Locking device with detection function

A locking and functional technology, applied in the direction of measuring devices, optical devices, manufacturing tools, etc., can solve the problems of rework, lack of automatic detection devices, increase production costs, etc., to ensure standardization and consistency, wide application range, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

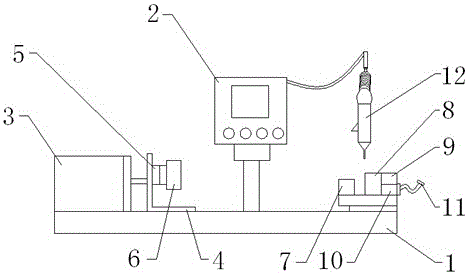

[0025] like figure 1 As shown, the present invention discloses a locking device with detection function suitable for locking processing of medical device parts with strict requirements on product specifications, including a base 1, a controller 2, a positioning mechanism, a detection mechanism and lock mechanism.

[0026] The controller 2 is fixedly arranged on the base 1, and the controller 2 is provided with switch buttons and a display screen for human-computer interaction. When the device starts to work, the working status, operating parameters and detection data of each part of the device can be displayed by means of the display screen, so that the operator can monitor the working status of the device in real time and complete the adjustment of the device in time. The controller 2 is electrically connected with the positioning mechanism, the detection mechanism and the locking mechanism respectively, and drives each mechanism to operate.

[0027] The positioning machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com