Lithium secondary battery having improved stability to overcharge

A lithium secondary battery, overcharge technology, applied in the direction of secondary battery, lithium storage battery, non-aqueous electrolyte storage battery, etc., can solve the problem of unable to provide reliable operation, reduce battery performance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

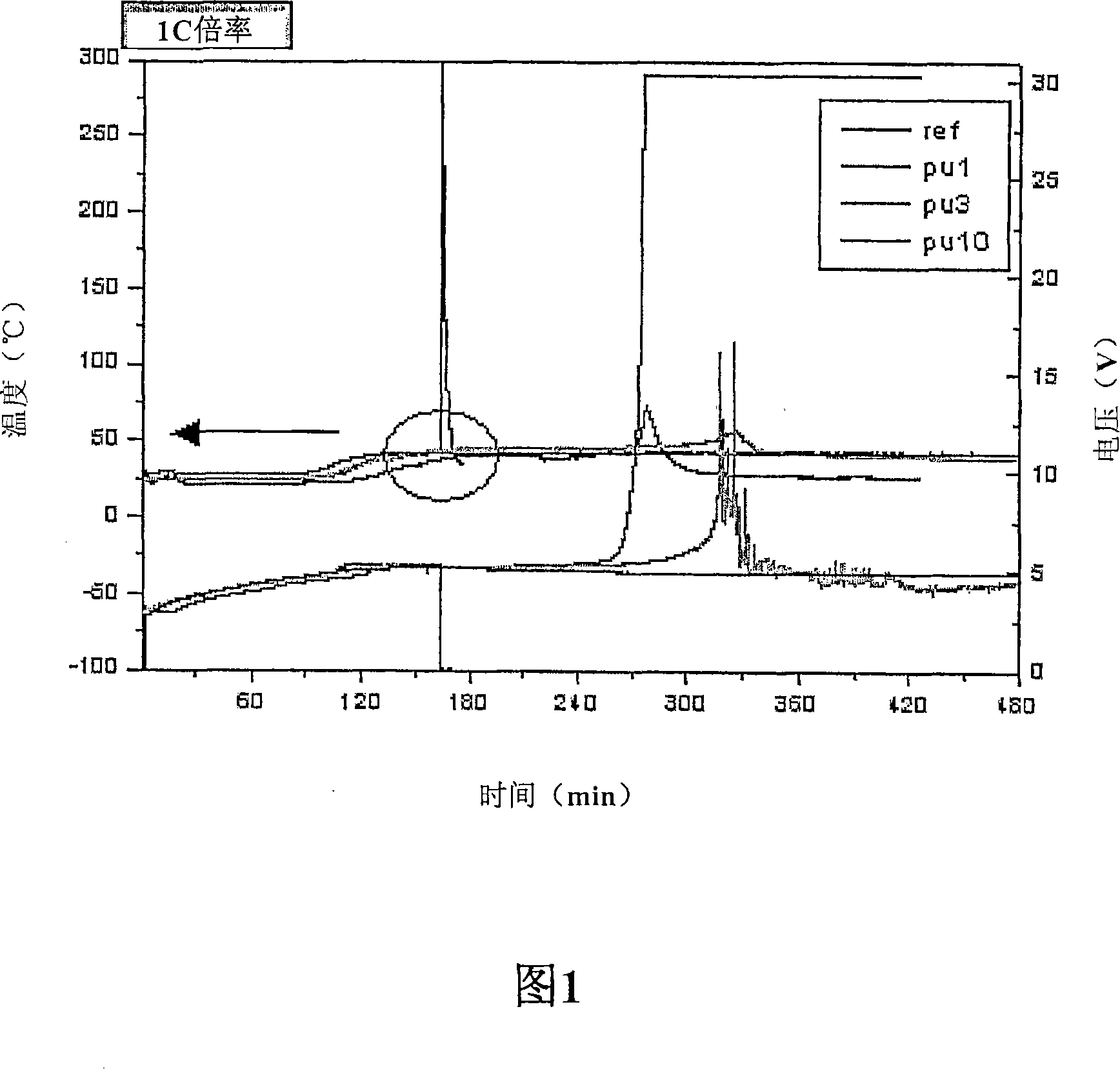

Embodiment 1

[0047] In N-methyl-2-pyrrolidone (NMP) as a solvent, 93% carbon active material (MCMB10-28, Osaka Gas Co.) and 7% polyvinylidene fluoride (PVDF) were mixed using a stirrer (IKAMixer). (Kynar 761, Elf Atochem) was mixed for two hours, and the resulting mixture was coated on a copper foil current collector, followed by drying at 130° C., thereby preparing an anode.

[0048] 1% by weight of polyurethane with a molecular weight of 42,000 to 45,000, added to 91% LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2, 3% PVDF (Kynar 761) and a mixture of 6% conductive carbon (KS-6, Lonza), and using a stirrer (IKA Mixer) to mix the resulting components in N-methyl-2-pyrrolidone (NMP ) for two hours, the resulting mixture was coated on an aluminum foil current collector, and then dried at 130° C., thereby preparing a cathode. The polyurethane is prepared by suspending polymerization of polyethylene glycol (PEG) as a polyol compound and toluene diisocyanate (TDI) as an isocyanate compound.

[0049] Then a s...

Embodiment 2

[0051] A battery was fabricated in the same manner as in Example 1 except that 3% by weight of polyurethane was added to the cathode.

Embodiment 3

[0053] A battery was fabricated in the same manner as in Example 1 except that 10% by weight of polyurethane was added to the cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com