Patents

Literature

41results about How to "Guaranteed reliable performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

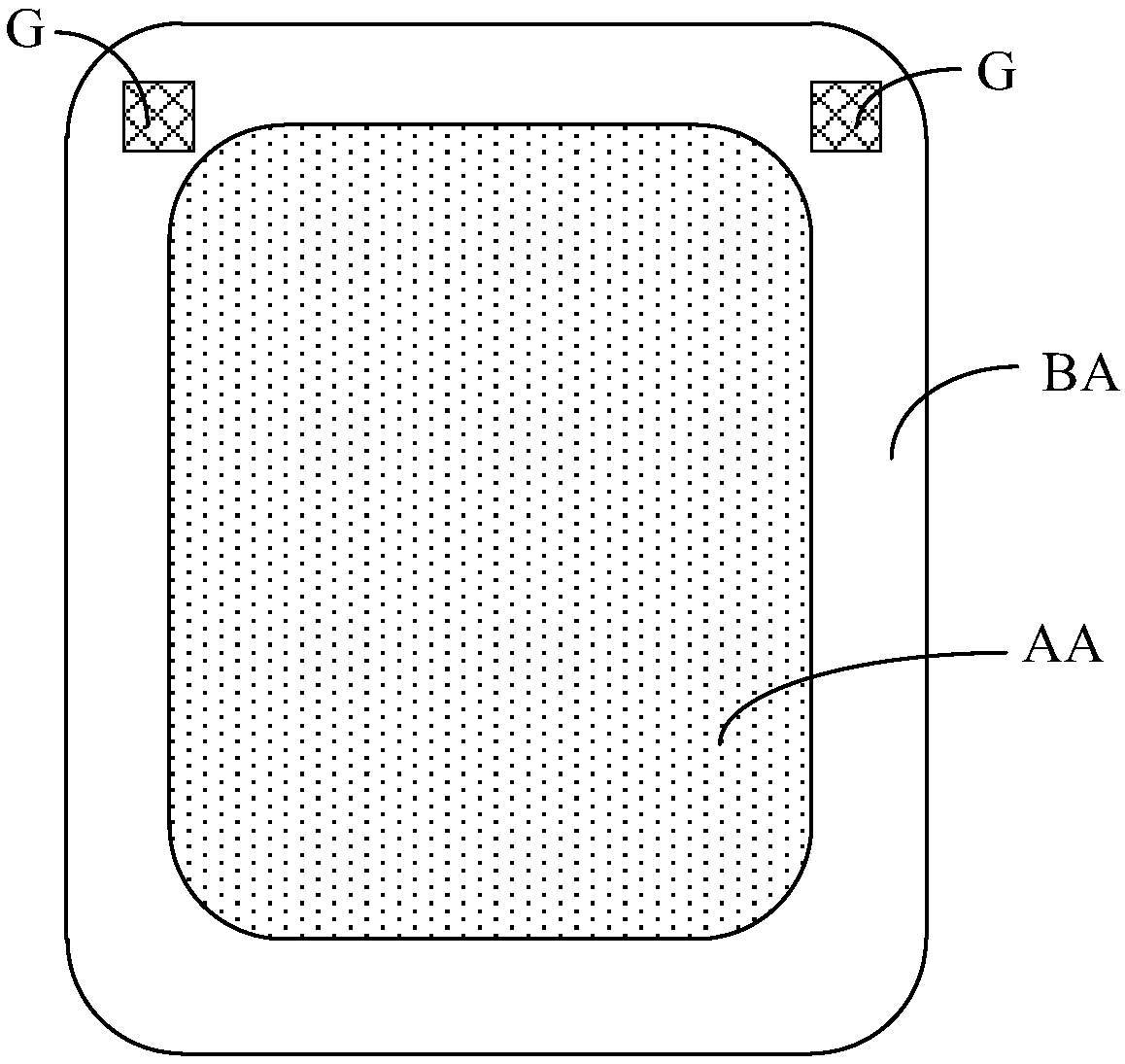

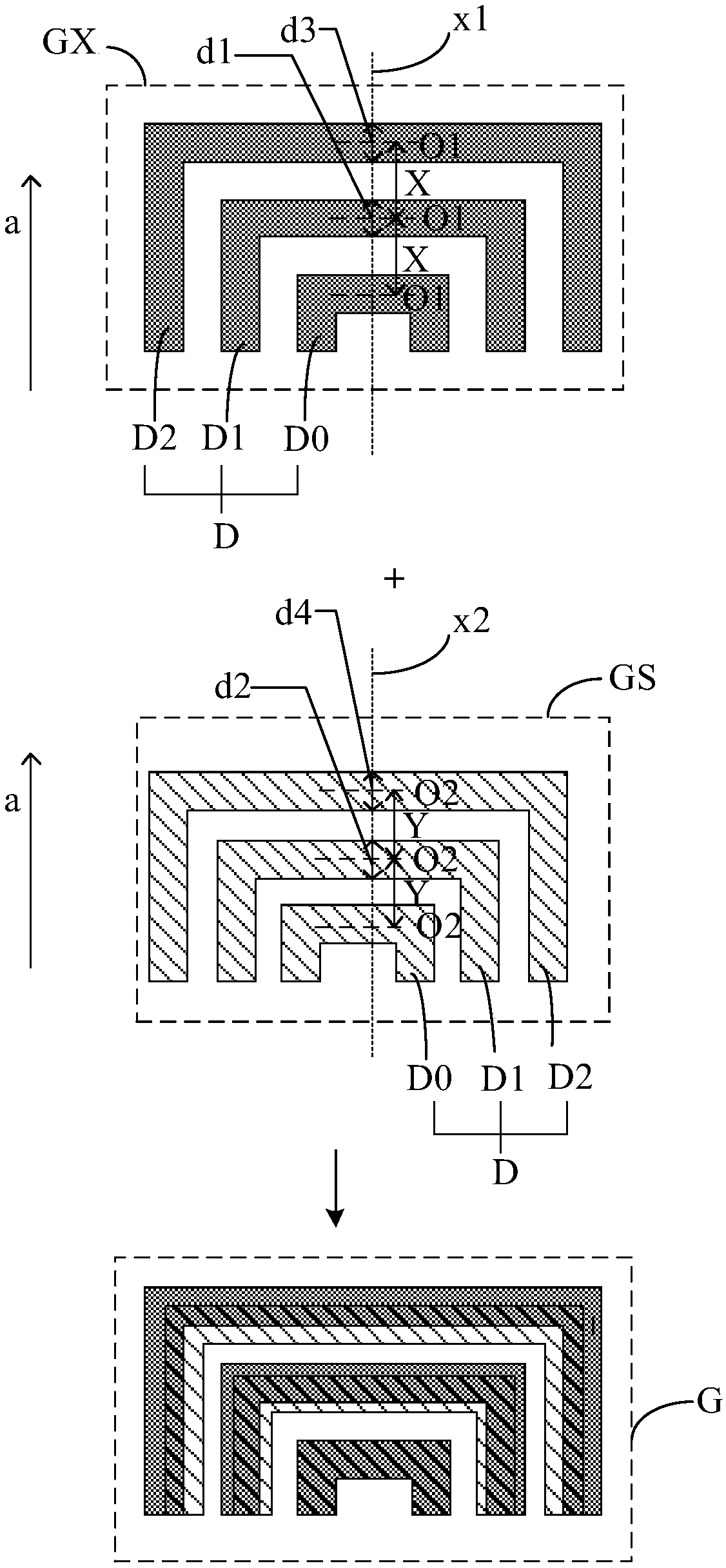

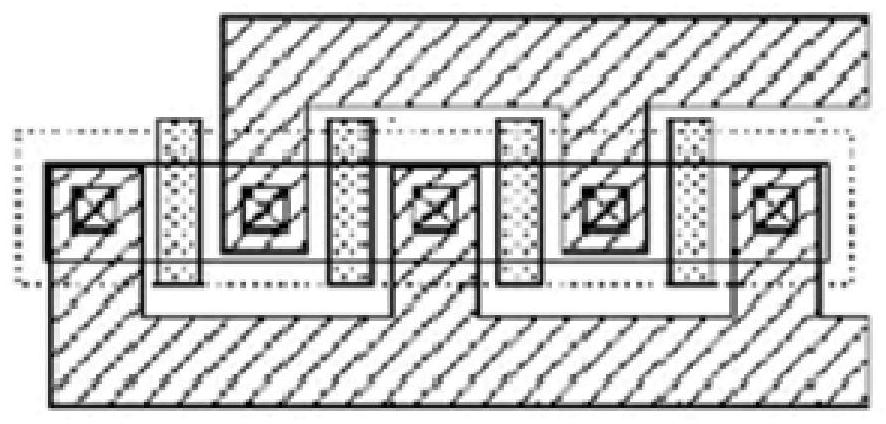

Display panel and display device

InactiveCN108663852APrevent static electricityGuaranteed reliable performanceNon-linear opticsDisplay deviceComputer science

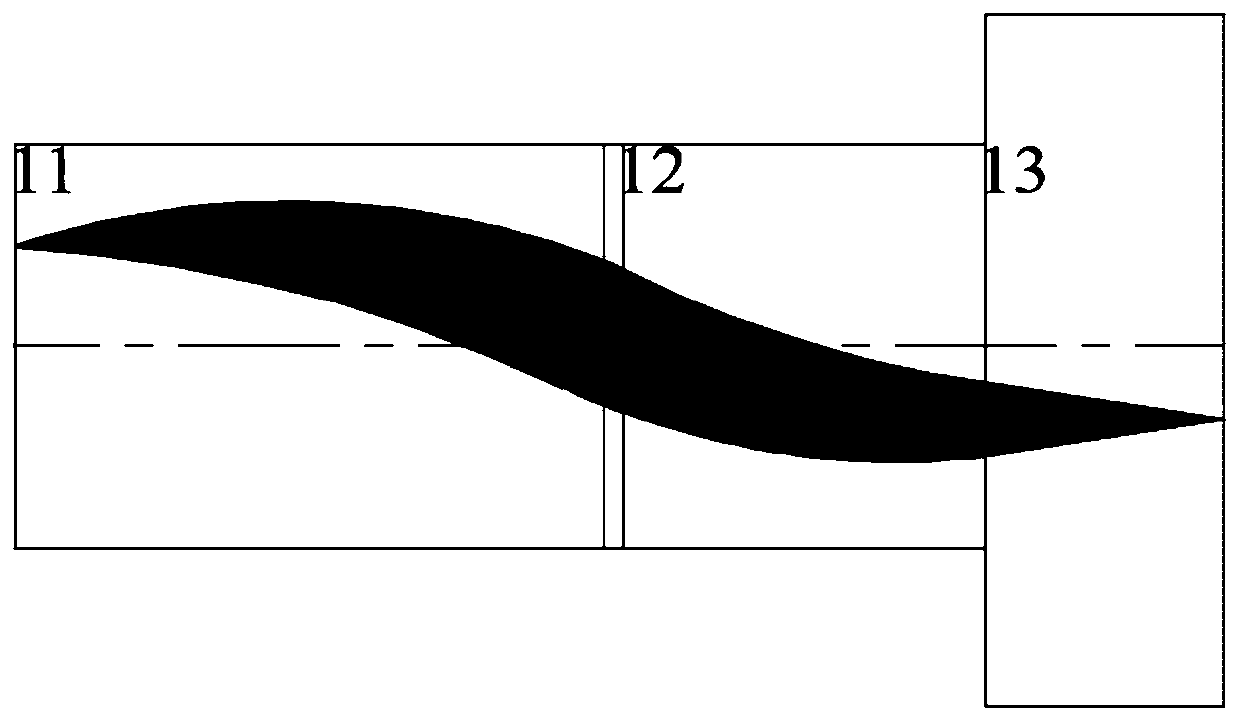

The invention discloses a display panel and a display device. The display panel comprises an array substrate, a colored film substrate and an alignment mark structure. A lower alignment mark and an upper alignment mark in the alignment mark structure both comprise at least two marking units, the number of the marking units is the same, the marking units are a 0 marking unit, a 1 markingunit and an N marking unit respectively in the first direction, and after the array substrate is aligned with the colored film substrate, the 0 marking unit in the lower alignment mark is aligned with the 0 marking unit in the upper alignment mark; the width of the projection of the n marking unit in the lower alignment mark on the array substrate in the first direction is samewith that of the projection of the n marking unit in the upper alignment mark on the colored film substrate in the first direction, the distance between two projection centers of two adjacent marking units on the array substrate in the lower alignment mark is X, the distance between two projection centers of two adjacent marking units on the colored film substrate in the upper alignment markis Y, and X is not equal to Y. The device can achieve a suitable alignment function and ensure the reliability of the display panel performance.

Owner:SHANGHAI AVIC OPTOELECTRONICS

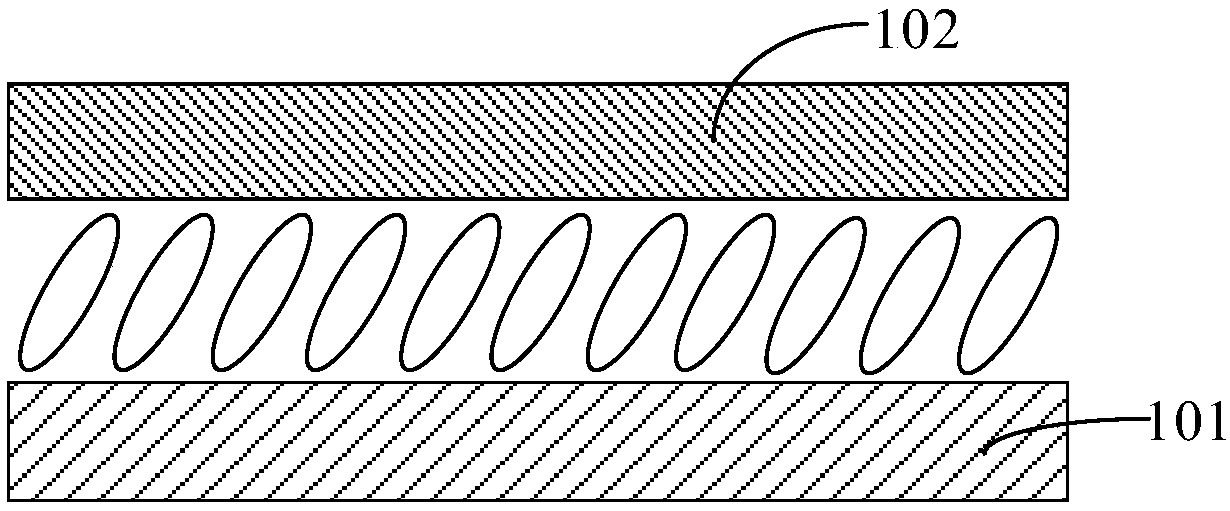

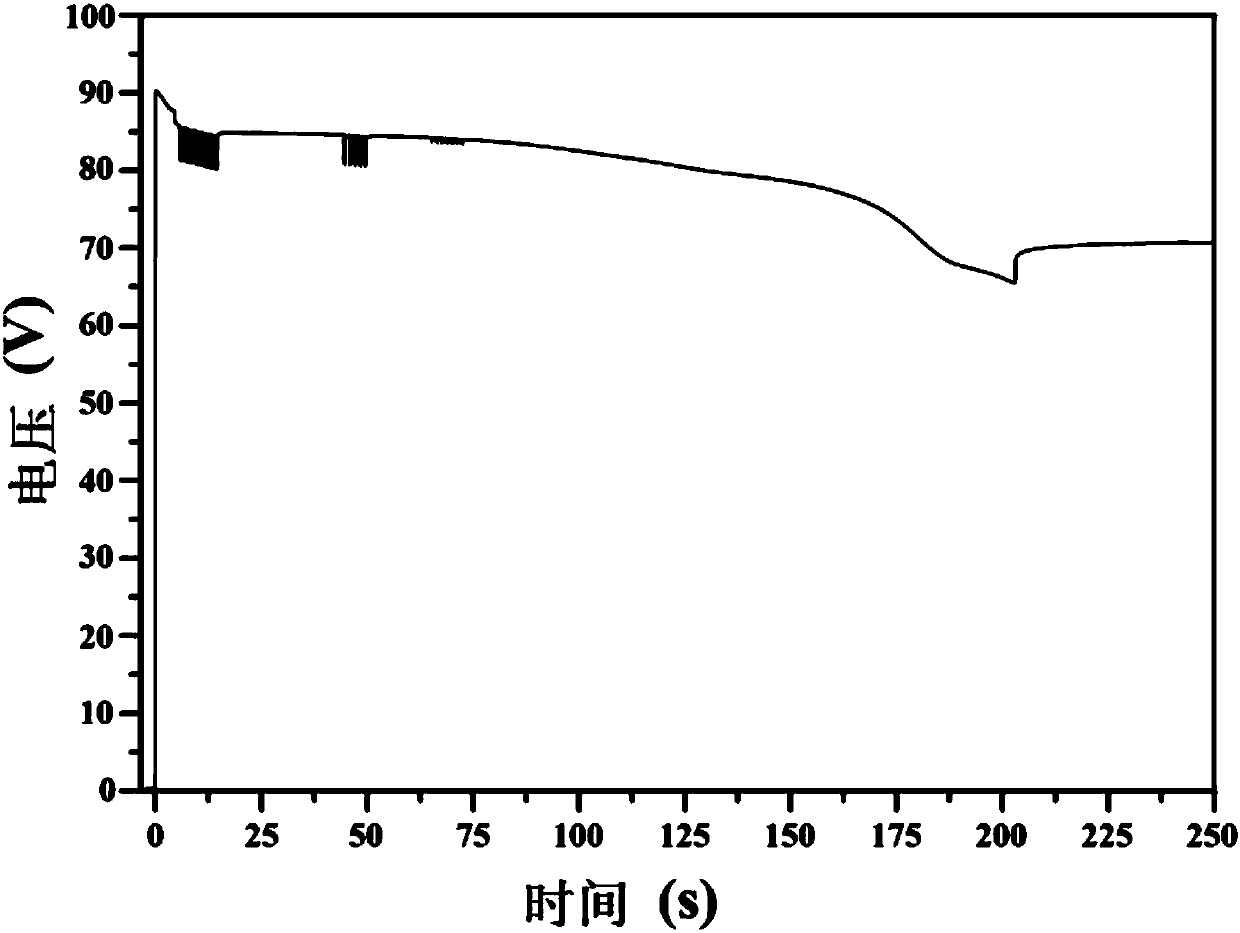

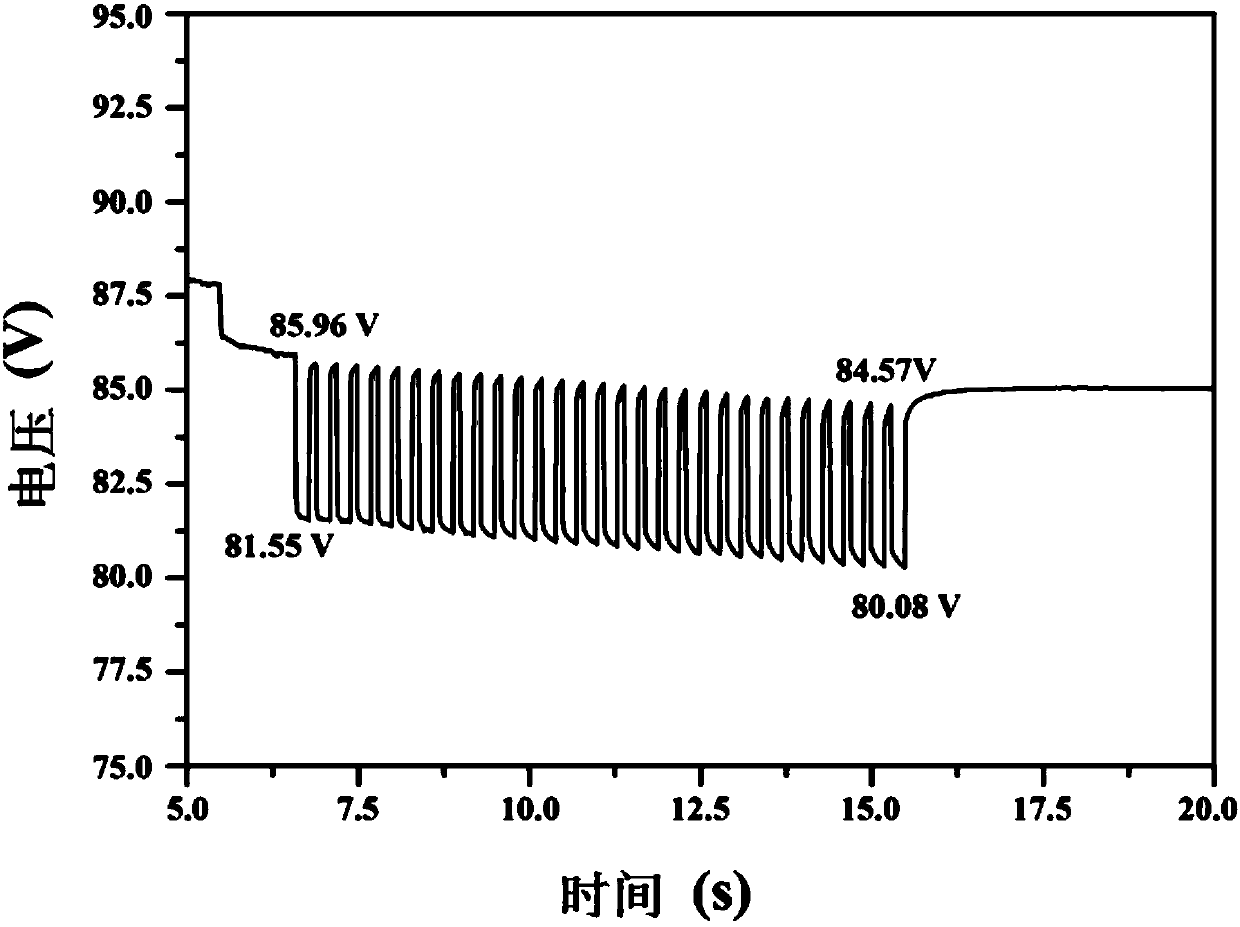

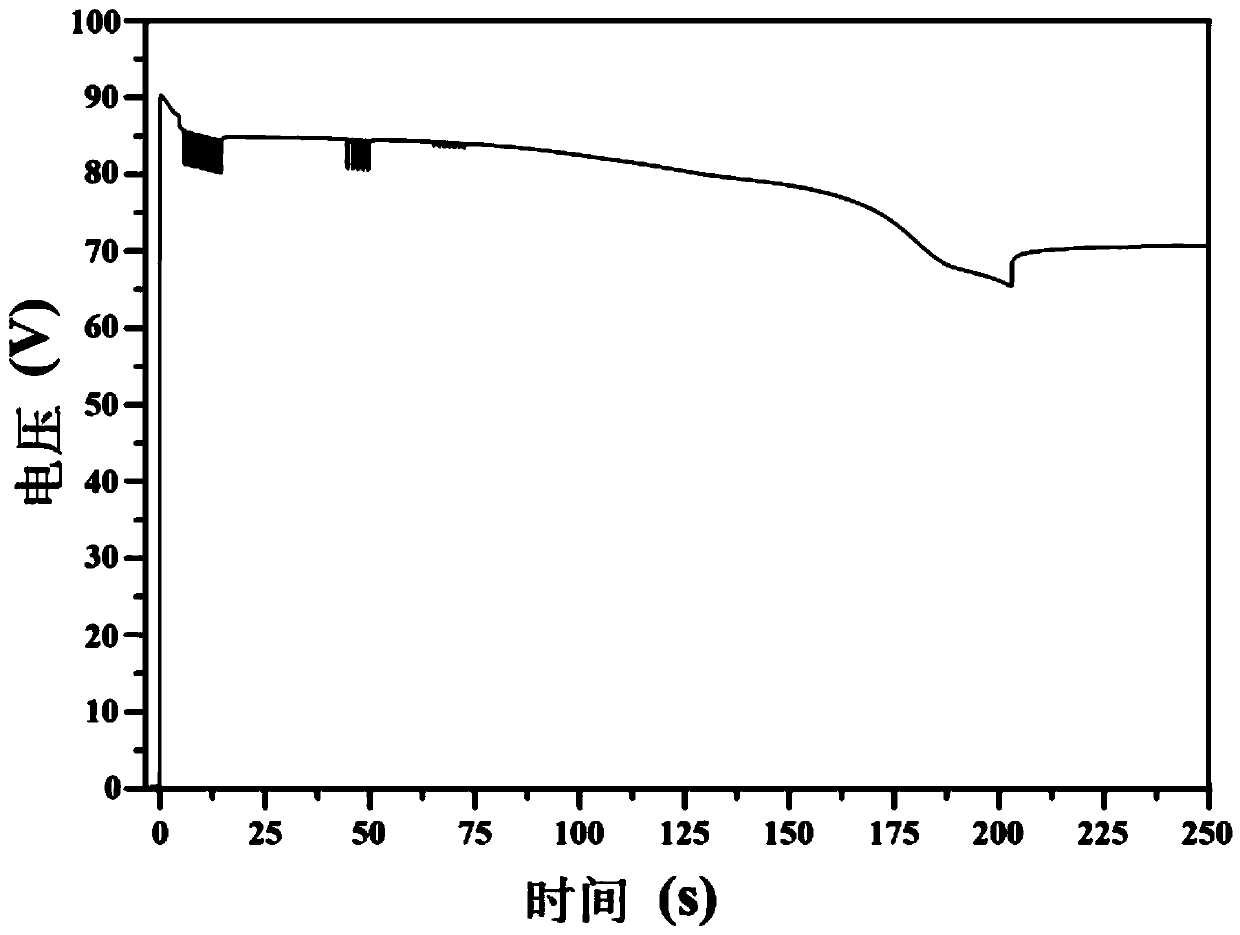

Battery cell of thermal battery for carrier rocket

ActiveCN107732268AGuaranteed adsorption effectGuaranteed reliable performanceDeferred-action cellsSorbentRocket

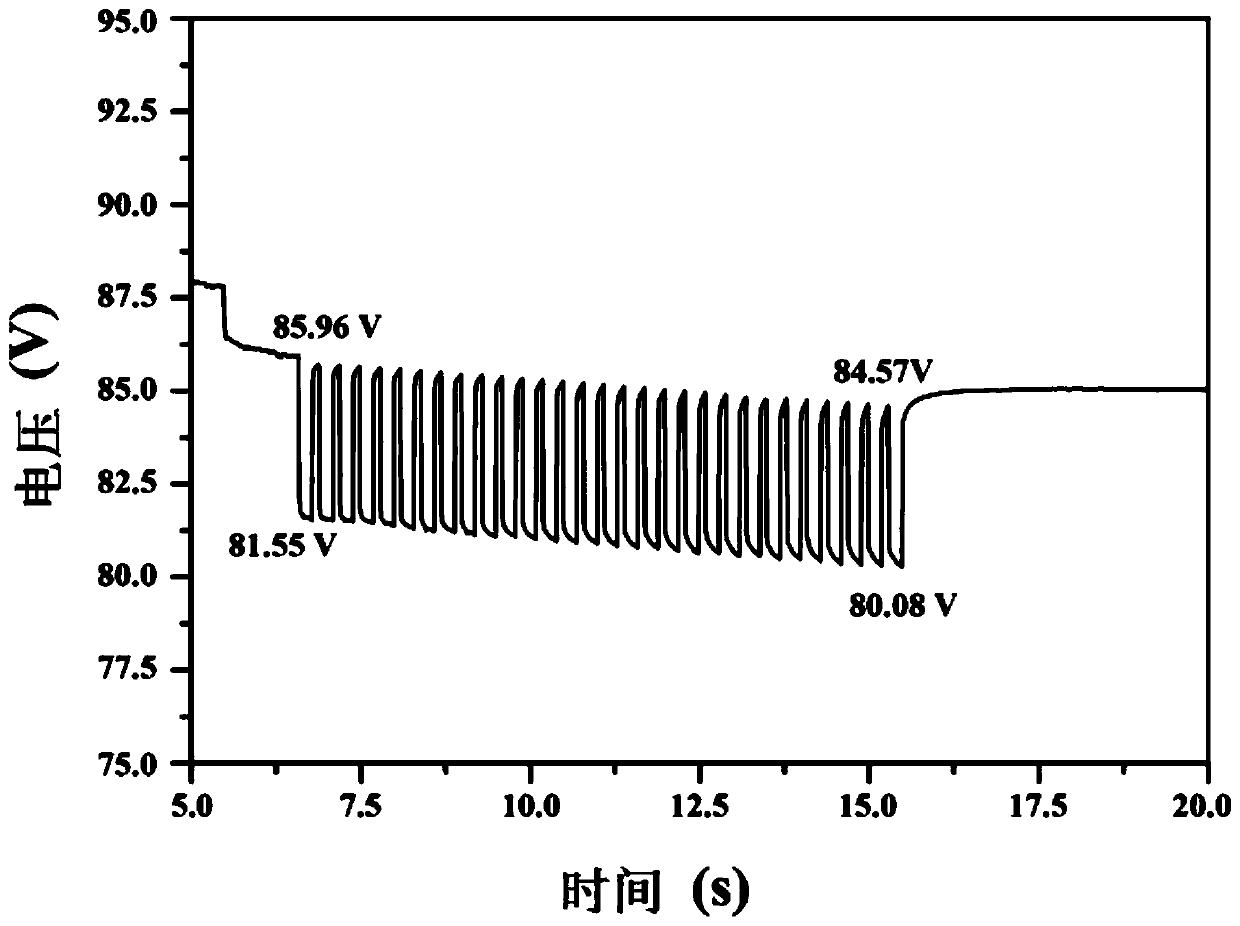

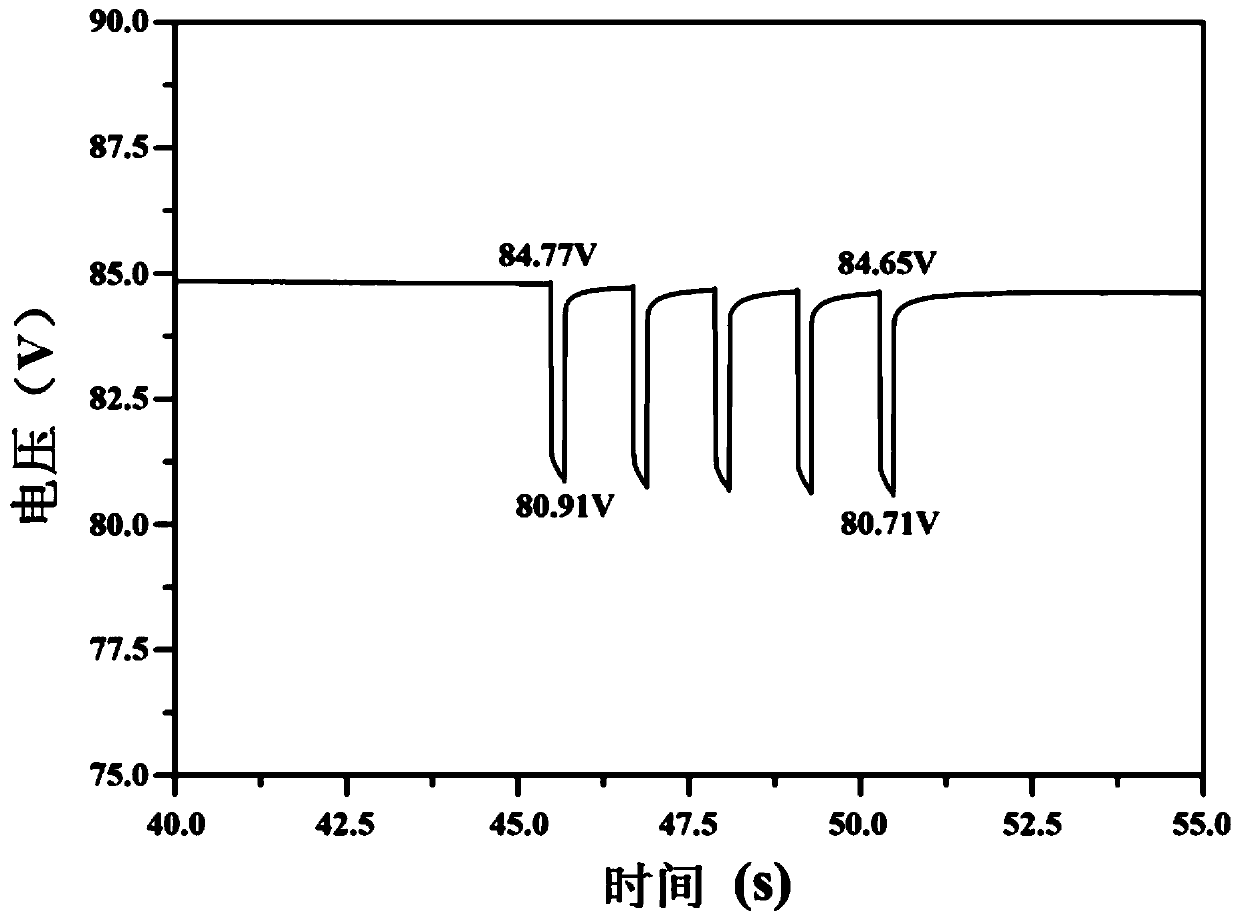

The invention discloses a battery cell of a thermal battery for a carrier rocket. The battery cell of the thermal battery for the carrier rocket comprises an isolating powder, a heating powder, a positive electrode powder and a negative electrode powder, wherein the isolating powder consists of LiF-LiCi-LiBr ternary all-lithium electrolyte molten salt and a molten salt adsorbent; the molten salt adsorbent accounts for 50-65% of the total mass of the isolating powder. A performance characteristic that the pulse voltage drop change rates of the thermal battery in three working time periods of 5-20s, 45-55s and 65-75s are lower than 2% is achieved, and the performance reliability of load equipment on the rocket is guaranteed. Raw materials and a component preparation technology of the batterycell of the thermal battery provided by the invention are the same as those of the conventional thermal battery, so that large-scale production can be carried out under the premise of not restructuring the conventional production line and the production process is high in universality; the cost pressure is low and the economic benefits are good while model development and production tasks of a new-generation solid carrier rocket are met.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

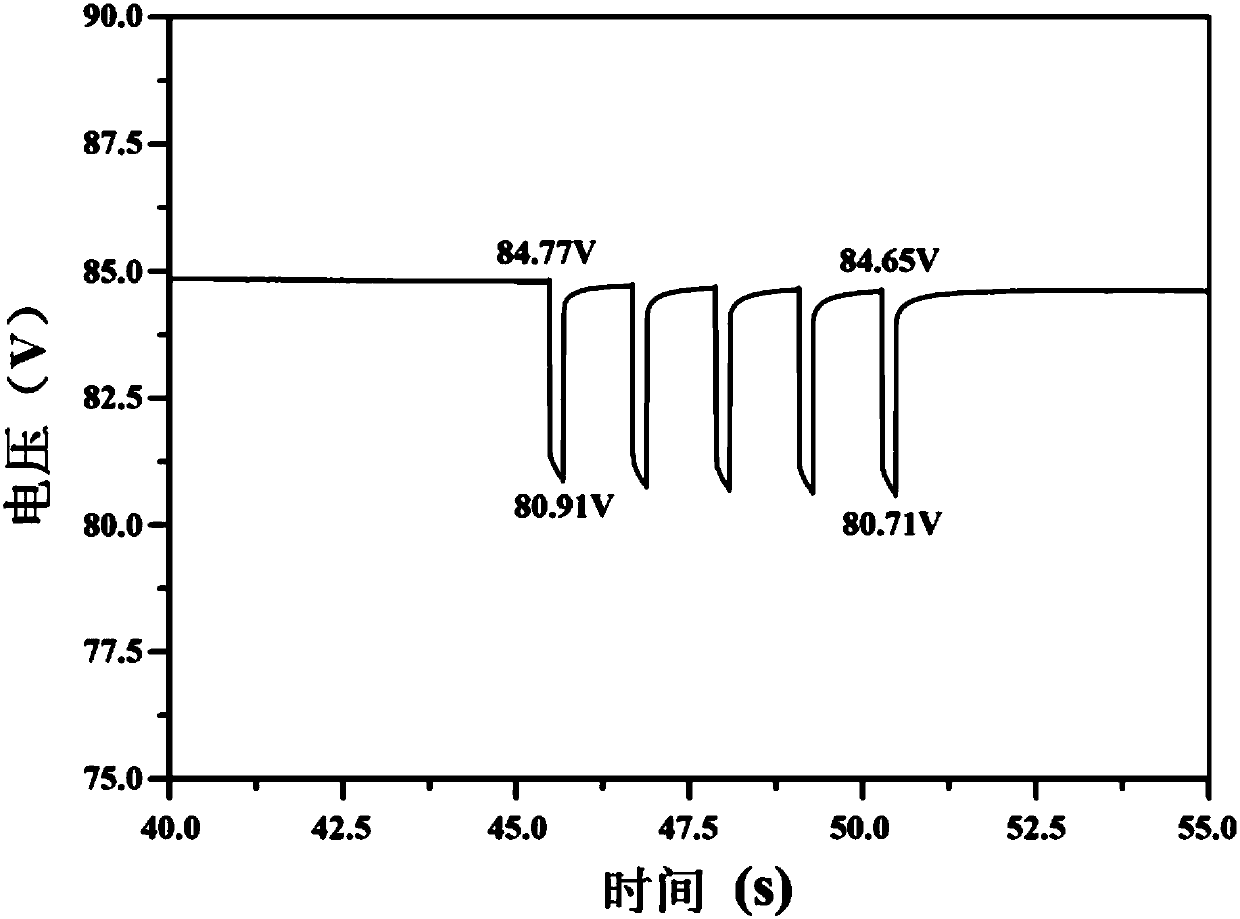

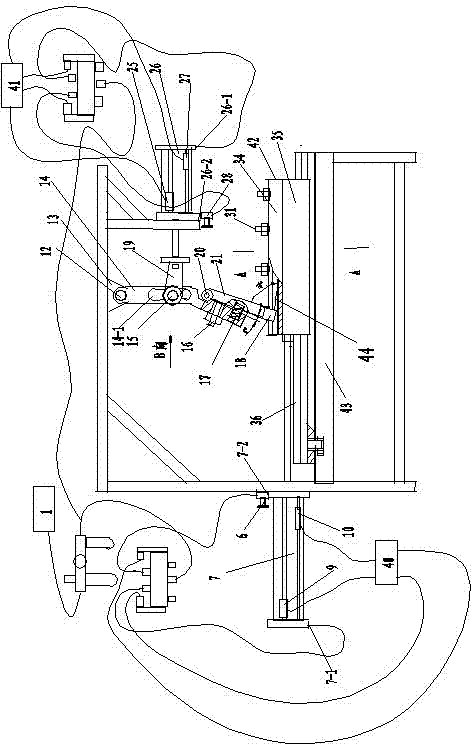

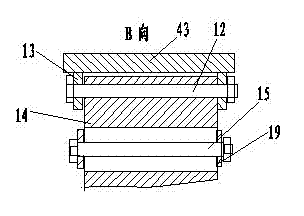

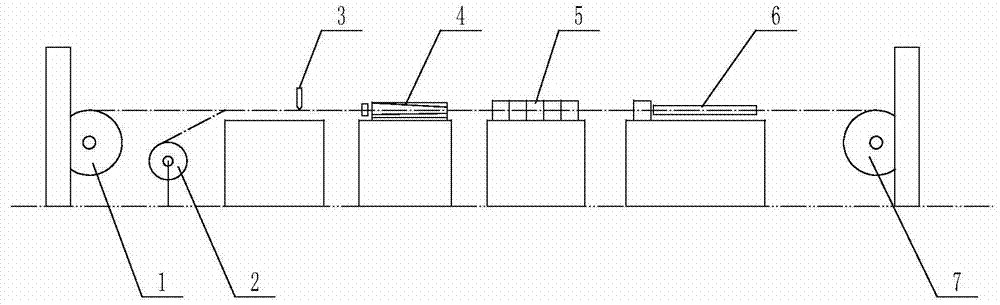

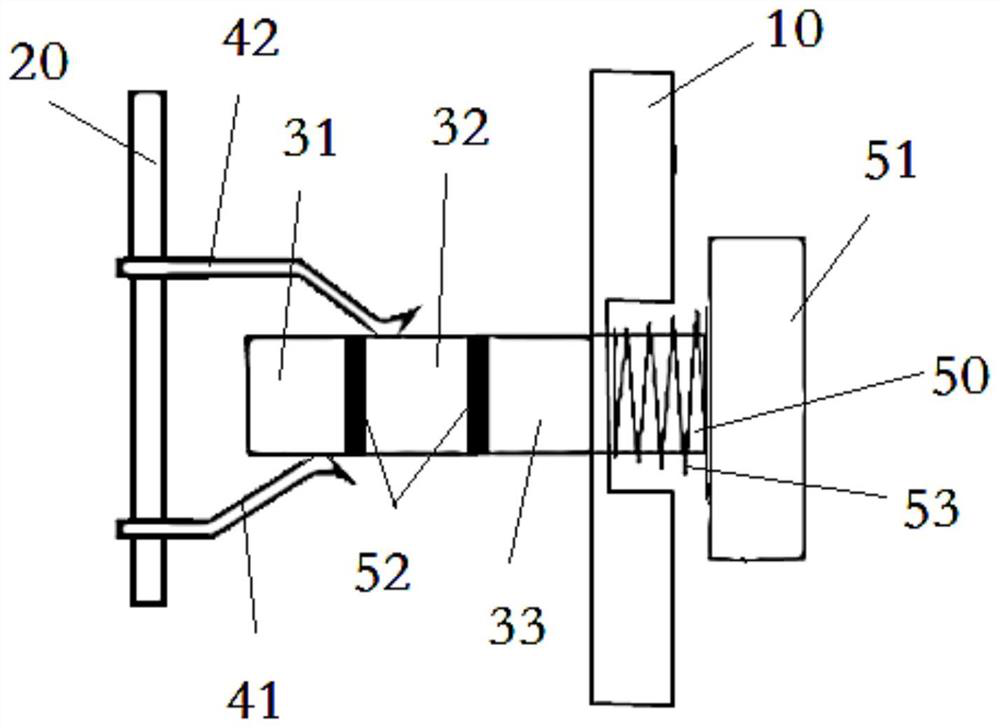

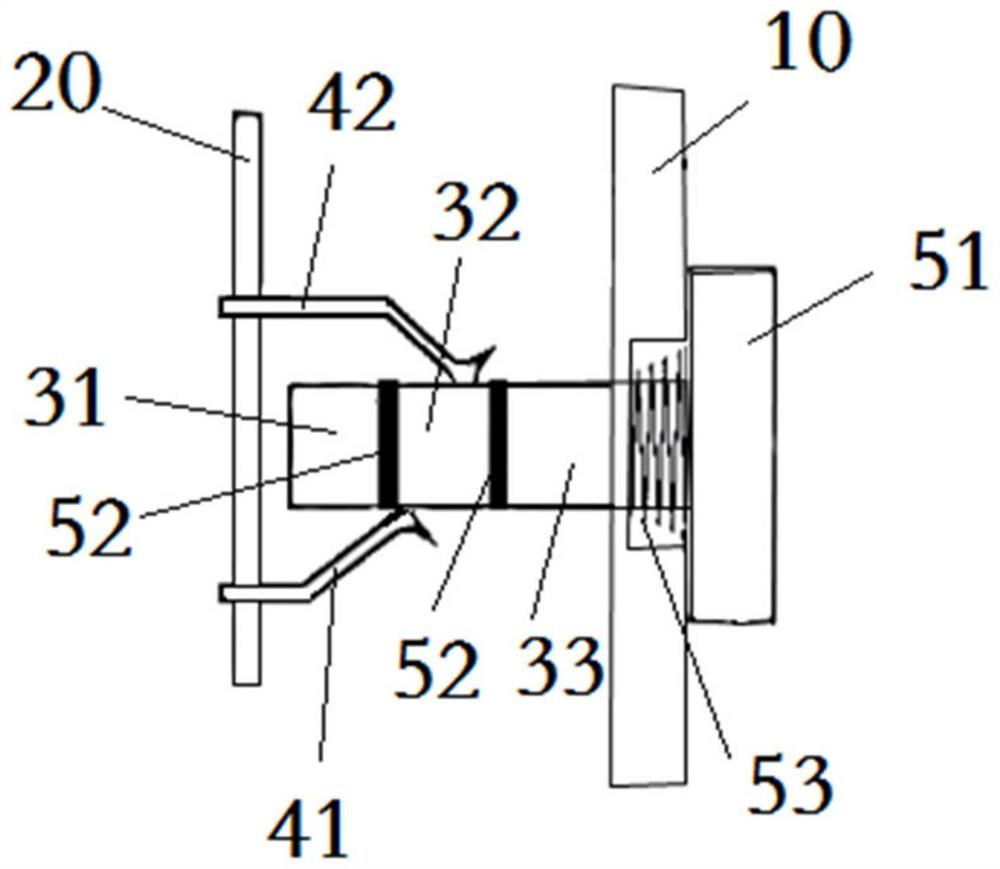

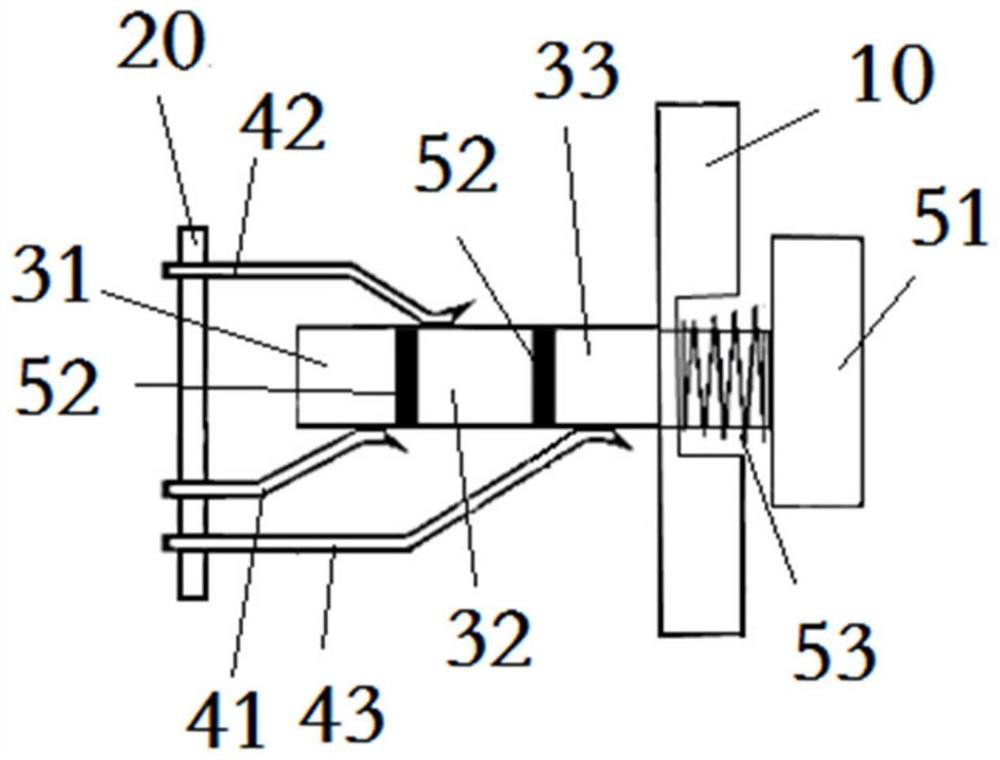

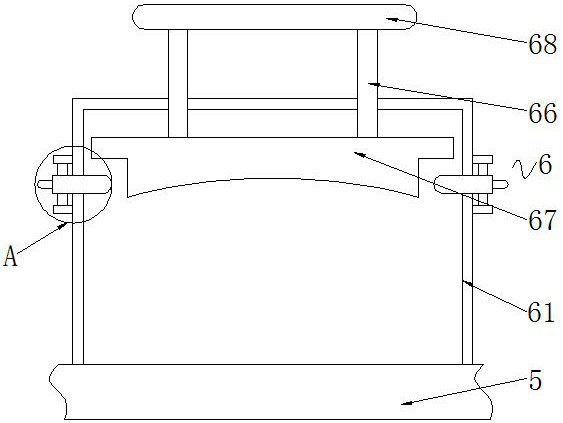

Pneumatic rubber scraper and method for producing automotive coating rubber performance test board

InactiveCN103170439AEnsure standardization and consistencyGuaranteed practical reliabilityLiquid surface applicatorsPreparing sample for investigationEngineeringElectromagnetic valve

The invention relates to a pneumatic rubber scraper and a method for producing an automotive coating rubber performance test board. A linear guide rail, two brackets, a scraper cylinder and a slider cylinder are fixed on a rack, a pushing magnetic switch II, a pullback magnetic switch II, a pullback magnetic switch I and a pushing magnetic switch I are respectively fixed on the scraper cylinder and the slider cylinder, a slider on which a test board seat is fixedly arranged is placed on the linear guide rail, the slider is connected with the slider cylinder, a scraper frame is connected with the two brackets, pull ears are respectively connected with the scraper frame and the scraper cylinder, a scraper holder on which a high-speed steel scraper head is fixedly arranged is connected with the scraper frame, and a spring is arranged between the inclined plane of the scraper frame and the surface of the scraper holder. The test board is fixed on the test board seat and is coated with a layer of coating rubber, an electric switch of a slider electromagnetic valve is started, the slider electromagnetic valve moves, and the slider cylinder is pulled back at a certain speed, so that the coating rubber on the test board can be scraped by the high-speed steel scraper head. The pneumatic rubber scraper and the method for producing the automotive coating rubber performance test board are characterized in that the standardization and the consistency of the scraped coating rubber performance test board can be guaranteed.

Owner:三友(天津)高分子技术有限公司

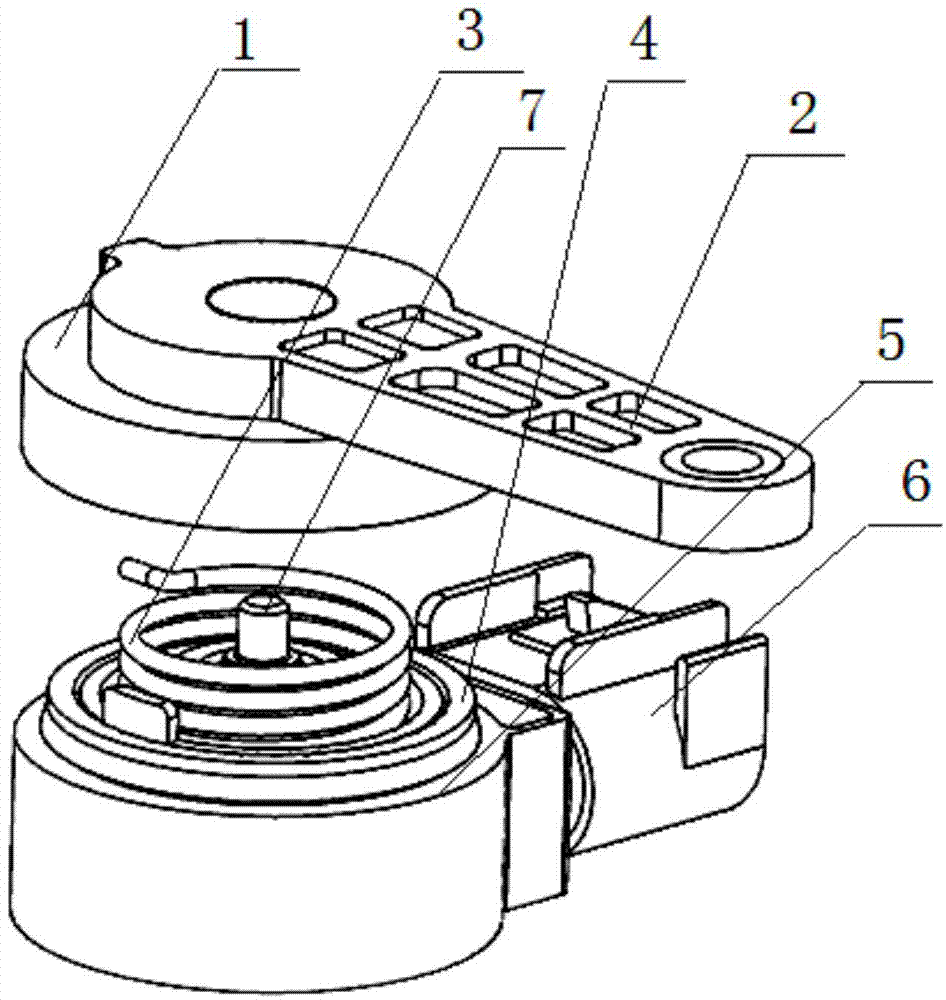

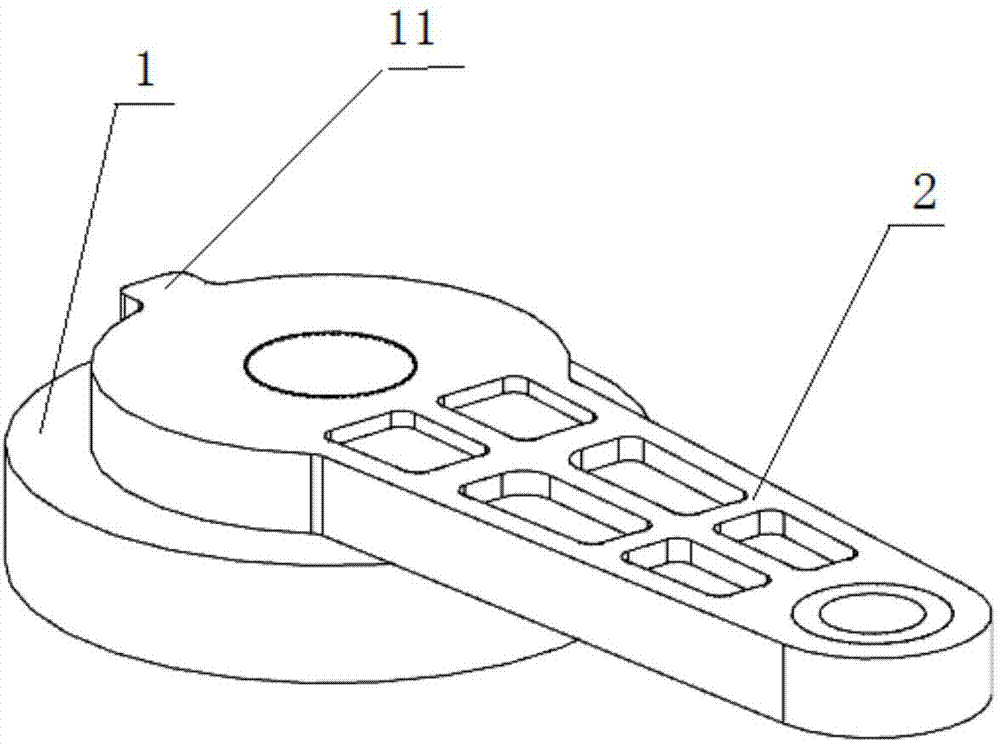

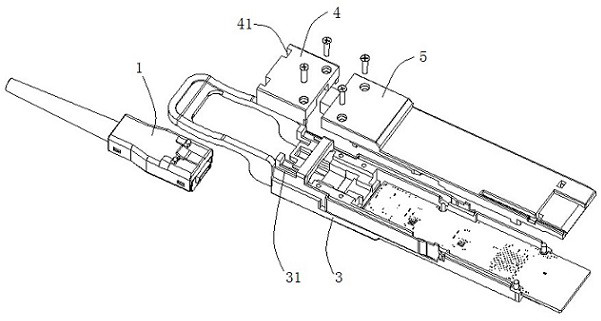

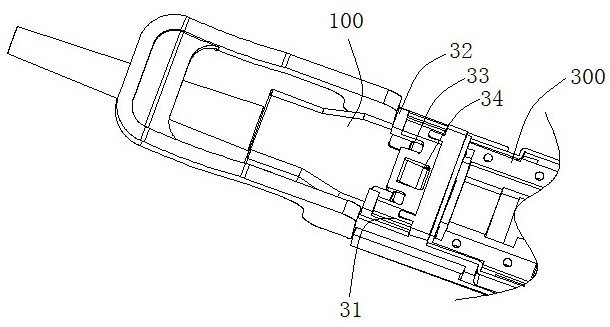

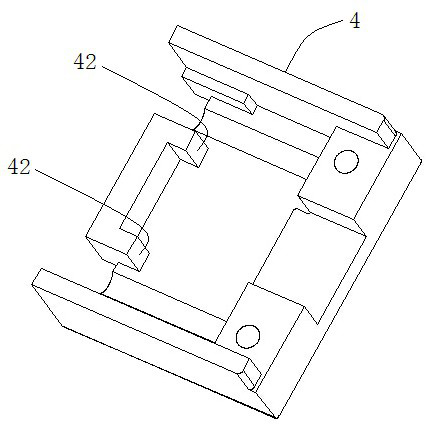

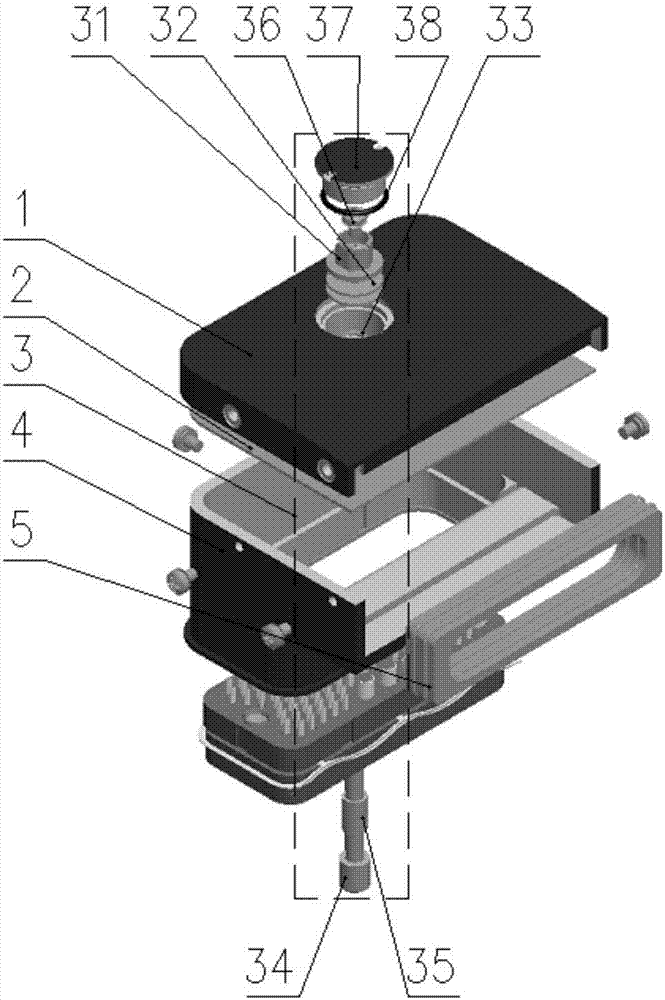

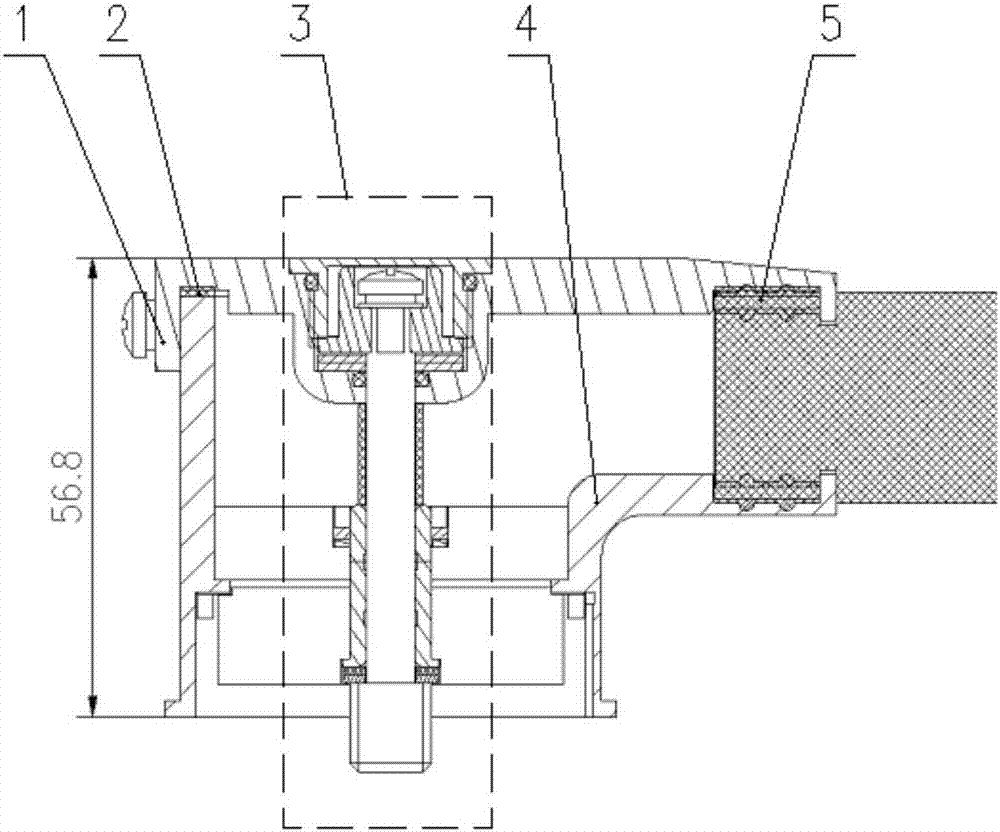

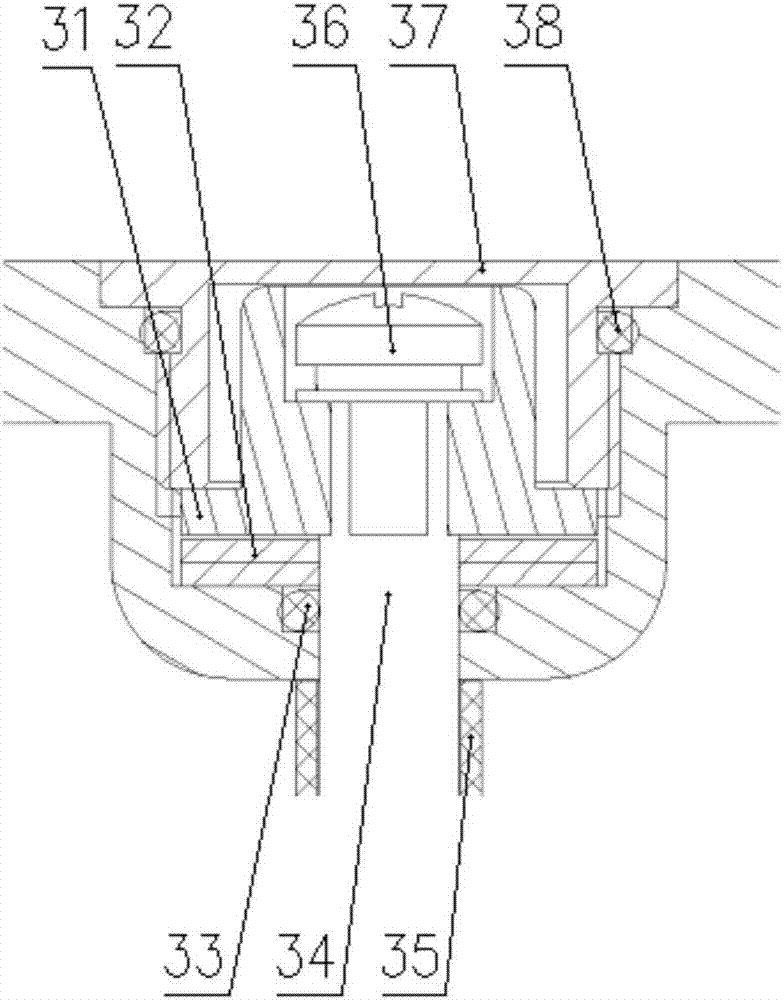

Automobile gear signal structural member and electronic gear shifter

PendingCN112096850ASimple structureHigh degree of reliabilityGearing controlEngineeringControl theory

The invention discloses an automobile gear signal structural member and an electronic gear shifter. The automobile gear signal structural member comprises a circuit board, a rotating support frame, aslide block, a sliding magnet, a fixed support frame and a rotating magnet, wherein the fixed support frame is arranged on the circuit board; the rotating magnet is rotatably arranged at the lower endof the fixed support frame; the slide block is arranged on the fixed support frame in a vertically slidable way; the sliding magnet is fixed on the slide block to slide along with the slide block; one end of the rotating support frame is connected with the rotating magnet and is used for pulling the rotating magnet to rotate, and the other end of the rotating support frame is glidingly connectedwith a position limiting type slide groove formed in the upper end of the slide block; the third end of the rotating support frame is rotatably connected with a gear sliding rod; and a rotating Hall sensor and a switch Hall sensor are arranged on the circuit board. The automobile gear signal structural member provided by the invention has the advantages of simple structure, high reliability degree, and high stability and consistency degree of gear shifting operation. By using the electronic gear shifter, the gear shifting comfort of the whole automobile, and the stability and reliability of signals are high.

Owner:NANJING AOLIAN AE&EA

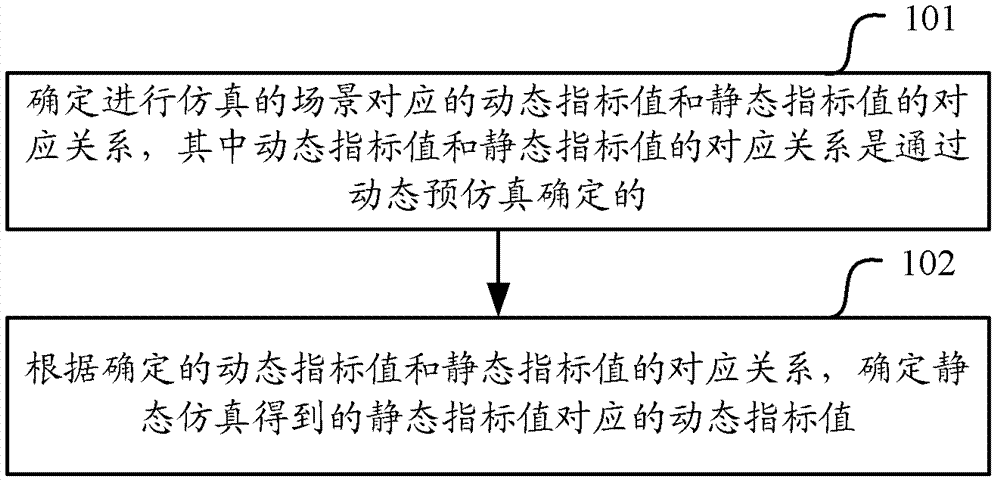

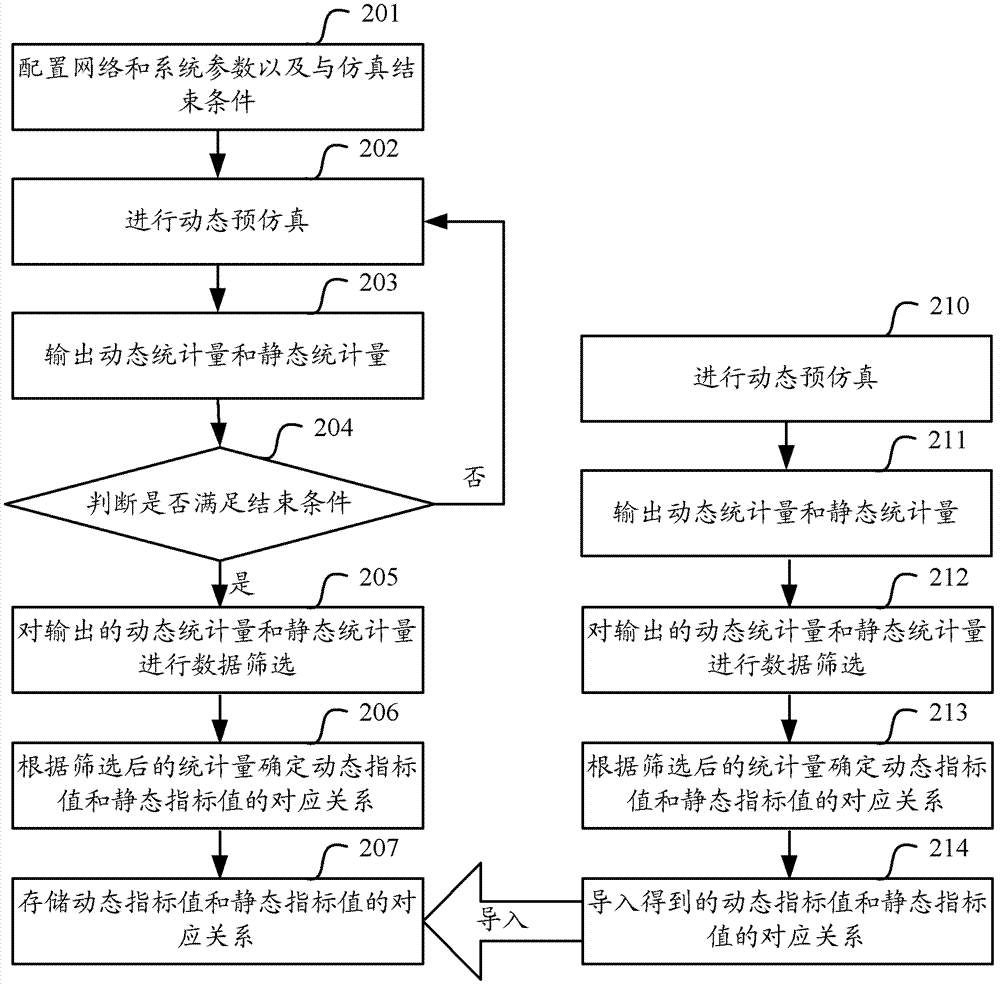

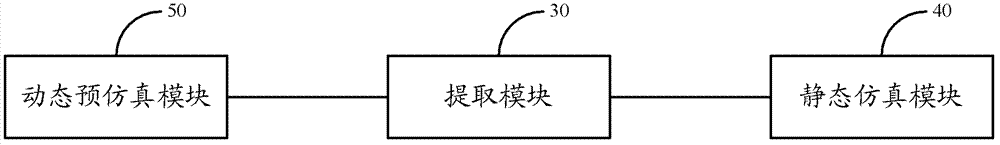

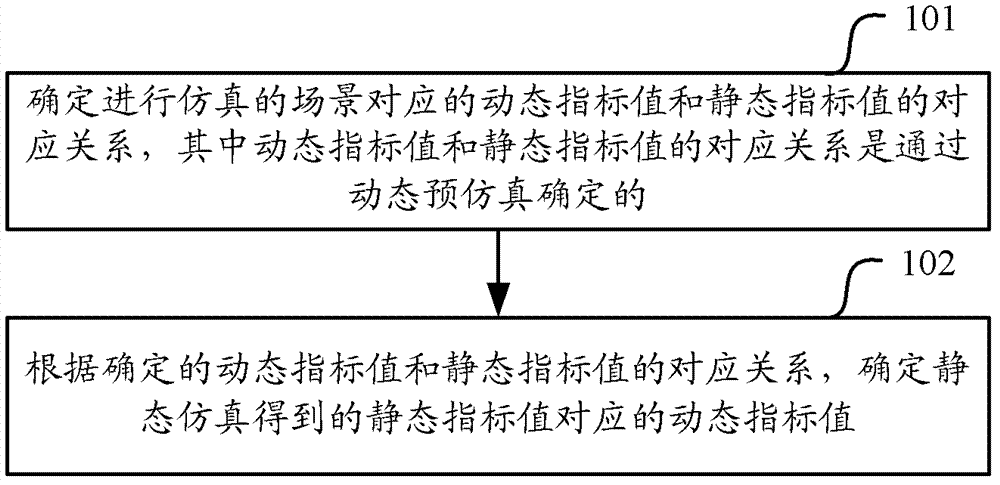

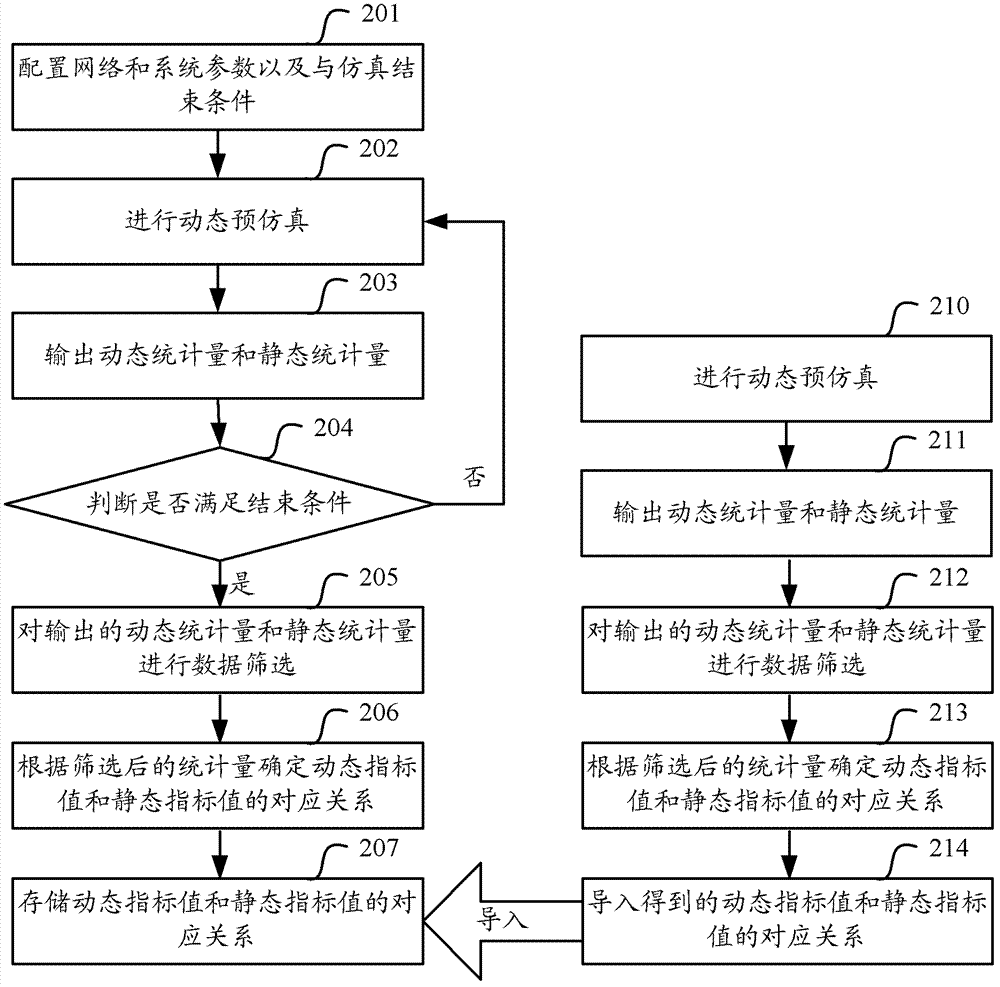

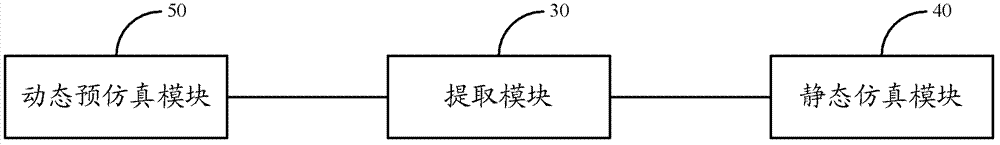

Simulation method and simulation device

ActiveCN102958089AReflect time-varying characteristicsImprove efficiencyTransmission monitoringChannel estimationTransfer modeDependability

An embodiment of the invention relates to the technical field of wireless communication, in particular to a simulation method and a simulation device, which are used for reflecting time-variation characteristic of signal channels on the premise of efficiency improvement and are capable of reflecting processing gain of transmission modes and algorithms such as detection algorithm. The simulation method includes: by means of dynamic pre-simulation, determining corresponding relation between a dynamic index value and a static index value which correspond to simulated scenes; according to the determined corresponding relation between the dynamic index value and the static index value, determining the dynamic index value, corresponding to the static index value, obtained by means of static simulation. By the simulation method and the simulation device, both simulation efficiency and performance of systems can be considered. Simulation efficiency is improved greatly since the simulation process is simplified and loss of the simulation performance is low. Assessment performance of dynamic simulation can be acquired according to the static simulation efficiency, so that the assessment performance is improved on the basis of guaranteeing performance reliability.

Owner:DATANG MOBILE COMM EQUIP CO LTD

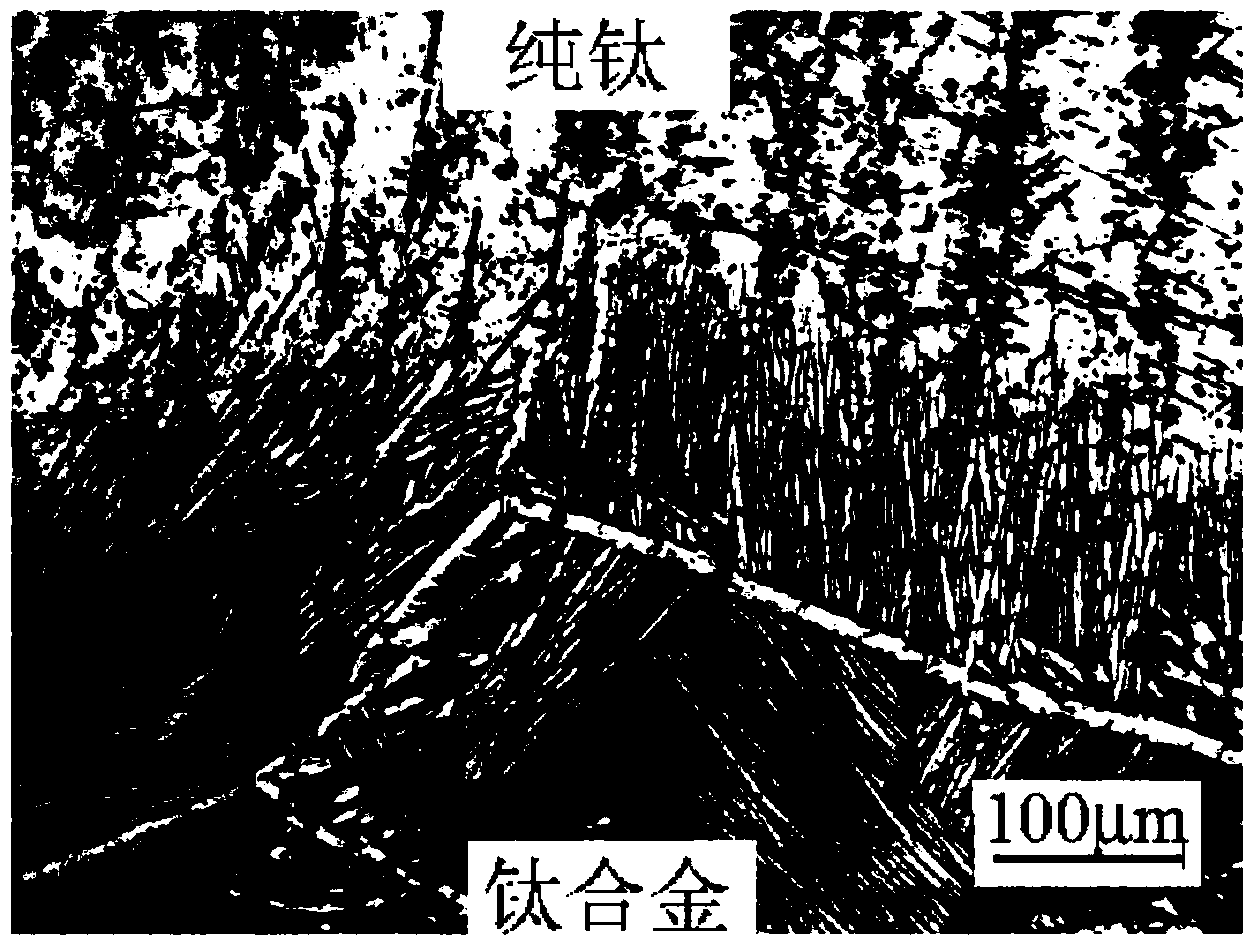

Rivet sleeve for titanium self-plugging rivet and preparation method of rivet sleeve

The invention discloses a rivet sleeve for titanium self-plugging rivet and a preparation method of the rivet sleeve, and solves the problems that titanium self-plugging rivets for aerospace in China rely on imports for a long time, are high in cost and are controlled by others, and breaks through the monopoly of an individual manufacturer. The titanium self-plugging rivet for aerospace is composed of a plastic deformation part and a bearing part and is made from high-strength titanium alloy, and the plastic deformation part is made from industrial pure titanium of which an alloy designation is TA1-TA4 or the alloy designation is TA5-TA10. The preparation method comprises the following steps: firstly, designing the position and length of the plastic deformation part of the rivet and the bearing part as required; secondly, calculating and weighing material powder; thirdly, paving horizontally; and fourthly, hot pressed sintering in vacuum. The preparation method provided by the invention is used for manufacturing the titanium self-plugging rivets for aerospace which is used for the field of aerospace.

Owner:HARBIN INST OF TECH

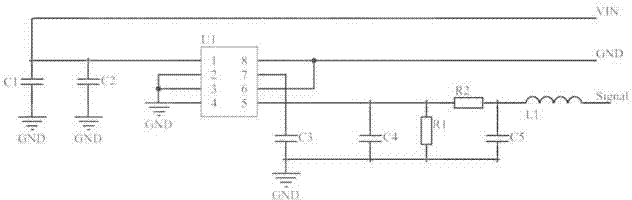

Vehicle body height sensor

InactiveCN104748659AGuaranteed performance reliabilityGood vibration resistanceUsing electrical meansNormal posturesTorsion spring

The invention provides a vehicle body height sensor. The vehicle body height sensor comprises a shell and a rotor, wherein a Hall chip and a bearing are arranged in the shell; the rotor comprises a rotating shaft, a swing arm and a magnetic ring; the swing arm is connected with the rotating shaft and is connected with a vehicle body; the magnetic ring is placed on the rotating shaft; the rotating shaft penetrates in the bearing; a torsional spring which keeps the posture of the swing arm sleeves the rotating shaft; one end of the torsional spring is fixed on the rotor; and the other end of the torsional spring is fixed on the shell. The torsional spring is arranged in the shell, the normal posture of the swing arm can be always kept through the torsional spring, the posture of the swing arm includes the position and the direction of the swing arm in space, even if the swing arm is impacted and the posture of the swing arm is changed when the vehicle body height sensor is mounted, the swing arm can be reset to be in the original state through the torsional spring, the reliability of the using performance of the vehicle body height sensor can be ensured after the vehicle body height sensor is mounted, and the vehicle body height sensor has high vibration resistance.

Owner:SHANGHAI SEEYAO ELECTRONICS CO LTD

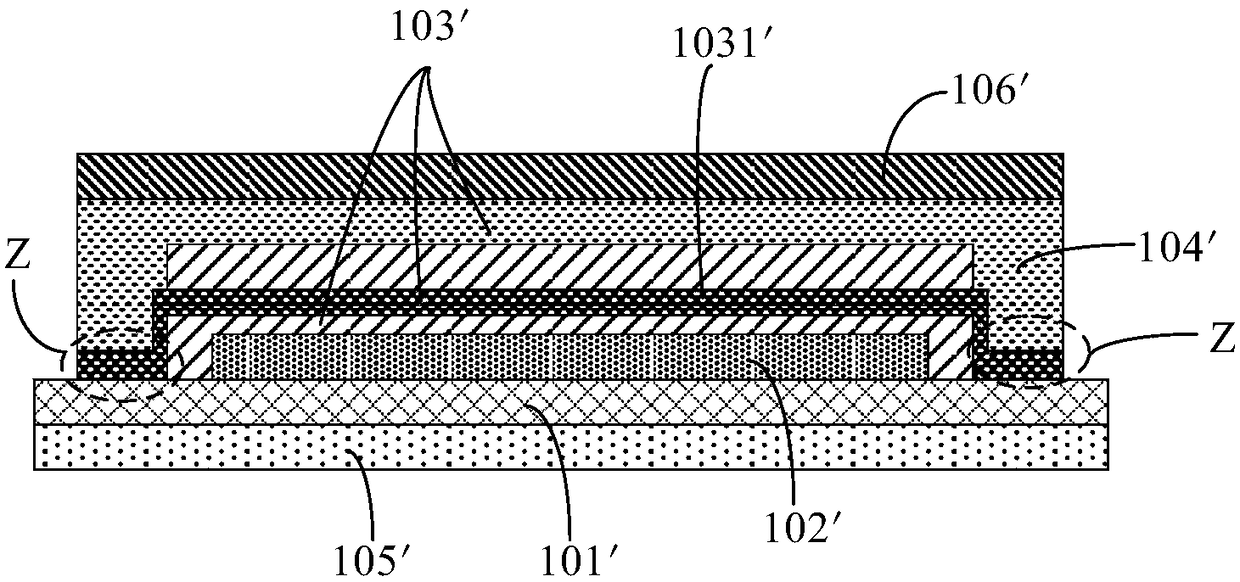

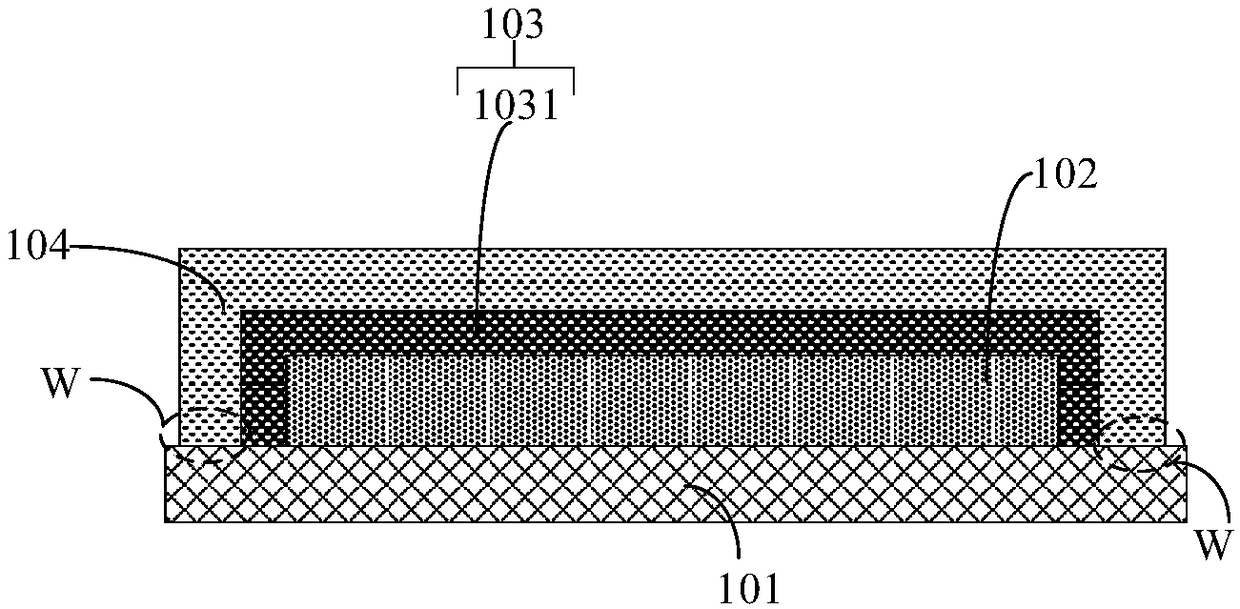

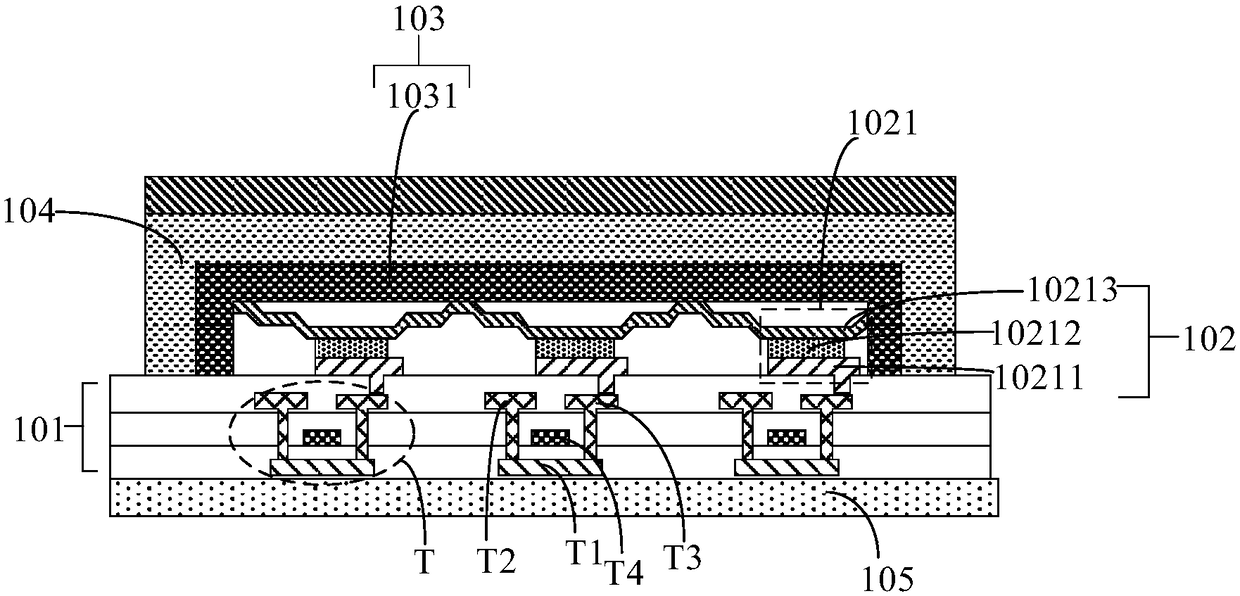

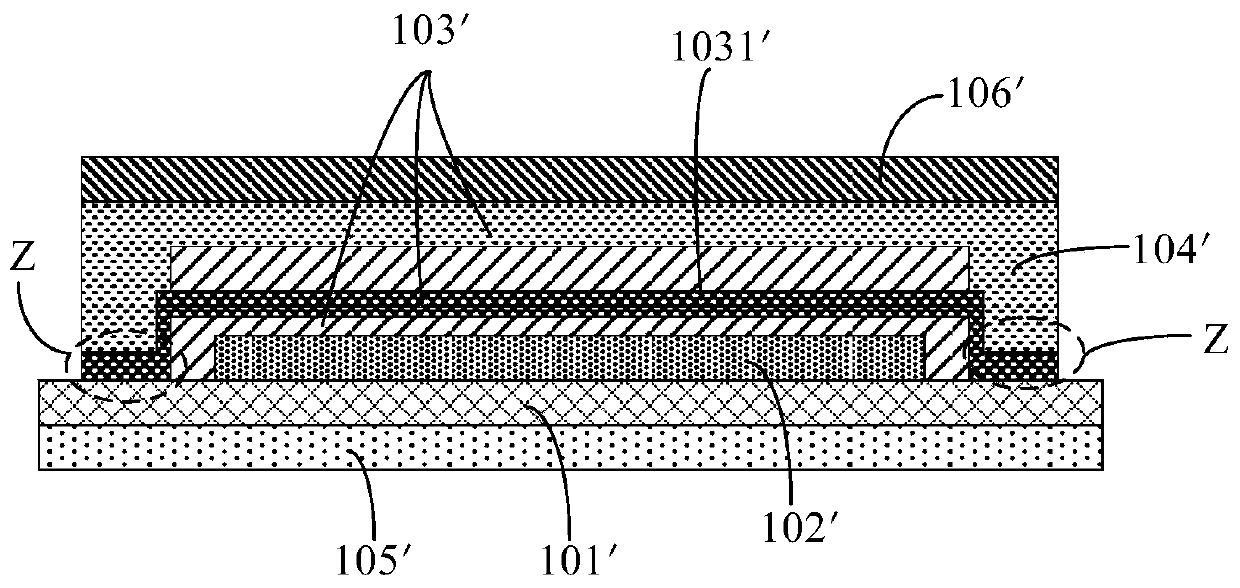

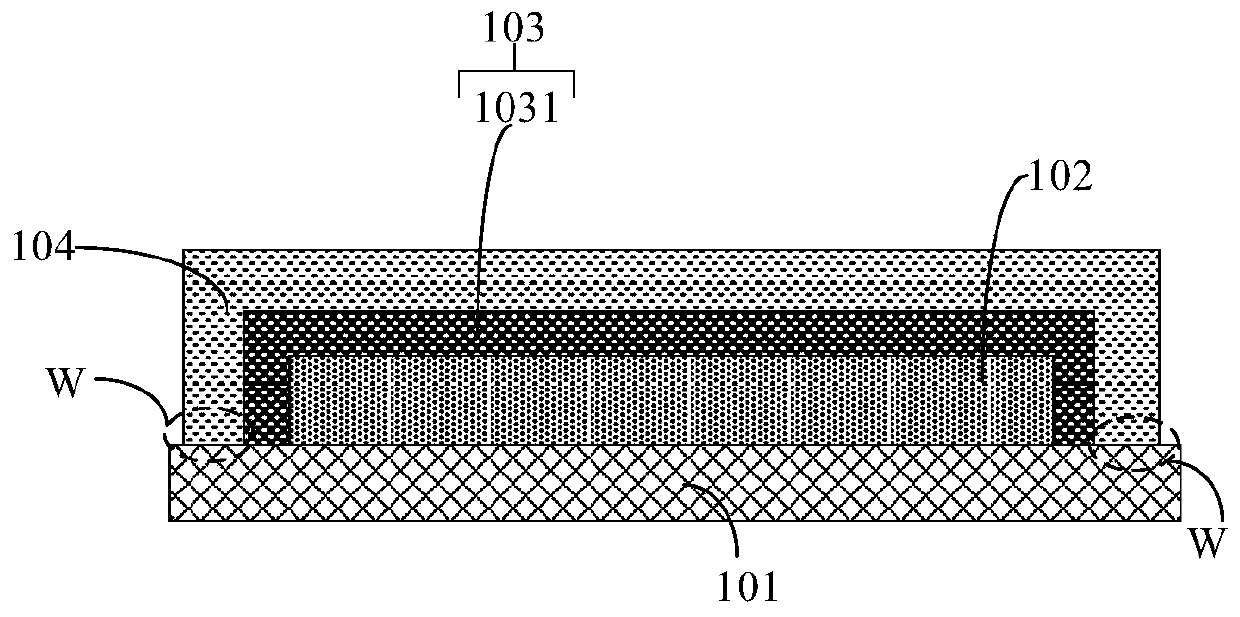

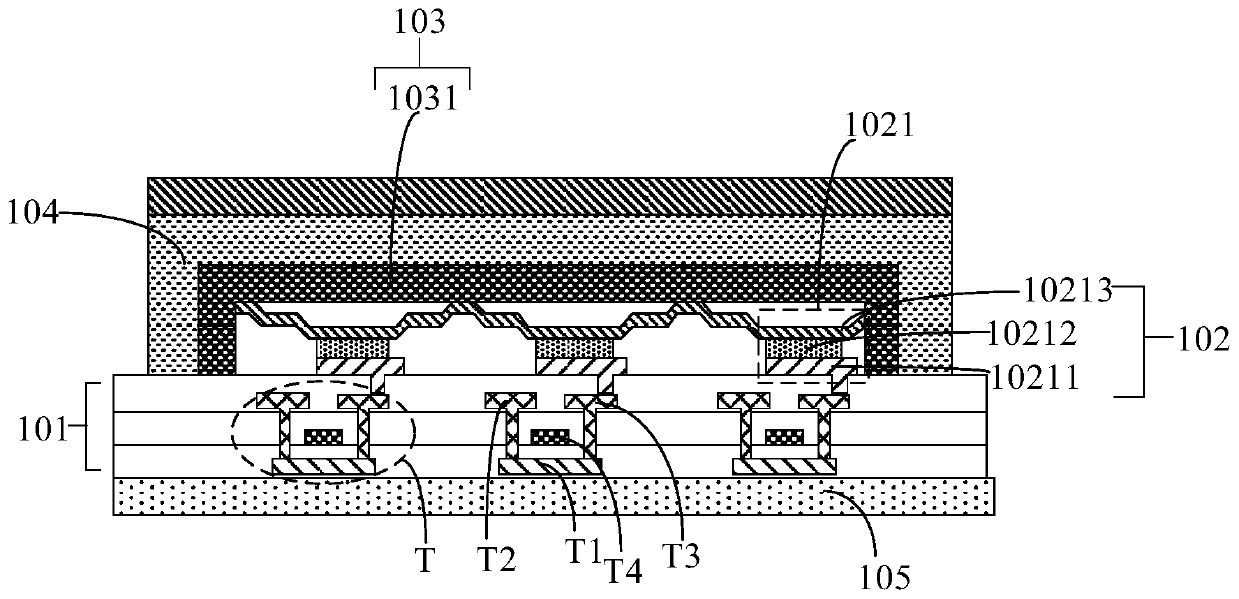

Display panel, manufacturing method thereof and display device

ActiveCN108321304AGuaranteed service lifeGuaranteed reliable performanceSolid-state devicesSemiconductor/solid-state device manufacturingOxideSurface plate

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel comprises an array layer, a light emitting device layer, a package structure and an adhesive layer; the light emitting device layer is located on the array layer; the package structure is located at one side of the light emitting device layer which is far away from the array layer and comprises a metal oxide layer; and the adhesive layer is located at one side of the package structure which is away from the light emitting device layer; the orthographic projection of the package structure in the array layer is located in the orthographic projection of the adhesive layer on the array layer; and the orthographic projection of the adhesive layer on the array layer is greater than theorthographic projection of the package structure on the array layer. The edge of the adhesive layer does not contact with the metal oxide layer produced by an atomic layer deposition process, and therefore, the upwarp and falling off of a corresponding position due to poor bonding performance can be avoided, and the reliability of the performance of the display panel can be ensured.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

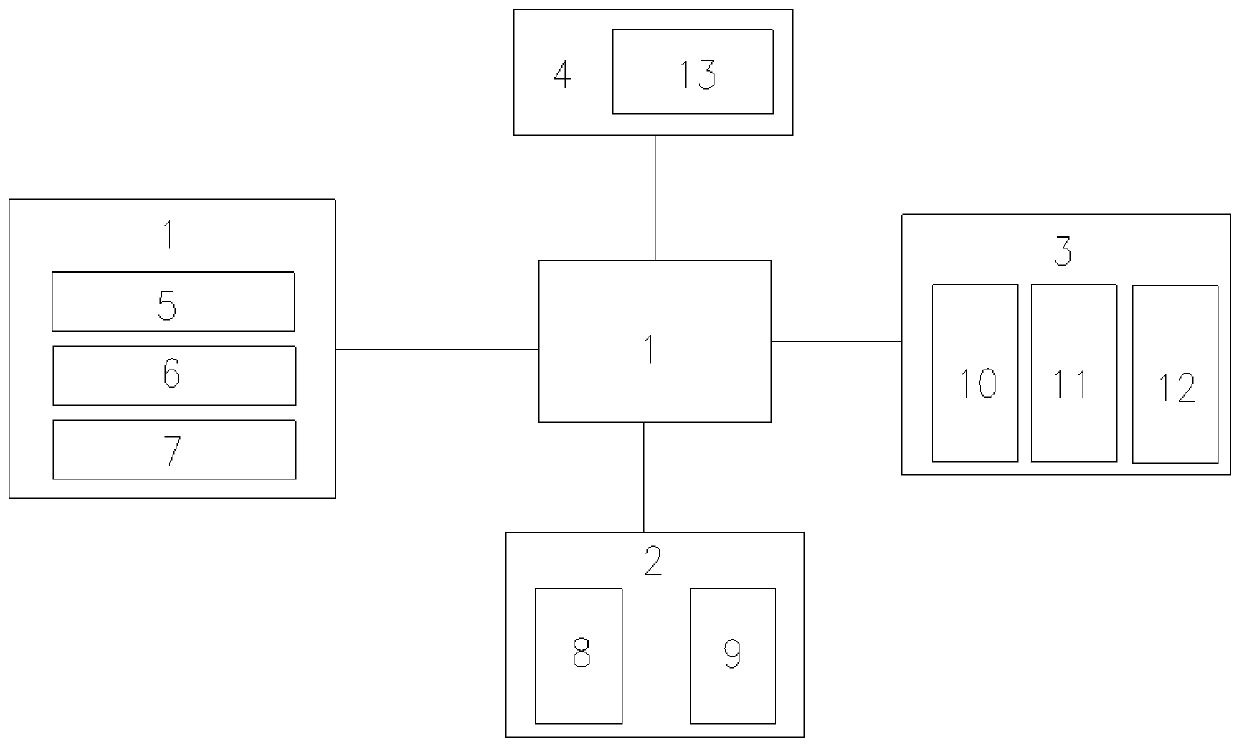

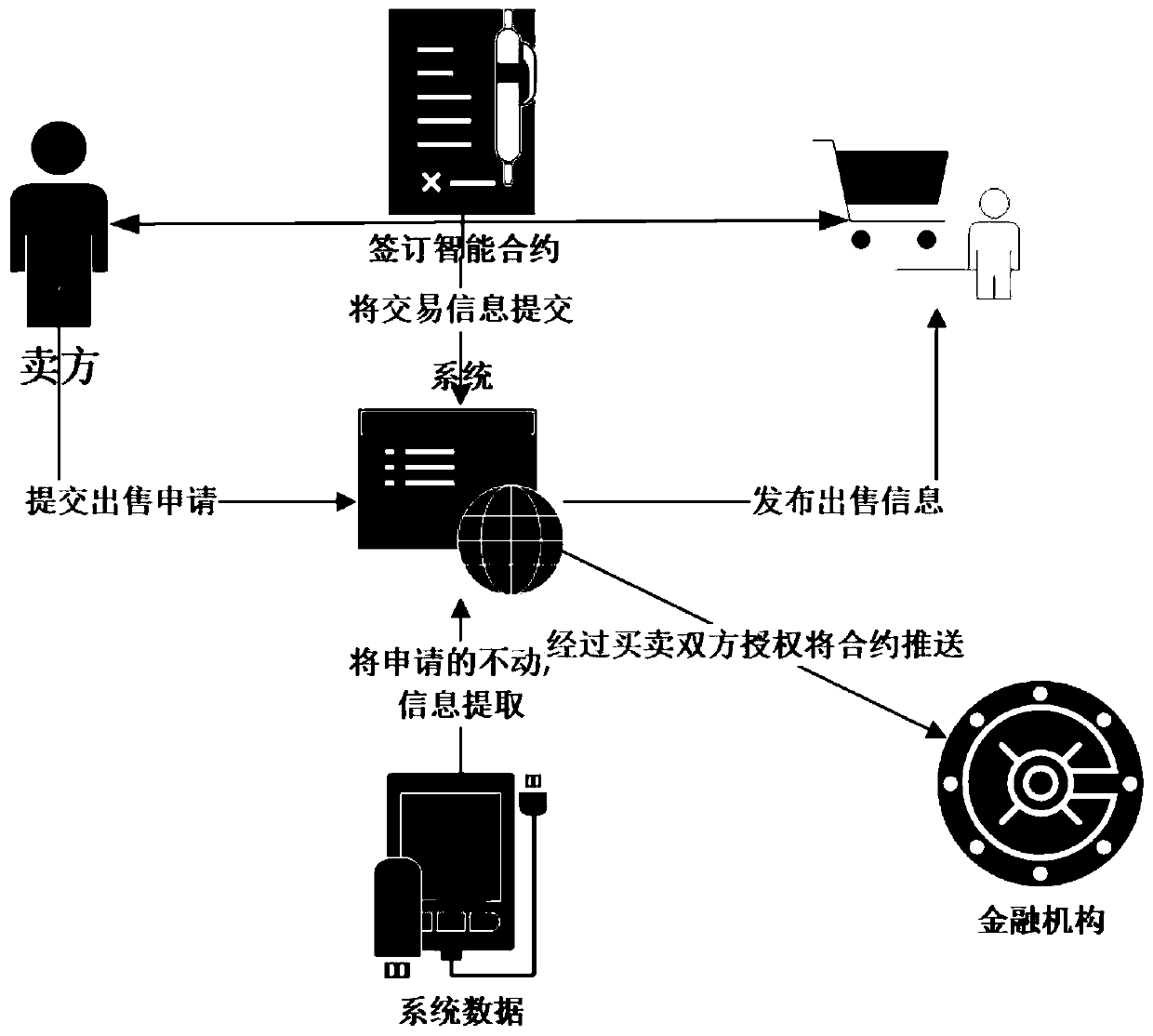

Real estate transaction system and method based on super account book

PendingCN110969530AGuaranteed reliabilityReliability guaranteeFinanceFinancial transactionApplication module

The invention discloses a real estate transaction system and method based on a super account book. The transaction system comprises a login / registration module, a transaction release / revocation application module, a transaction module, a transaction information query module and a control module. The control module is connected with the login / registration module, the transaction release / revocationapplication module, the transaction module and the transaction information query module separately, so that the situation that the real estate information of other real estate transaction platforms isnot real can be fundamentally solved, and the authenticity and effectiveness of real estate data on the platforms are ensured; information is shared with a real estate department database, real-timeinformation of real estate is interacted, and the real-time performance and effectiveness of transaction are ensured; the whole real estate buying and selling process is completely communicated by thebuyer and the seller, the addition of an intermediary agency is avoided, and the contract signed through the intelligent contract is safe and irreversible.

Owner:NANTONG UNIVERSITY

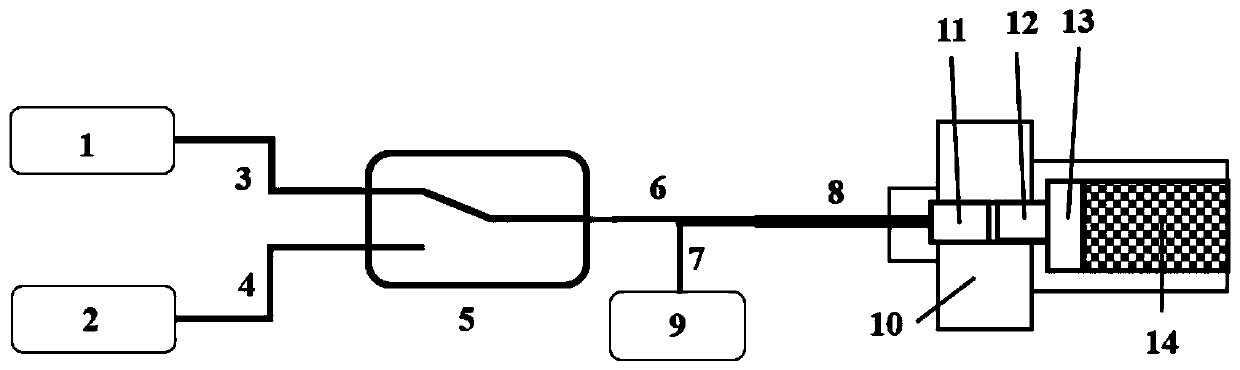

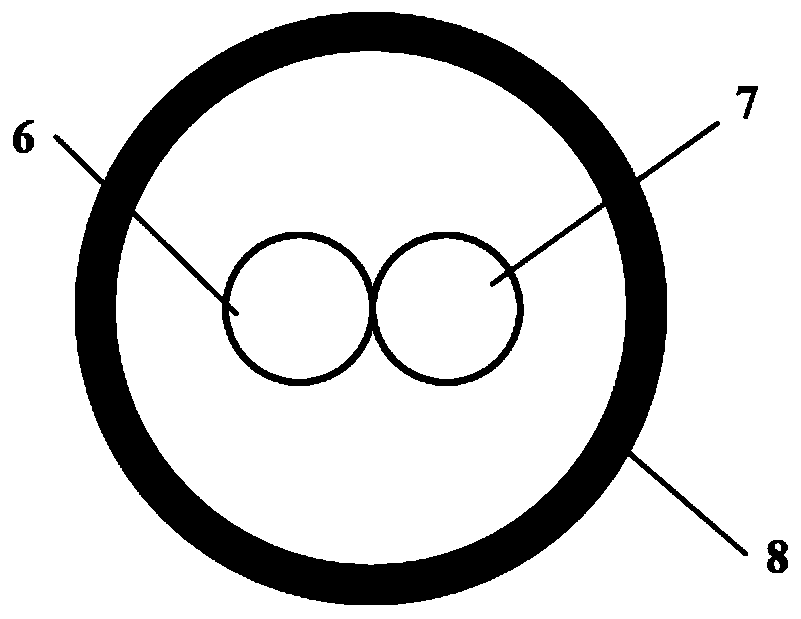

Optical window based on double-self-focusing lens structure

InactiveCN110411283AEffective protectionReduce randomnessBlasting cartridgesFiberPhotovoltaic detectors

The invention belongs to the field of laser initiating explosive devices, and particularly relates to an optical window based on a double-self-focusing lens structure. The optical window comprises anignition laser, a detection laser, an optical switch, a photoelectric detector, a first self-focusing lens, a second self-focusing lens and a sapphire transparent window, wherein the ignition laser isconnected to the optical switch through an ignition input fiber and a detection input fiber correspondingly, the optical switch is connected with the first self-focusing lens through the ignition optical fiber, the photoelectric detector is connected with the first self-focusing lens through the detection optical fiber, the second self-focusing lens and the sapphire transparent window are sequentially placed behind the first self-focusing lens, and optical axes of the first self-focusing lens, the second self-focusing lens and the sapphire transparent window are coaxial. According to the optical window, the technical defects of an existing laser initiating explosive device optical window are overcome, the laser radiation power density is avoided, a certain proportion of detection light isguaranteed to enter the detection optical fiber, the consistency of the reflectivity of the initiating explosive devices is improved, and the capability of the chamber pressure resistance of the optical window is improved.

Owner:NANJING UNIV OF SCI & TECH

Electronic water pump and casing assembly

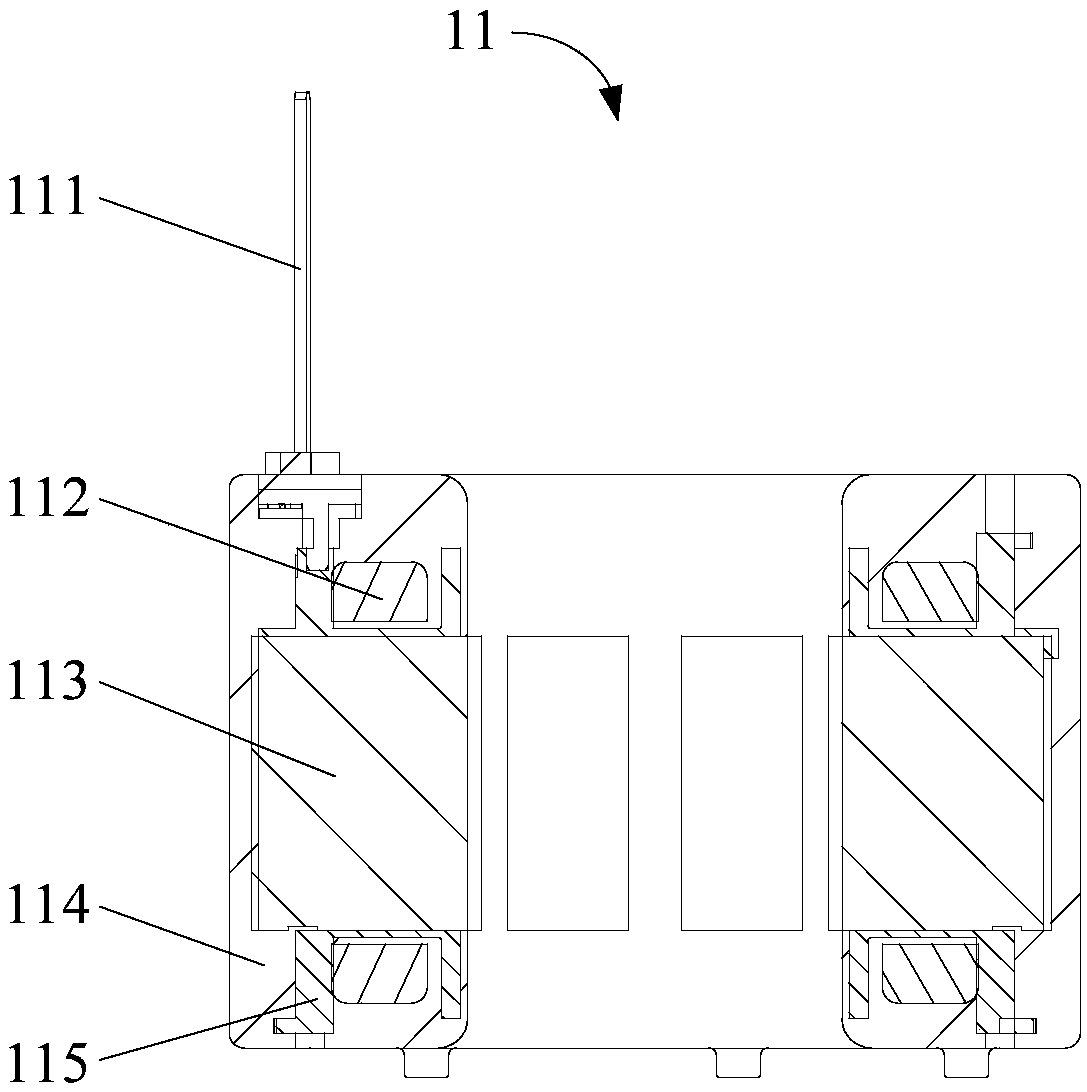

PendingCN110873062ALow costSimplify the assembly processPump componentsPump installationsPhysicsStator

The invention provides an electronic water pump and a casing assembly. The casing assembly of the electronic water pump comprises a stator assembly, a rotating shaft, a shaft base and a casing injection body, wherein the stator assembly is formed by overall injection molding, the casing assembly is formed by secondary injection molding, the rotating shaft and the shaft base are both embedded intothe casing injection body, and the stator assembly is wrapped in the casing injection body to form self-sealing. According to the casing assembly of the electronic water pump, the stator assembly is formed by overall injection molding and then subjected to secondary injection molding with the casing and realizes the self-sealing action with a rotor, a distance sleeve in the middle of an air gap ofthe stator and the rotor is omitted, cost of a casing material is reduced, meanwhile, the assembling process of the electronic water pump is simplified, rigidity of the stator assembly is improved, noise improvement of the electronic water pump is facilitated, operating reliability of the electronic water pump is improved, and therefore, the casing assembly of the electronic water pump in the scheme has obvious advantages in aspects of mounting process, cost and properties.

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

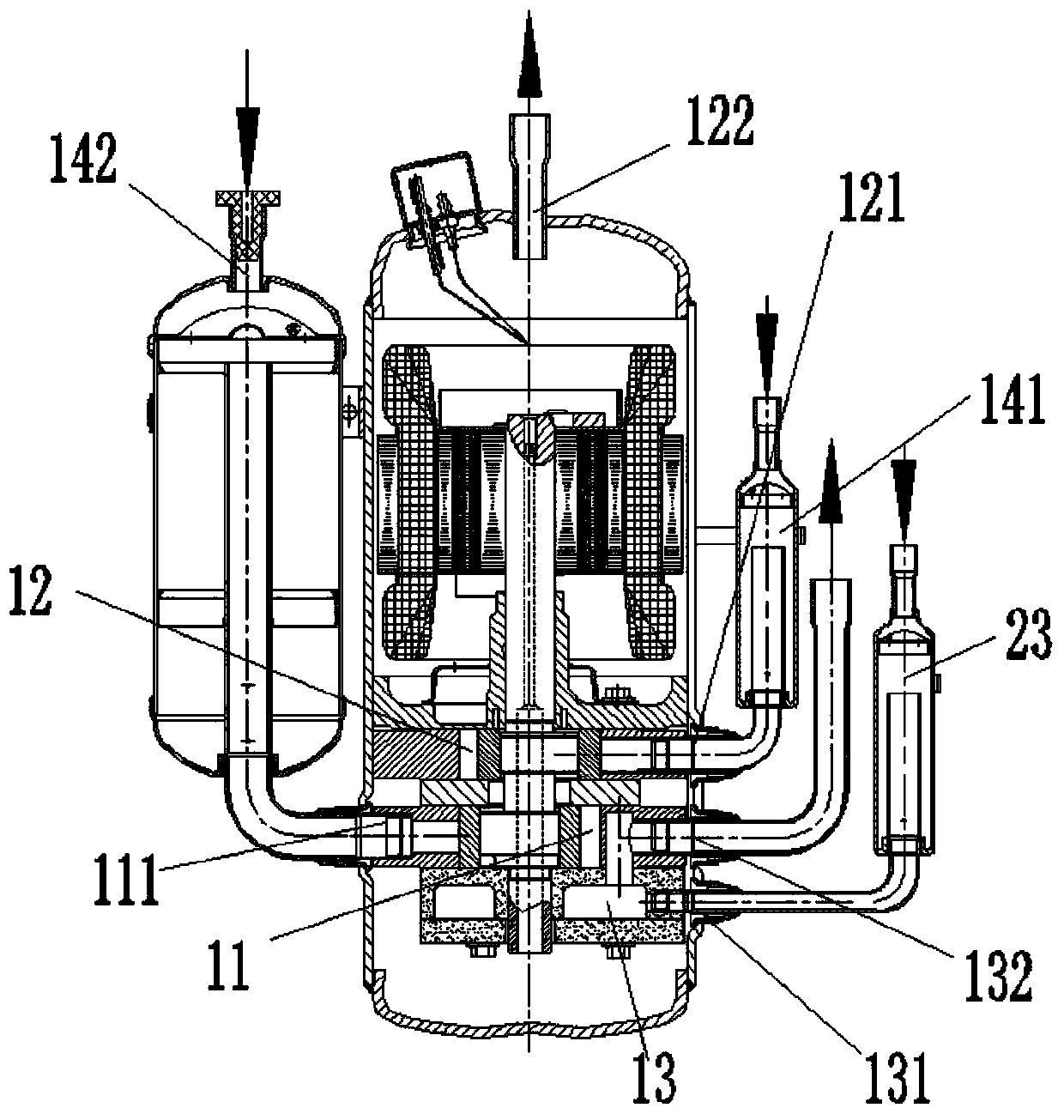

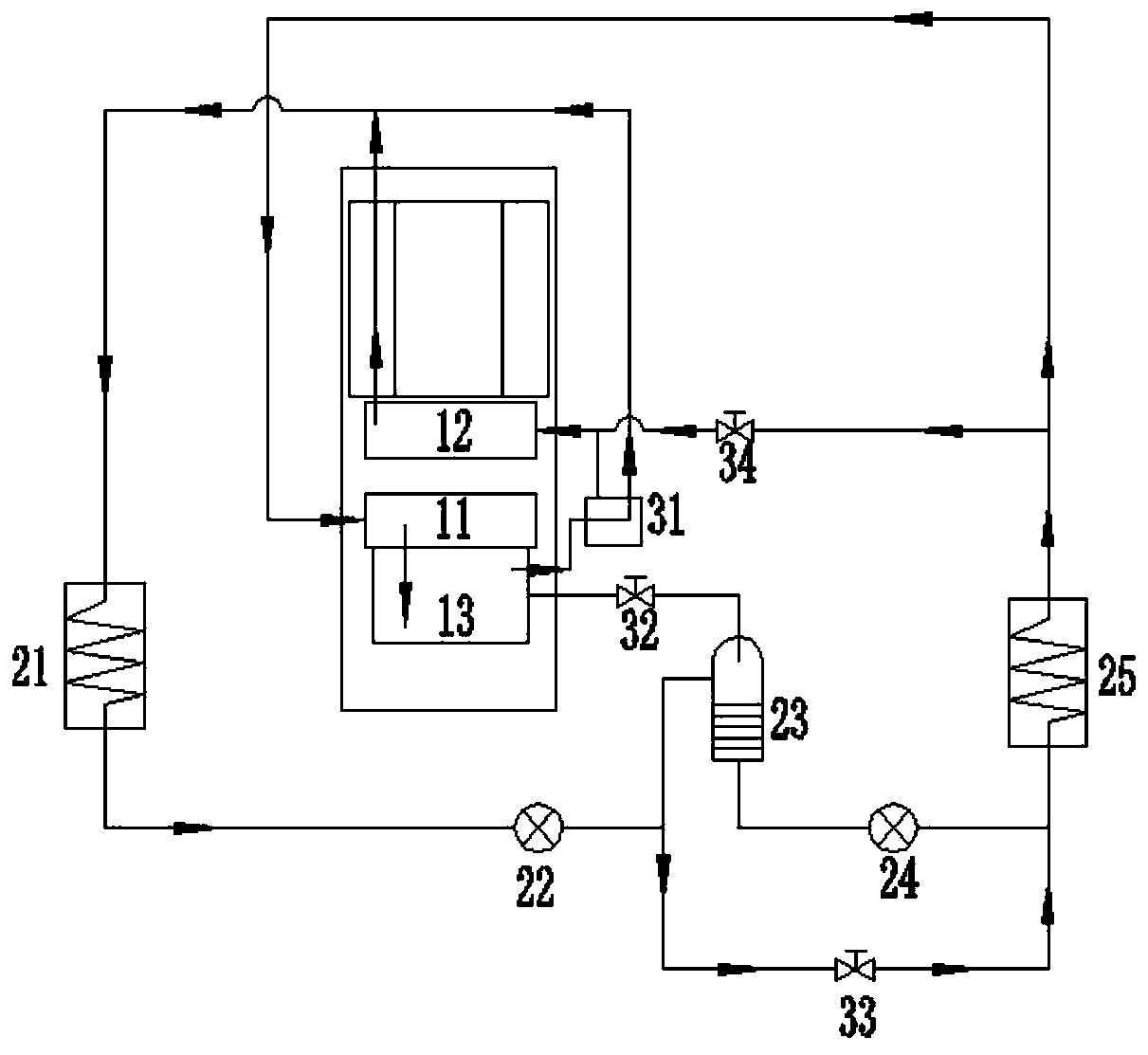

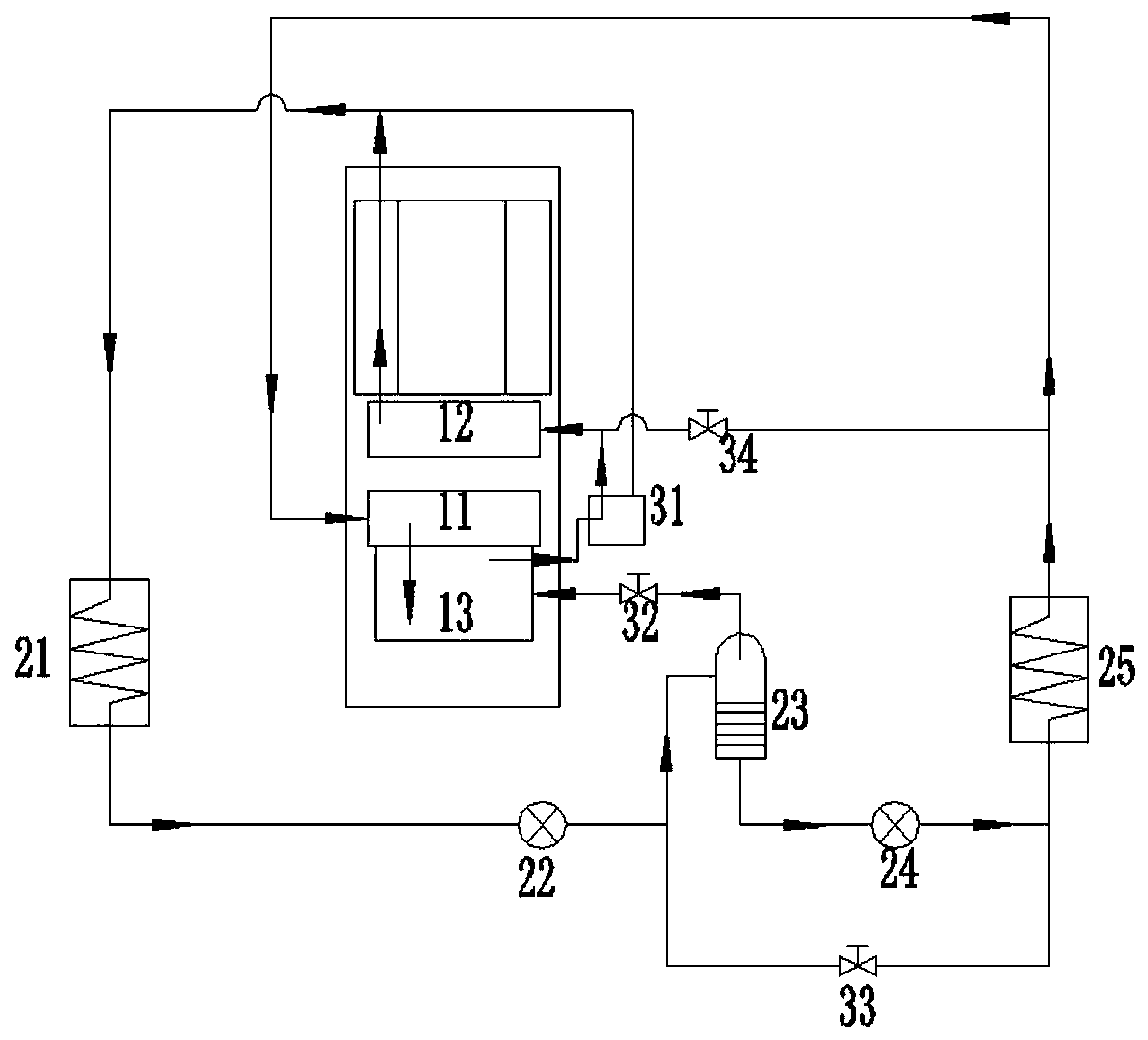

Double-stage air replenishing compressor, freezing and cold storage refrigerating system and control method

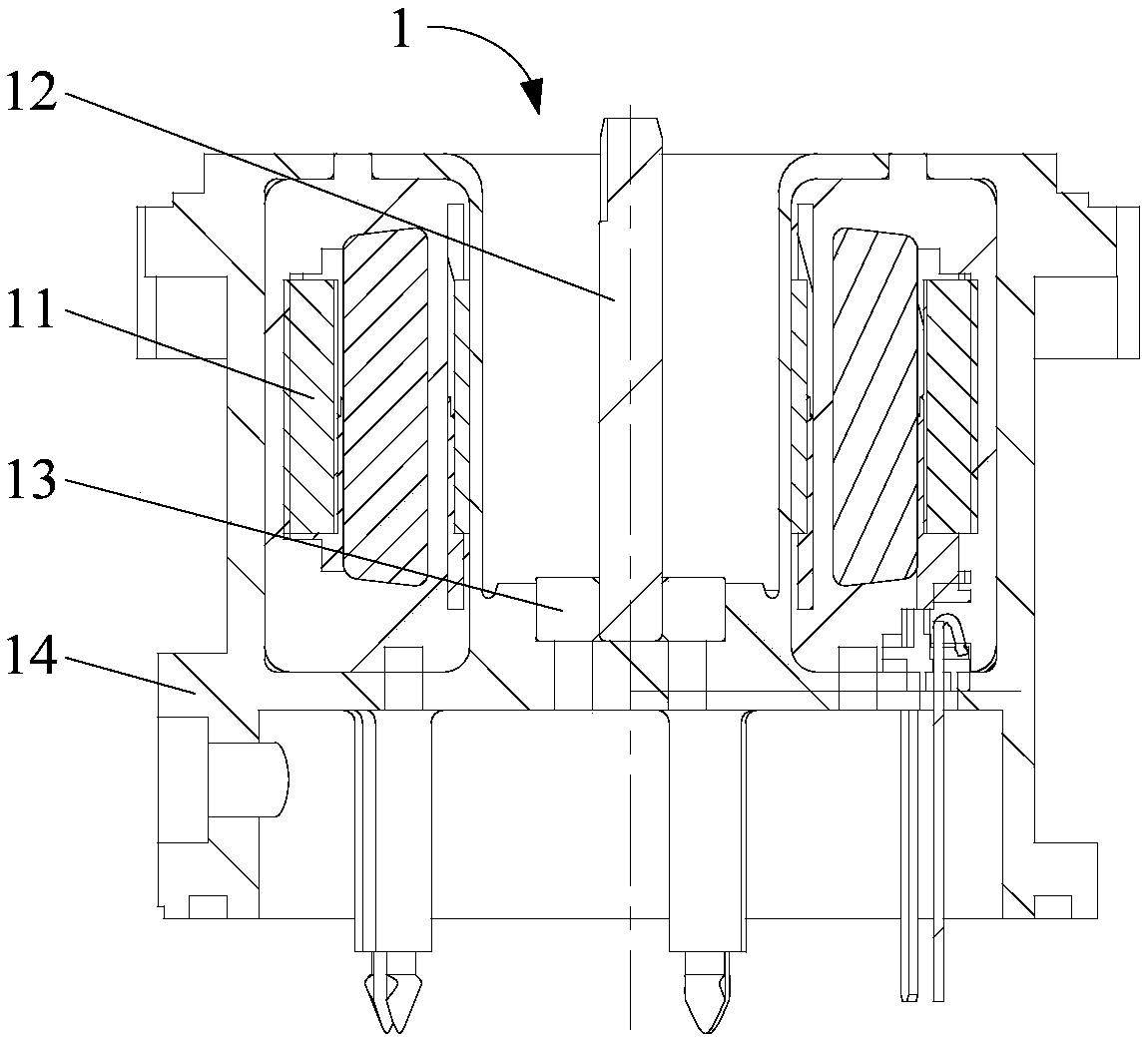

PendingCN111022322AReduce operating frequencyEliminate collision noiseRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cyclePhysicsCool storage

The invention provides a double-stage air replenishing compressor, a freezing and cold storage refrigerating system and a control method. The double-stage air replenishing compressor comprises a low-pressure-stage compression cavity, a high-pressure-stage compression cavity and a middle air replenishing cavity. The low-pressure-stage compression cavity is provided with a low-pressure-stage suctionport and a low-pressure-stage exhaust port. The high-pressure-stage compression cavity is provided with a high-pressure-stage suction port and a high-pressure-stage exhaust port. The middle air replenishing cavity is provided with an air replenishing port and a mixing exhaust port. The low-pressure-stage compression cavity is connected with the middle air replenishing cavity through the low-pressure-stage exhaust port in a communicating manner. According to the double-stage air replenishing compressor, the freezing and cold storage refrigerating system and the control method, when the external environment temperature is low, the system is switched into the state that a high-pressure-stage air cylinder and a low-pressure-stage air cylinder run in parallel, thus, the operating frequency ofthe compressor can be reduced while the requirements of the refrigerating capacity are met, then the phenomenon that a slip sheet and a roller in the high-pressure-stage air cylinder disengage to generate collision noise is effectively eradicated completely, and the performance reliability of the compressor is guaranteed.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

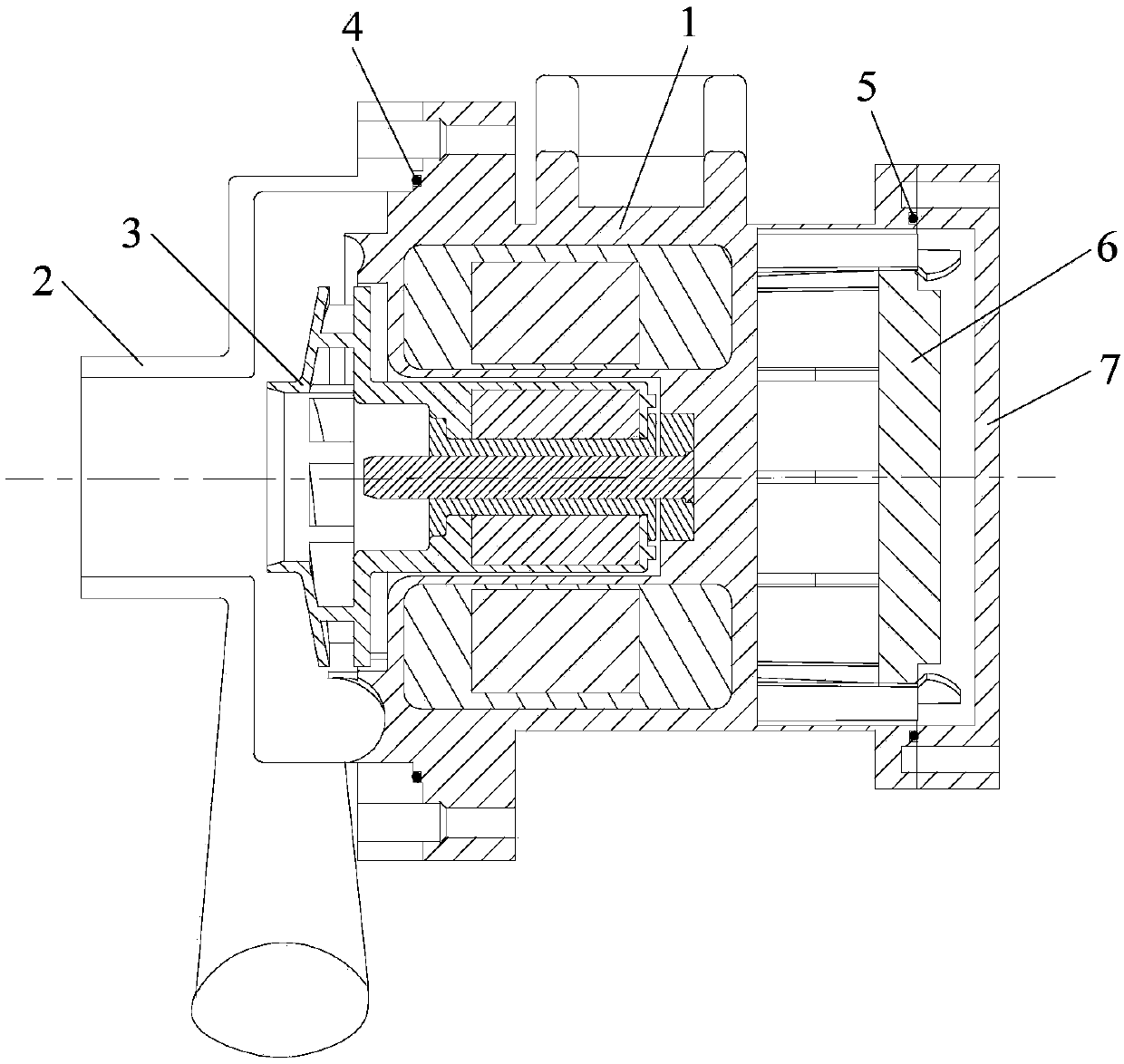

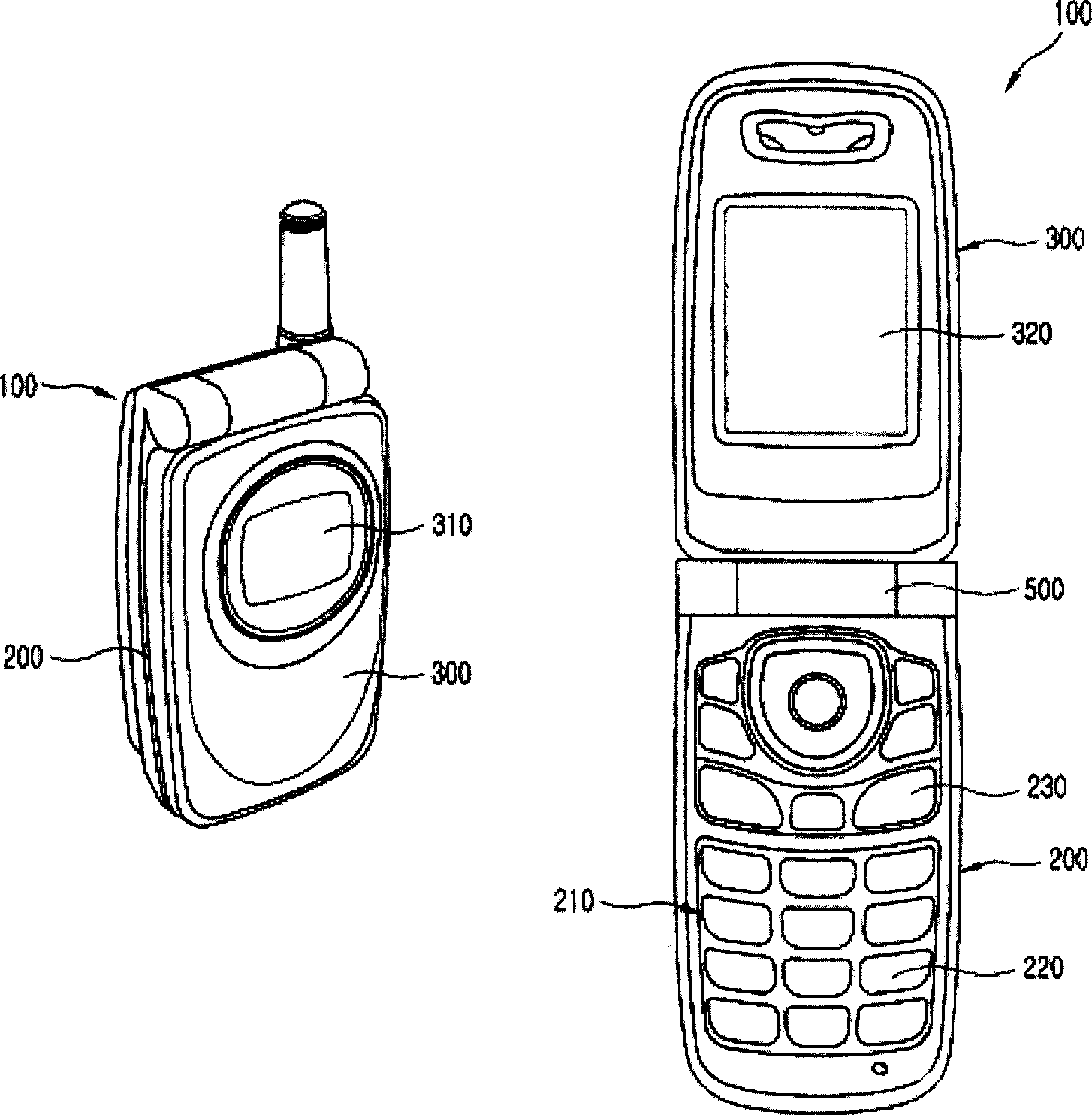

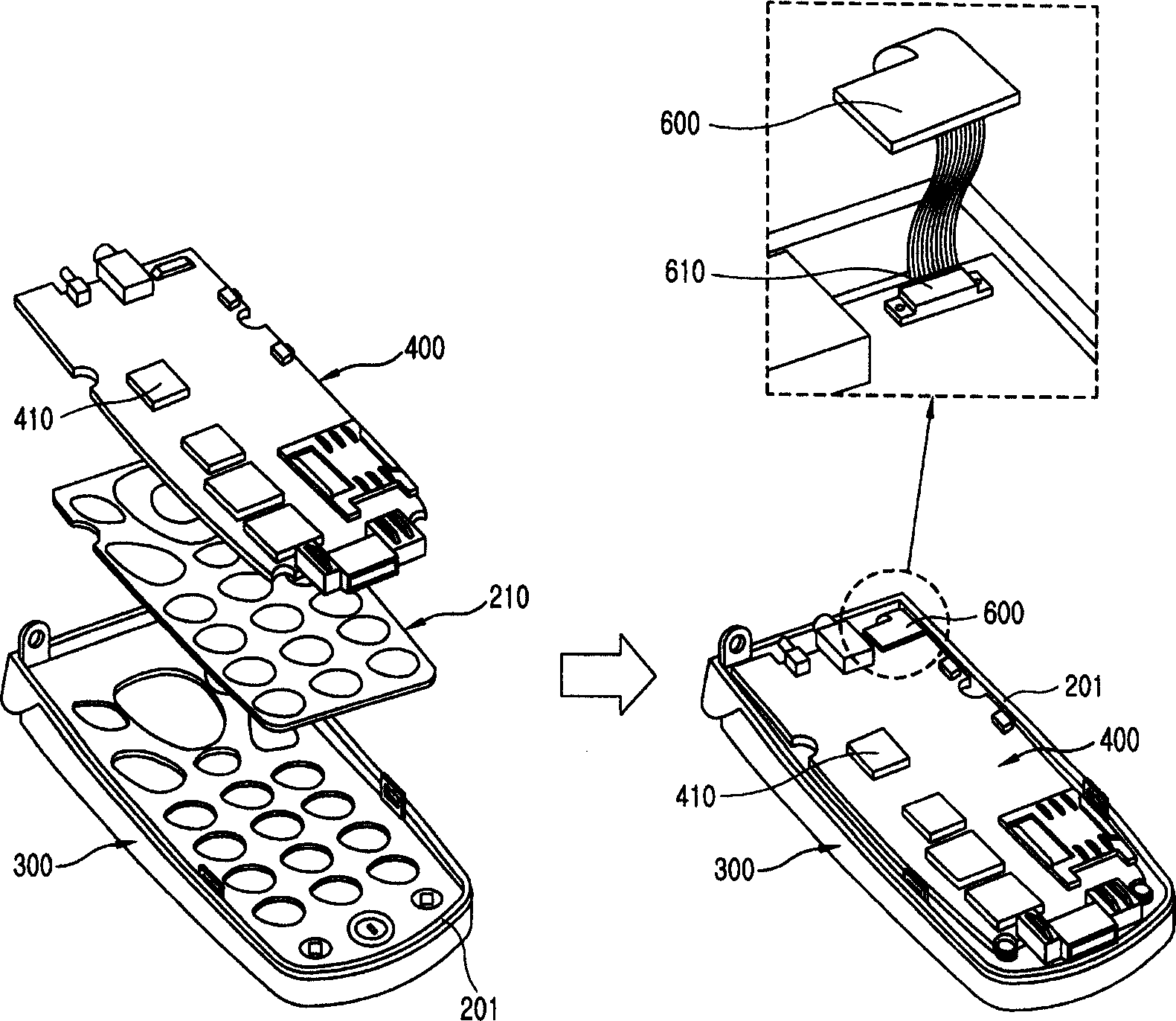

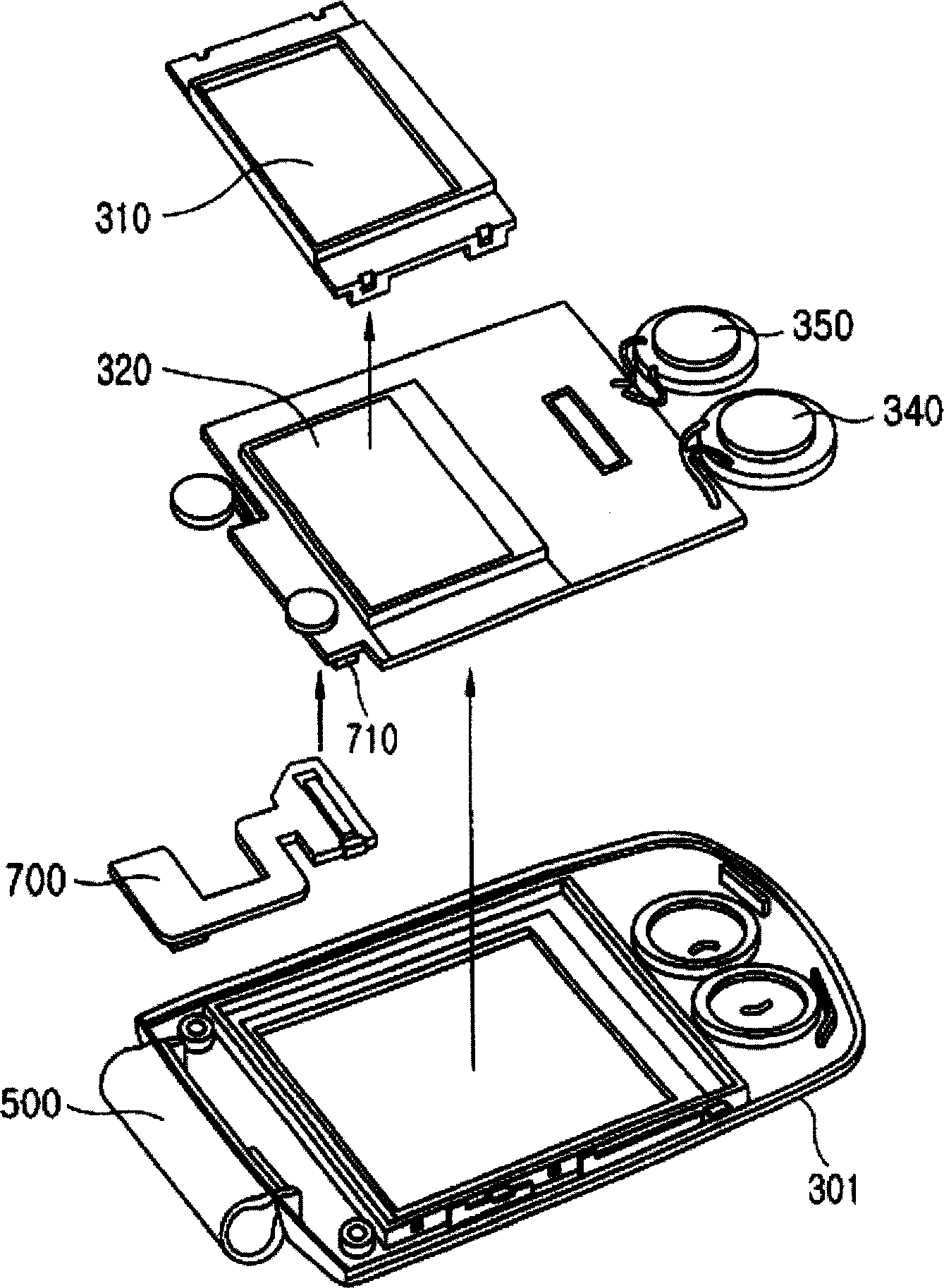

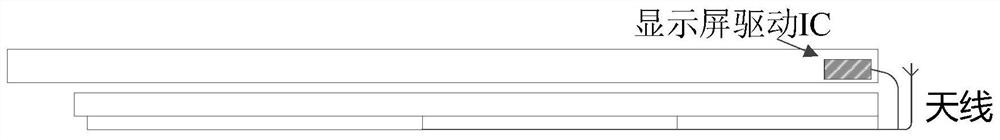

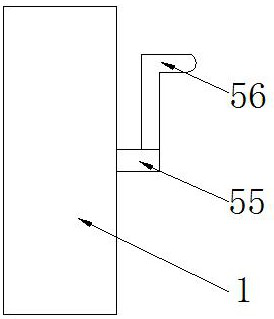

Mobile communication terminal with signal connector

InactiveCN1764204AShorten the connection distanceReduce noise disturbanceTelephone set constructionsFlexible/turnable line connectorsPrinted circuit boardEngineering

The invention discloses a mobile communication terminal with a signal connection device, which is characterized in that: a device capable of connecting signals between a printed circuit board mounted with multiple chips and a functional part such as a screen display device module is provided. In the flip-type mobile communication terminal of the signal connecting device, the above-mentioned signal connecting device includes: a hinge part connecting the body part of the above-mentioned flip-type mobile communication terminal with the flip part; A plurality of fixed terminals for transmitting the above-mentioned signals; a plurality of spring terminals that maintain elastic contact with each of the above-mentioned fixed terminals and perform relative movement with the above-mentioned fixed terminals. The use of the mobile communication terminal with the signal connection device of the present invention can make the internal space of the mobile communication terminal freely available, and can also greatly reduce the risk of physical damage caused by the opening and closing of the hinge part.

Owner:INSPUR LG DIGITAL MOBILE COMMUNICATIONS CO LTD

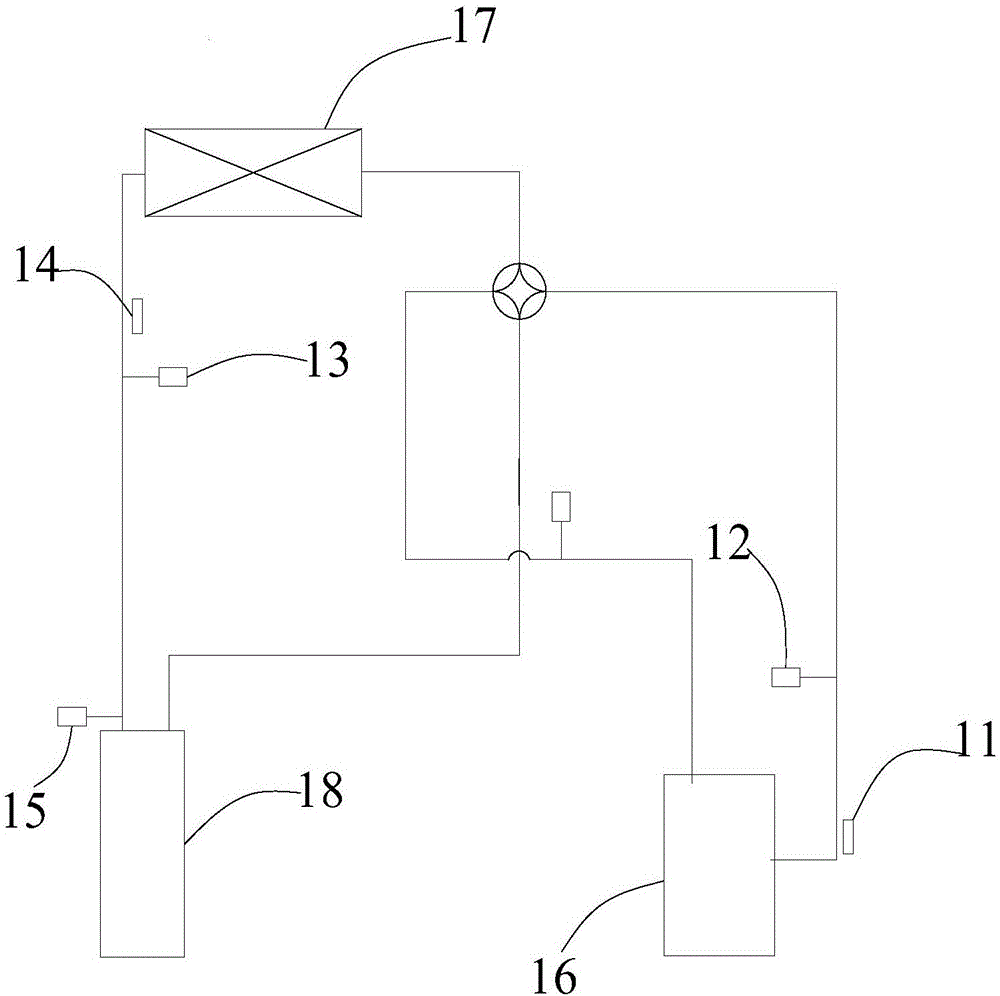

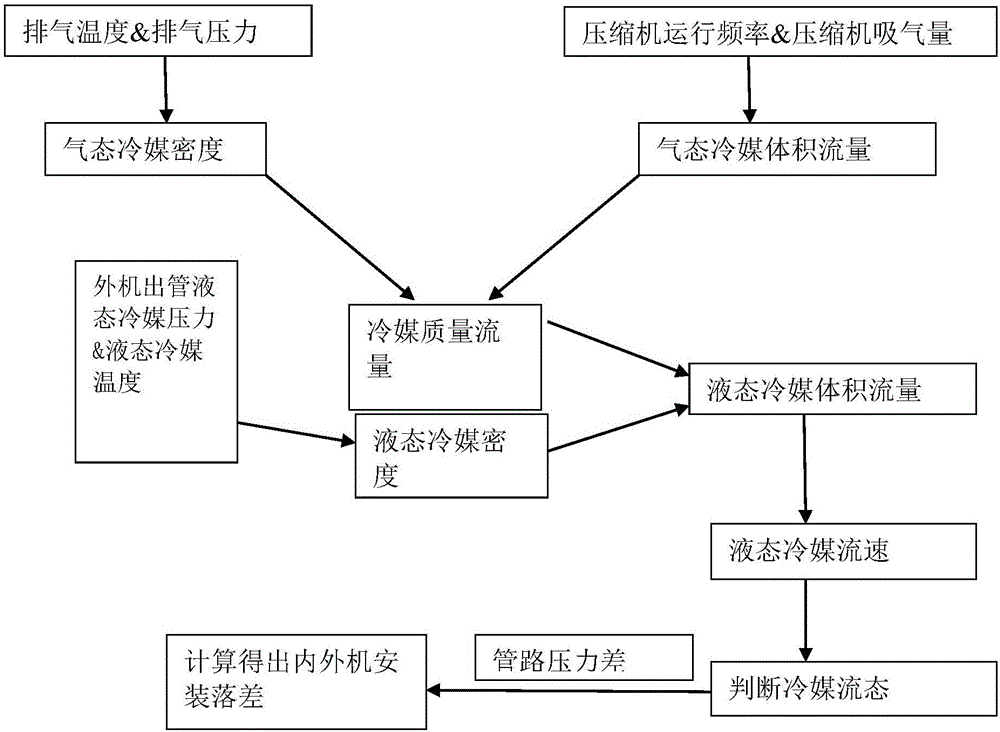

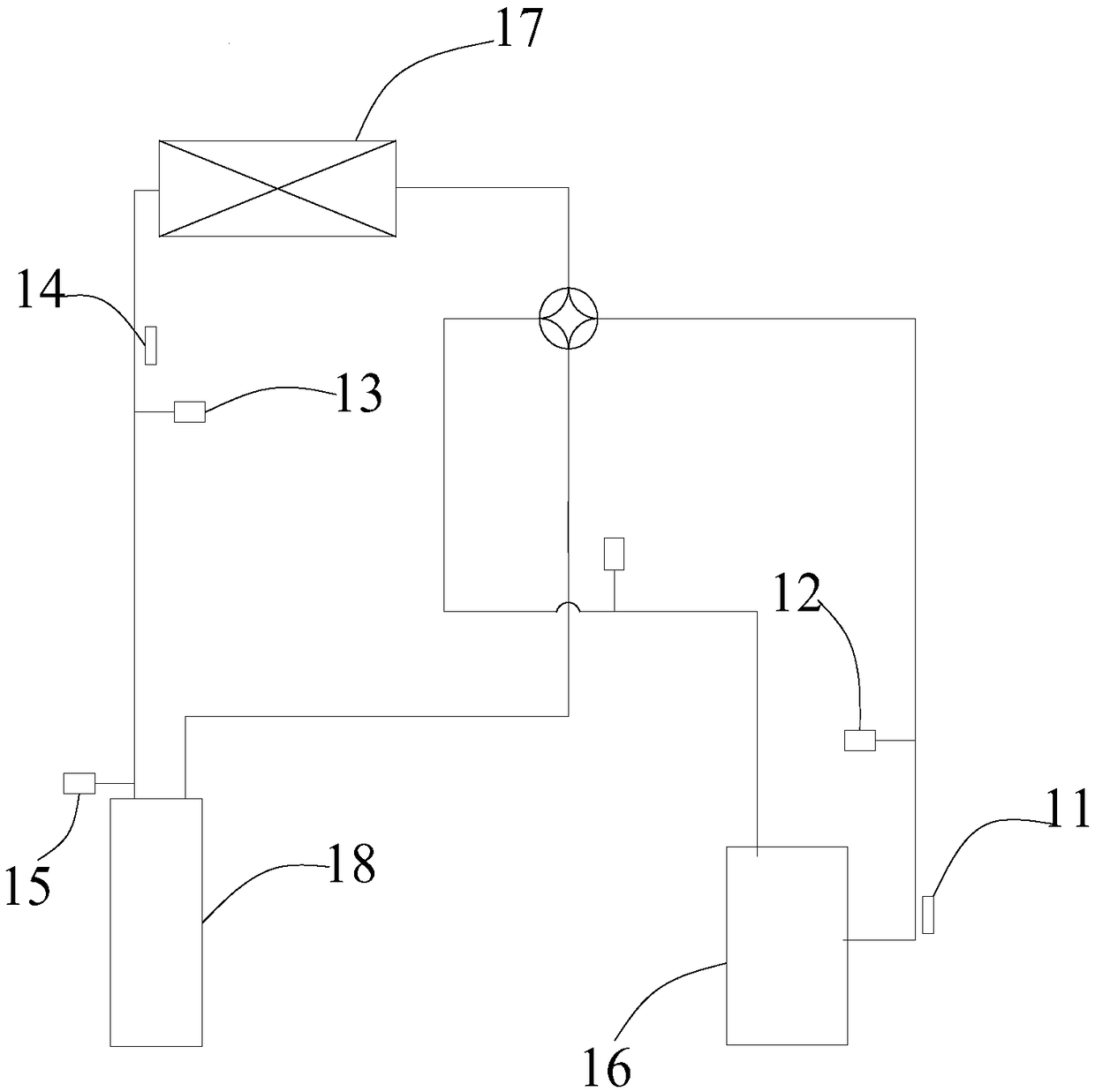

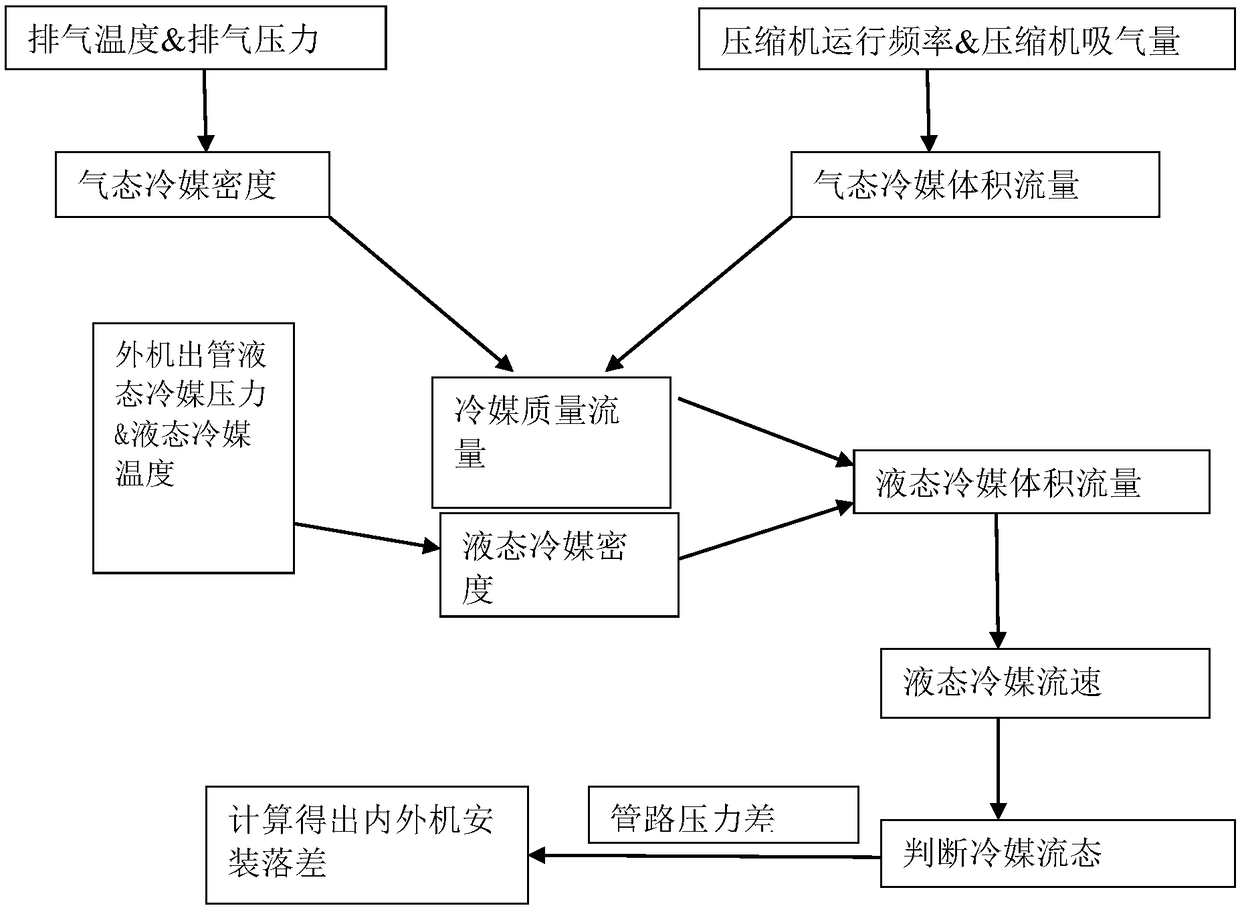

Detection device and method for detecting installation head and air-conditioning system control method

ActiveCN106352827AImplement automatic detectionGuaranteed reliable performanceMeasurement devicesDischarge pressureEngineering

The invention discloses a detection device and method for detecting installation head and an air-conditioning system control method. The detection device comprises an exhaust temperature sensor, an exhaust pressure sensor, a compressor detection system, an outlet pipe pressure sensor, an outlet pipe temperature sensor, an inlet pipe pressure sensor and a processor, wherein the exhaust temperature sensor is used for acquiring the exhaust temperature of a compressor, the exhaust pressure sensor is used for acquiring the exhaust pressure of the compressor, the compressor detection system is used for acquiring the running frequency and the suction intensity of the compressor, the outlet pipe pressure sensor is used for acquiring the outlet pipe liquid refrigerant pressure of an outdoor unit heat exchanger, the outlet pipe temperature sensor is used for acquiring the outlet pipe liquid refrigerant temperature of the outdoor unit heat exchanger, the inlet pipe pressure sensor is used for acquiring the inlet pipe refrigerant pressure of an indoor unit, and the processor is connected with the exhaust temperature sensor, the exhaust pressure sensor, the compressor detection system, the outlet pipe pressure sensor, the outlet pipe temperature sensor and the inlet pipe pressure sensor in a communicable manner. Therefore, the installation head between the indoor unit and an outdoor unit can be automatically calculated by the detection device for detecting the installation head.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Production method for metal coated cable

ActiveCN103198905AGuaranteed reliable performancePracticalityCable/conductor manufactureShielded cableButt joint

The invention relates to a production method for a metal coated cable. The production method comprises the following steps: a step of unreeling, namely unreeling a core cable wire and a metal band respectively, a step of coating, namely adopting a method of curling the metal band to be a tube and continuously and lengthways wrapping to enable the core cable wire to be continuously led out, wherein the metal band is continuously and curly wrapped outside the core cable wire, after the curly wrapping is finished, a metal tube is formed on the surface of the cable wire, and a lengthways butt joint is reserved, a step of continuously welding the lengthways joint on line, namely adopting a welding method to carry out continuous on-line lengthways joint welding on the lengthways butt joint, a step of stretching, namely carrying out hole shrinkage stretching on the welded metal coated cable to enable the diameter of the cable to reach a desired size and enable the outer metal tube to be closely attached to the inner cable, a step of washing, namely carrying out degreasing washing on the stretched metal coated cable, a step of on-line annealing, namely carrying out the annealing on the metal coated cable, and a step of compound winding rolling, namely carrying out compound winding rolling on the annealed metal coated cable. The production method is suitable for manufacturing a railway penetration ground wire or a shield cable.

Owner:江苏薪泽奇机械股份有限公司

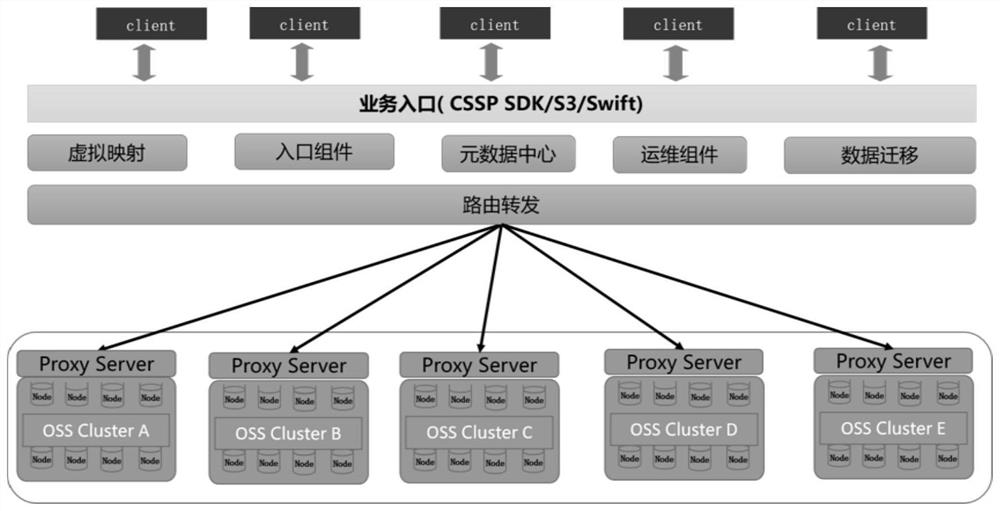

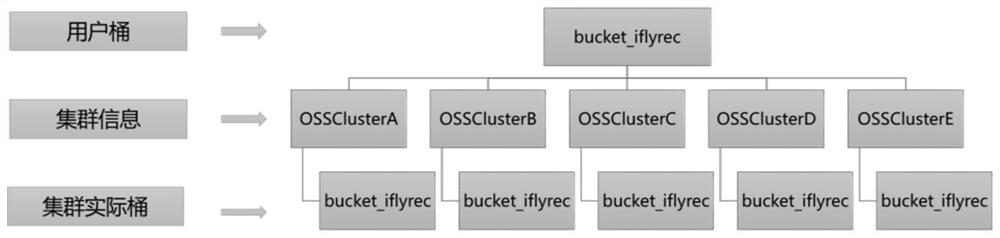

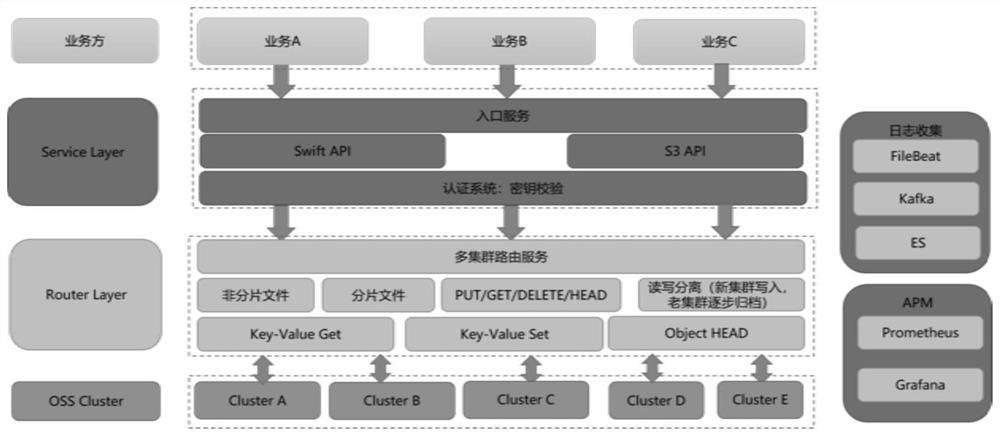

Capacity expansion method for gigabit-level object storage bucket

PendingCN112860186AGuaranteed reliable performanceCluster type requirements are lowInput/output to record carriersGigabitBottleneck

The invention discloses a capacity expansion method for a gigabit-level object storage bucket. The capacity expansion method comprises that: a unified management platform comprising a virtual mapping layer, a metadata center, an entry component and an operation and maintenance component is constructed; and the control planes and the data planes stored by the heterogeneous objects are managed in a unified mode through the unified management platform, and smooth switching in the expansion period is achieved. The capacity expansion method specifically comprises that: 1) the scale risk of a single cluster and a single bucket is avoided, and horizontal capacity expansion can be realized naturally; the service is not perceived during capacity expansion, and the hot switching configuration directly takes effect; 2) the performance bottleneck of a single cluster and a single bucket does not exist, and the performance reliability of the object storage service is ensured by accessing a plurality of heterogeneous object storage clusters and a virtual mapping method; and 3) the performance bottleneck of a single cluster and a single bucket does not exist, and the performance reliability of the object storage service is ensured by accessing a plurality of heterogeneous object storage clusters and a virtual mapping method.

Owner:UNIV OF SCI & TECH OF CHINA

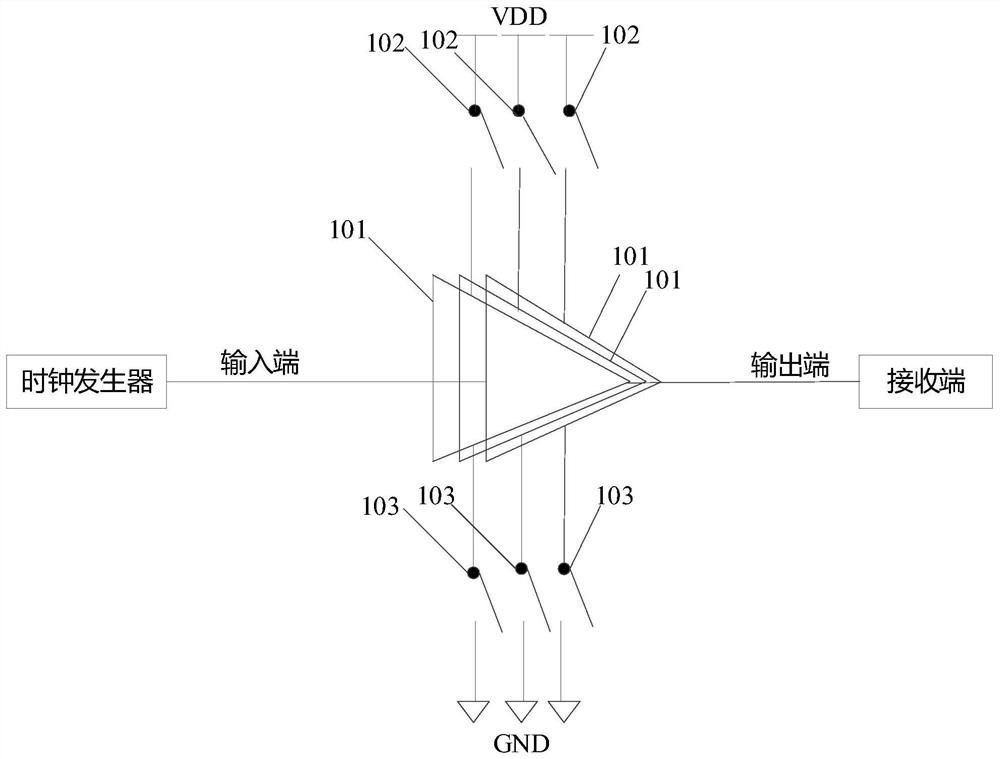

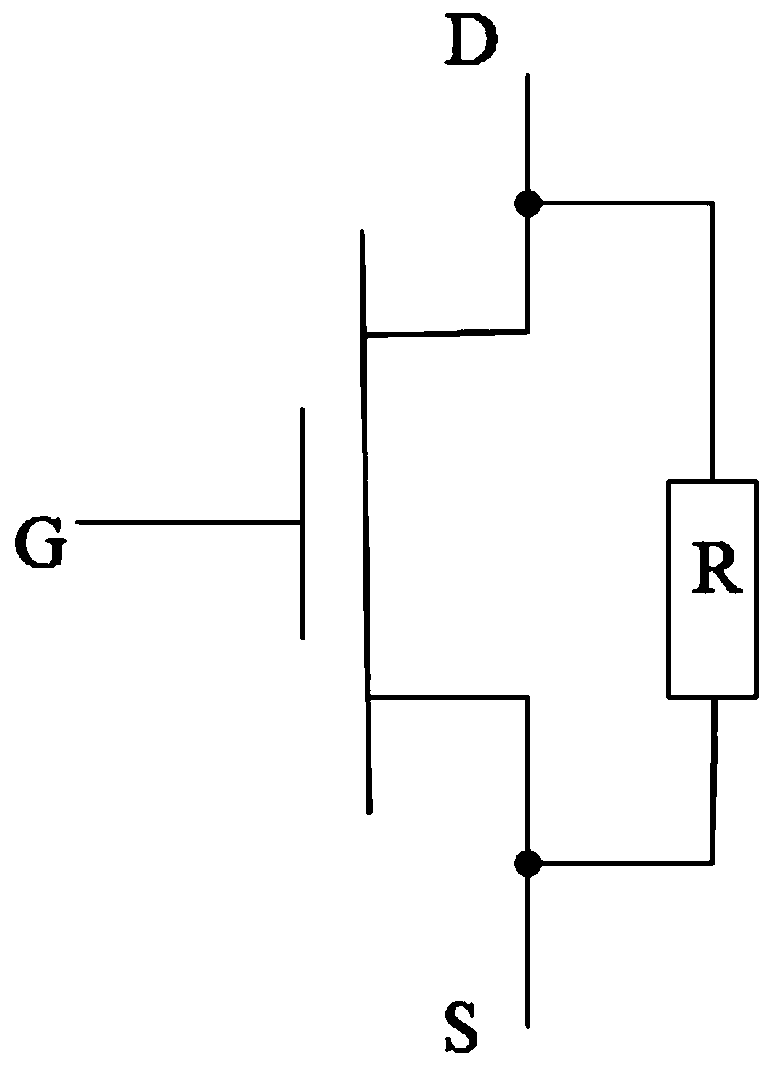

Buffer circuit, integrated circuit and electronic equipment

PendingCN112398467AFlexible adjustment of driving capacityGuaranteed reliable performanceReliability increase in field effect transistorsVoltage/current interference eliminationHemt circuitsComputer science

The invention discloses a buffer circuit, an integrated circuit and electronic equipment, the buffer circuit comprises M driving units, M first switches and M second switches, and M is a positive integer greater than 1; the first ends of the M driving units are respectively connected with a power supply through the M first switches and are respectively grounded through the M second switches, the second ends of the M driving units are connected with one another to be used as the input end of the buffer circuit, and the third ends of the M driving units are connected with one another to be usedas the output end of the buffer circuit; and the M first switches and the M second switches are used for controlling the working modes of the M driving units, and the M driving units are used for amplifying signals received by the input end of the buffer circuit so as to output driving signals with the driving capacity corresponding to the working modes at the output end of the buffer circuit, andthe working mode is used for representing the driving capability of the M driving units. According to the embodiment of the invention, the EMI performance of the buffer circuit can be optimized.

Owner:VIVO MOBILE COMM CO LTD

A single battery of a thermal battery for a launch vehicle

ActiveCN107732268BGuaranteed adsorption effectGuaranteed reliable performanceDeferred-action cellsProcess engineeringRocket

The invention discloses a battery cell of a thermal battery for a carrier rocket. The battery cell of the thermal battery for the carrier rocket comprises an isolating powder, a heating powder, a positive electrode powder and a negative electrode powder, wherein the isolating powder consists of LiF-LiCi-LiBr ternary all-lithium electrolyte molten salt and a molten salt adsorbent; the molten salt adsorbent accounts for 50-65% of the total mass of the isolating powder. A performance characteristic that the pulse voltage drop change rates of the thermal battery in three working time periods of 5-20s, 45-55s and 65-75s are lower than 2% is achieved, and the performance reliability of load equipment on the rocket is guaranteed. Raw materials and a component preparation technology of the batterycell of the thermal battery provided by the invention are the same as those of the conventional thermal battery, so that large-scale production can be carried out under the premise of not restructuring the conventional production line and the production process is high in universality; the cost pressure is low and the economic benefits are good while model development and production tasks of a new-generation solid carrier rocket are met.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Solar photovoltaic panel for efficient utilization of solar energy

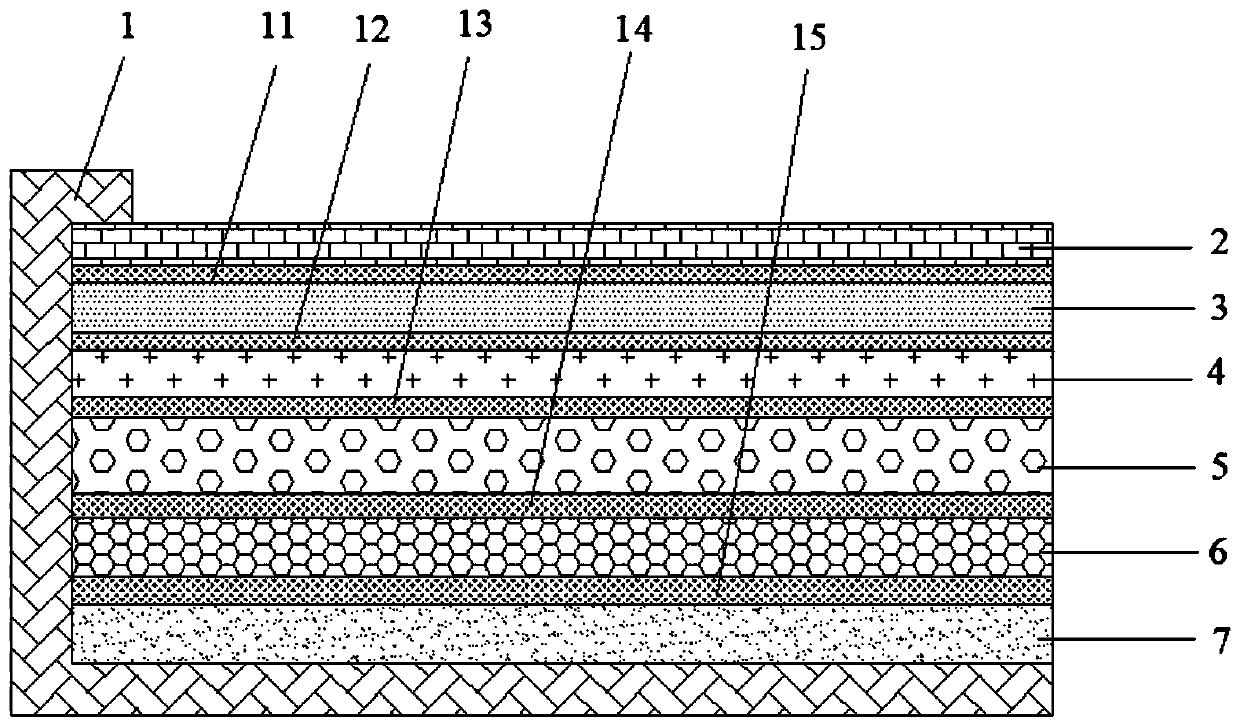

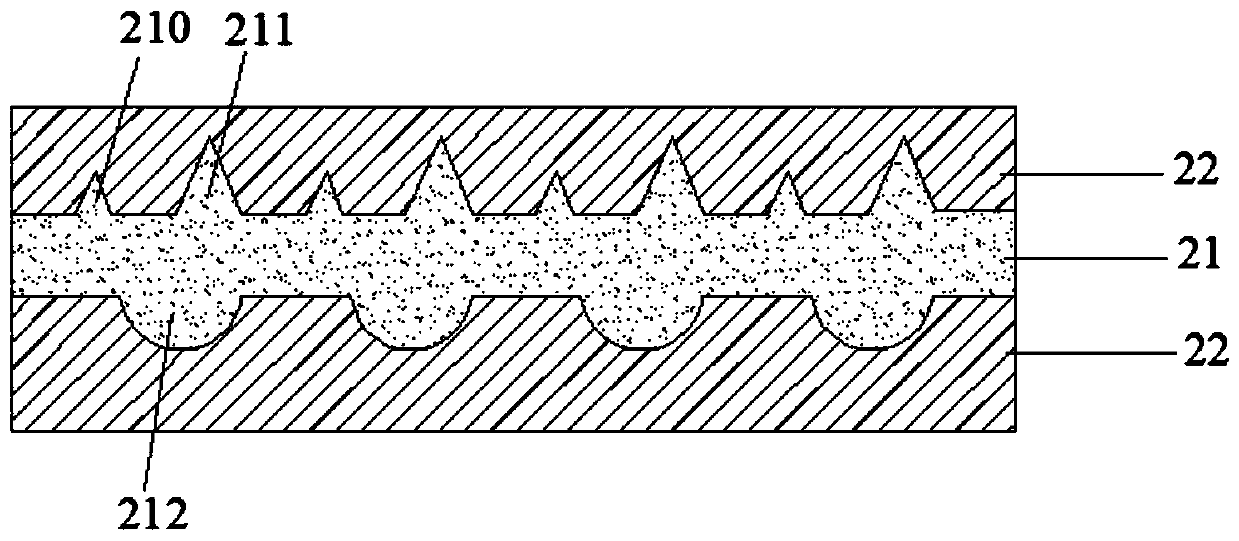

InactiveCN110224039AAvoid reflectionsIncrease profitPhotovoltaic energy generationSemiconductor devicesCells panelLight energy

The invention discloses a solar photovoltaic panel for efficient utilization of solar energy, which comprises a photovoltaic module and a frame arranged around the edge of the photovoltaic module. Thephotovoltaic module comprises a solar energy collection layer, a toughened glass layer, an anti-aging layer, a cell panel, a backplane layer and a heat dissipation layer which are laminated in turn.By setting the solar energy collection layer, the reflection of sunlight can be well avoided, and the utilization rate of sunlight can be improved. By setting the anti-aging layer, the radiation resistance and aging resistance of the solar photovoltaic panel can be improved. By setting the heat dissipation layer, the heat caused by a large amount of absorbed light energy is greatly evacuated, theperformance reliability of the solar photovoltaic panel is ensured, the degumming and other phenomena of the layers at high temperature are prevented, and the service life is increased.

Owner:扬州市李伟照明电器有限公司

A kind of nanometer anti-corrosion coating for the metal surface under acid-related environment and preparation method thereof

ActiveCN109370364BImprove acid resistanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsNano al2o3Firming agent

The invention relates to a metal surface anticorrosion nano-coating for acid environments and a preparation method of the nano-coating, and belongs to the technical field of anticorrosion coatings. The anticorrosion nano-coating comprises a main agent, a curing agent and a diluent and is characterized in that the weight ratio of the main agent to the curing agent is 100:(15-50), the main agent comprises modified phenolic resin, modified epoxy resin with an IPN (interpenetrating polymer network) structure, nano-titanium dioxide, carbon black, barium sulfate, talcum powder, flaky mica powder, nano-aluminum oxide, nano-silicon carbide, polyaniline, rare earth materials, modified zinc phosphate, organic siloxane surface modification agents, wetting dispersing agents, defoaming agents, anti-settling agents, anti-sagging agents, dimethylbenzene and butyl alcohol, the curing agent comprises modified amine and dimethylbenzene, and the diluent comprises dimethylbenzene and butyl alcohol. The anticorrosion nano-coating has excellent acid resistance, corrosion resistance and adhesive force, and the preparation method of the nano-coating is simple, easy to operate, low in device requirement and suitable for industrial production.

Owner:兰伟

aoc optical module and its charged aging method

ActiveCN113031168BSatisfy the feature of not being pulled outAvoid breakingCoupling light guidesOptical ModuleTransceiver

The present invention provides an AOC optical module and a charging aging method thereof. The AOC optical module includes an AOC optical cable assembly and an AOC optical transceiver module that are plugged and fixed to each other. The AOC optical cable assembly includes a housing and an optical cable assembly located in the housing. , the AOC optical transceiver module includes a base assembly, an upper cover assembly and an optical transceiver assembly, the optical transceiver assembly is located in the base assembly, the upper cover assembly includes a first upper cover and a second upper cover, and the first An upper cover and the second upper cover jointly cover the base assembly, the front end of the base assembly has a docking cavity for the housing of the AOC optical cable assembly to be plugged in, and the first upper cover is provided with It is above the docking cavity and locked and fixed with the housing. The AOC optical module of the present invention is highly efficient and high-quality, and does not need to disassemble the main part of the optical module, avoiding the risk of fiber breakage, device damage, and component drop inside the optical module, and ensuring the performance and reliability of the module after reinstalling the case.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH CO LTD

Electronic device

PendingCN114173500AAvoid Metal FatigueAvoid insufficient reboundElectronic time-piece structural detailsCasings/cabinets/drawers detailsElectrical connectionElectronic equipment

The invention discloses electronic equipment. The electronic equipment comprises a frame body; the circuit board is arranged on the frame body; the key is movably arranged on the frame body, a first conductive part and a second conductive part are arranged on the key, and the first conductive part and the second conductive part are insulated from each other; one end of the first vibrating needle is electrically connected with the first area of the circuit board; one end of the second vibrating needle is connected with the second area of the circuit board; when the key is in a first state, the other end of the first vibrating needle is electrically connected with the first conductive part, and the other end of the second vibrating needle is electrically connected with the second conductive part; and when the key is in the second state, the other end of the first vibrating needle and the other end of the second vibrating needle are electrically connected with the second conductive part, and when the key is in the first state and the second state, the levels of the second vibrating needle are different. The use state of the key can be judged through the level of the second elastic needle, different responses can be made according to the state of the key, metal fatigue of the metal elastic sheet can be avoided, and the performance of the ECG is guaranteed.

Owner:VIVO MOBILE COMM CO LTD

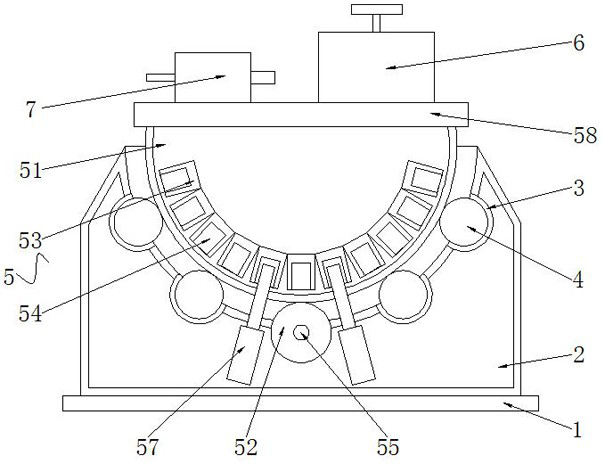

Auxiliary device for vascular disease treatment

The invention discloses an auxiliary device for vascular disease treatment and relates to the technical field of vascular diseases. The auxiliary device comprises a horizontal supporting plate, wherein a base hard box is fixedly connected to the top of the horizontal supporting plate, auxiliary grooves are formed in the surface of the base hard box, supporting wheels are rotatably connected to theinner surfaces of the auxiliary grooves, a bracket supporting device is movably connected to the surfaces of the supporting wheels, a limb fixing device is fixedly connected to the right side of thetop of the bracket supporting device, and the bracket supporting device comprises an arc-shaped plate and a driving friction wheel. According to the auxiliary device for vascular disease treatment, through the arrangement of the bracket supporting device, a worker can adjust the overall treatment angle of the device only by rotating a manual handle, meanwhile, the device can be clamped and fixed in cooperation with extension of a positioning telescopic rod, the overall stability of the device is high, meanwhile, through supporting of the supporting wheels in the auxiliary grooves, the reliability of the device during operation is guaranteed, related structures are simple, and the device is easy to operate by the worker.

Owner:李东

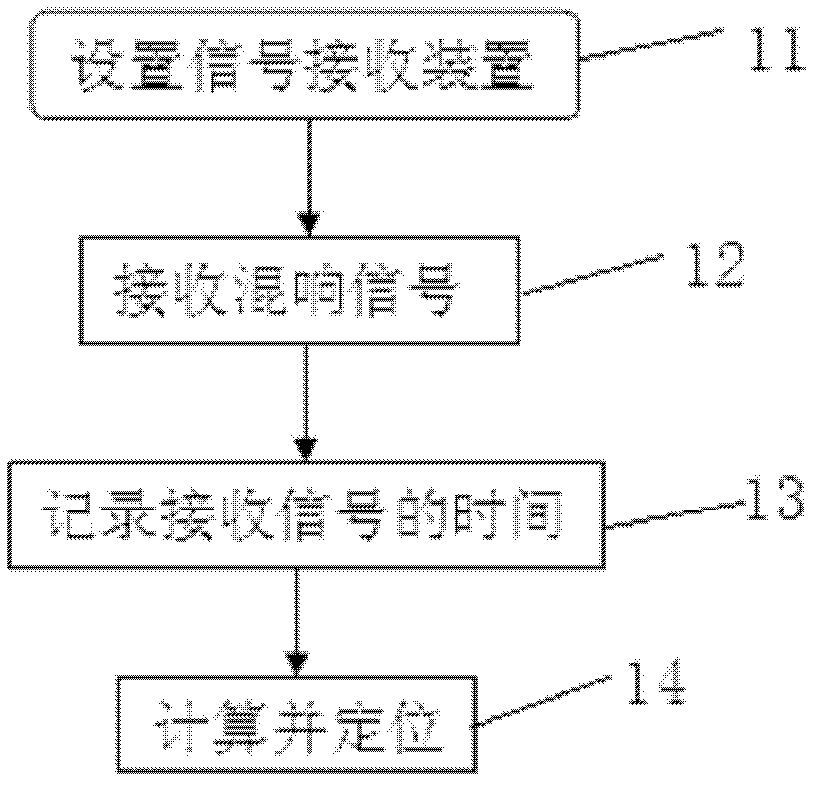

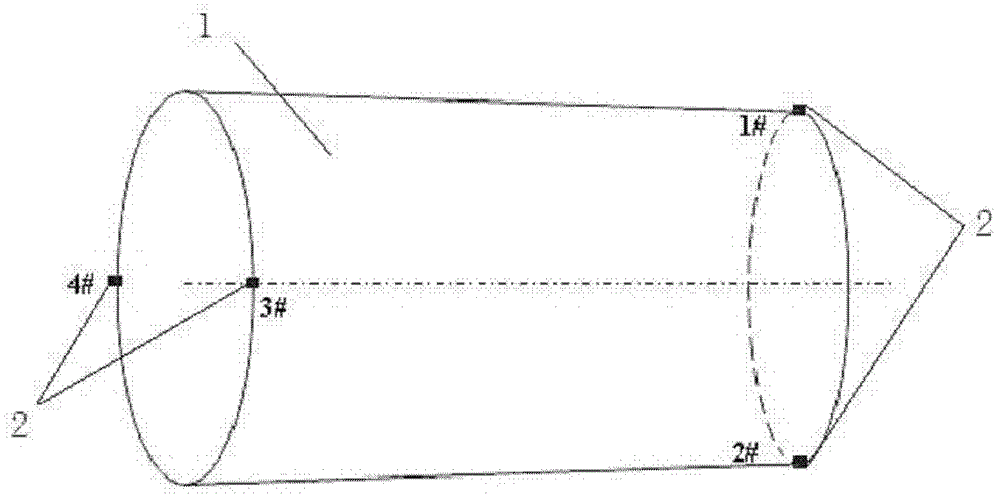

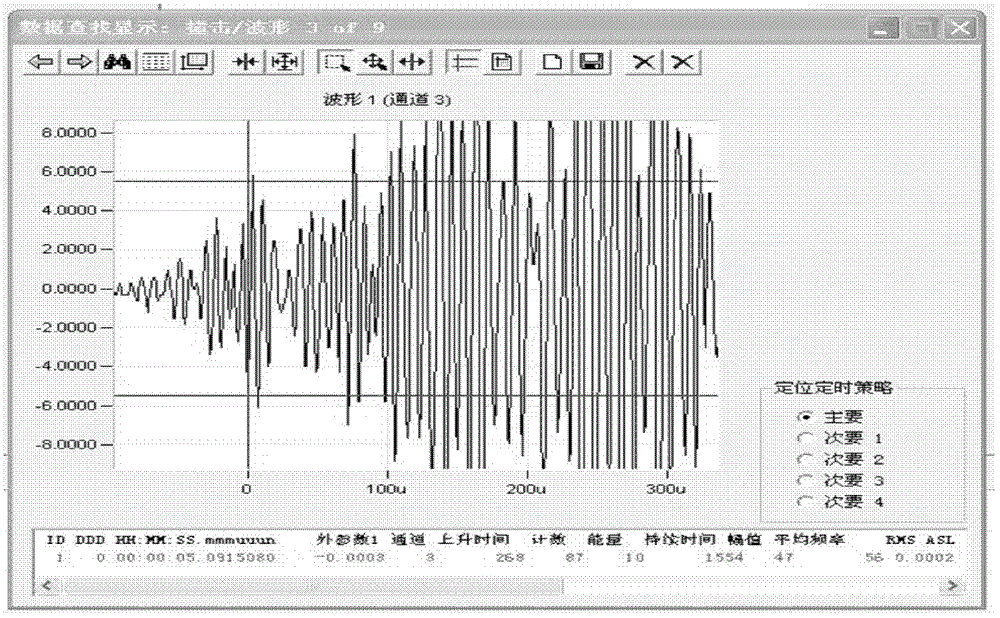

Redundancy time difference positioning method and redundancy time difference positioning system

ActiveCN102590788BRealize three-dimensional positioningEasy to removePosition fixationAlgorithmTransducer

The invention discloses a redundancy time difference positioning method and a redundancy time difference positioning system. Piezoelectric transducers are fixedly arranged on a truncated-cone-shaped cabin section in advance for receiving redundancy signals, and a signal processing device determines signal source positions of the redundancy signals in the time difference positioning method. The redundancy time difference positioning method and the redundancy time difference positioning system can help detectors to determine specific positions of redundancy in the cabin section, facilitate removing of moving redundancy, and can help the detectors to distinguish signals of some moving parts in the cabin section and reduce analyzing time of moving redundancy signals.

Owner:CASIC DEFENSE TECH RES & TEST CENT

Non-contact nuclear-grade limit switch

ActiveCN114220705ALittle need for deformationSolution to short lifeMagnetic movement switchesStructural engineeringSwitching frequency

The invention discloses a non-contact nuclear-grade limit switch which comprises a reed bouncing module, a socket arranged at the top of the reed bouncing module and a magnetic driving module arranged at the bottom of the reed bouncing module. The whole non-contact nuclear-grade limit switch is triggered through in and out of a magnet, manual triggering is not needed, the false triggering or non-triggering phenomenon is avoided, the requirement of the reed bouncing module for the deformation of the reed is very small, the service life of the elastic element can be very long under the condition of very small deformation, and the limit switch is of a pure mechanical structure and is convenient to use. The switching frequency can reach more than ten millions, and the linear bearing of the magnet driving module is arranged, so that the low-damping characteristic of axial movement is ensured, and the performance reliability of the product is effectively ensured.

Owner:CHENGDU KAITIAN ELECTRONICS

Simulation method and simulation device

ActiveCN102958089BReflect time-varying characteristicsImprove efficiencyTransmission monitoringChannel estimationTransfer modeParallel computing

Owner:DATANG MOBILE COMM EQUIP CO LTD

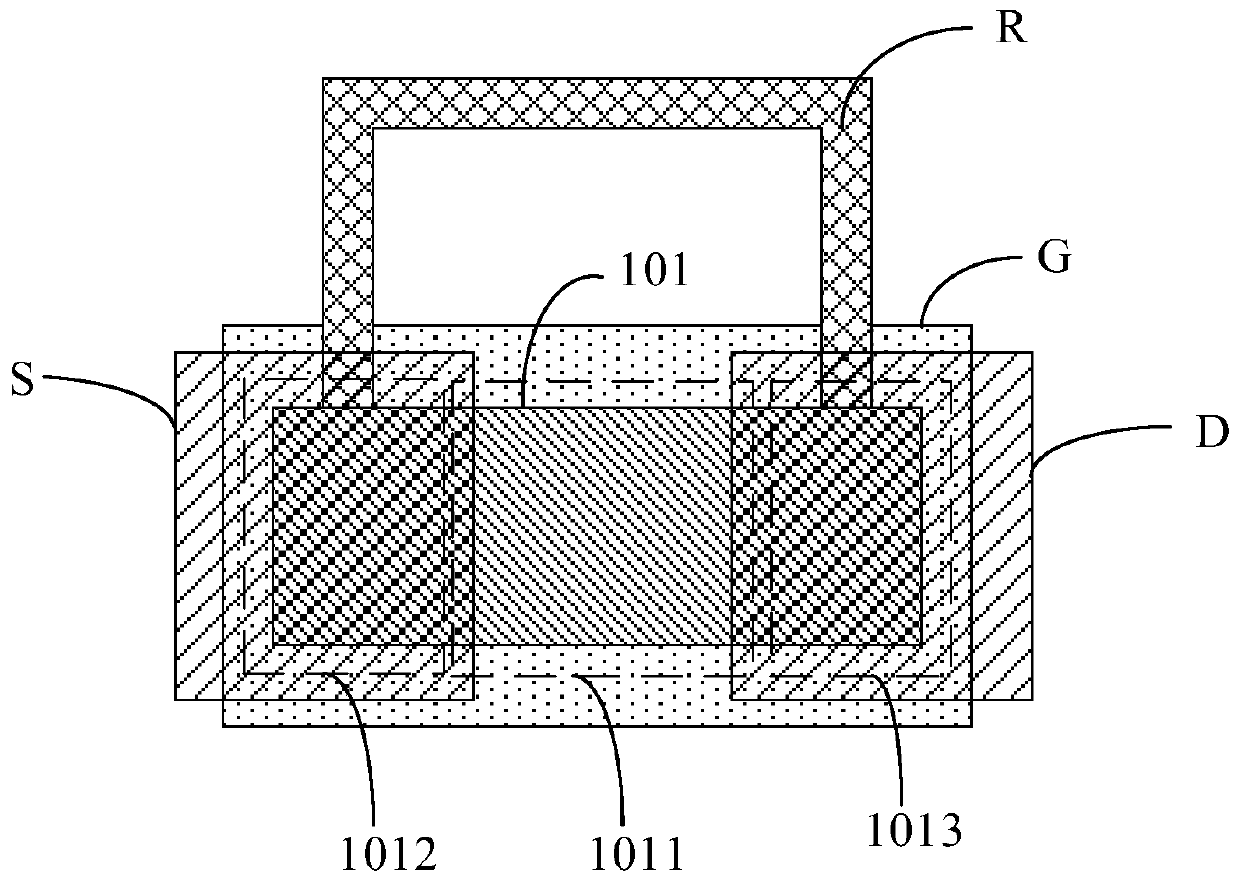

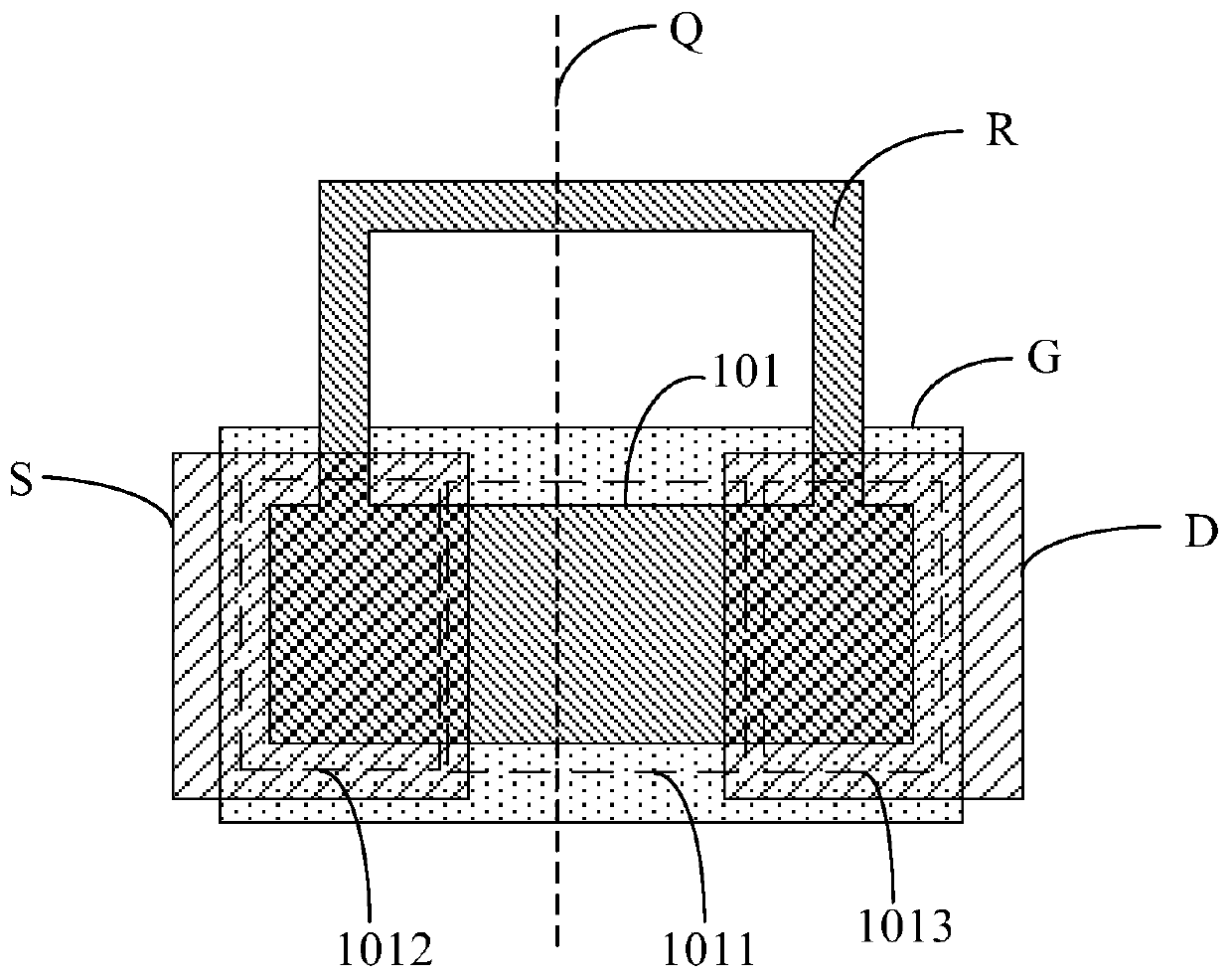

Thin film transistor and its manufacturing method and array substrate

ActiveCN108172631BIncrease off-state currentAvoid afterimageTransistorSolid-state devicesOxide thin-film transistorHemt circuits

The invention discloses a thin film transistor, a manufacturing method thereof and an array substrate. The thin film transistor comprises a gate, a source, a drain, and a semiconductor layer; the semiconductor layer includes a channel region, a source region, and a drain region; and the source region and the drain region are respectively located at two sides of the channel region; and the semiconductor layer is made of an oxide semiconductor material. The thin film transistor further comprises a resistor element; one end of the resistor element is electrically connected with the source region,and the other end of the resistor element is electrically connected with the drain region; and the resistor element is used for increasing the off-state current of the thin film transistor. Accordingto the thin film transistor of the invention, the resistor element is connected in parallel between the source and the drain, and therefore, the off-state current of the oxide thin film transistor can be appropriately increased, and the problem of ghosts of pixels during the off state of a thin film transistor in a pixel driving circuit can be solved, and the timely release of static electricityin an static electricity release circuit can be ensured.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Detection device and method for detecting installation drop, and air-conditioning system control method

Owner:GREE ELECTRIC APPLIANCES INC

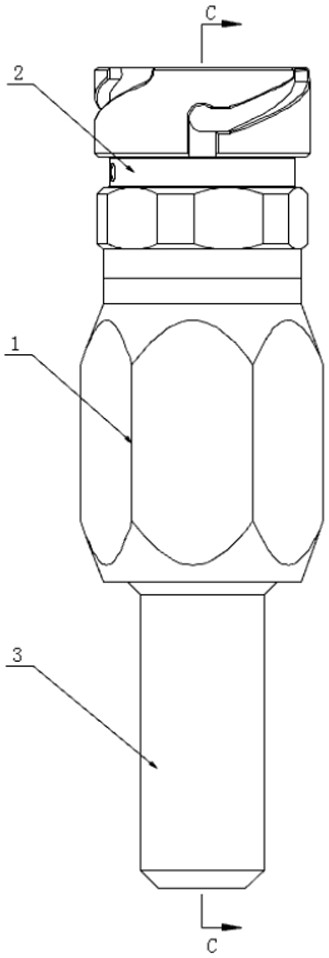

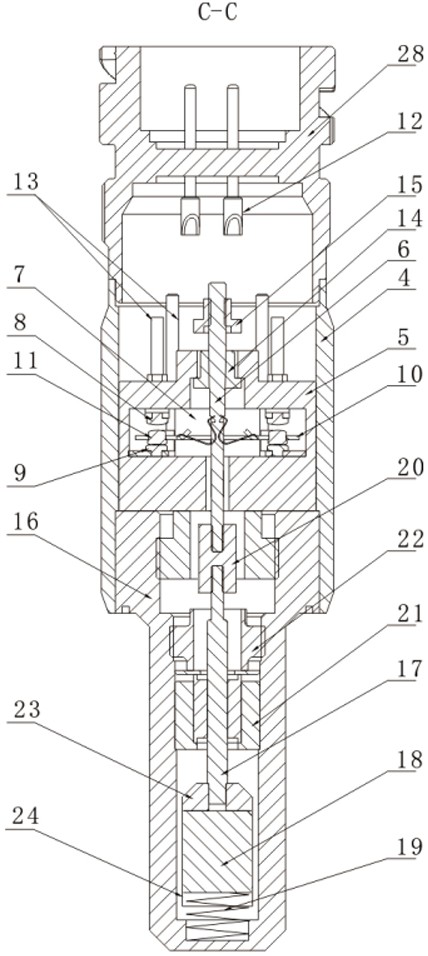

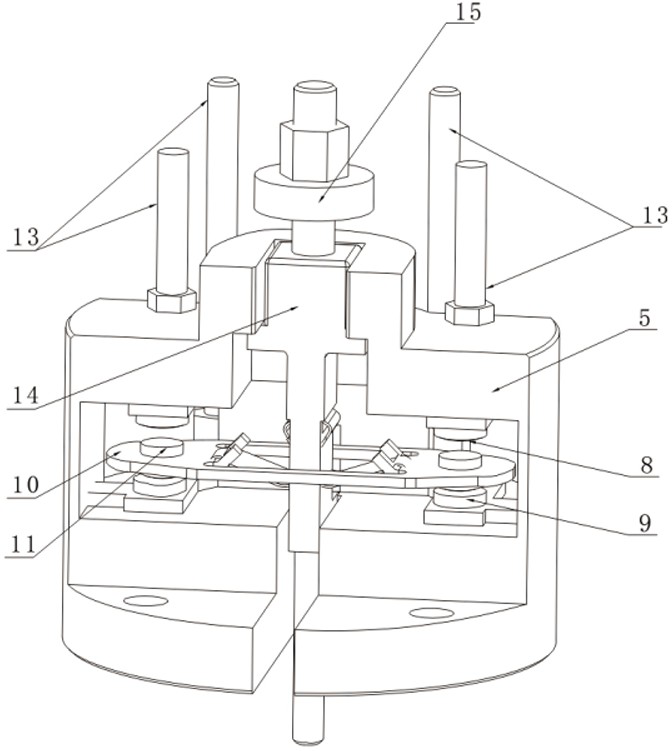

A handwheel-free central screw type electrical connector plug

ActiveCN105048197BReduce structural designSmall footprintCouplings bases/casesEngineeringElectrical connector

The invention relates to a central screw-type electric connector plug without a hand wheel. The central screw-type electric connector plug comprises a top cover, a sealing gasket, a locking device, a plug shell and a sealing ring, wherein the locking device also comprises a locking nut, a gasket, a first O-shaped ring, a locking screw rod, a jacket, a bolt, a locking cover and a second O-shaped ring; the top cover covers the plug shell; the sealing gasket is arranged on the upper end surface of the plug shell and arranged between the top cover and the plug shell; a wire outlet of the plug shell is arranged at one side of the plug shell; the sealing ring is arranged on the inner surface of the wire outlet of the plug shell; a boss is formed on the lower surface of the top cover and internally provided with a stepped through-hole structure; the locking nut is arranged in the boss; the gasket is arranged between the locking nut and the boss; one end of the locking screw rod is connected with the locking nut via the bolt; the first O-shaped ring is arranged in a sealing groove of the boss and is pressed with the locking screw rod; the locking cover is arranged at the top of the boss of the top cover via a thread; the second O-shaped ring is arranged between the locking cover and the top cover; and the jacket coats the outer surface of the locking screw rod.

Owner:杭州航天电子技术有限公司

Display panel, manufacturing method thereof, and display device

ActiveCN108321304BGuaranteed service lifeGuaranteed reliable performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMechanical engineering

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel includes: an array layer; a light-emitting device layer located on the array layer; a package structure located on the side of the light-emitting device layer away from the array layer, and the package structure includes a metal oxide layer; an adhesive layer located on the side of the package structure away from the light-emitting device layer ; Wherein, the orthographic projection of the packaging structure on the array layer is located within the orthographic projection of the adhesive layer on the array layer, and the orthographic projection of the adhesive layer on the array layer is larger than the orthographic projection of the packaging structure on the array layer. The bonded edge of the adhesive layer is not in contact with the metal oxide layer produced by the atomic layer deposition process, which avoids warping or even peeling off at this position due to poor bonding performance, and ensures the performance reliability of the display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com