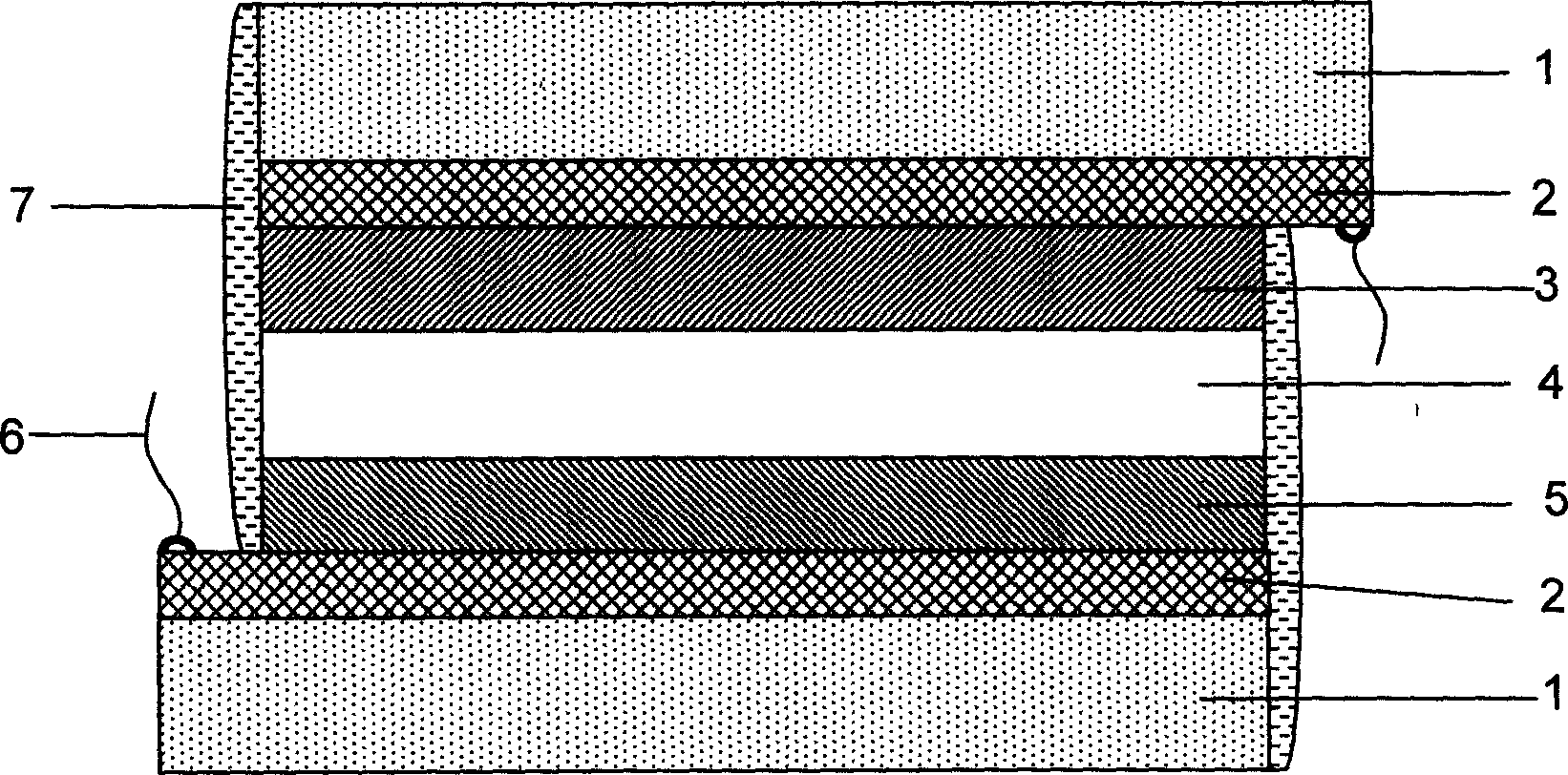

Method for preparing electrochromism glass windows in sandwich type

An electrochromic and electrochromic layer technology, applied in the field of glass processing, can solve the problems of high production cost of electrochromic glass windows, difficult to put into commercial production, low stability, etc., and achieves stable discoloration range and discoloration range. And the effect of life improvement and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]First, mix 1 mole of γ-glycidyl ether propyltrimethylsilane with 0.2 moles of tetramethoxysilane, add 60 grams of hydrochloric acid with a molar concentration of 0.1, and stir the mixture at 30°C for 24 hours. The resulting methanol Separation by rotary vacuum distillation at 60°C.

[0048] Mix 1 mole of pre-hydrolyzed γ-glycidyl ether propyl trimethoxysilane with 1.5 moles of ethylene glycol, add 0.1 moles of methylimidazole, stir at 30°C for 60 minutes, add 0.65 moles of lithium perchlorate and stir well, Adjust the pH to 8.0.

[0049] Add 10% distilled water to this electrolyte before use.

[0050] The electrolyte is suitable for all electrochromic devices using inorganic oxides as electrochromic coatings and ion storage coatings.

Embodiment 2

[0052] A: Preparation of tungsten oxide coating

[0053] The tungsten oxide coating is made of pre-treated conductive glass, that is, pre-cleaned conductive glass, with a thickness of 4 mm and an area resistance of 17 ohms / □. It is prepared from tungsten oxide sol by dipping and pulling. The tungsten oxide sol is mixed with 30% hydrogen peroxide aqueous solution and insufficient tungsten powder, and the reactor is kept in a water bath at 10°C. After the reaction is over, add 8 ml of ethanol per gram of tungsten, stir at 20°C for 2 hours, and rotate to evaporate to obtain dry tungsten oxide powder. Dissolve in ethanol at 25% to obtain tungsten oxide sol.

[0054] Using the dipping and pulling method at a pulling speed of 10 mm per second, coating the conductive glass in a constant temperature and constant humidity environment of 20° C. and 30% humidity, and heat-treating at 200° C. for 1 hour.

[0055] B: Preparation of non-discoloration ion storage coating

[0056] The non-d...

Embodiment 3

[0065] A: The preparation of the tungsten oxide coating is the same as in Example 2, except that the tungsten trioxide sol is 10% ethanol sol. Using the dipping and pulling method at a pulling speed of 4 mm per second, coating the conductive glass in a constant temperature and constant humidity environment of 15° C. and 5% humidity, and heat-treating it at 80° C. for 1 hour.

[0066] C: Preparation of Electrolyte

[0067] Mix 1 mole of vinyltrimethoxysilane with 0.01 mole of tetraethoxysilane, add 20 grams of hydrochloric acid with a molar concentration of 0.1, and stir the mixture at 30°C for 3 hours, and the generated methanol is reduced by rotating at 60°C. Autoclaved flow separation.

[0068] Mix 1 mole of pre-hydrolyzed vinyltrimethoxysilane with 0.01 mole of polyvinyl alcohol doped with 0.01 mole of lithium perchlorate, add 0.01 mole of aluminum isobutyrate, stir at 30°C for 60 minutes, and adjust the pH value to 4.0. This electrolyte was added with 0.001% distilled wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com