Lithium ion battery electrolyte

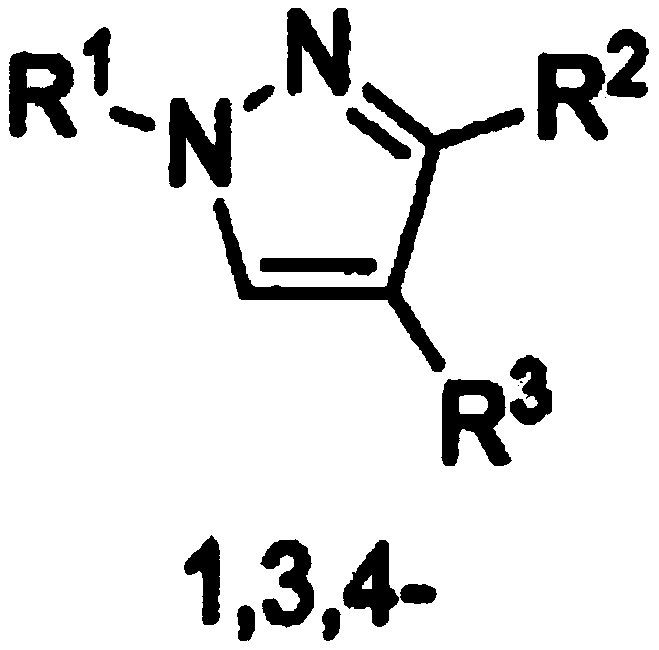

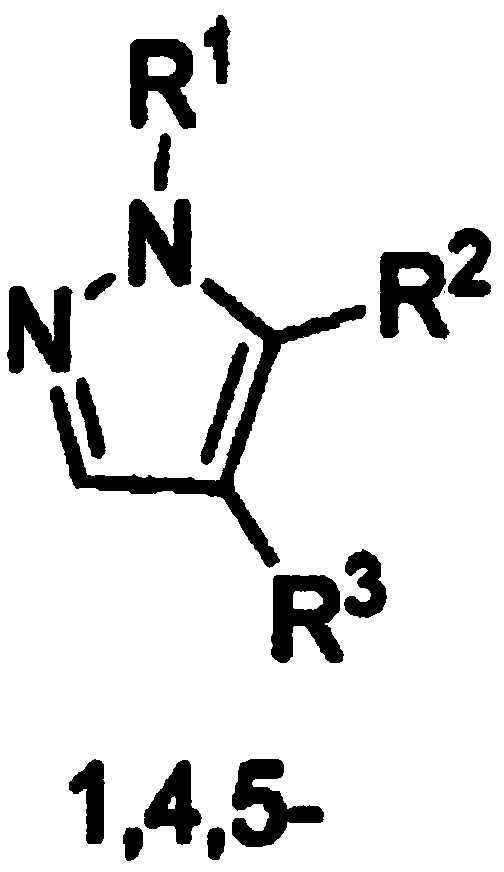

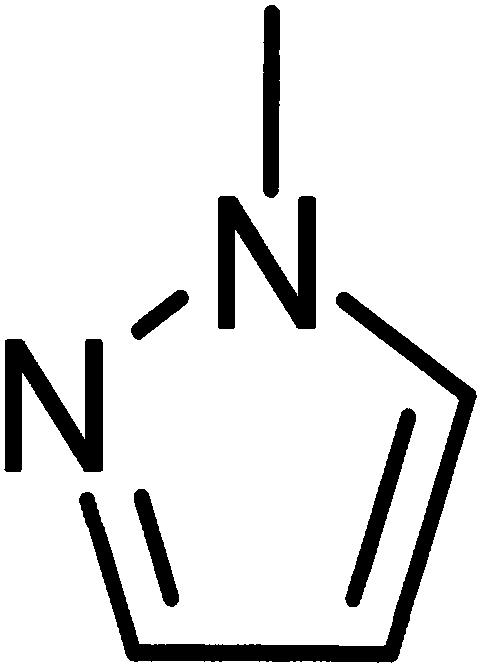

An electrolyte and electrolyte additive technology, applied in the field of pyrazole compound electrolyte additives and high-voltage electrolytes, can solve the problems of low charge and discharge efficiency, fast cycle decay, poor cycle performance, etc., to improve cycle performance, reduce The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a glove box filled with argon (moisture <1ppm, oxygen <1ppm), mix ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl methyl carbonate (EMC) in a mass ratio of 1:1:1 As an organic solvent, lithium salt LiPF6 is added thereto to form an electrolyte solution with a lithium salt concentration of 1.0Mol / L; then functional additive succinonitrile is added to the prepared electrolyte solution in an amount of 1%. Then add a pyrazole compound additive in an amount of 0.5 wt%, to obtain an electrolyte solution for a lithium secondary battery. The structure of the pyrazole additive is as follows: especially methylpyrazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com