Three-dimensional nanometer linear pore carbon material and manufacturing technology of high-voltage miniature supercapacitor

A three-dimensional nanotechnology, manufacturing process technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, nanotechnology, etc., can solve the problems of low energy density, small specific surface area, limitations, etc., to achieve high area capacity, increase ratio Surface area, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

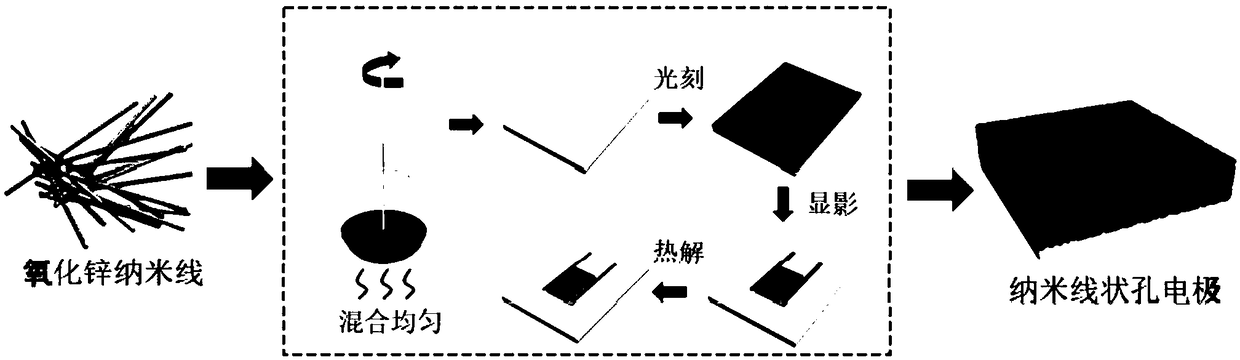

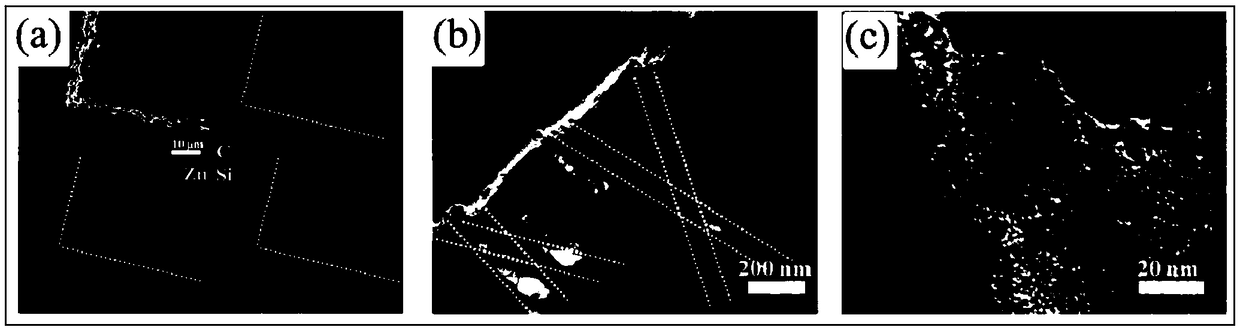

[0029] A manufacturing process of a high-voltage three-dimensional nanowire-like porous carbon material micro-supercapacitor comprises the following steps:

[0030] (1) Using the hydrothermal method to prepare zinc oxide nanowires:

[0031] 1a) Add 0.4g of zinc chloride and 20g of sodium carbonate into 35ml of deionized water, mix and stir for 1 hour.

[0032] 1b) The above solution was added into a polytetrafluoroethylene reactor, and a hydrothermal reaction was carried out at 120° C. for 12 hours. After cooling, wash and centrifuge five times with deionized water and alcohol, and dry in an oven at 80°C.

[0033] (2) Using ultrasonic stirring method to uniformly disperse the zinc oxide nanowires in the photoresist:

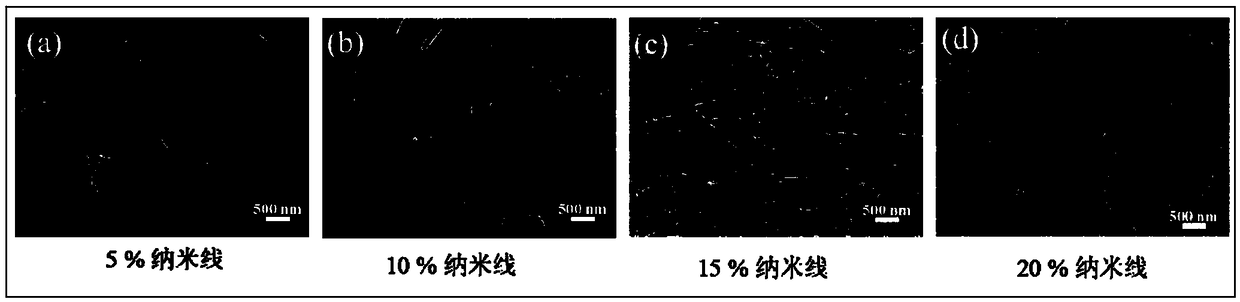

[0034] 2a) Measure 9000A photoresist in the flask, and add zinc oxide nanowires to the photoresist at a mass fraction of 15%;

[0035] 2b) Put the flask into an ultrasonic cleaning machine, the ultrasonic time is 10 hours, and electric stirring is used at the ...

Embodiment 2

[0050] A manufacturing process of a high-voltage three-dimensional nanowire-like porous carbon material micro-supercapacitor comprises the following steps:

[0051] (1) Using the hydrothermal method to prepare zinc oxide nanowires:

[0052] 1a) Add 0.6g of zinc chloride and 20g of sodium carbonate into 35ml of deionized water, mix and stir for 1 hour.

[0053] 1b) The above solution was added into a polytetrafluoroethylene reactor, and a hydrothermal reaction was carried out at 120° C. for 12 hours. After cooling, wash and centrifuge five times with deionized water and alcohol, and dry in an oven at 80°C.

[0054] (2) Using ultrasonic stirring method to uniformly disperse the zinc oxide nanowires in the photoresist:

[0055] 2a) Measure 9000A photoresist in the flask, and add zinc oxide nanowires to the photoresist at a mass fraction of 10%.

[0056] 2b) Put the flask into an ultrasonic cleaning machine, the ultrasonic time is 10 hours, and electric stirring is used at the ...

Embodiment 3

[0064] A manufacturing process of a high-voltage three-dimensional nanowire-like porous carbon material micro-supercapacitor comprises the following steps:

[0065] (1) Using the hydrothermal method to prepare zinc oxide nanowires:

[0066] 1a) Add 0.4g of zinc chloride and 20g of sodium carbonate into 35ml of deionized water, mix and stir for 1 hour.

[0067] 1b) The above solution was added into a polytetrafluoroethylene reactor, and a hydrothermal reaction was carried out at 120° C. for 12 hours. After cooling, wash and centrifuge five times with deionized water and alcohol, and dry in an oven at 80°C.

[0068] (2) Using ultrasonic stirring method to uniformly disperse the zinc oxide nanowires in the photoresist:

[0069] 2a) Measure 9000A photoresist in the flask, and add zinc oxide nanowires in the photoresist at a mass fraction of 5%.

[0070] 2b) Put the flask into an ultrasonic cleaning machine, the ultrasonic time is 10 hours, and electric stirring is used at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com