Lithium ion secondary battery and preparation method thereof

A secondary battery and lithium ion technology, applied in secondary battery, electrolyte battery manufacturing, battery electrodes, etc., can solve the problems of poor battery cycle performance, re-agglomeration of particles, large volume effect, etc., to improve cycle performance and avoid re- Agglomeration, slow down the effect of pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

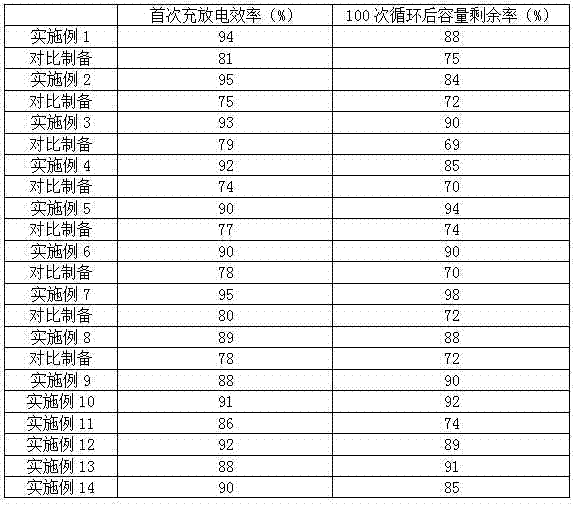

Examples

Embodiment 1

[0033] Gel coat solution: In a flowing nitrogen atmosphere, polyhexafluoropropylene-vinylidene fluoride (HFP-PVDF, in which HFP content is 10%), dimethyl carbonate (DMC) containing 1.0mol / L lithium hexafluorophosphate / Ethylene carbonate (EC) was mixed at a mass ratio of 1:84:15 and stirred at 75°C until dissolved.

[0034] Positive electrode composition and positive electrode: lithium cobaltate (LiCO 2 ) as the positive electrode active material, prepare the positive electrode slurry according to the methods known to those skilled in the art; coat the slurry on both sides of a 16 micron aluminum foil; vacuum bake at 90°C for 3.5h (vacuum degree is - 90kPa), rolling, and slicing; the energy density of the obtained positive electrode is 1.0mAh / cm 2 .

[0035] Negative electrode composition and negative electrode: 10% by weight of nano-silicon (D50=100nm) and 90% by weight of artificial graphite are mixed to form the negative electrode active material, and the negative electro...

Embodiment 2

[0044] Gel coat solution: In a flowing nitrogen atmosphere, polyhexafluoropropylene-vinylidene fluoride (HFP-PVDF, in which HFP content is 10%), dimethyl carbonate (DMC) containing 2.0mol / L lithium hexafluorophosphate (DMC) / Ethylene carbonate (EC) was mixed at a mass ratio of 1:84:15 and stirred at 75°C until dissolved.

[0045] Positive electrode composition and positive electrode: lithium cobaltate (LiCO 2 ) as the positive electrode active material, prepare the positive electrode slurry according to the methods known to those skilled in the art; coat the slurry on both sides of a 16 micron aluminum foil; vacuum bake at 90°C for 3.5h (vacuum degree is - 90kPa), rolling, and slicing; the energy density of the obtained positive electrode is 1.0mAh / cm 2 .

[0046] Negative electrode composition and negative electrode: 10% by weight of nano-silicon (D50=100nm) and 90% by weight of artificial graphite are mixed to form the negative electrode active material, and the negative e...

Embodiment 3

[0055] Gel coating solution: In a flowing nitrogen atmosphere, polyhexafluoropropylene-vinylidene fluoride (HFP-PVDF, in which HFP content is 10%), dimethyl carbonate (DMC) containing 0.5mol / L lithium hexafluorophosphate / Ethylene carbonate (EC) was mixed at a mass ratio of 1:84:15 and stirred at 75°C until dissolved.

[0056] Positive electrode composition and positive electrode: lithium cobaltate (LiCO 2 ) as the positive electrode active material, prepare the positive electrode slurry according to the methods known to those skilled in the art; coat the slurry on both sides of a 16 micron aluminum foil; vacuum bake at 90°C for 3.5h (vacuum degree is - 90kPa), rolling, and slicing; the energy density of the obtained positive electrode is 1.0mAh / cm 2 .

[0057] Negative electrode composition and negative electrode: 10% by weight of nano-silicon (D50=100nm) and 90% by weight of artificial graphite are mixed to form the negative electrode active material, and the negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com