High-capacity lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low compaction density, reduced electrical performance, and low specific capacity of lithium cobalt oxide, and achieves increased specific capacity and electrical conductivity. The effect of improving the stability and voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Will LiNi 0.8 co 0.15 al 0.05 o 2 The two active materials and lithium cobalt oxide were dry mixed at a ratio of 5:5, and the mixing time was 2 hours.

[0029] Aluminum nitrate is prepared into aluminum nitrate solution at room temperature, and the above-mentioned mixed active material is added to the aluminum nitrate solution and stirred to form a solid-liquid mixture, so that the aluminum nitrate solution is evenly coated on the surface of the active material particles; after being calcined by aluminum nitrate form Al 2 o 3 The mass accounts for 1% of the active substance mass after mixing.

[0030] Dry the above-mentioned solid-liquid mixture, put the dried solid material into a furnace for roasting, raise the temperature to 500°C at a rate of 4°C / min, keep it at 500°C for 7 hours, cool, pulverize, and sieve to obtain a compound Cathode material.

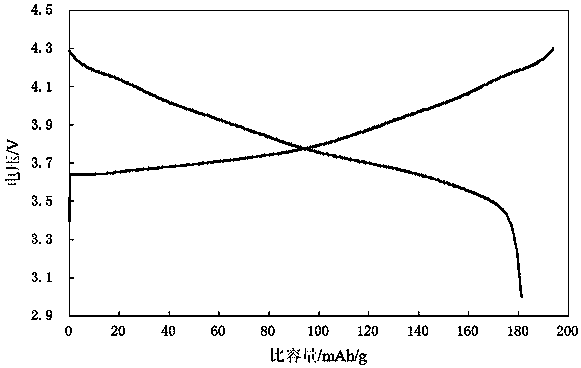

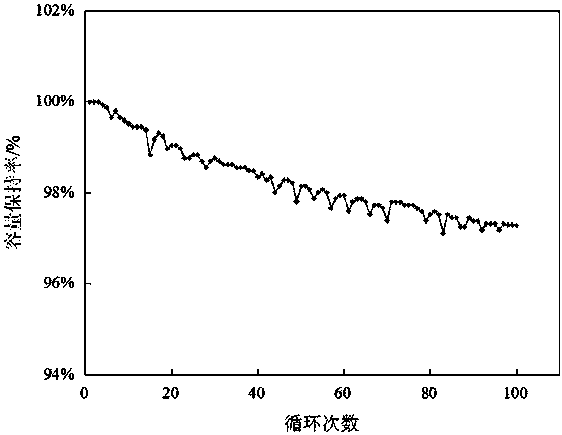

[0031] The electrochemical performance test of the material is tested at 25°C with a blue battery test system, an...

Embodiment 2

[0033] Will LiNi 0.8 co 0.15 al 0.05 o 2 and lithium cobaltate two active materials were dry mixed at a ratio of 6:4, and the mixing time was 2 hours.

[0034] Aluminum nitrate is prepared into aluminum nitrate solution at room temperature, and the above-mentioned mixed active material is added to the aluminum nitrate solution and stirred to form a solid-liquid mixture, so that the aluminum nitrate solution is evenly coated on the surface of the active material particles; after being calcined by aluminum nitrate form Al 2 o 3 The mass accounts for 0.5% of the active substance mass after mixing.

[0035] Dry the above-mentioned solid-liquid mixture, put the dried solid material into a furnace for roasting, raise the temperature to 600°C at a rate of 4°C / min, keep it at 600°C for 6 hours, cool, pulverize, and sieve to obtain a compound Cathode material.

Embodiment 3

[0037] Will LiNi 0.8 co 0.1 al 0.1 o 2 and lithium cobaltate two active materials were dry mixed at a ratio of 4:6, and the mixing time was 2 hours.

[0038] Aluminum nitrate is prepared into aluminum nitrate solution at room temperature, and the above-mentioned mixed active material is added to the aluminum nitrate solution and stirred to form a solid-liquid mixture, so that the aluminum nitrate solution is evenly coated on the surface of the active material particles; after being calcined by aluminum nitrate form Al 2 o 3 The mass accounts for 2% of the active substance mass after mixing.

[0039] Dry the above-mentioned solid-liquid mixture, put the dried solid material into a furnace for roasting, raise the temperature up to 700°C at a rate of 4°C / min, keep it at 700°C for 5 hours, cool, pulverize, and sieve to obtain a compound Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com