High-output energy storage greenhouse

A high-value, greenhouse technology, applied in greenhouse cultivation, energy-saving measures, general water supply conservation, etc., can solve the problems that agricultural machinery cannot enter, is difficult to transform, and the heat utilization is not very sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

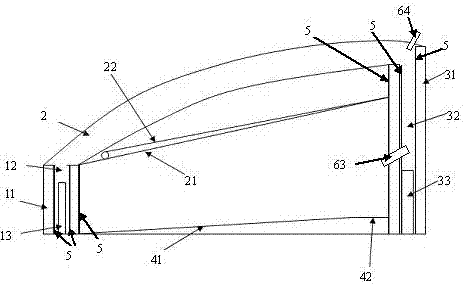

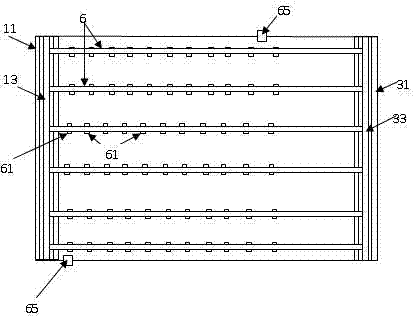

[0035] Such as figure 1 and figure 2 shown.

[0036] An energy storage high-value greenhouse includes a front wall, a rear wall, a shed surface, a water circulation system and an air circulation system.

[0037] The front wall is a wall made of hollow bricks, which is hollow inside the front wall to form a hollow area of the front wall. The hollow area of the front wall is a hollow area with an upper opening, and is set in the hollow area of the front wall There is a front wall water tank, and the front wall water tank is only fixedly connected with the bottom end of the hollow area of the front wall, leaving gaps with its side and upper parts.

[0038] The back wall is a wall made of hollow bricks, which is hollow inside the back wall to form a hollow area of the back wall. The hollow area of the back wall is a hollow area with an upper opening, and is set in the hollow area of the back wall. There is a rear wall water tank, and the rear wall water tank is onl...

Embodiment 2

[0051] An energy storage high-value greenhouse includes a front wall, a rear wall, a shed surface, a water circulation system and an air circulation system.

[0052] The front wall is a wall made of hollow bricks, which is hollow inside the front wall to form a hollow area of the front wall. The hollow area of the front wall is a hollow area with an upper opening, and is set in the hollow area of the front wall There is a front wall water tank, and the front wall water tank is only fixedly connected with the bottom end of the hollow area of the front wall, leaving gaps with its side and upper parts.

[0053] The back wall is a wall made of hollow bricks, which is hollow inside the back wall to form a hollow area of the back wall. The hollow area of the back wall is a hollow area with an upper opening, and is set in the hollow area of the back wall. There is a rear wall water tank, and the rear wall water tank is only fixedly connected to the bottom end of the hol...

Embodiment 3

[0068] An energy storage high-value greenhouse includes a front wall, a rear wall, a shed surface, a water circulation system and an air circulation system.

[0069] The front wall is a wall made of hollow bricks, which is hollow inside the front wall to form a hollow area of the front wall. The hollow area of the front wall is a hollow area with an upper opening, and is set in the hollow area of the front wall There is a front wall water tank, and the front wall water tank is only fixedly connected with the bottom end of the hollow area of the front wall, leaving gaps with its side and upper parts.

[0070] The back wall is a wall made of hollow bricks, which is hollow inside the back wall to form a hollow area of the back wall. The hollow area of the back wall is a hollow area with an upper opening, and is set in the hollow area of the back wall. There is a rear wall water tank, and the rear wall water tank is only fixedly connected with the bottom end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com