Highly stable lithium nickel cobalt aluminate positive electrode material and its preparation method

A technology of nickel cobalt lithium aluminate and cathode material, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of electrolyte side reactions and impurity gas release, so as to slow down side reactions and prevent battery output characteristics Effects of deterioration, improved thermal stability and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

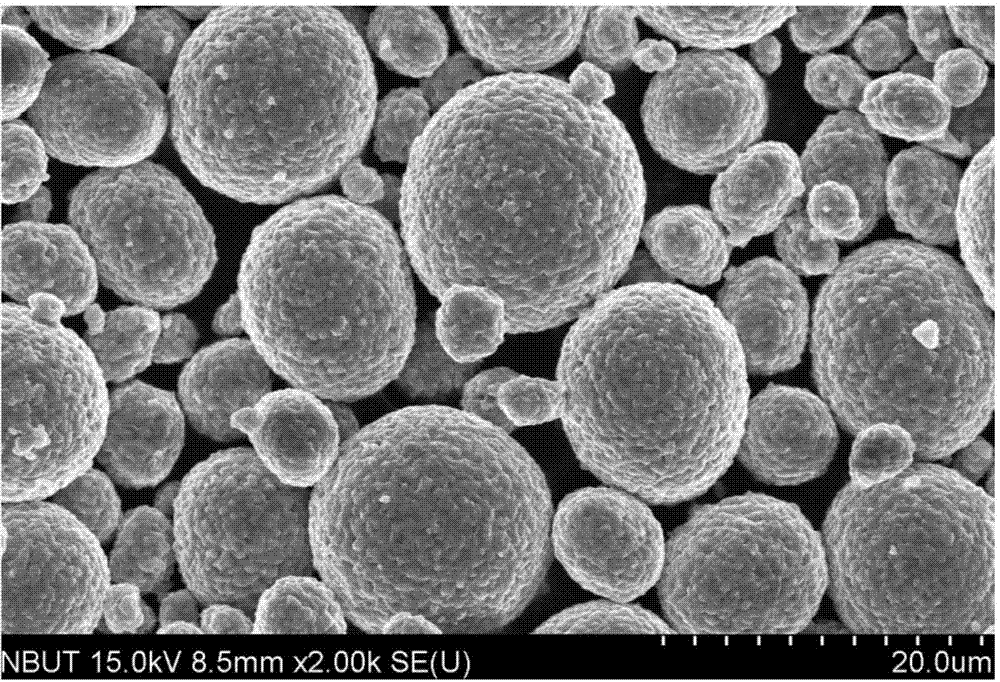

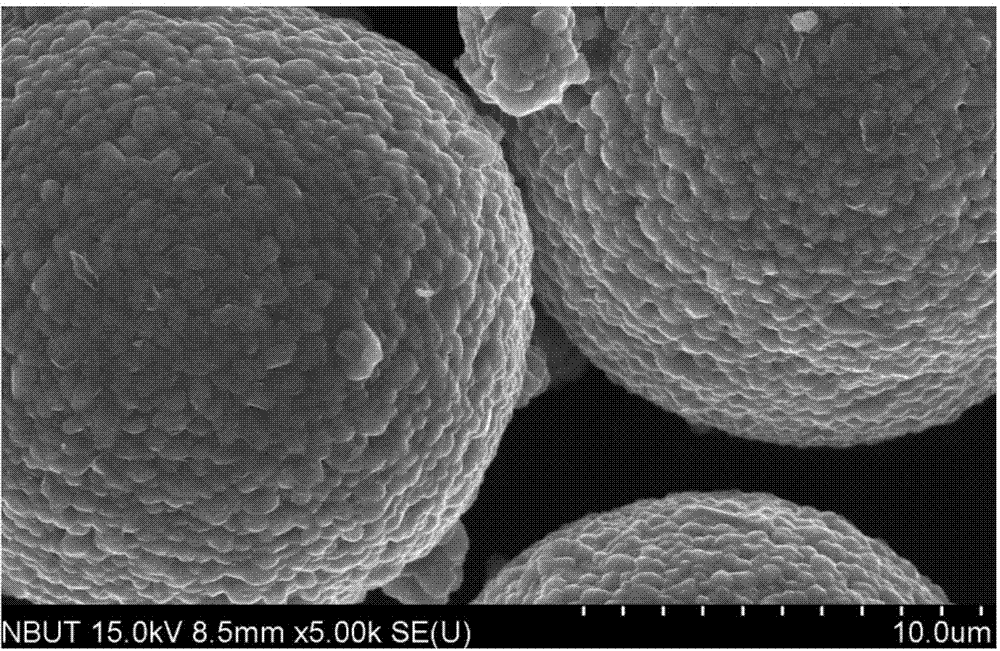

[0040] (1) Preparation of nickel-cobalt-aluminum hydroxide: Mix nickel sulfate solution, cobalt sulfate solution, and aluminum sulfate solution as raw materials with Ni:Co:Al atomic ratio of 0.80:0.15:0.05, and mix the metal ion concentration in the solution 1.0mol / L. Then add 5 mol / L ammonia solution, 5 mol / L sodium hydroxide solution and the mixed solution together into the reactor containing 1 / 4 deionized water. The reaction control temperature is 50°C, the pH value is 11.0, and the ammonia value is 10g / L. Stir to carry out the precipitation and crystallization reaction. After the reaction is complete, the solid-liquid separation of the overflowing slurry is started. The separated solid product is washed and dried to obtain Spherical nickel cobalt aluminum hydroxide powder.

[0041] (2) The nickel-cobalt-aluminum hydroxide powder obtained above was heat-treated at 400° C. for 10 hours under air condition to obtain nickel-cobalt-aluminum oxide.

[0042] (3) The nickel-coba...

Embodiment 2

[0046] (1) Preparation of nickel-cobalt-aluminum hydroxide: Ni:Co atomic ratio is 0.90:0.10 nickel sulfate solution and cobalt sulfate solution are mixed evenly as raw materials, and the metal ion concentration in the mixed solution is 2.0mol / L. Then add 10 mol / L ammonia solution, 3 mol / L sodium hydroxide solution and the mixed solution together into the reactor filled with 1 / 3 deionized water. The reaction control temperature is 60°C, the pH value is 10.5, and the ammonia value is 20g / L. Stir to carry out the precipitation and crystallization reaction. After the reaction is complete, the solid-liquid separation of the overflowing slurry is started. The separated solid product is washed and dried to obtain Spherical nickel cobalt hydroxide. Slurry the nickel-cobalt hydroxide particles with a solution containing 5% aluminum, and precipitate aluminum as hydroxide on the surface of the nickel-cobalt hydroxide particles through a crystallization reaction to form a nickel-cobalt co...

Embodiment 3

[0052] (1) Preparation of nickel-cobalt-aluminum hydroxide: Mix nickel sulfate solution, cobalt sulfate solution, and aluminum sulfate solution as raw materials according to Ni:Co:Al atomic ratio of 0.85:0.12:0.03, and mix the metal ion concentration in the solution It is 1.5mol / L. Then add 5 mol / L ammonia solution, 5 mol / L sodium hydroxide solution and the mixed solution together into the reaction kettle equipped with 1 / 4 deionized water. The reaction temperature is controlled at 45°C, the pH value is 11.5, and the ammonia value is 5g / L. Stir to carry out the precipitation and crystallization reaction. After the reaction is complete, the solid-liquid separation of the overflowing slurry is started. After the separated solid product is washed and dried, it is obtained Almost spherical nickel cobalt aluminum hydroxide.

[0053] (2) The nickel-cobalt-aluminum hydroxide powder obtained above was heat-treated at 150° C. for 15 hours under air condition to obtain nickel-cobalt-alu...

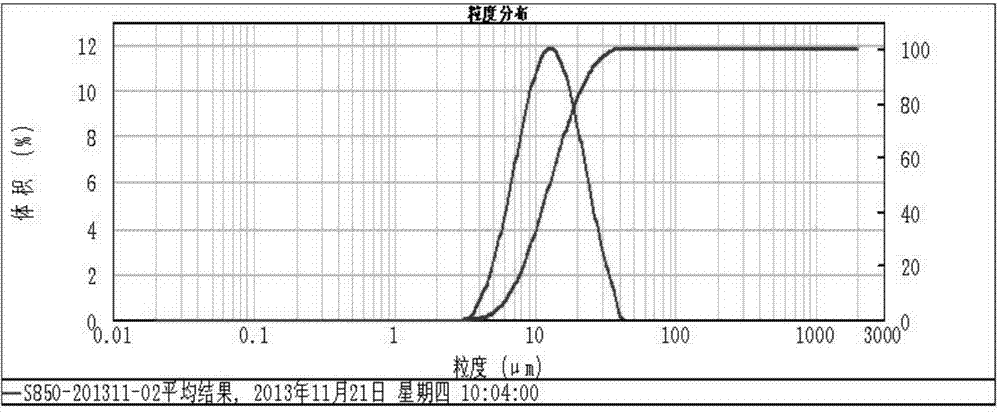

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com