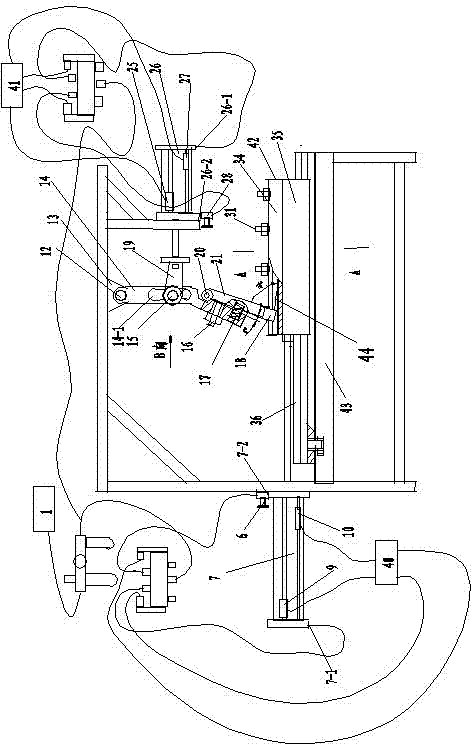

Pneumatic rubber scraper and method for producing automotive coating rubber performance test board

A test board and pneumatic scraping technology, applied in the preparation of test samples, devices for coating liquid on the surface, coating, etc., can solve the problems of failure to meet the requirements of use, irregularities, and the inability to guarantee the actual correctness of test data, etc. problems, to achieve the effect of ensuring practical reliability, avoiding losses, and ensuring standardization and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

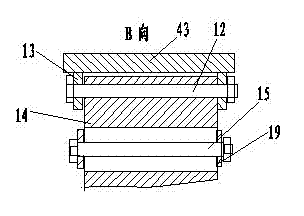

Embodiment 1

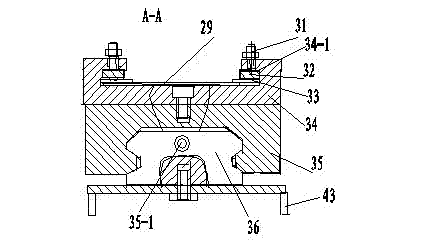

[0043] Put the test plate 29 coated with electrophoretic paint (the size of the test plate 29 is: 0.8mm thick, 75mm wide, and 150mm long) on the seat surface of the test plate seat 34, and use two feeler gauges with a thickness of 1.5mm, a width of 14mm, and a length of 100mm. The template 33 is respectively placed on the two sides of the test board seat 34 in the groove 34-1 symmetrically provided with on the test board seat 34, and a compression block 32 is placed on each template 33, and several compression bolts 31 The test board 29 is fixed on the seat surface of the test board base 34 through the pressing block 32 and the template 33 in the screw holes correspondingly provided on the test board base 34 by screwing.

[0044] Apply one of the skirt glues in the coating glue 44 evenly on the test plate 29, but the coating must be higher than the template 33. After stopping for 10 minutes, turn on the air source 1 to supply air, and the air source 1 is pressure-regulated an...

Embodiment 2

[0051] Put the test plate 29 coated with anti-sticking silicon (the size of the test plate 29 is: 0.8 mm thick, 75 mm wide, and 150 mm long) on the seat surface of the test plate seat 34, and use a feeler gauge to superimpose a thickness of 3.5 mm, a width of 14 mm, and a length of 150 mm. Two templates 33 of 100 mm are respectively placed on the two sides of the test board seat 34 in the groove 34-1 symmetrically provided with on the test board seat 34, and a pressing block 32 is placed on each template 33, several The compression bolts 31 are screwed into the screw holes correspondingly provided on the test board base 34 to fix the test board 29 on the seat surface of the test board base 34 through the compression block 32 and the template 33 .

[0052] Apply one of the welding sealants in the coating glue 44 evenly on the test board 29, but the coating must be higher than the template 33. After stopping for 10 minutes, turn on the air source 1 to supply air, and the air so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com