Rivet sleeve for titanium self-plugging rivet and preparation method of rivet sleeve

A technology of blind rivets and rivet sleeves, applied in rivets and other directions, can solve the problems of high cost and achieve the effect of simple method, good combination and accurate plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

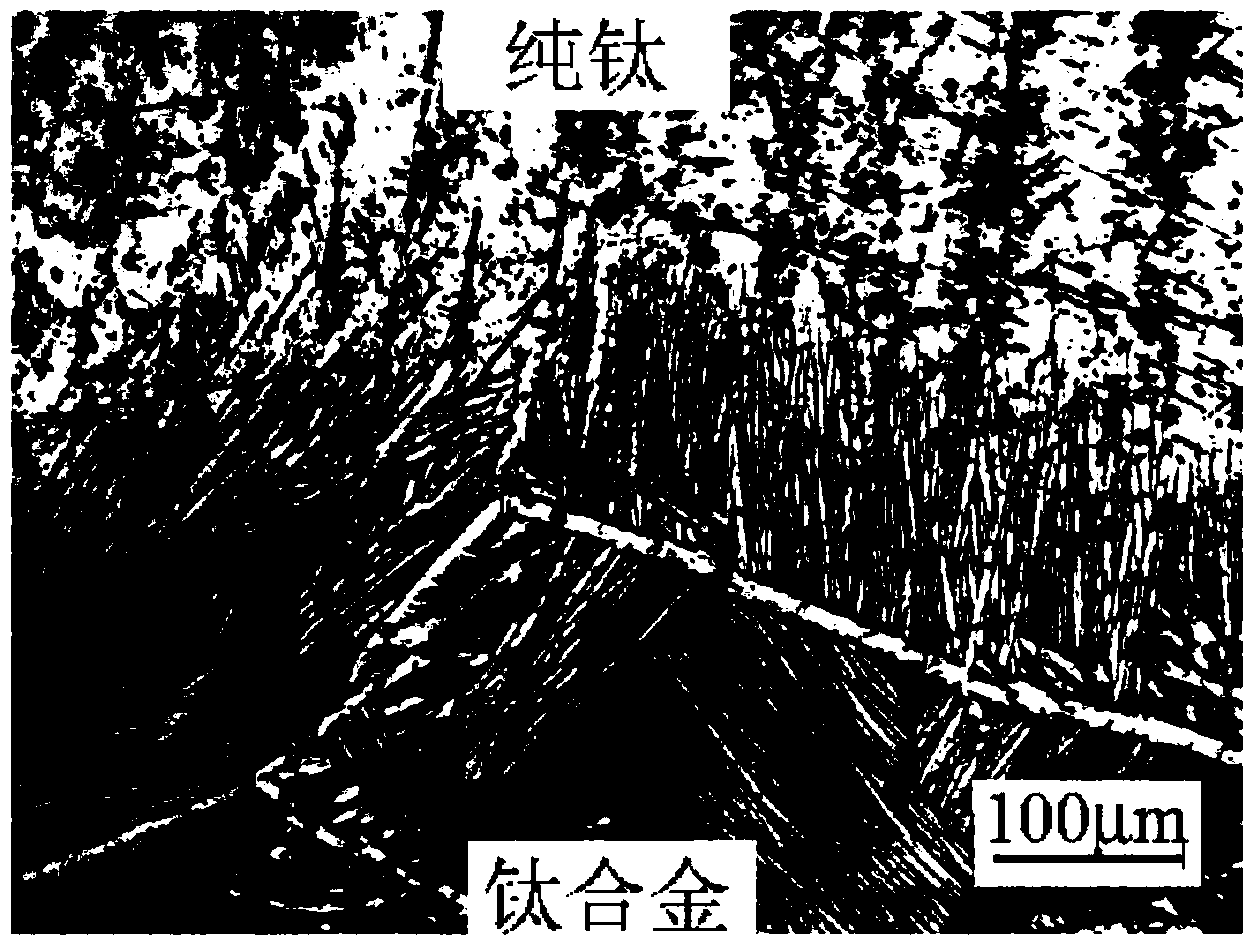

[0026] Specific Embodiment 1: In this embodiment, the titanium blind rivet sleeve for aerospace is composed of a plastic deformation part and a bearing part; the bearing part of the titanium blind rivet sleeve for aerospace is made of high-strength titanium alloy, and the plastic deformation part It is made of industrial pure titanium with alloy grades TA1~TA4 or titanium alloy with alloy grades TA5~TA10.

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-strength titanium alloy is a high-strength duplex titanium alloy with an alloy grade of TC3-TC23, a β-type titanium alloy with an alloy grade of TB2-TB10 or The alloy grade is near α-type titanium alloy of TA11~TA26. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: the load-bearing parts of the titanium blind rivet sleeves for aerospace are discontinuously distributed along the axial direction. Others are the same as the first or second embodiment.

[0029] The plastic deformation part of the titanium blind rivet sleeve for aerospace can be designed between two load-bearing parts; N plastic deformation parts and N+1 load-bearing parts can also be designed according to special needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com