Method for manufacturing insulating metal base plate of electronic circuit

An insulating metal and electronic circuit technology, which is used in the improvement of metal adhesion of insulating substrates, printed circuits, and printed circuit manufacturing, etc. Low cost and the effect of increasing the micro-interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

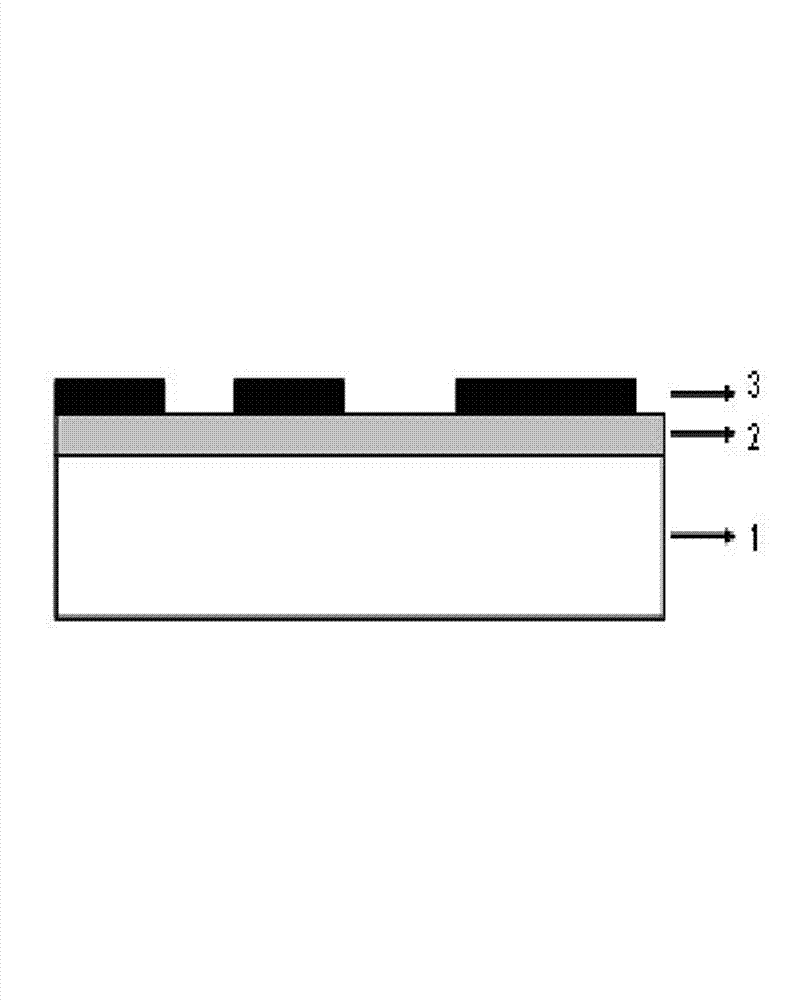

[0023] Aluminum alloy as the base material of the insulating metal substrate is generally selected to have a higher thermal conductivity and a certain mechanical strength, but also can withstand a certain temperature, such as 5052, 6061 and other brands of aluminum. The ceramic used to prepare the insulating layer is aluminum nitride, and the conductive material is copper.

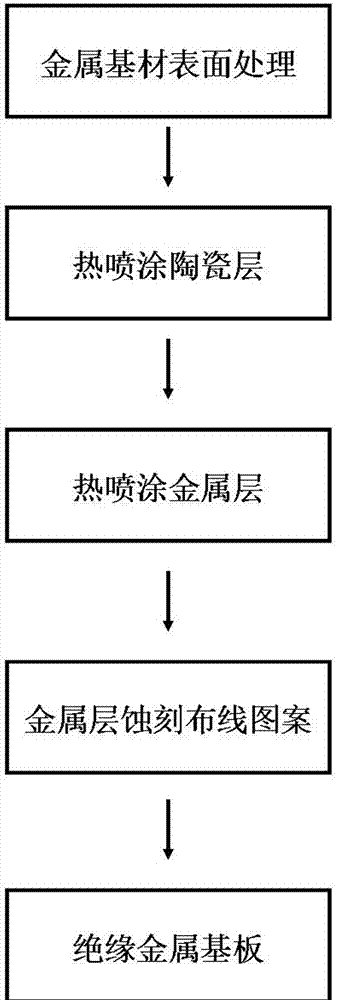

[0024] 1. First use mechanical or chemical methods to remove oil and impurities on the surface of the aluminum plate, and then use the sandblasting process to obtain a clean surface of the workpiece. The thickness of the aluminum plate is 0.5mm;

[0025] 2. Using plasma spraying to grow an aluminum nitride ceramic layer on the surface of the aluminum plate, and controlling the plasma spraying process, the bonding strength of the obtained aluminum nitride coating and the aluminum plate layer is greater than 30MPa, the thickness of the aluminum nitride layer is 0.2mm, and the porosity is low Less than 5%, the r...

Embodiment 2

[0031] Copper alloy is used as the base material for insulating metal substrates, and industrial pure copper with high thermal conductivity is generally selected. The ceramic used to prepare the insulating layer is alumina, and the conductive material is copper-covered silver, mainly to meet the high requirements of high-power package holders for the surface reflectivity of the conductive metal layer;

[0032] 1. First use mechanical or chemical methods to remove oil and impurities on the surface of the copper plate, and then use the sandblasting process to obtain a clean surface of the workpiece. The thickness of the copper plate is 1 mm;

[0033] 2. Using plasma spraying to grow an alumina ceramic layer on the surface of the aluminum plate, and controlling the plasma spraying process, the bond strength of the obtained alumina coating and the aluminum plate layer is greater than 30MPa, the thickness of the alumina layer is 0.4mm, and the porosity is less than 5% , The resistivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com