c-LLZO), c-LLZO-LSPO composite and varous lithium ion conducting sulfides are disclosed.

Owner:FISKER INC

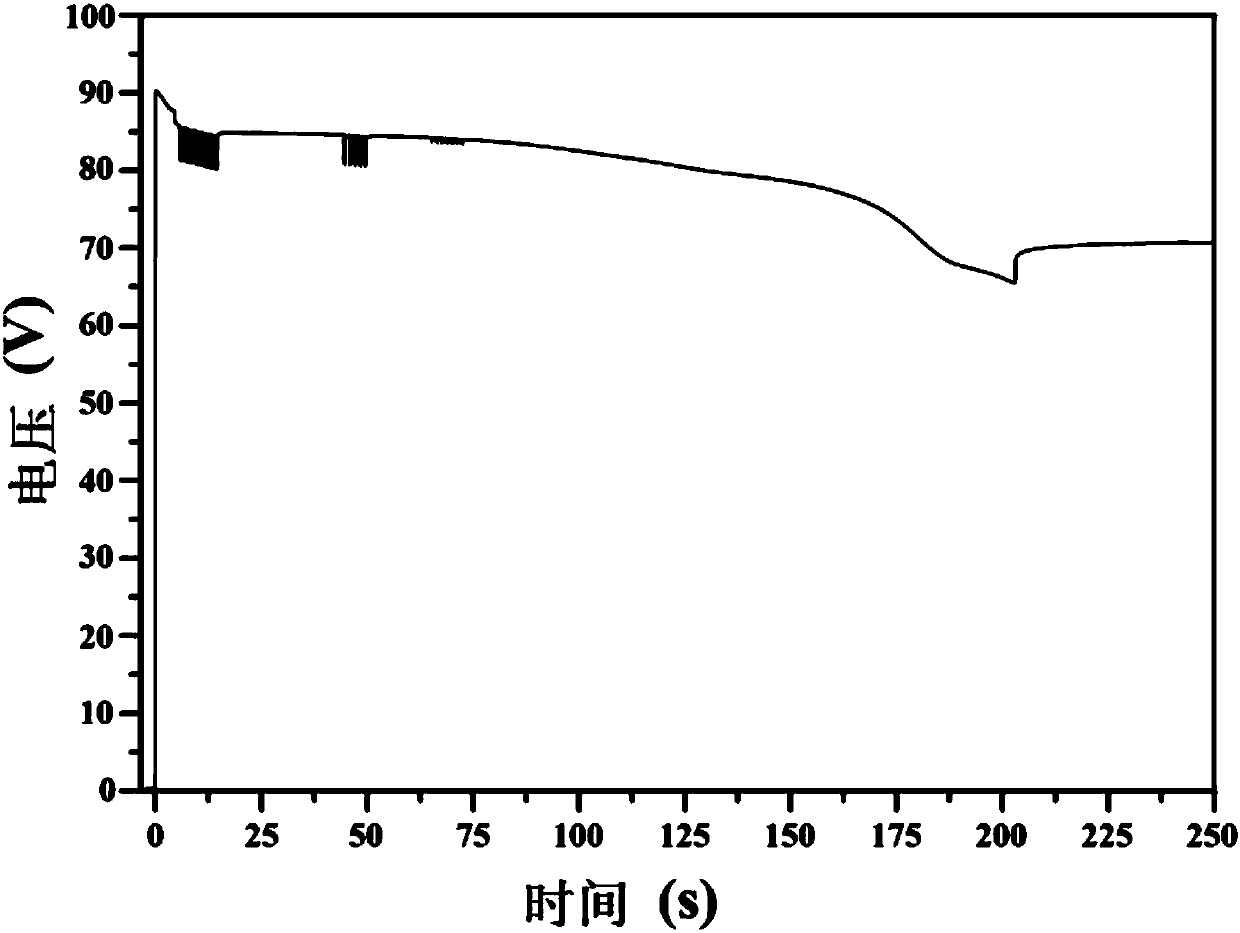

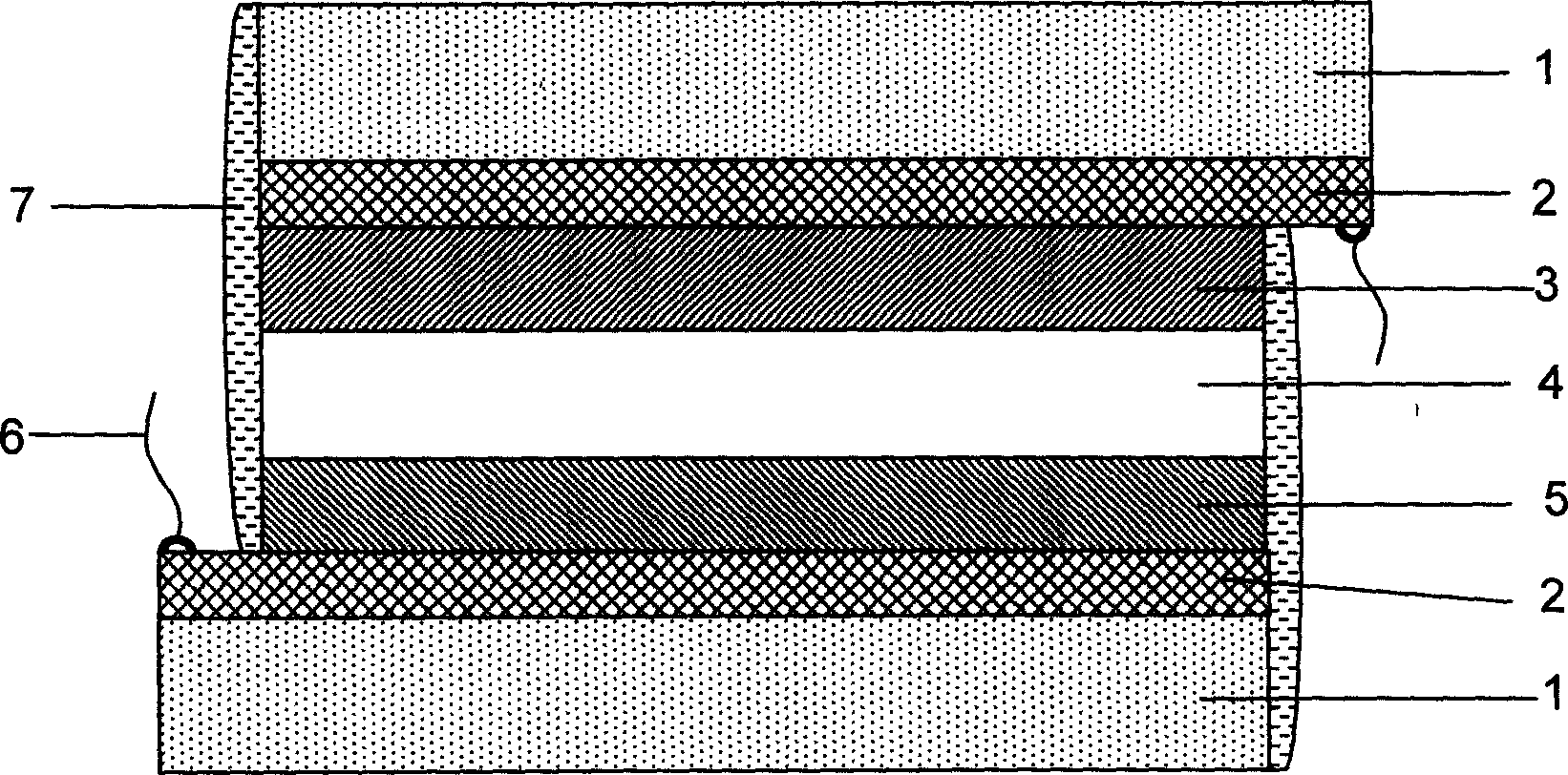

Lithium secondary battery having improved stability to overcharge

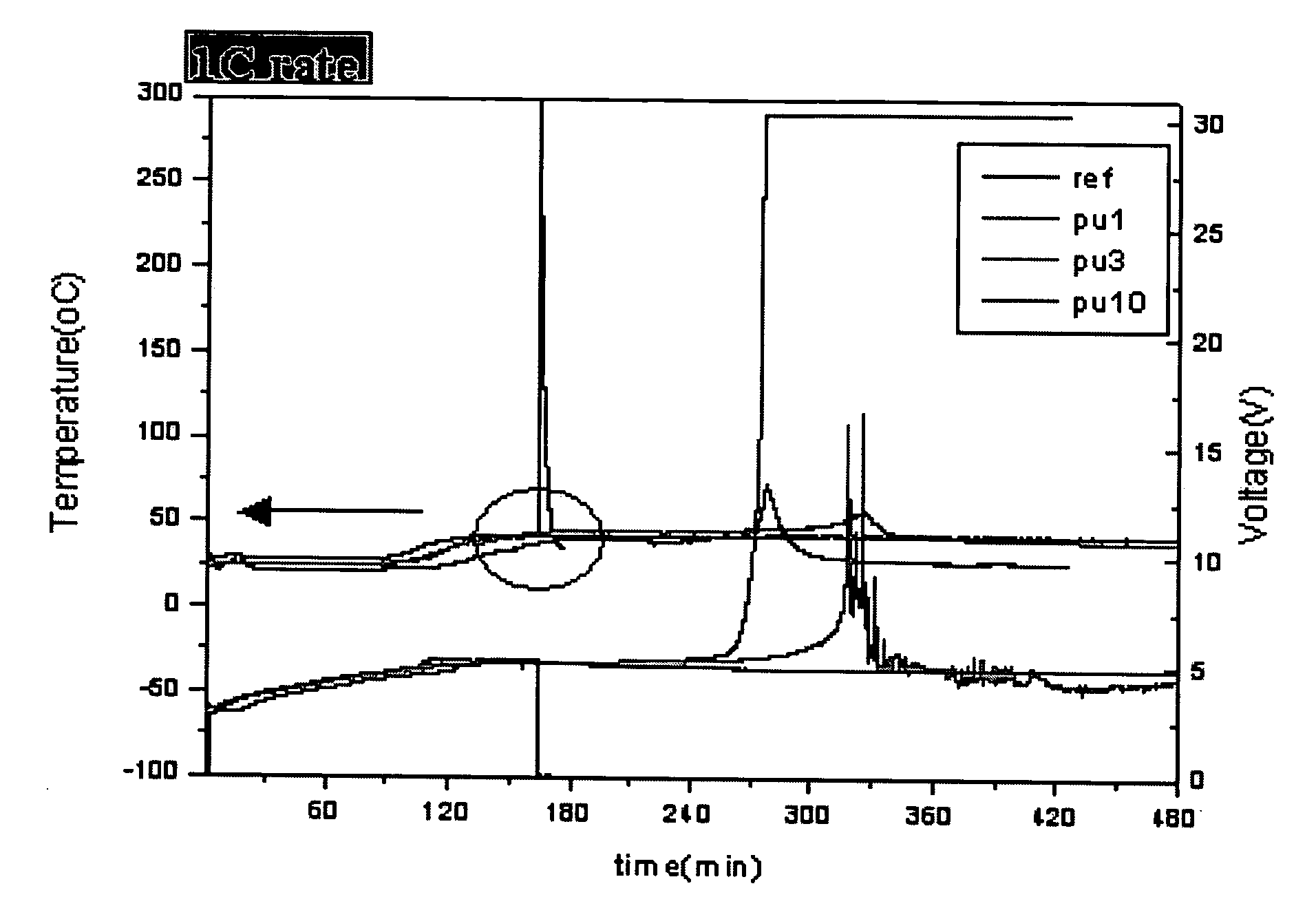

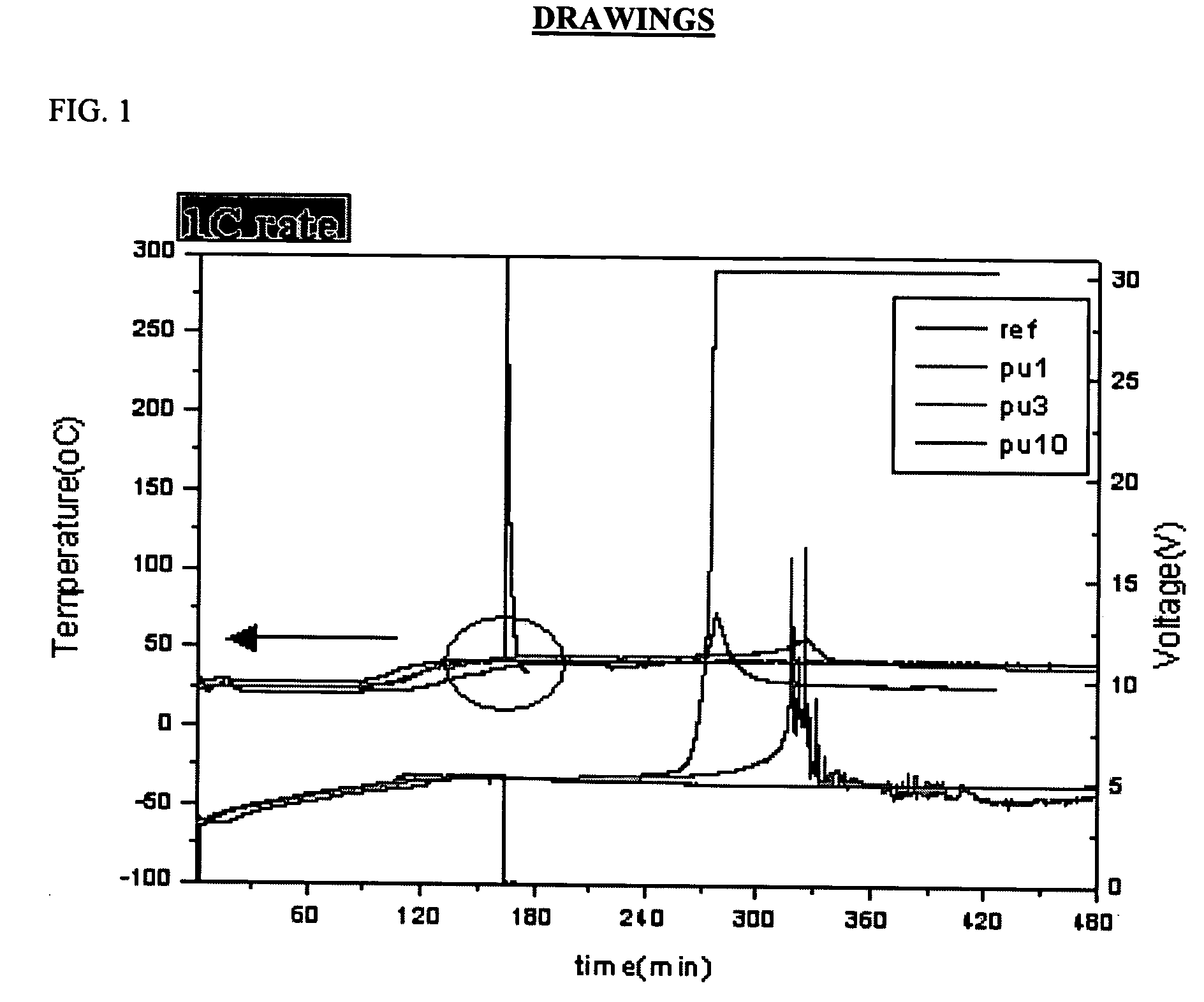

ActiveUS20060251956A1Suppress abnormal operationHigh reliability and safetyCell temperature controlSolid electrolyte cellsInternal resistanceDecomposition

Disclosed is a lithium secondary battery comprising an electrode assembly composed of a cathode, an anode and a separator, and a lithium electrolyte, wherein the electrodes and / or electrolyte include a compound (“urethane compound”) and / or polymer (“poly urethane”) which are decomposed upon overcharge of the battery and contain a urethane group in a molecular structure thereof. The lithium secondary battery of the present invention is characterized by addition of a compound or polymer having a urethane group to electrodes and / or electrolyte, wherein the thus-added compound and / or polymer have substantially no adverse effects on general performance of the battery under normal operating conditions and are decomposed with high reliability upon overcharge of the battery, thereby offering time delay effects for securing battery safety, and the decomposition products thereof result in sharply increased internal resistance of the battery, thereby increasing battery safety.

Owner:LG ENERGY SOLUTION LTD

Ion exchange fiber and its preparation method and use

InactiveCN1438074AEasy to makeRaw materials are easy to getAmphoteric ion-exchangersOrganic electrolyte cellsFiberSynthesis methods

The present invention relates to an ion-exchange fibre, its synthesis method and application. Said alkaline ion-exchange fibre adsorbent is acrylonitrile-methyl methacrylate-itaconate tripolymer containing amino functional group, can remote the acidic matter, transition metal ion and heavy metal ion from non-aqueous solution or non-aqueous solvent. Said invention is simple in preparation of product, and the adsorption volume of adsorbing acidic impurity from non-water is high, and its adsorption speed is high, its chemical property is stable. In the purification of lithium electrolyte by using said product the condition for removing impurity is moderate, at the same time of removing acidic impurity, the impurity into also can be removed.

Owner:FUDAN UNIV

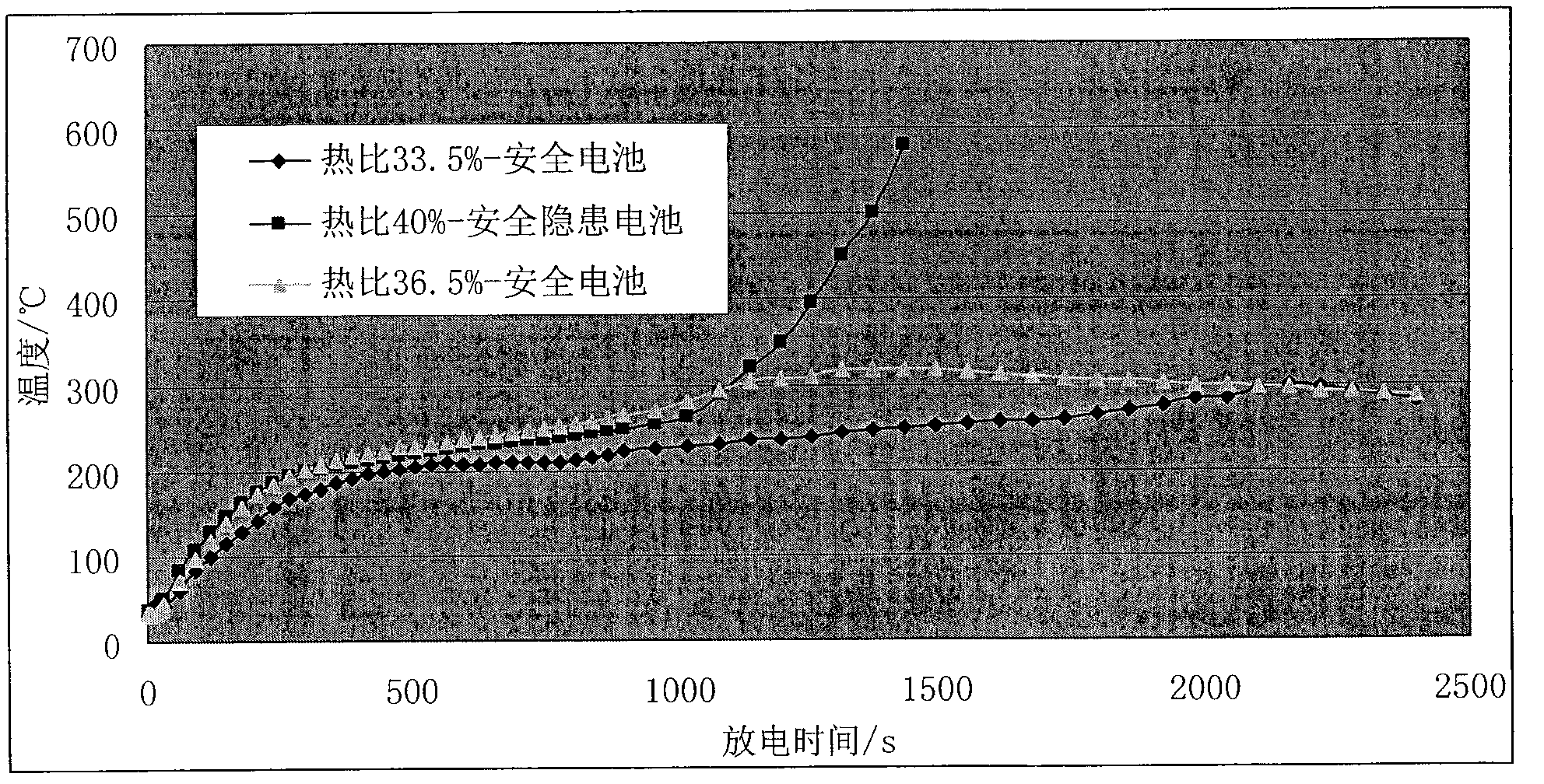

Cell unit for thermal cell with high specific energy

InactiveCN102856565AIncrease profitImprove conductivityDeferred-action cellsCell electrodesThermal impactOptimal weight

The invention relates to the field of thermal cell, and provides a cell unit for thermal cell with high specific energy (75 Wh / kg). The invention is characterized in that: (1) the optimal content of heating powder in the cell unit is 30-39 wt.% in the thermal balance design of the cell unit, and when the content of heating powder in the cell unit is above 40 wt.%, potential safety hazards are present in the thermal cell; (2) the optimal weight ratio of LiSi anode and CoS2 cathode is 1: 2.5 to 1: 3.5 in the compatibility design of cell unit for Li(Si) / LiCl-LiBr-LiF / CoS2 electrochemical system thermal cell; (3) 2-10% of LiCl-LiBr-LiF tertiary lithium electrolyte is added to the anode material for promoting conductivity and increasing the utilization rate of the anode active material; and (4) a graphite isolation material with good conductivity is arranged between the cathode sheet and the heating sheet for reducing thermal impact of the heating sheet on the cathode material and increasing the utilization rate of the cathode active material.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Nonaqueous electrolyte secondary battery and method of producing the same

InactiveUS20080220331A1Improve featuresIncrease temperatureAlkaline accumulatorsFinal product manufactureLithium electrolyteLayered structure

To obtain a nonaqueous electrolyte secondary battery which has a high capacity and excellent storage characteristics at elevated temperatures. A nonaqueous electrolyte secondary battery having a positive electrode including a positive active material having a layered structure, a negative electrode including a negative active material, and a nonaqueous electrolyte including a lithium electrolyte salt and a solvent, wherein carbon dioxide is dissolved in the nonaqueous electrolyte, and the concentration of the lithium electrolyte salt in the nonaqueous electrolyte is 1.0 mol / liter or more, and the battery is charged in such a way that an end-of-charge potential of the positive electrode becomes 4.40 V (vs. Li / Li+) or more.

Owner:SANYO ELECTRIC CO LTD

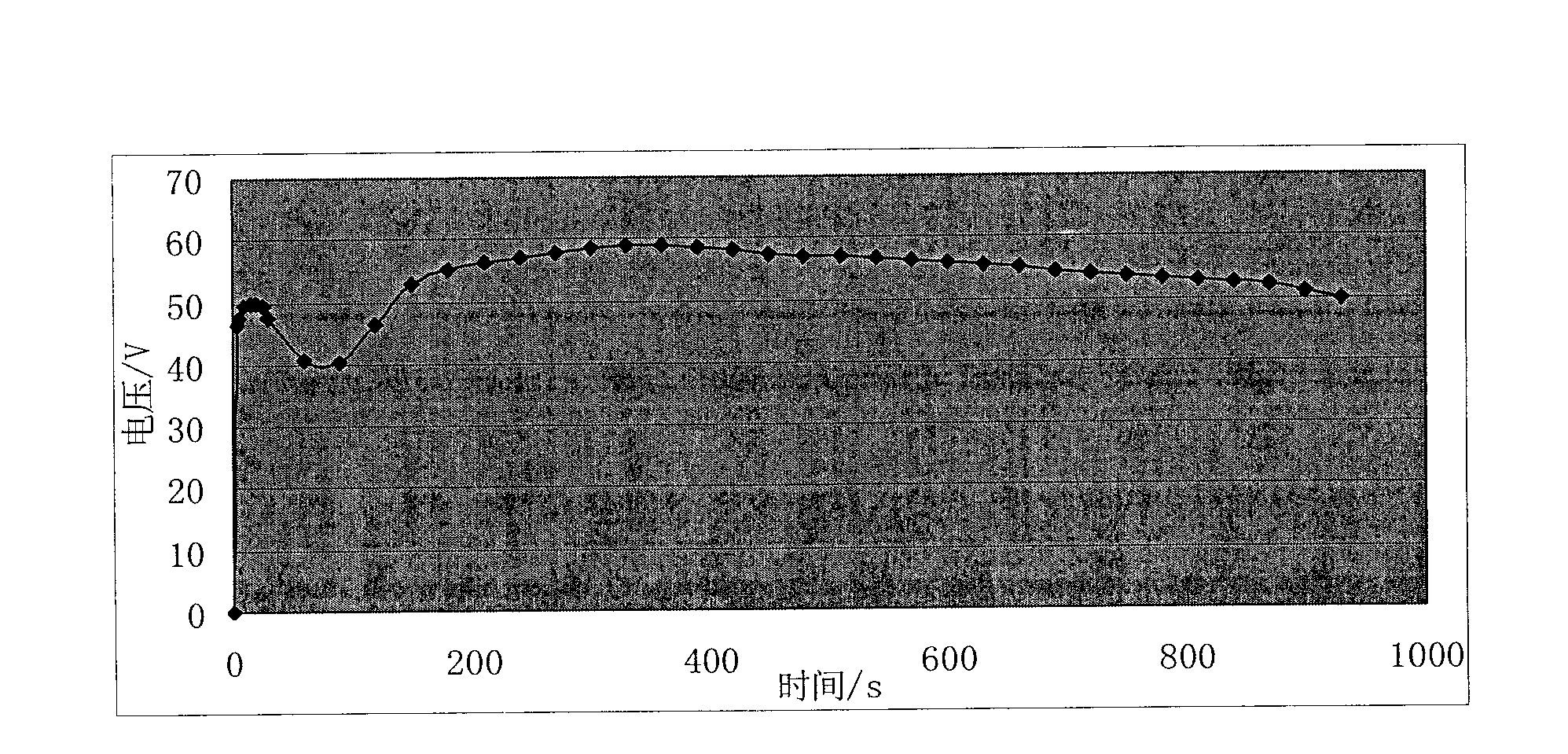

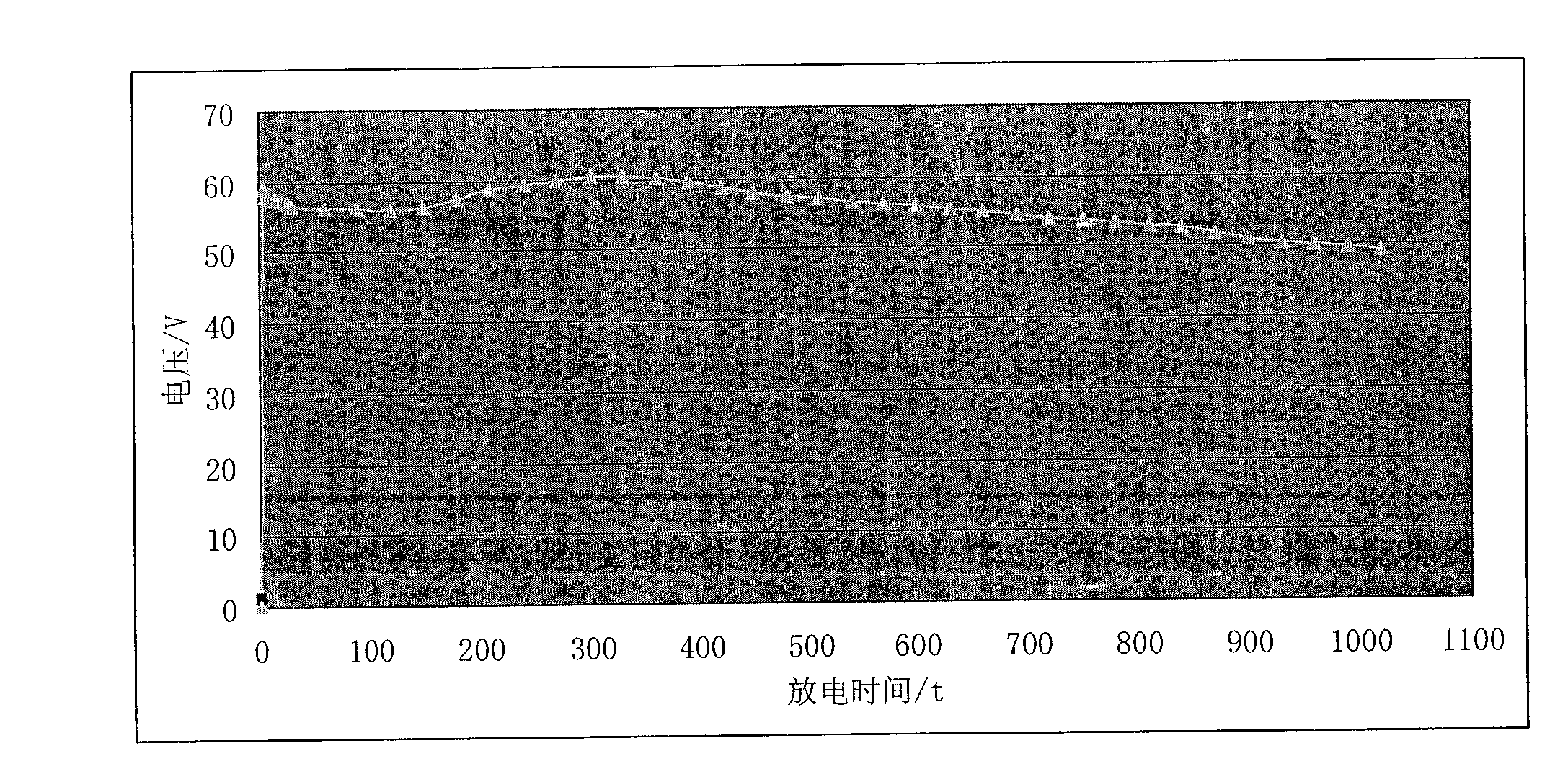

Battery cell of thermal battery for carrier rocket

ActiveCN107732268AGuaranteed adsorption effectGuaranteed reliable performanceDeferred-action cellsSorbentRocket

The invention discloses a battery cell of a thermal battery for a carrier rocket. The battery cell of the thermal battery for the carrier rocket comprises an isolating powder, a heating powder, a positive electrode powder and a negative electrode powder, wherein the isolating powder consists of LiF-LiCi-LiBr ternary all-lithium electrolyte molten salt and a molten salt adsorbent; the molten salt adsorbent accounts for 50-65% of the total mass of the isolating powder. A performance characteristic that the pulse voltage drop change rates of the thermal battery in three working time periods of 5-20s, 45-55s and 65-75s are lower than 2% is achieved, and the performance reliability of load equipment on the rocket is guaranteed. Raw materials and a component preparation technology of the batterycell of the thermal battery provided by the invention are the same as those of the conventional thermal battery, so that large-scale production can be carried out under the premise of not restructuring the conventional production line and the production process is high in universality; the cost pressure is low and the economic benefits are good while model development and production tasks of a new-generation solid carrier rocket are met.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Hybrid solid electrolyte membrane, method of manufacturing the same, and lithium ion capacitor comprising the same

InactiveCN102543448AImprove securityHybrid capacitor separatorsHybrid capacitor electrolytesInorganic materialsLithium electrolyte

The present invention provides a hybrid solid electrolyte membrane including a lithium electrolyte salt, an organic polymer, and an inorganic material, and a lithium ion capacitor comprising the same. It is possible to overcome damage of a separator and failure of a capacitor due to deposition of lithium ions on a cathode by using a hybrid solid electrolyte membrane in accordance with the present invention in a lithium ion capacitor. Further, it is possible to simplify manufacturing processes without a pre-doping process. Further, the hybrid solid electrolyte membrane can also perform a role of a separator.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

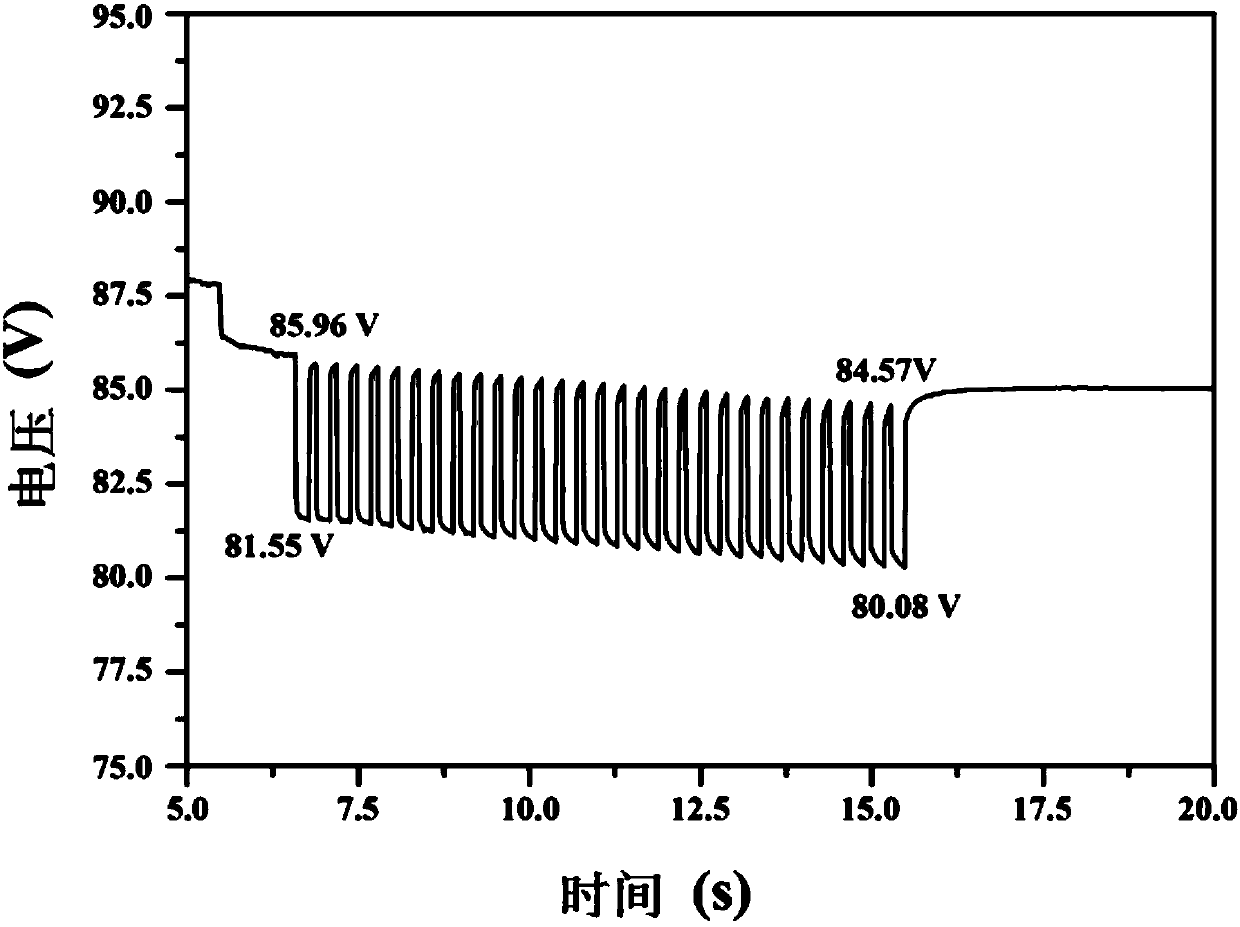

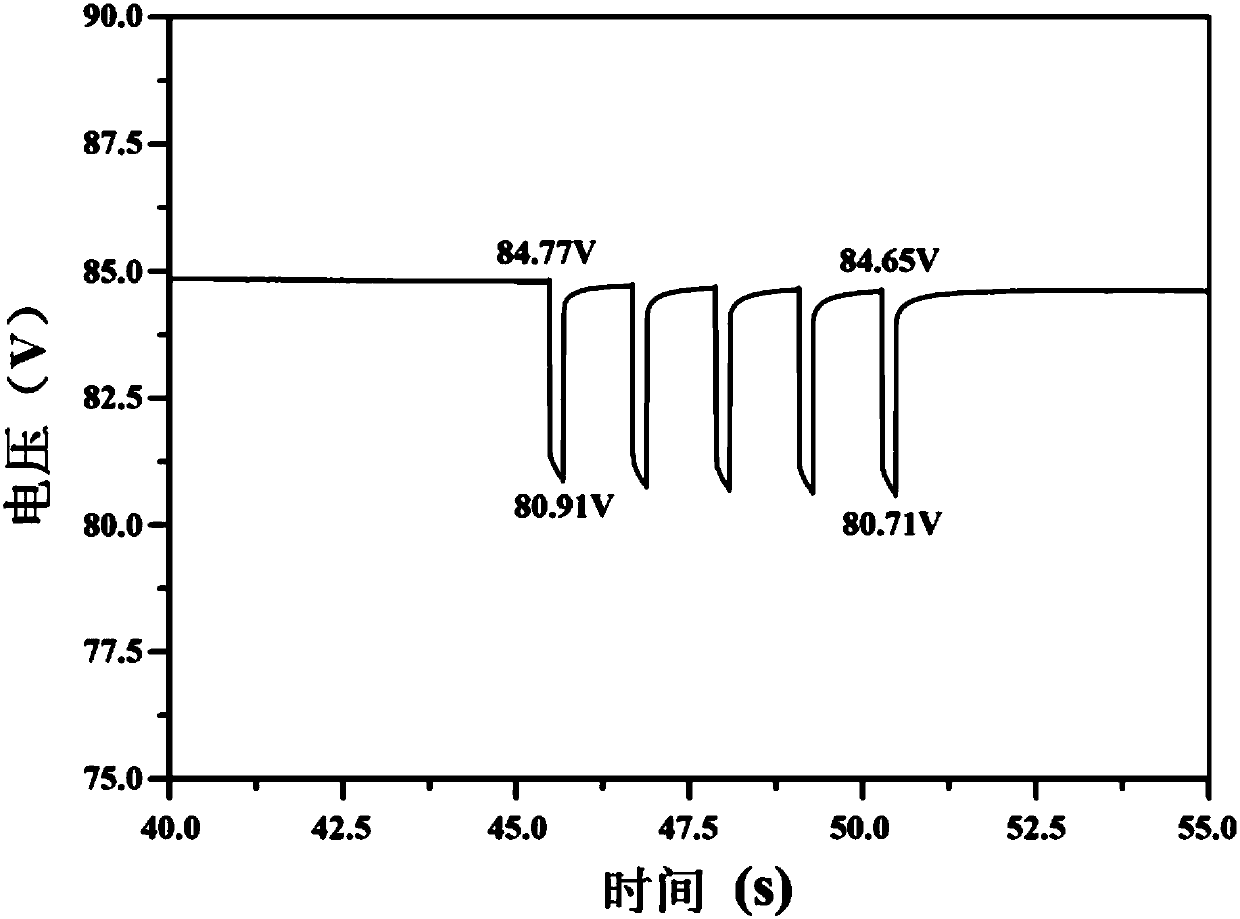

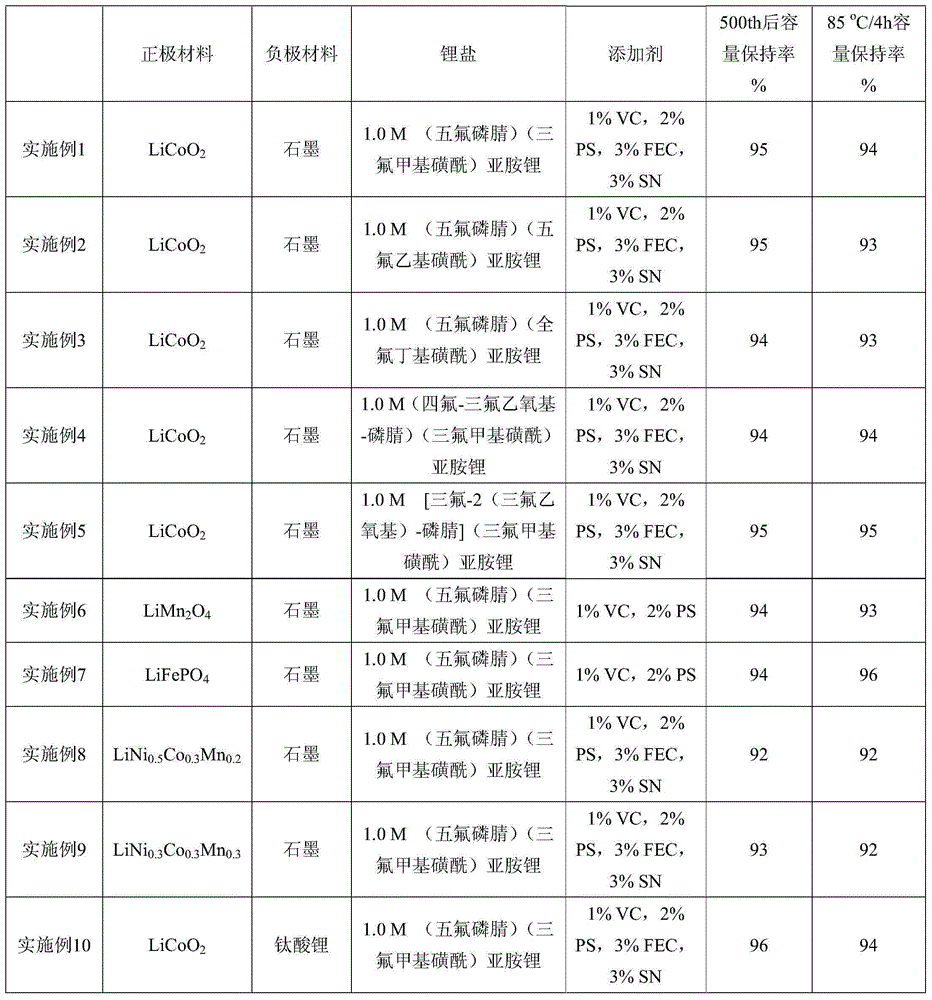

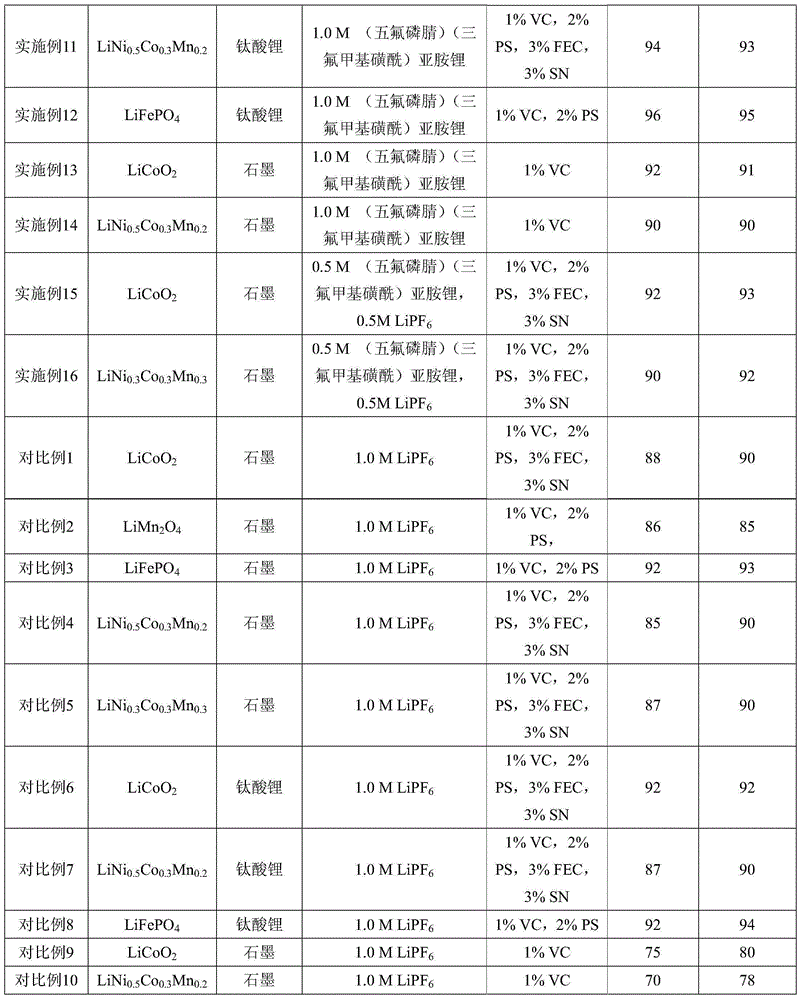

Phosphazene perfluoroalkanesulfonylimide lithium electrolyte and battery using electrolyte

ActiveCN105206873AImprove thermal stabilityImprove water resistanceSecondary cellsComposite electrolytesOrganic solventCarbonate ester

The invention provides a phosphazene perfluoroalkanesulfonylimide lithium electrolyte which includes a conductive lithium salt, a nonaqueous organic solvent and an additive, wherein the conductive lithium salt includes phosphazene perfluoroalkanesulfonylimide lithium with the structural formula being shown in the description. In the formula, M+ is Li, R1-5 = -OR7 or -M[NSO2-R6], R6 is fluorinated alkyl containing 1-8 carbon atoms, R7 is an alkanes group containing 1-10 carbon atoms. Phosphazene perfluoroalkanesulfonylimide lithium provided by the invention is good in thermal stability and hydrolysis resistance, has high electrical conductivity and oxidation potential in the traditional carbonate ester solution, and is good in compatibility with the extensively used electrode materials.

Owner:GUANGZHOU TINCI MATERIALS TECH

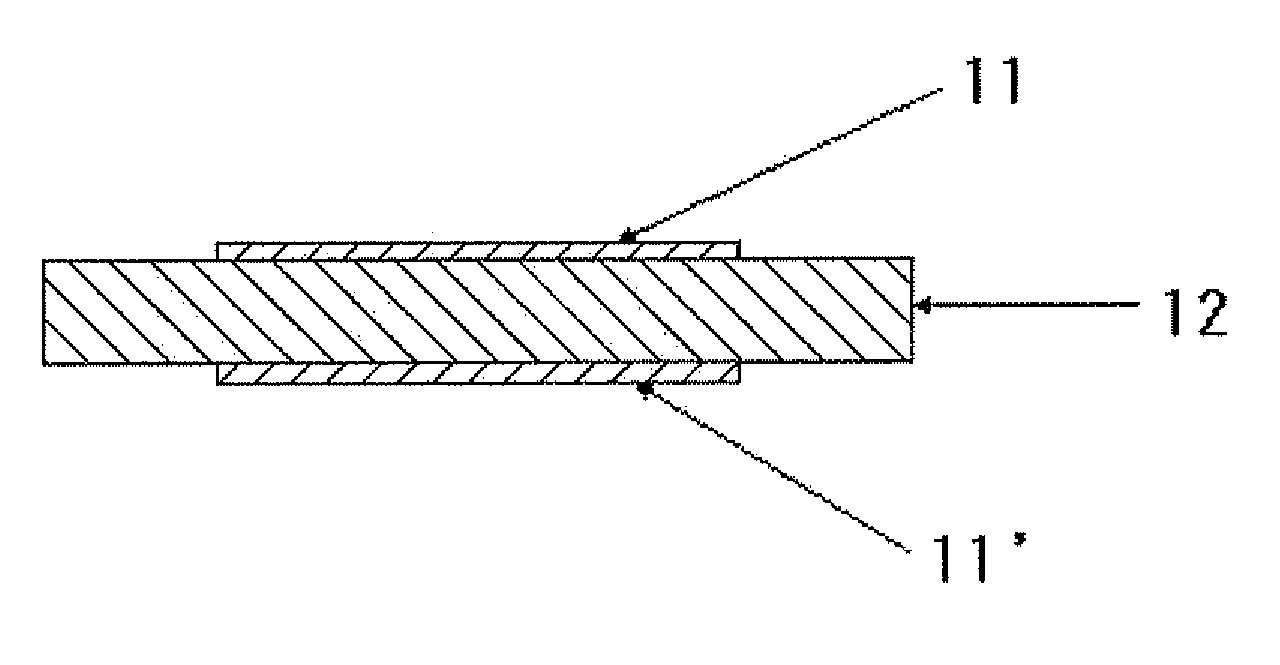

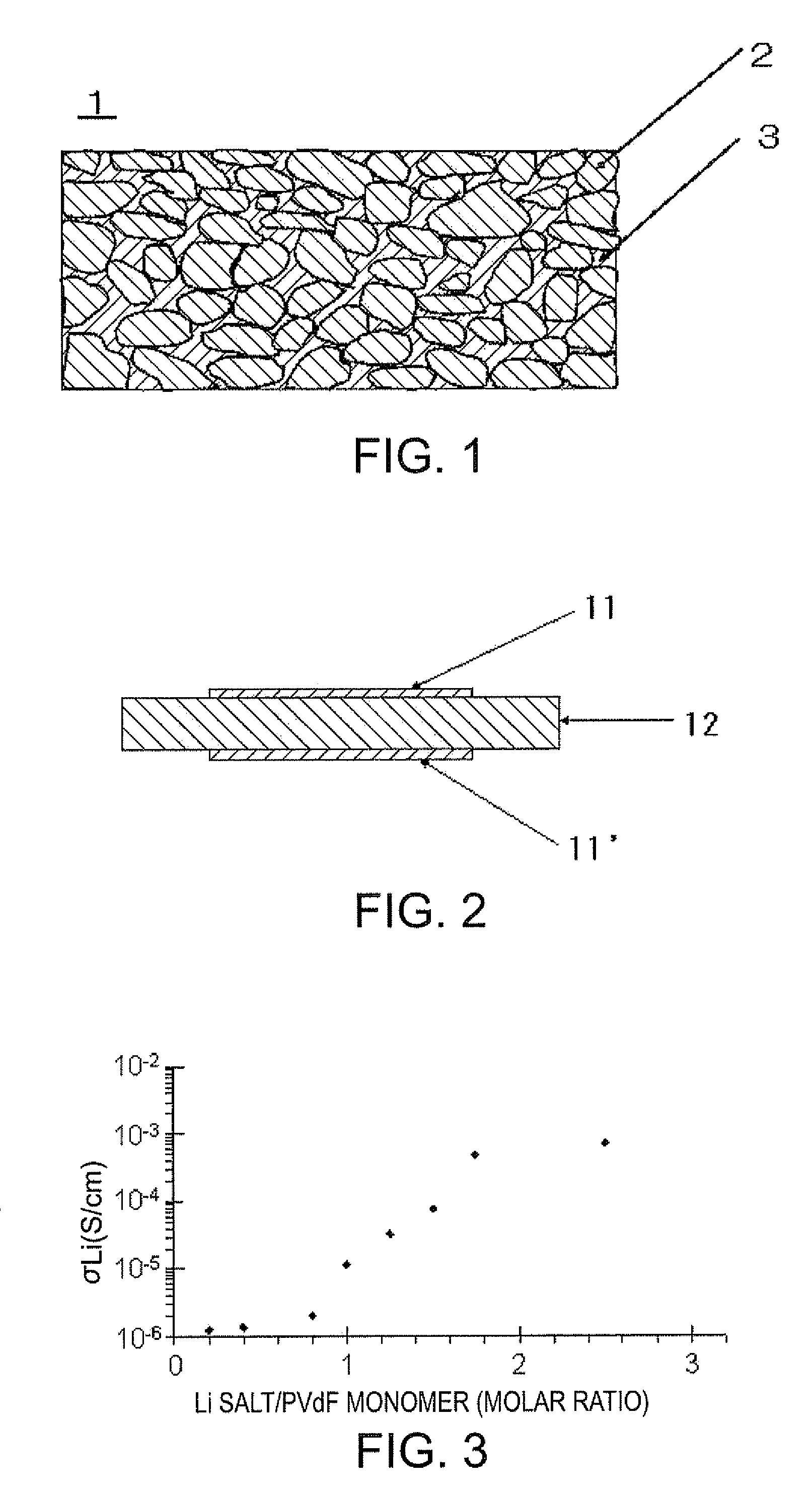

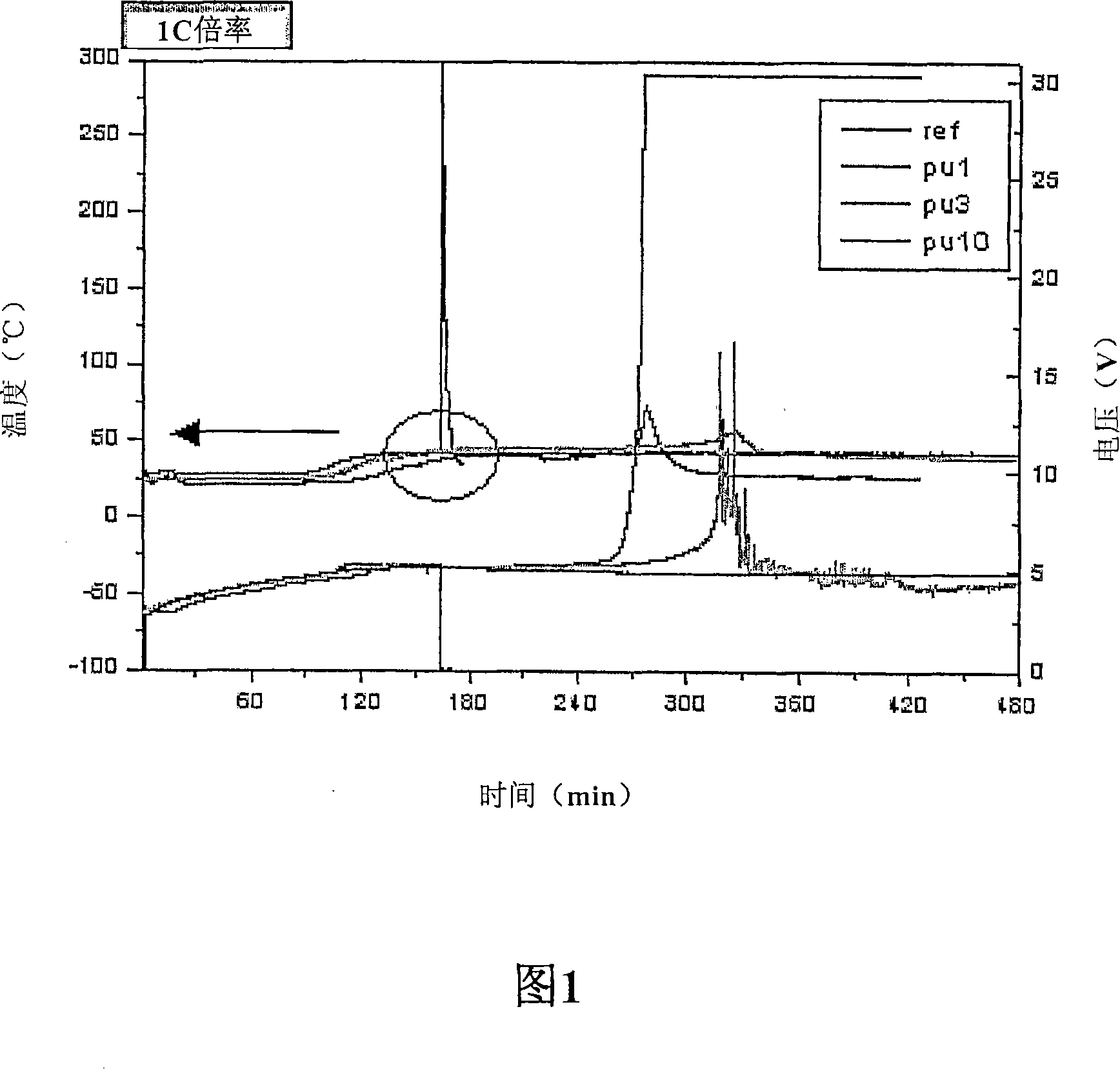

Polymer solid electrolyte, method of production thereof, and lithium ion secondary battery

ActiveUS20120288770A1High strengthImprove ionic conductivitySolid electrolytesSolid electrolyte cellsConductive polymerPhysical chemistry

A polymer solid electrolyte is provided that includes anatase-type titanium oxide, a lithium electrolyte salt, and an ion conductive polymer that binds the titanium oxide.

Owner:SEIKO EPSON CORP

Lithium secondary battery having improved stability to overcharge

ActiveCN101156263AEnsure safetyIncrease resistanceCell electrodesLi-accumulatorsTime delaysInternal resistance

Disclosed is a lithium secondary battery comprising an electrode assembly composed of a cathode, an anode and a separator, and a lithium electrolyte, wherein the electrodes and / or electrolyte include a compound (''urethane compound'') and / or polymer (''poly urethane'') which are decomposed upon overcharge of the battery and contain a urethane group in a molecular structure thereof. The lithium secondary battery of the present invention is characterized by addition of a compound or polymer having a urethane group to electrodes and / or electrolyte, wherein the thus-added compound and / or polymer have substantially no adverse effects on general performance of the battery under normal operating conditions and are decomposed with high reliability upon overcharge of the battery, thereby offering time delay effects for securing battery safety, and the decomposition products thereof result in sharply increased internal resistance of the battery, thereby increasing battery safety.

Owner:LG ENERGY SOLUTION LTD

Method for preparing electrochromism glass windows in sandwich type

InactiveCN1872761AImprove ion storage capacityImprove the color change effectSilicon oxygenPhysical chemistry

This invention relates to a method for improving the properties of sandwich electrochromic glazing window. The glazing window comprises an electrochromic layer, an ion-storing coating layer, and an electrolyte between them, wherein the electrolyte contains silicon-oxygen band skeleton structure and alkali metal as conductive ions. Water 0.001-20 wt. % is added to the electrolyte. This invention uses inorganic-organic silicon as the precursor and lithium electrolyte as conductive ions to improve the ion-storing capacity of the ion-storing coating layer and the electrochromic capacity of the electrochromic layer.

Owner:孙冬兰

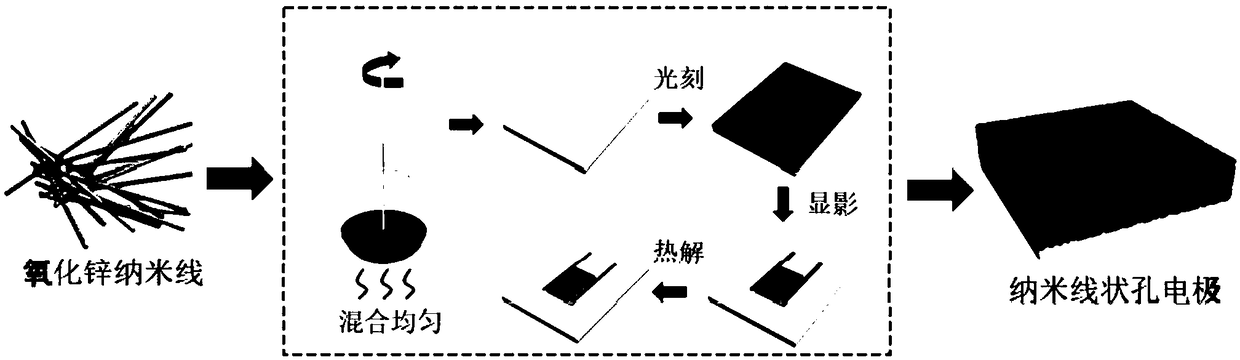

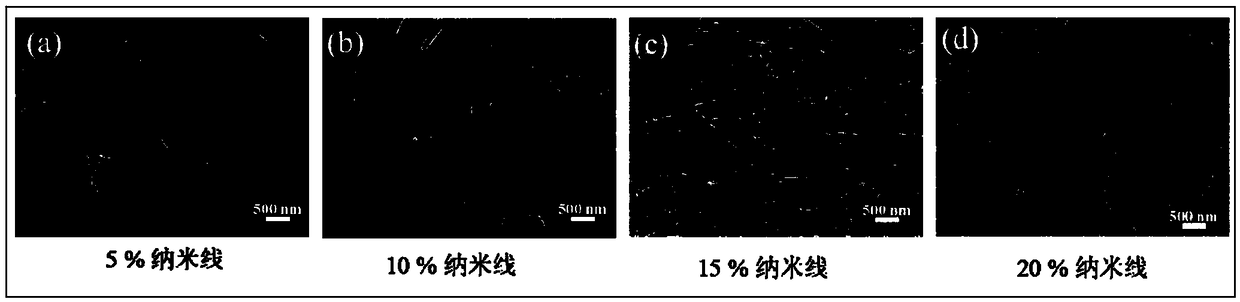

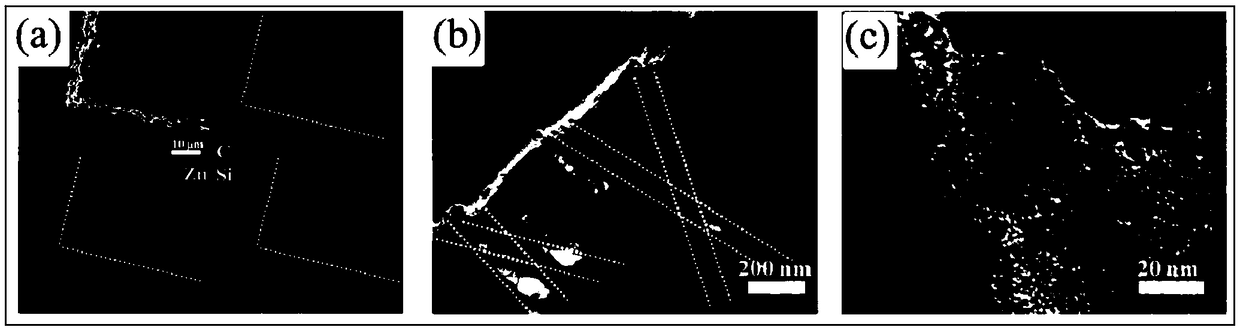

Three-dimensional nanometer linear pore carbon material and manufacturing technology of high-voltage miniature supercapacitor

ActiveCN108807007APromote infiltrationLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesHigh concentrationManufacturing technology

The invention relates to a three-dimensional nanometer linear pore carbon material. A thickness is 2-4 micron. The material has nanometer linear macropores, and a pore diameter is 80-120nm. The poresare overlapped to form a network structure. A mesopore with a 2-5nm size and a micropore below 2nm are arranged in the pore groove of each nanometer linear macropore. The macropores are generated through reducing and evaporating zinc oxide nanowires. The mesopores and the micropores are generated through activating the zinc oxide nanowires on macropore pipe walls. The material has advantages thatthrough activating cheap zinc oxide nanowires, three-dimensional hole structures which are connected are formed, which is good for the infiltration of an electrolyte; through a macropore-mesopore-micropore and other multistage pore channel structures, the specific surface area of a carbon material is increased; a miniature supercapacitor has a high area capacity and high cycle stability; a high-concentration bistrifluoromethane sulfonimide lithium electrolyte is used to expand the voltage window of a water system miniature supercapacitor and increase device energy density; and the technology is simple, cost is low and so on.

Owner:WUHAN UNIV OF TECH

Preparation method for lead acid battery electrolyte

InactiveCN102800896AIncrease internal resistanceIncrease capacityLead-acid accumulatorsElectrolytic agentColloidal silica

The invention discloses a preparation method for lead acid battery electrolyte, wherein the electrolyte activator comprises: deionized water, nickel sulfate, cobalt sulfate, aluminum sulfate, sodium sulfate, lithium iodide and lithium carbonate, and the electrolyte ingredients are prepared as follows: 5-10 parts by weight of a stabilizing agent, 6-13 parts by weight of colloidal silica, 5-12 parts by weight of analytically pure sulfuric acid, 20-30 parts by weight of pure water, and 2-5 parts by weight of the electrolyte activator. By using the electrolyte prepared by the method, the internal resistance of the lead acid battery can be reduced, and the capacity and the service life of the lead acid battery can be improved.

Owner:嘉兴金日升工具股份有限公司

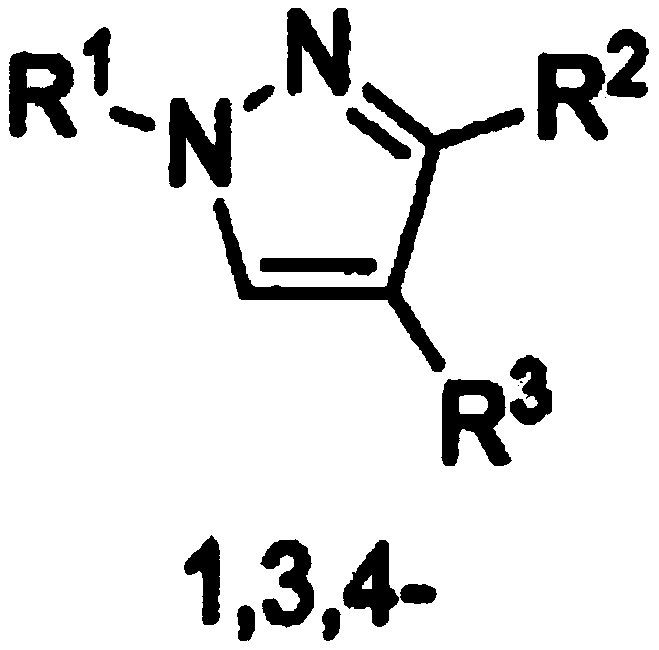

Lithium ion battery electrolyte

InactiveCN108270034ALower impedanceImprove cycle performanceSecondary cellsOrganic solventStructural formula

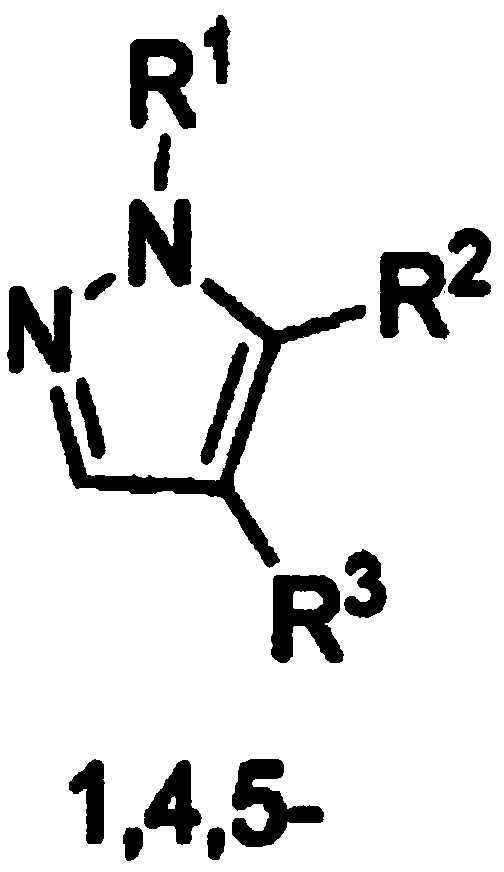

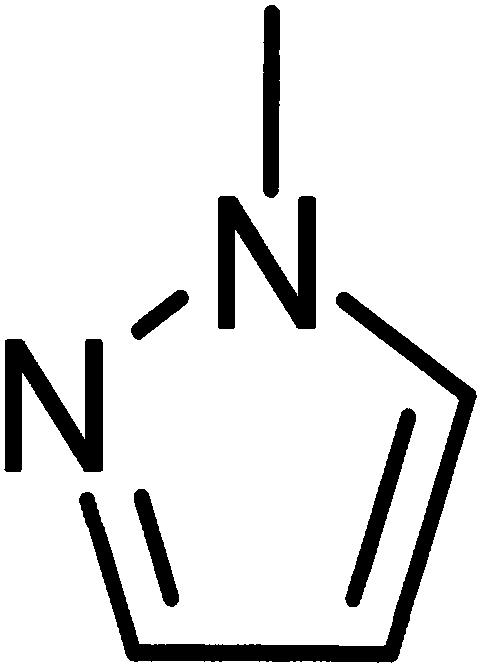

The invention relates to a pyrazole compound electrolyte additive. The structural formula of the additive is 1R<1>,3R<2>,4R<3>-pyrazole or 1R<1>,4R<2>,5R<3>-pyrazole, wherein each of R<1>, R<2> and R<3> is a linear or branched C1-4 structure. A lithium ion battery electrolyte includes a lithium salt, an organic solvent, the pyrazole compound and other functional additives, and the mass of the pyrazole compound is 0.1-10% of the mass of the lithium battery electrolyte. The pyrazole compound is beneficial for forming an interface film having a certain conductivity on the surface of a positive electrode, and can be used together with other positive electrode film forming additives to reduce the impedance of the surface of a positive electrode, so the safety performance of the lithium ion battery and the cycle performances under a high voltage are improved.

Owner:SUZHOU RUNHE CHEM MATERIAL CO LTD

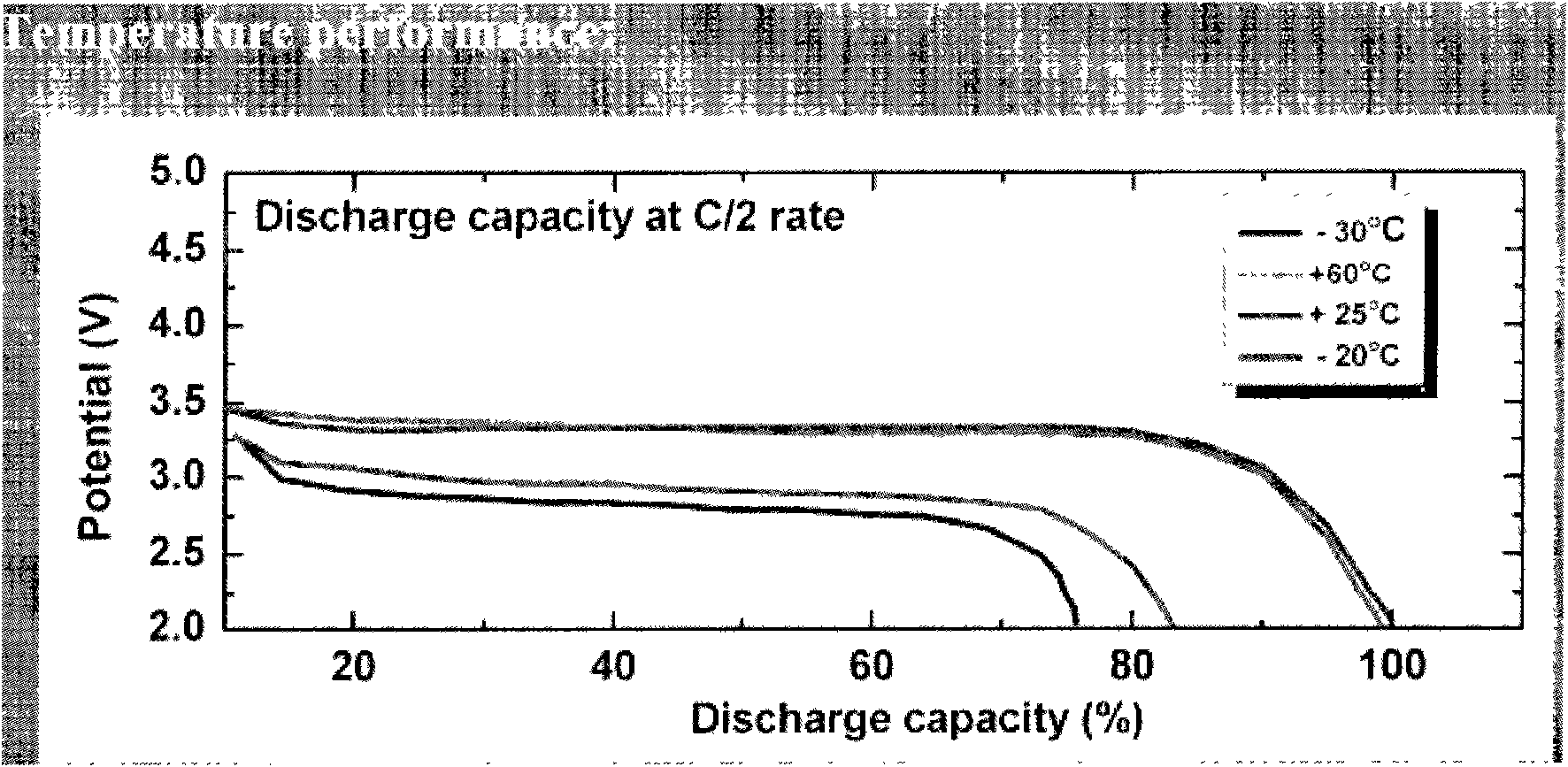

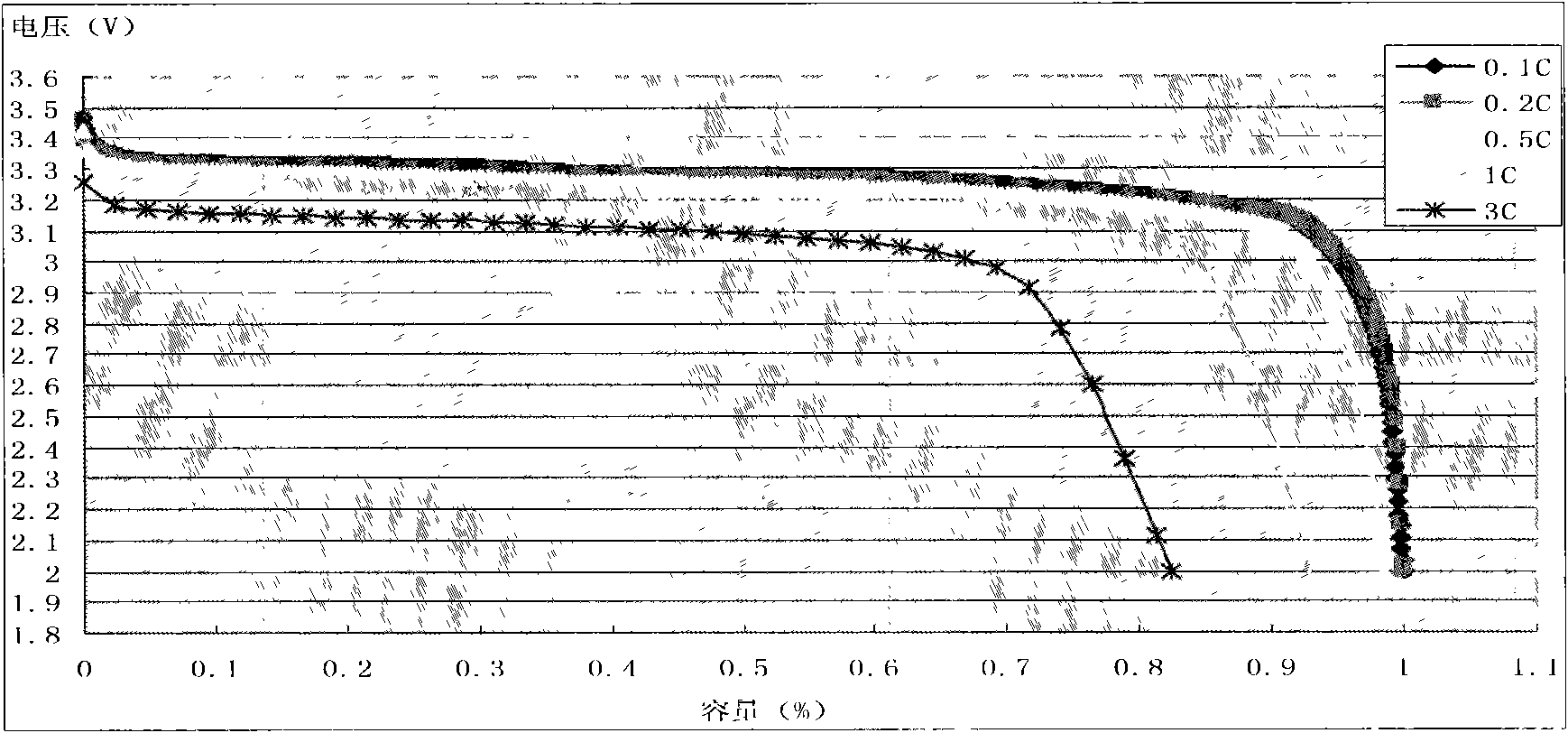

Low-temperature electrolyte of lithium iron phosphate power battery and preparation method thereof

InactiveCN101841061AExcellent low temperature charge and discharge performanceImprove solubilitySecondary cellsPower batteryOrganic solvent

The invention provides a low-temperature electrolyte of lithium iron phosphate power battery and a preparation method thereof, and belongs to the technical field of lithium iron phosphate power batteries. The low-temperature electrolyte of the lithium iron phosphate power battery is prepared from 65 to 95 percent of organic solvent, 3 to 15 percent of additive and 0.7 to 1.4 mol / L of lithium salt. The preparation method comprises the following steps of: fully and uniformly mixing one or more selected organic solvents in a glove box at the humidity of below 1 percent for preparing electrolyte solution; adding the selected additive into the solution; finally adding the required lithium electrolyte salts into the solution; and when all the added lithium electrolyte salts are fully dissolved, standing for 30 to 40 hours to obtain the low-temperature electrolyte of the lithium iron phosphate power battery. The low-temperature electrolyte of the lithium iron phosphate power battery of the invention has the advantages of suitability for a low-temperature environment, rational component selection and matching, good low-temperature charging-discharging performance, magnification performance and cycling performance, simple preparation method and easy operation.

Owner:陈韵吉 +1

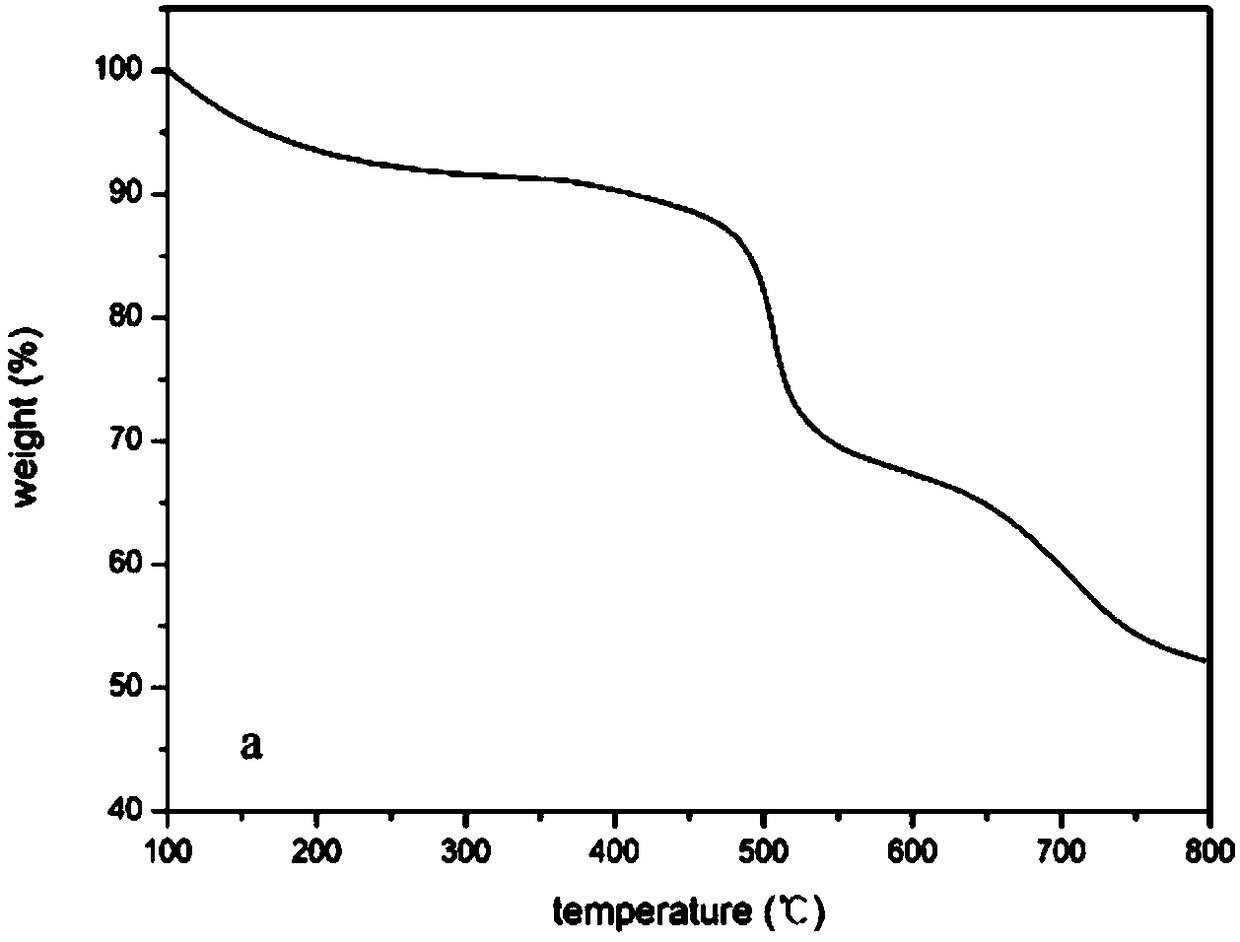

A lithium ion polymer electrolyte membrane and preparation method and application thereof

ActiveCN109193027AHigh room temperature ionic conductivityImprove electrochemical stabilitySolid electrolytesFinal product manufactureSolid state electrolyteSulfonate

A lithium ion polymer electrolyte membrane and its preparation method and application relate to that field of solid electrolyte. The preparation method of the lithium ion polymer electrolyte membraneof the embodiment of the invention is that the sulfonated poly (phosphodiazole) stock solution is solidified to obtain the sulfonated poly (phosphodiazole) film, and the sulfonated poly (phosphodiazole) film is reacted with lithium salt to obtain the poly (phosphodiazole) sulfonate lithium electrolyte membrane; and the sulfonated poly (phosphodiazole) film is solidified to obtain the sulfonated poly (phosphodiazole) film; or preparing lithium poly (1, 2-diazole sulfonate) solution by sulfonated poly (1, 2-diazole sulfonate) stock solution and lithium salt, and coagulating to form membrane to obtain poly (1, 2-diazole sulfonate) lithium electrolyte membrane. The method is simple and easy to operate. The poly (phthalazinesulfonic acid) lithium electrolyte membrane of the embodiment of the invention has high room temperature ionic conductivity, good electrochemical stability, flame retardancy and excellent heat resistance; a lithium ion polymer electrolyte membrane accord to an embodimentof that present invention is used as a solid-state electrolyte membrane of a solid-state lithium battery.

Owner:张家港保税区宝邦新能源材料科技有限公司

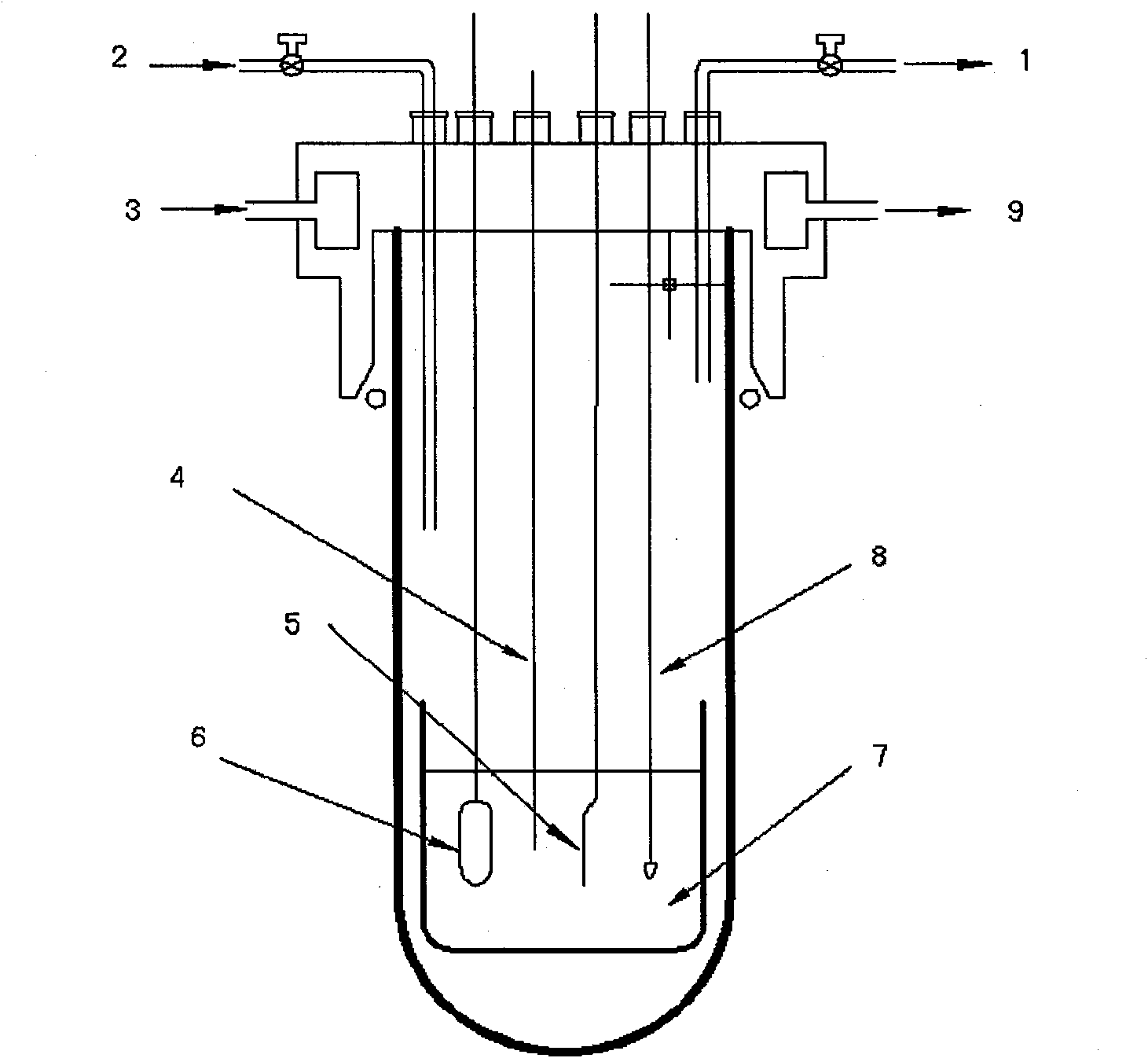

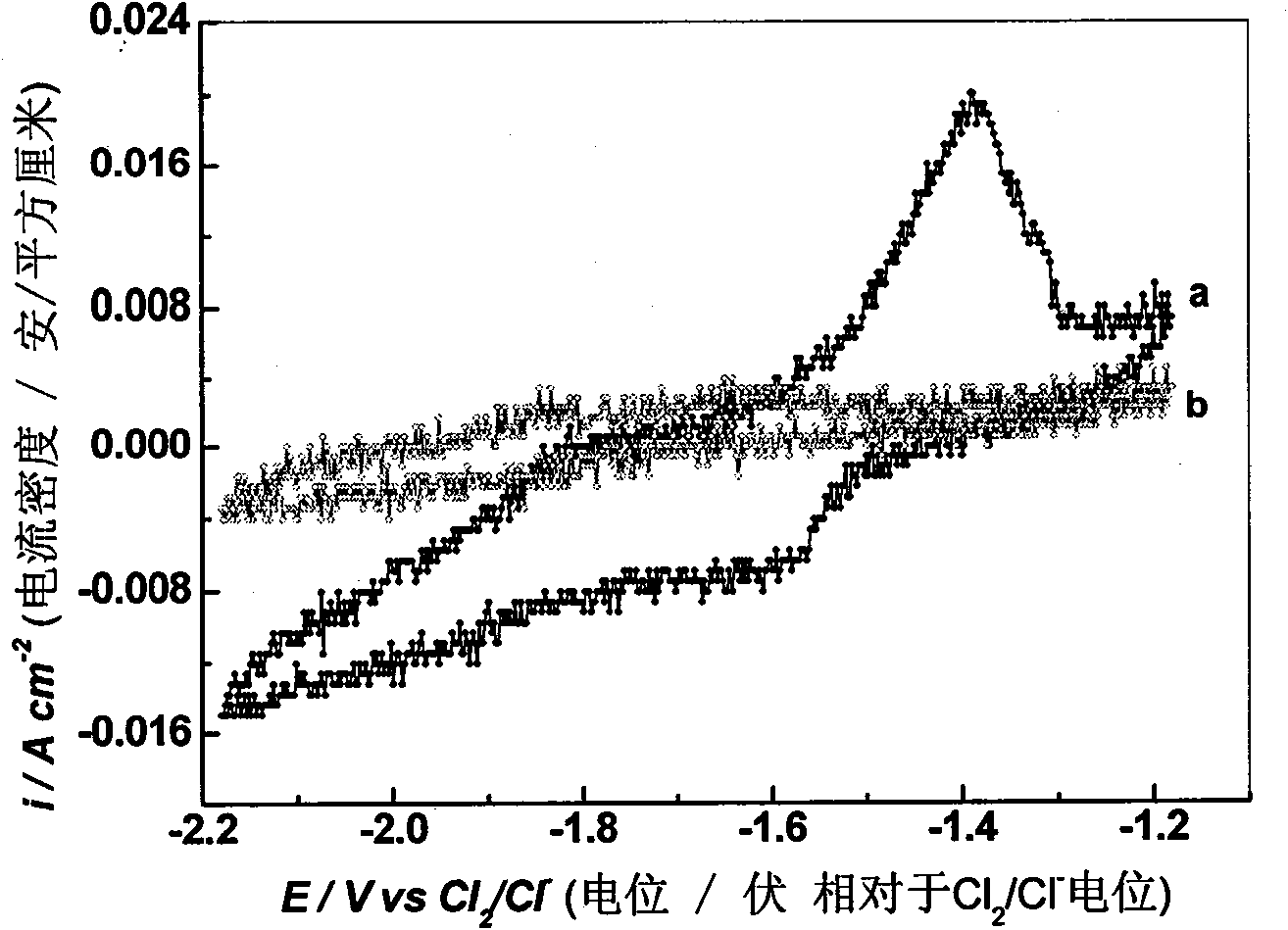

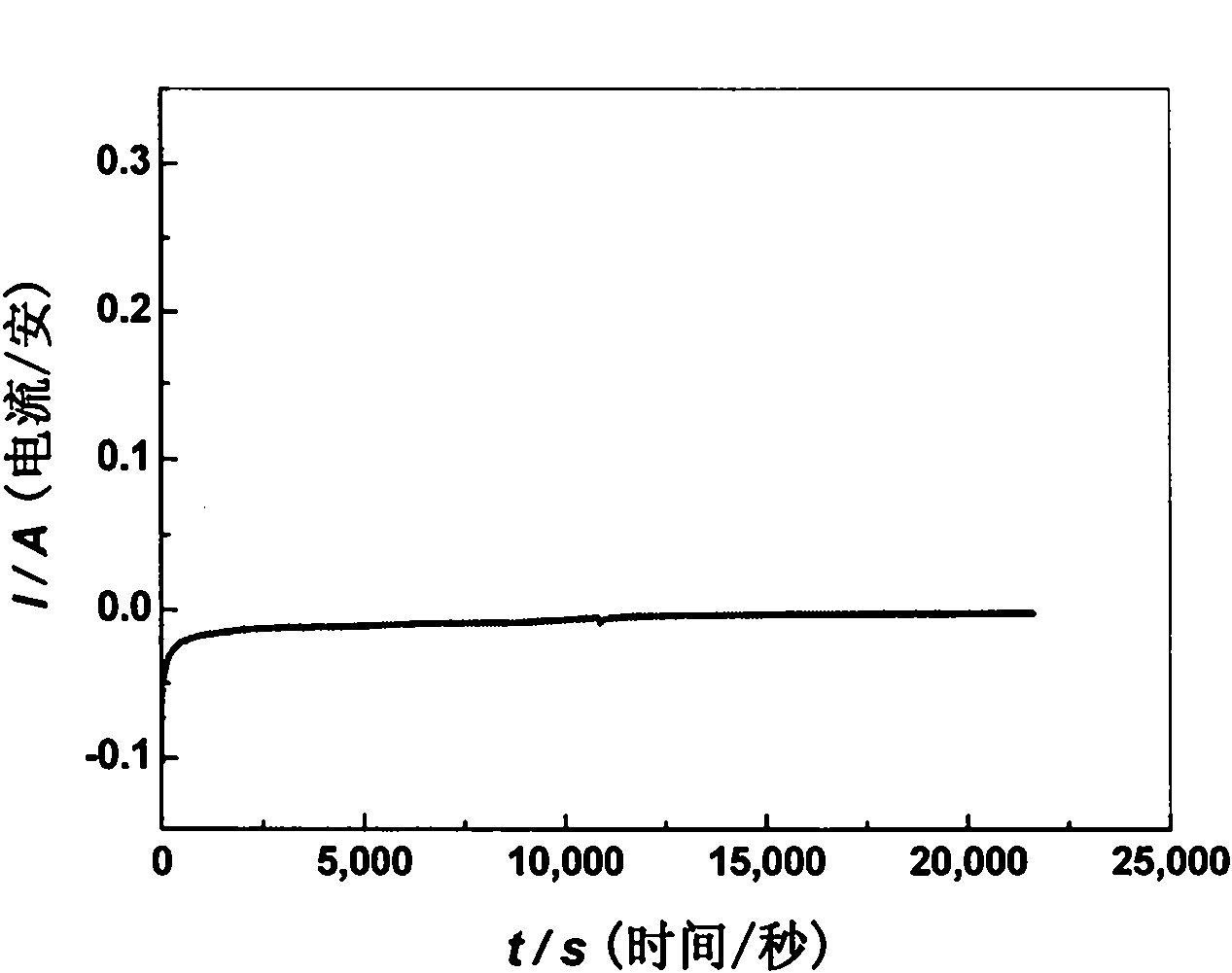

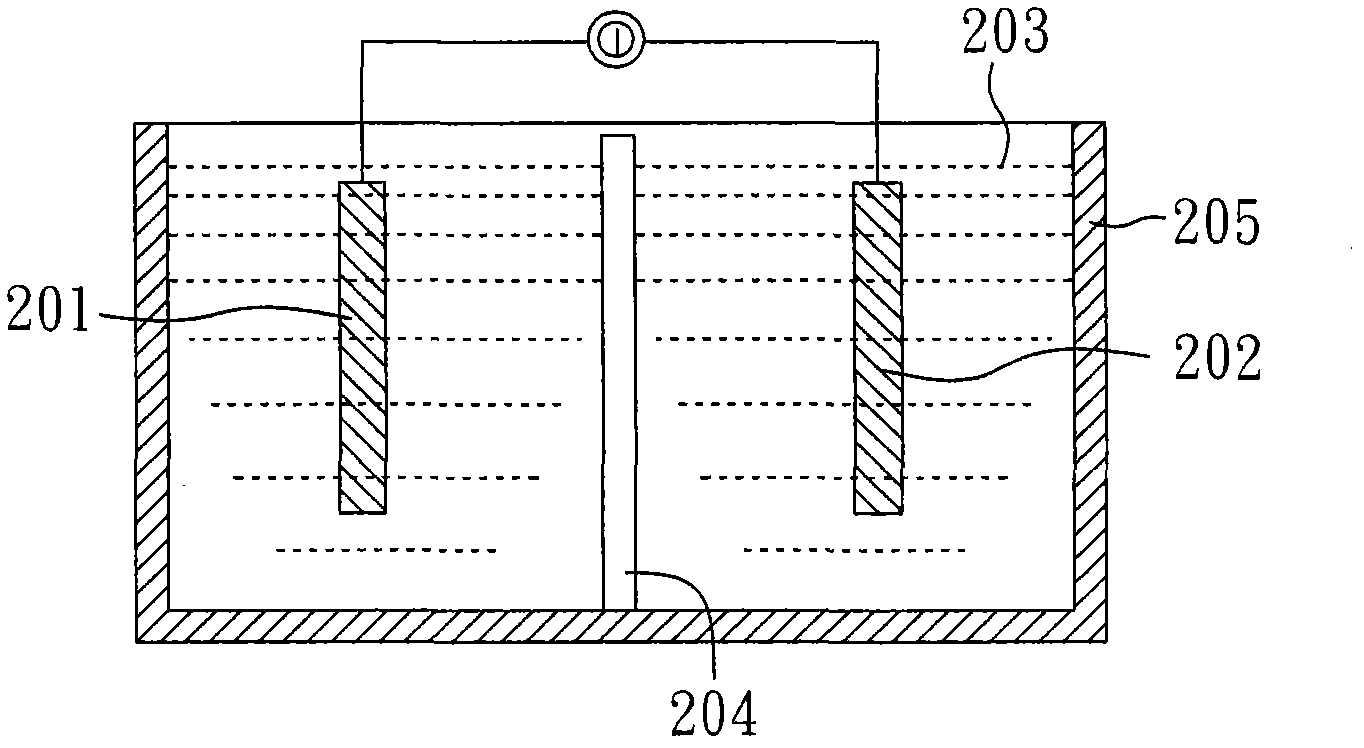

Method for removing Al impurity from KCl-LiCl lithium electrolyte

InactiveCN101962782AEliminate the cumbersome process of purificationLow costElectrolysisFluorescence

The invention relates to an alkali metal Li purification process, which belongs to the field of electrochemical metallurgy and is a process for removing an impurity by a molten salt electrochemical method. The invention adopts an electrochemical method for removing an Al impurity from KCl-LiCl lithium electrolyte. The method comprises: determining the deposition potential of metal aluminum by cyclic voltammetry; performing constant potential electrolysis at the potential; precipitating the metal aluminum on a carbon steel strip cathode; and after electrolyzing for 4.5 to 10 hours, removing the carbon steel strip cathode out from the electrolyte, and removing the carbon steel strip cathode from a reactor completely. According to the researches on the impurity-removing effect by the electrochemical method and the analysis on the Al content of the electrolyte by a fluorescence flame spectrum ICP-AES (Varian 710-ES), and the Al content of the purified electrolyte is lowered greatly. In the invention, the method is simple and convenient to operate, and over 96 percent of Al in the molten salt can be removed after 10 hours of electrolysis.

Owner:EAST CHINA UNIV OF SCI & TECH

Lithium ion battery

InactiveCN102386438ADiffusion fastImprove discharge efficiencySecondary cellsNon-aqueous electrolyte accumulator electrodesGrapheneLithium-ion battery

The invention relates to a lithium ion battery. The lithium ion battery comprises an anode, a cathode and a lithium electrolyte, wherein the lithium electrolyte is contacted with the anode and the cathode; the cathode is provided with a graphene multi-layer structure; the graphene multi-layer structure comprises a plurality of two-dimensional flake graphene layers and a plurality of metal nickel layers staggered among the two-dimensional flake graphene layers; and the lithium ions are fully embedded into or separated from the space among the layers of the graphene layers.

Owner:宋健民

Lithium supplementing composition, lithium supplementing electrolyte and lithium supplementing method for lithium secondary battery

InactiveCN112448037AMitigating capacity drop issuesPrevent floatingSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentPhysical chemistry

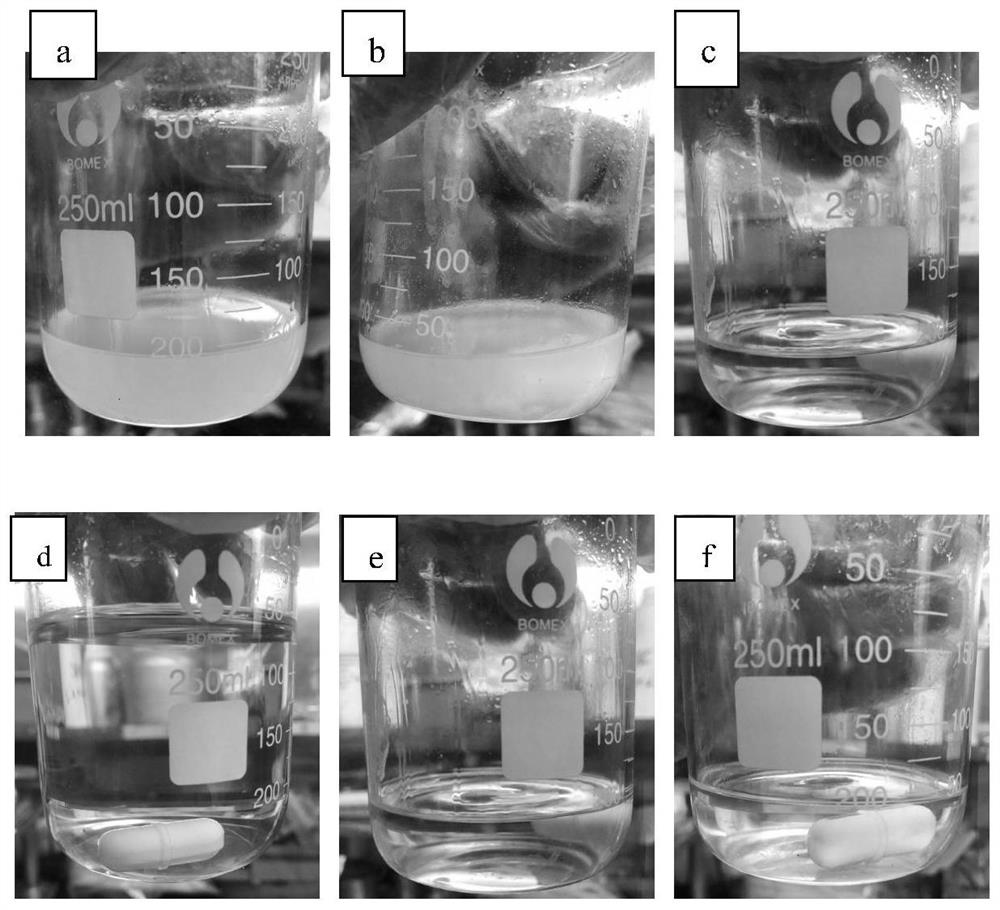

The invention belongs to the technical field of lithium ion batteries, and provides a lithium supplementing composition which comprises a lithium supplementing compound and a cosolvent, and the lithium supplementing compound is lithium nitride and / or lithium oxalate; and the cosolvent is at least one of tris (pentafluorophenyl) borane, tris (pentafluorophenyl) phosphine and tris (pentafluorophenyl) silane. After the lithium supplementing composition is used for the lithium supplementing electrolyte, the lithium supplementing electrolyte has high lithium supplementing activity, the problems oflow initial coulombic efficiency and poor cycle performance of the silicon-based negative electrode lithium ion battery can be effectively solved, and the energy density of the lithium ion battery isobviously improved. Meanwhile, the invention also provides a lithium supplementing method based on the lithium supplementing electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

Method for recycling retired lithium battery negative electrode material

ActiveCN111392718AReasonable useImprove qualityCarbon compoundsNegative electrodesPower batteryPyrrolidinones

The invention relates to the field of lithium battery recovery, in particular to a method for recycling a retired lithium battery negative electrode material. The method comprises the following steps:dipping a negative electrode material obtained by disassembling a retired lithium battery into an N-methyl pyrrolidone solution, and standing until a copper foil is separated from a graphite matrix,so as to obtain a pre-sheet; placing the pre-sheet as a negative plate in a lithium electrolyte for discharge treatment, and removing residual impurities on the surface of the pre-sheet to obtain graphite flakes; and crushing and ball-milling the graphite flakes into graphite powder, and recycling graphene oxide through an oxidation stripping method. According to the invention, the retired lithiumpower battery negative electrode material can be reasonably and effectively utilized; single-layer graphene powder with relatively high quality can be prepared by adopting a proper process; and greateconomic benefits can be generated.

Owner:余姚市鑫和电池材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com