Rear-earth surface-modified hollow glass microsphere and preparation method thereof

A hollow glass microsphere and surface modification technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of high cost, long process flow, unsuitable for large-scale industrialization, etc., and achieve low cost , the process is simple, the effect of improving the interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

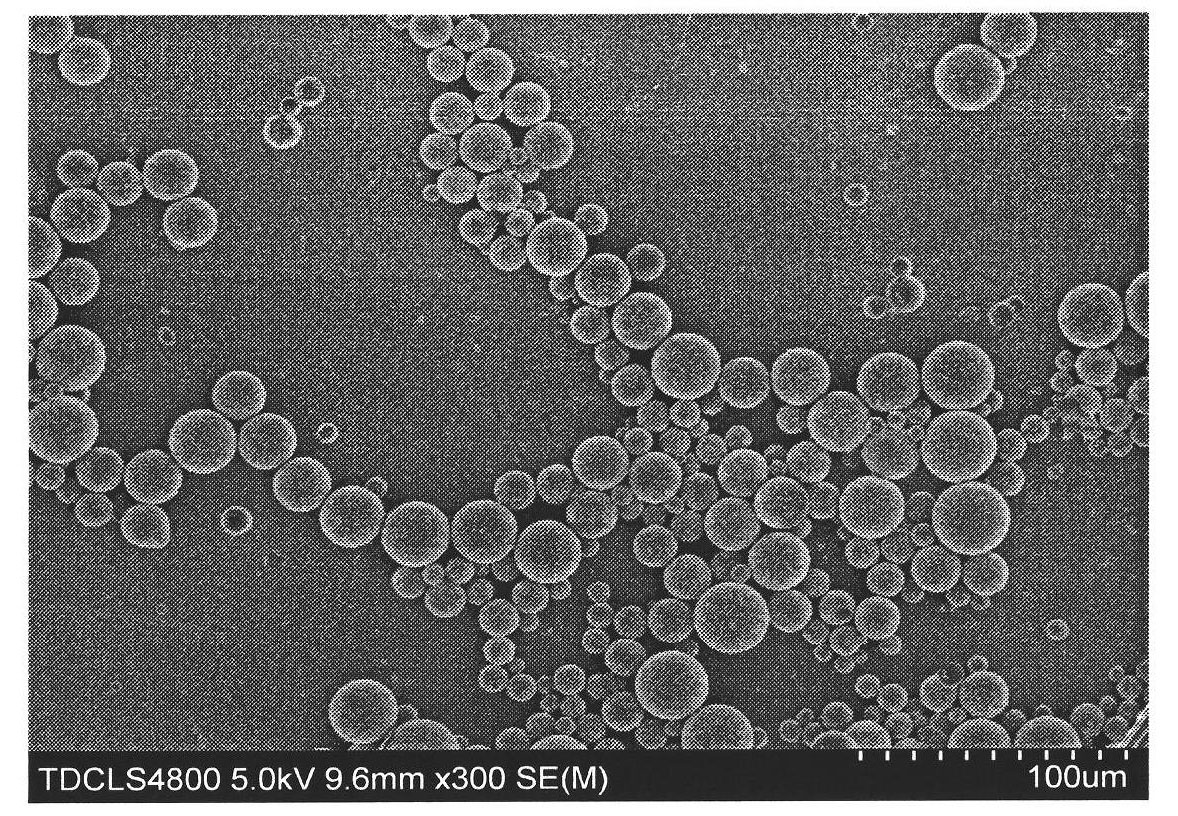

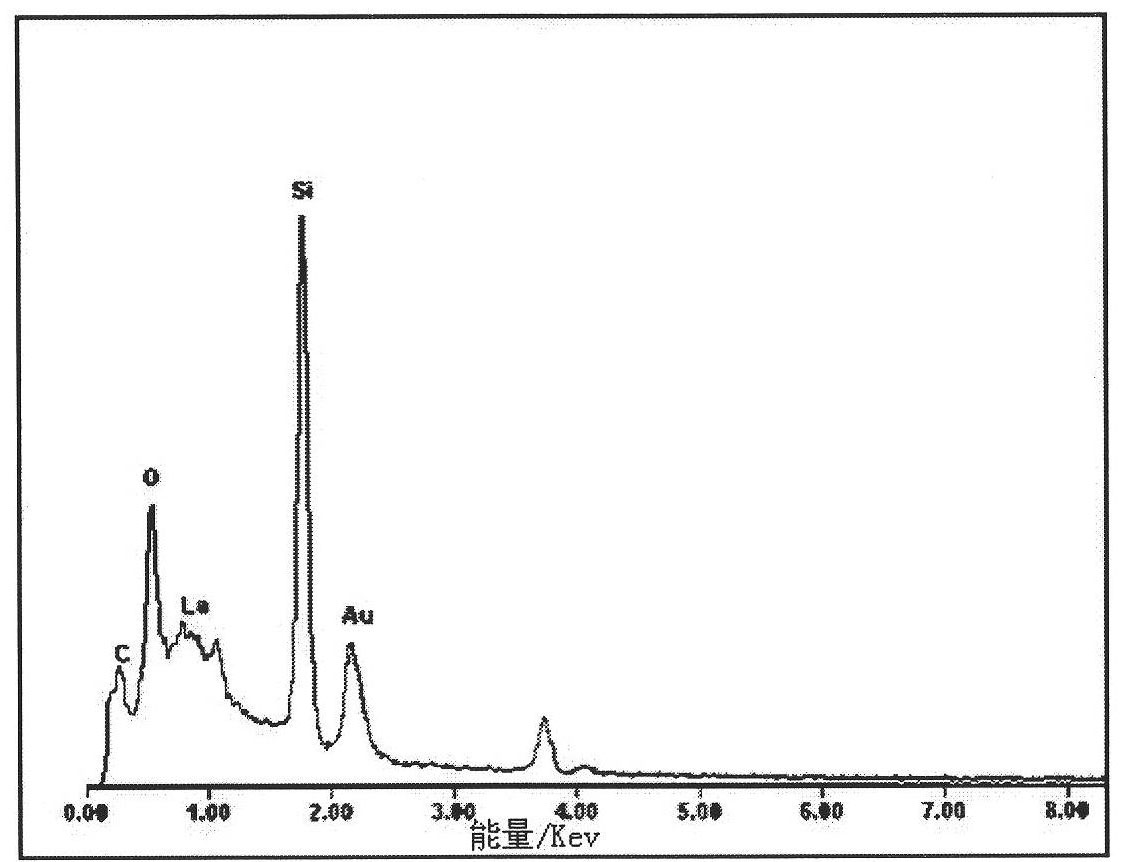

[0025] Example 1: Stir 100 parts of hollow glass microspheres with an average particle size of 5 μm in 300 parts of 0.1 mol / l sodium hydroxide solution at 300 to 600 rpm for 1 hour at 80°C, filter and set aside for use; then 0.9g of lanthanum nitrate is fully dissolved in 299.1g of distilled water to prepare a lanthanum nitrate solution with a mass fraction of 0.3%; then the pretreated hollow glass microspheres are directly added to the above-mentioned rare earth solution, stirred to make it fully dispersed, Among them, the stirring time is controlled at 15-20 minutes, the stirring rate is controlled at 300-600 rpm, and the stirring is stopped for 3 hours, then filtered, washed with distilled water and dried at 100-120°C for 2 hours to obtain the modified product. Hollow glass microspheres.

example 2

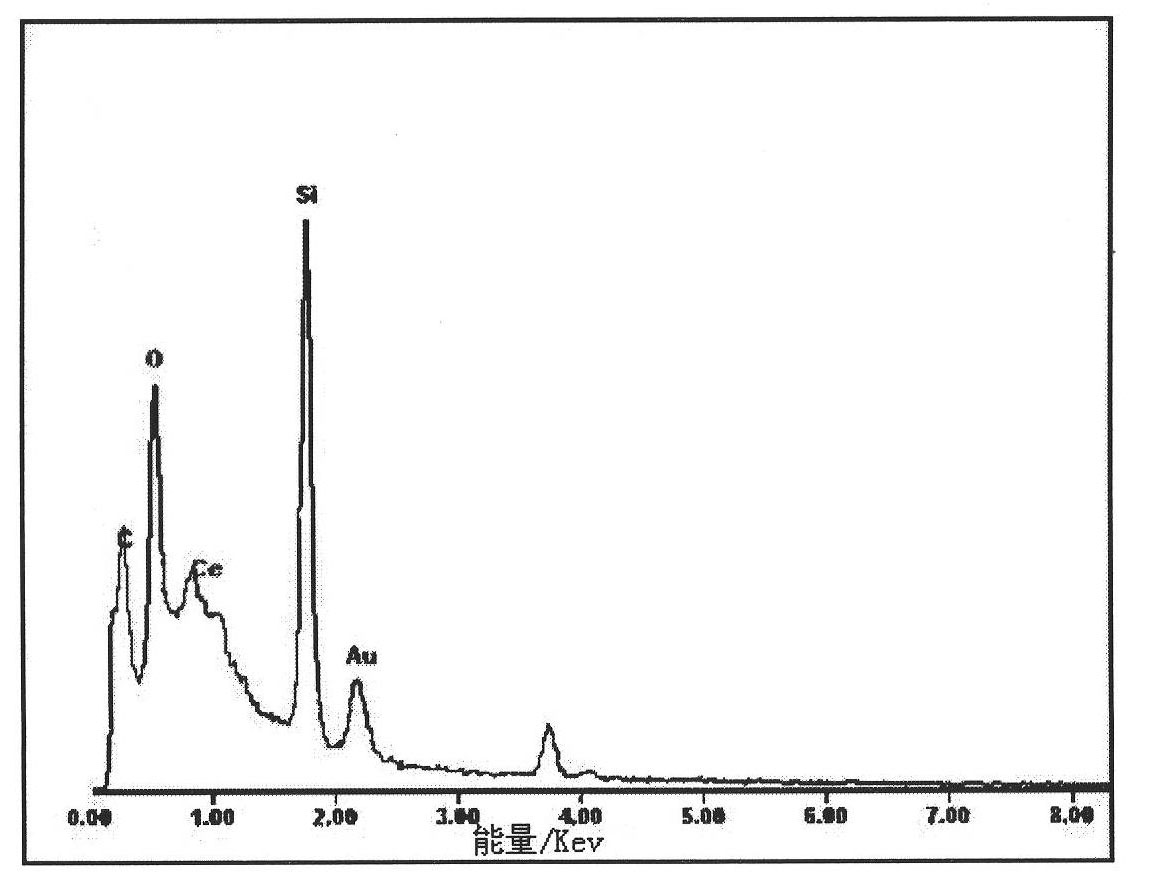

[0026] Example 2: Stir 100 parts of hollow glass microspheres with an average particle size of 10 μm in 300 parts of 0.4 mol / l sodium hydroxide solution at 300 to 600 rpm for 1 hour at 80°C, filter and set aside for use; then 3.6g of cerium nitrate was fully dissolved in 296.4g of distilled water to prepare a cerium nitrate solution with a mass fraction of 1.2%; then the pretreated hollow glass microspheres were directly added to the above-mentioned rare earth solution, stirred to make it fully dispersed, Among them, the stirring time is controlled at 15-20 minutes, the stirring rate is controlled at 300-600 rpm, and the stirring is stopped for 3 hours, then filtered, washed with distilled water and dried at 100-120°C for 2 hours to obtain the modified product. Hollow glass microspheres.

[0027] In order to test the modification effect, the hollow glass microspheres without surface treatment and those prepared by the surface treatment method of the present invention were blen...

example 3

[0028] Example 3: Stir 100 parts of hollow glass microspheres with an average particle size of 30 μm in 300 parts of 0.5 mol / l sodium hydroxide solution at 300 to 600 rpm for 1 hour at 80°C, filter and set aside for use; then 6.0g of yttrium nitrate was fully dissolved in 294.0g of distilled water to prepare a 2.0% yttrium nitrate solution; then the pretreated hollow glass microspheres were directly added to the above-mentioned rare earth solution, stirred to make it fully dispersed, Among them, the stirring time is controlled at 15-20 minutes, the stirring rate is controlled at 300-600 rpm, and the stirring is stopped for 3 hours, then filtered, washed with distilled water and dried at 100-120°C for 2 hours to obtain the modified product. Hollow glass microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com