Color-changing particle and preparation method thereof

A particle and polymer technology, applied in the field of hybrid color-changing particles containing responsive polymers and inorganic components and their preparation, can solve problems such as limiting the scope of application, and achieve improved color-changing performance, improved color-changing performance, and easy process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1, Preparation of tungsten oxide / poly(N-isopropylacrylamide) intelligent color-changing particles

[0069] Add 10 g of poly(N-isopropylacrylamide) particles (containing N N'-methylenebisacrylamide cross-linking agent in a 250 mL flask, in which N-isopropylacrylamide monomer and N N'-methylene The mass ratio of the base bisacrylamide crosslinking agent is 10:1), add 150mL of water, fully disperse, add 1g of sodium tungstate, stir for 10 minutes, add 10mL of 10M hydrochloric acid, react for 1 hour, centrifuge and wash with water Get smart color-changing particles.

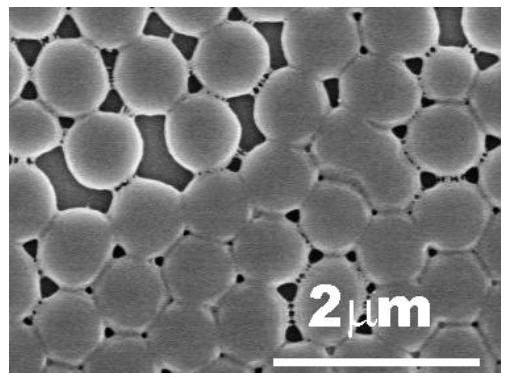

[0070] figure 1 It is the SEM picture of the prepared tungsten oxide / poly(N-isopropylacrylamide) intelligent color-changing particles.

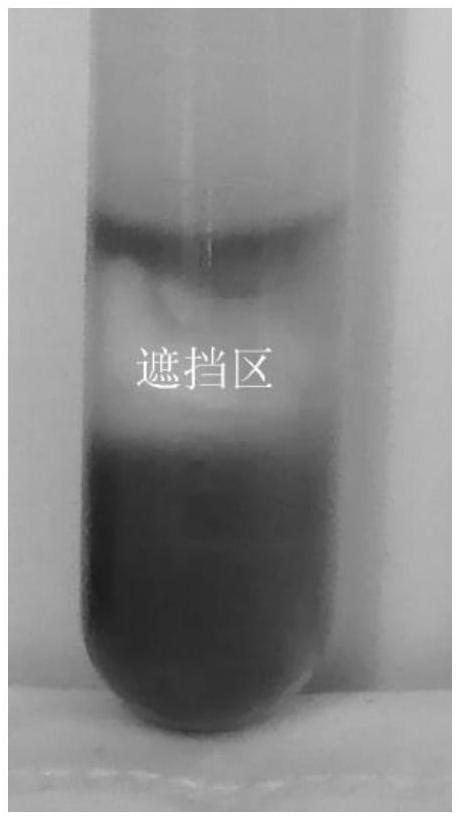

[0071] figure 2 It is a photo of the prepared tungsten oxide / poly(N-isopropylacrylamide) intelligent color-changing particles under ultraviolet irradiation and a photo of visible light irradiation.

[0072] It can be seen from the figure that the tungsten oxide / p...

experiment example 2

[0073] Experimental example 2. Preparation of tungsten oxide / poly(N-isopropylacrylamide-acrylic acid) intelligent color-changing particles

[0074] Add 1 g of poly(N-isopropylacrylamide-acrylic acid) (containing divinylbenzene crosslinking agent, the molar ratio of N-isopropylacrylamide to acrylic acid is 10:1, The addition amount of the joint agent is 2% of the total moles of the two monomers), add 200mL of water, fully disperse and add 2g of potassium tungstate, stir for 1 hour, add 10mL of 1M hydrochloric acid, react for 10 hours, centrifuge, and water Wash well to get smart granules.

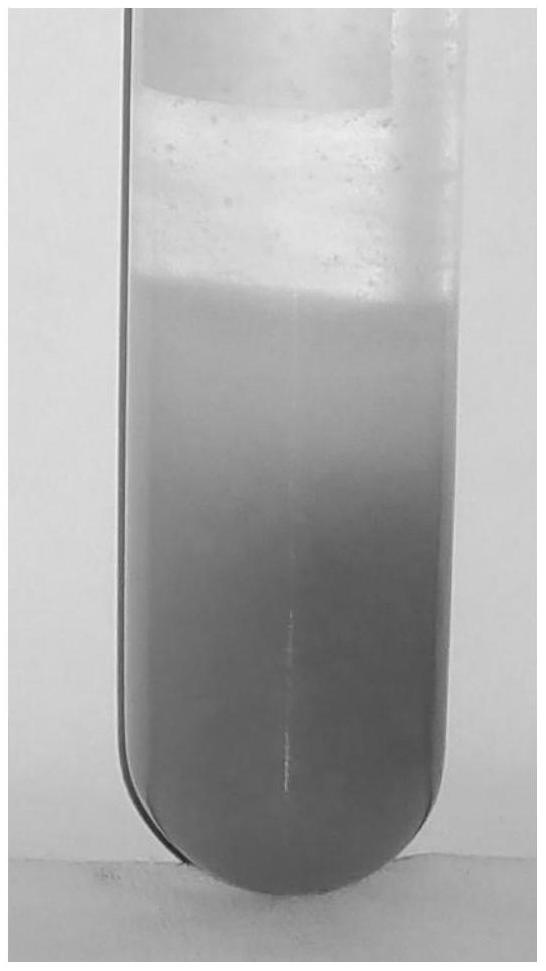

[0075] image 3 For the discoloration pictures of the prepared tungsten oxide / poly(N-isopropylacrylamide-acrylic acid) intelligent discoloration particles,

[0076] It can be seen from the figure that the tungsten oxide / poly(N-isopropylacrylamide-acrylic acid) intelligent color-changing particles turn blue-blue after ultraviolet irradiation, and the parts that are not illuminated are yellow....

experiment example 3

[0077] Experimental example 3, preparation of molybdenum oxide / poly(N-isopropylacrylamide) intelligent color-changing particles

[0078] Disperse 0.1g of poly(N-isopropylacrylamide) particles in 200mL of water; then add 0.1g of potassium molybdate and 0.001g of sodium zincate, stir and add 10mL of 1M hydrochloric acid, react for 1 hour and then separate and wash to obtain smart Discoloration particles.

[0079] The color of the molybdenum oxide / poly(N-isopropylacrylamide) particles obtained by irradiating with ultraviolet light changes from yellow to dark blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com