Automobile gear signal structural member and electronic gear shifter

A technology of electronic shifter and signal structure, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of affecting the driving comfort of the vehicle, structural reliability failure, and false triggering of shift signals and other problems, to achieve the effect of simple and reliable design, maintaining stability and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

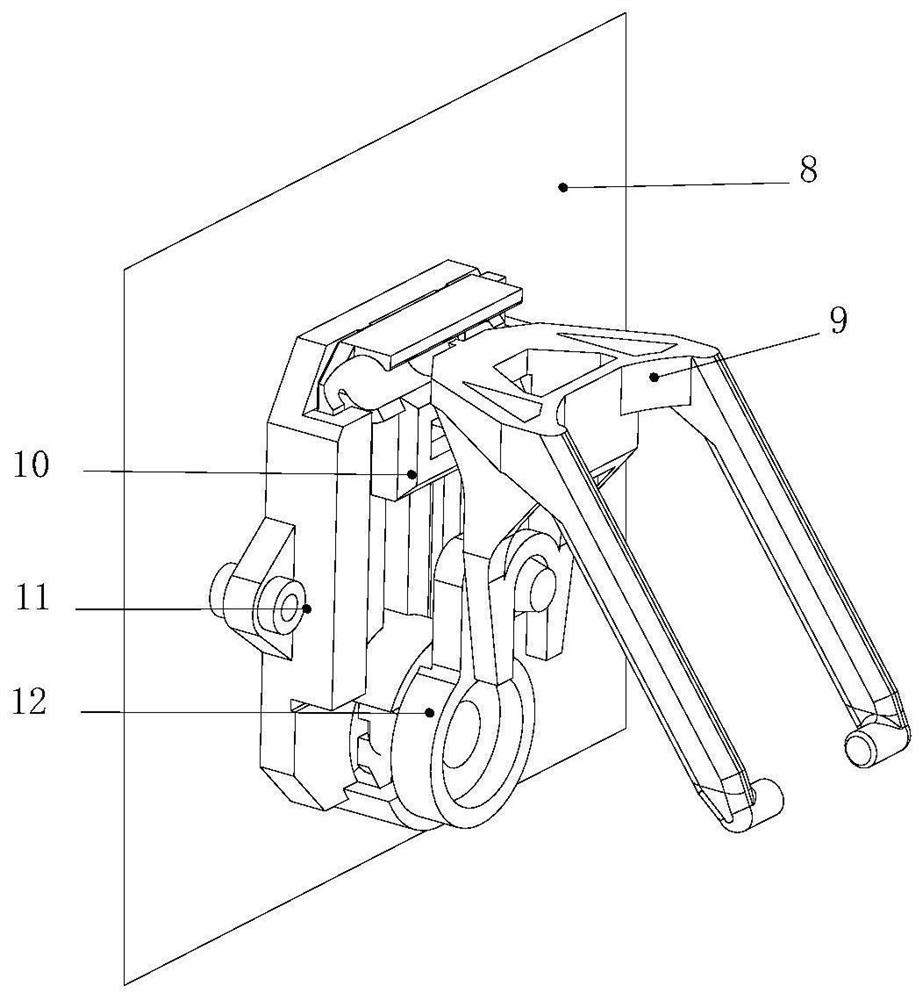

[0034] refer to figure 1 , the present embodiment provides an automobile gear position signal structure, the gear position signal structure comprises a circuit board 8 , a rotating bracket 9 , a slider 10 , a sliding magnet, a fixed bracket 11 and a rotating magnet 12 .

[0035] The circuit board 8 is provided with a rotating Hall sensor and a switch Hall sensor. The rotating Hall sensor cooperates with the rotating magnet 12. When the rotating magnet 12 rotates, the rotating Hall sensor can sense the magnetic field deflection, thereby outputting a gear signal . The switch hall sensor is used to detect the position of the sliding magnet, thereby controlling the circuit board 8 to remain on the circuit of the automatic gear.

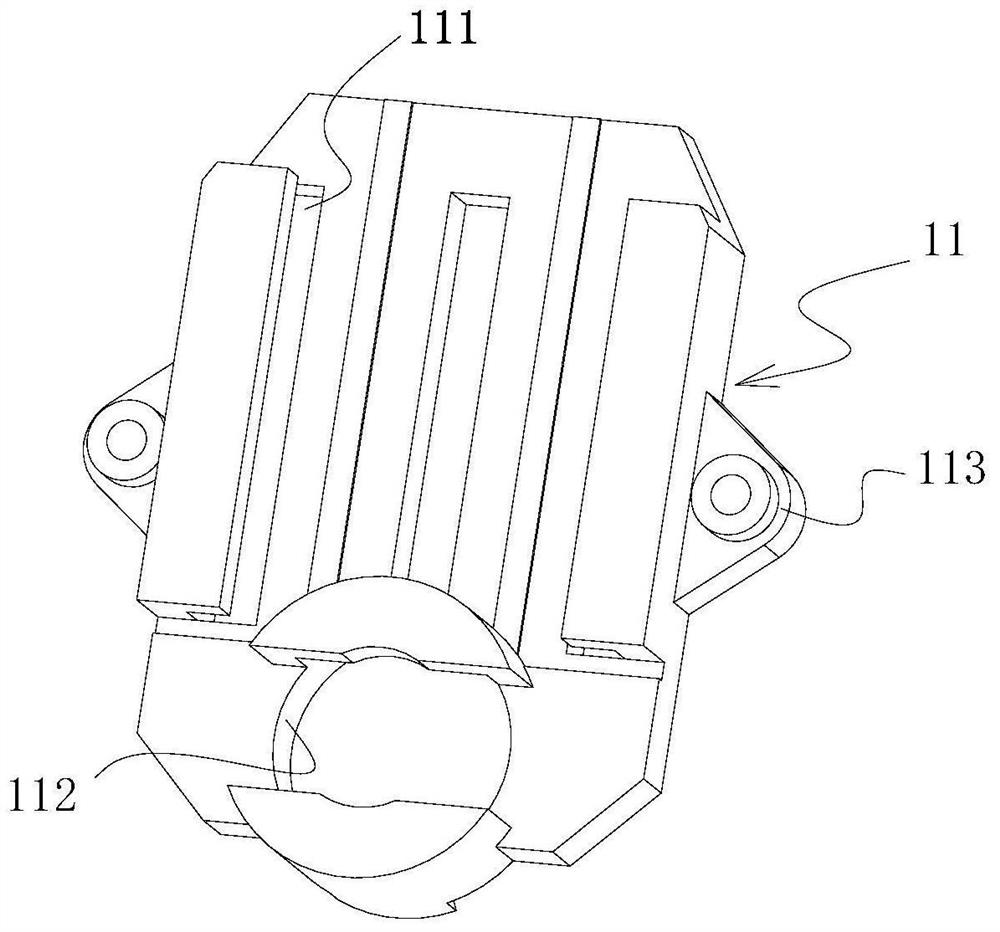

[0036] refer to image 3 and figure 1 , Both sides of the fixing bracket 11 are provided with lugs 113, and the lugs 113 are provided with threaded holes. The fixing bracket 11 is installed on the outer surface of the circuit board 8 by a self-tapping...

Embodiment 2

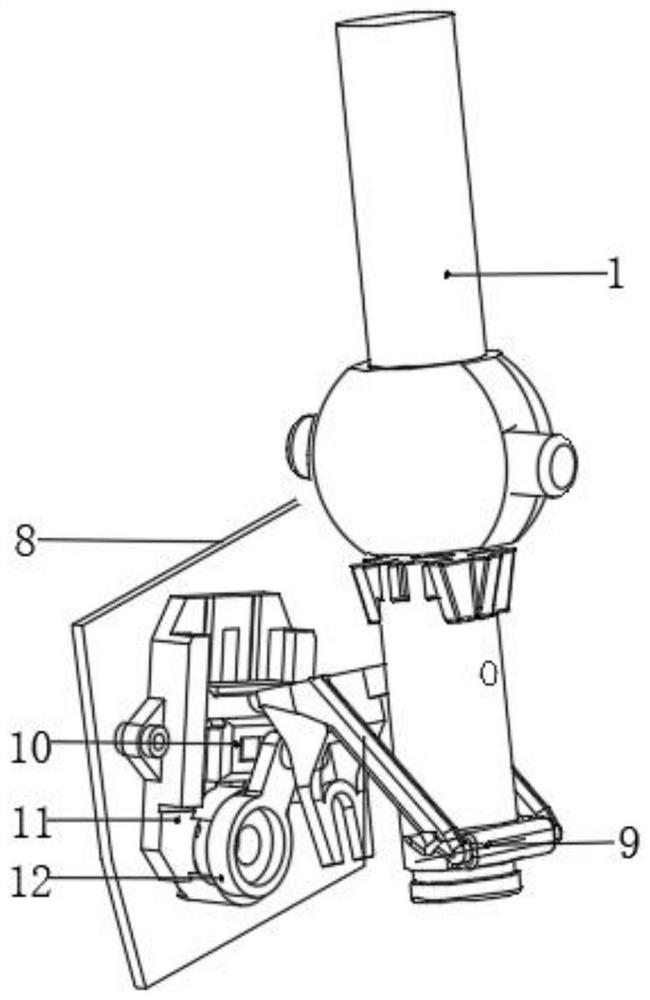

[0044] refer to Figure 7 and Figure 8 , the present embodiment provides an automotive electronic shifter, including a housing assembly, a shift lever assembly, toothed grooves, and a shift signal structural member. The structure of the shift signal structure is the same as that of Embodiment 1, and its structure will not be repeated.

[0045] The shell assembly includes an upper shell 3 and a lower shell 6 . The top of the upper housing 3 is provided with an upper opening, the inner side wall of the upper opening protrudes axially from the top surface of the housing to form a ring-shaped protrusion, and the ring-shaped protrusion is provided with two bayonet sockets, and the side wall of the housing There is a positioning slot. The bottom of the upper casing 3 is provided with screw holes. The bottom of the lower casing 6 is provided with a positioning column, the left inner wall of the lower casing 6 is provided with a positioning hole, and the front and rear inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com