Automatic pasting and scanning equipment of embryos bar codes

A technology for scanning equipment and barcodes, applied in labeling machines, labels, packaging, etc., can solve the problems of increasing unsuccessful barcode scanning rate, increasing labor intensity of workers, and irregular barcode sticking, ensuring instant binding and reducing manual labor. Effects of scanning intensity, ensuring accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

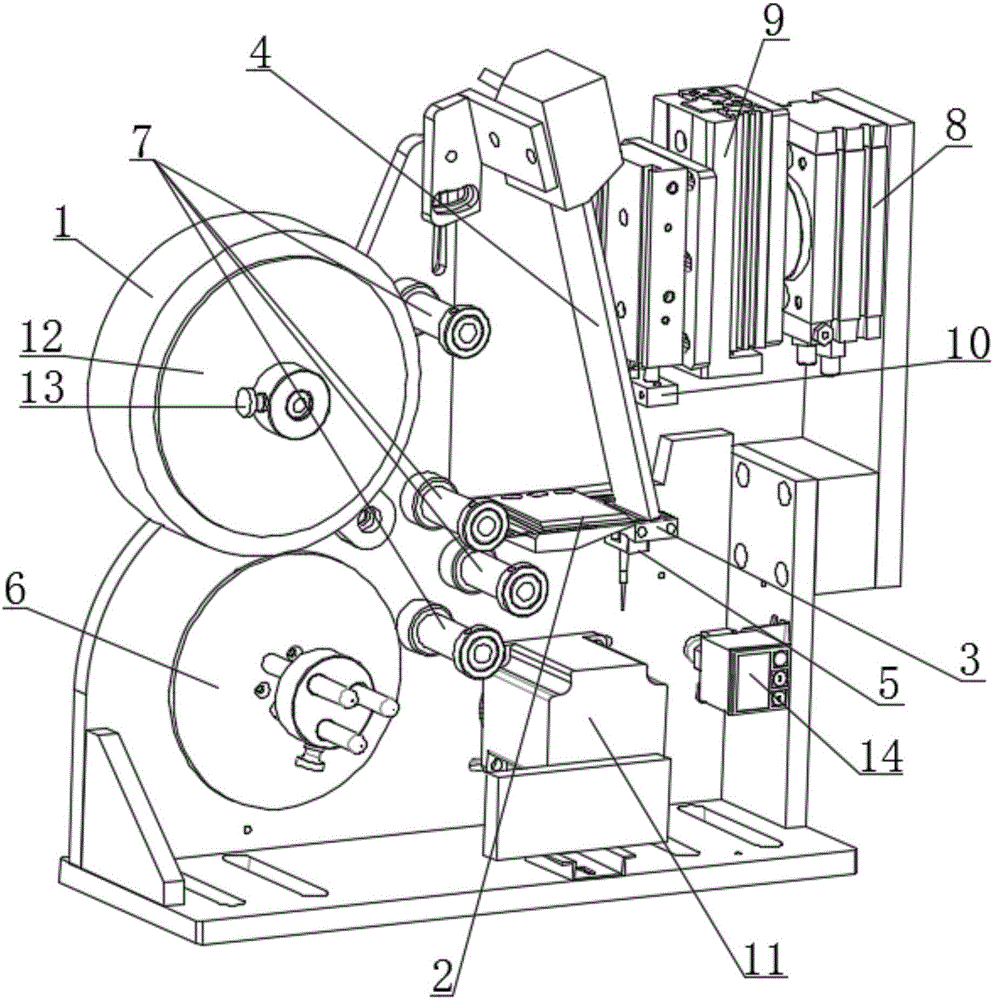

[0029] like figure 1 As shown, the tire blank barcode automatic pasting and scanning equipment includes a PLC, a frame, and a barcode conveying scanning unit and a barcode pasting unit arranged on the frame.

[0030] The barcode conveying and scanning unit includes a feeding mechanism 1 for feeding the backing tape pasted with a barcode, a label peeling mechanism 2 for stripping the backing tape pasted with a barcode from the barcode and the backing tape, and a label peeling mechanism 2 for storing the stripped backing tape. The barcode storage platform 3 of the barcode, the scanning component 4 for barcode scanning on the barcode on the barcode storage platform 3, the label detection mechanism 5 for ensuring that the unique barcode is stripped to the barcode storage platform 3, and the label detection mechanism 5 for stripping the barcode The material receiving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com