Surface modification technology of cathode material for lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor consistency, increased material surface area, and reduced capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

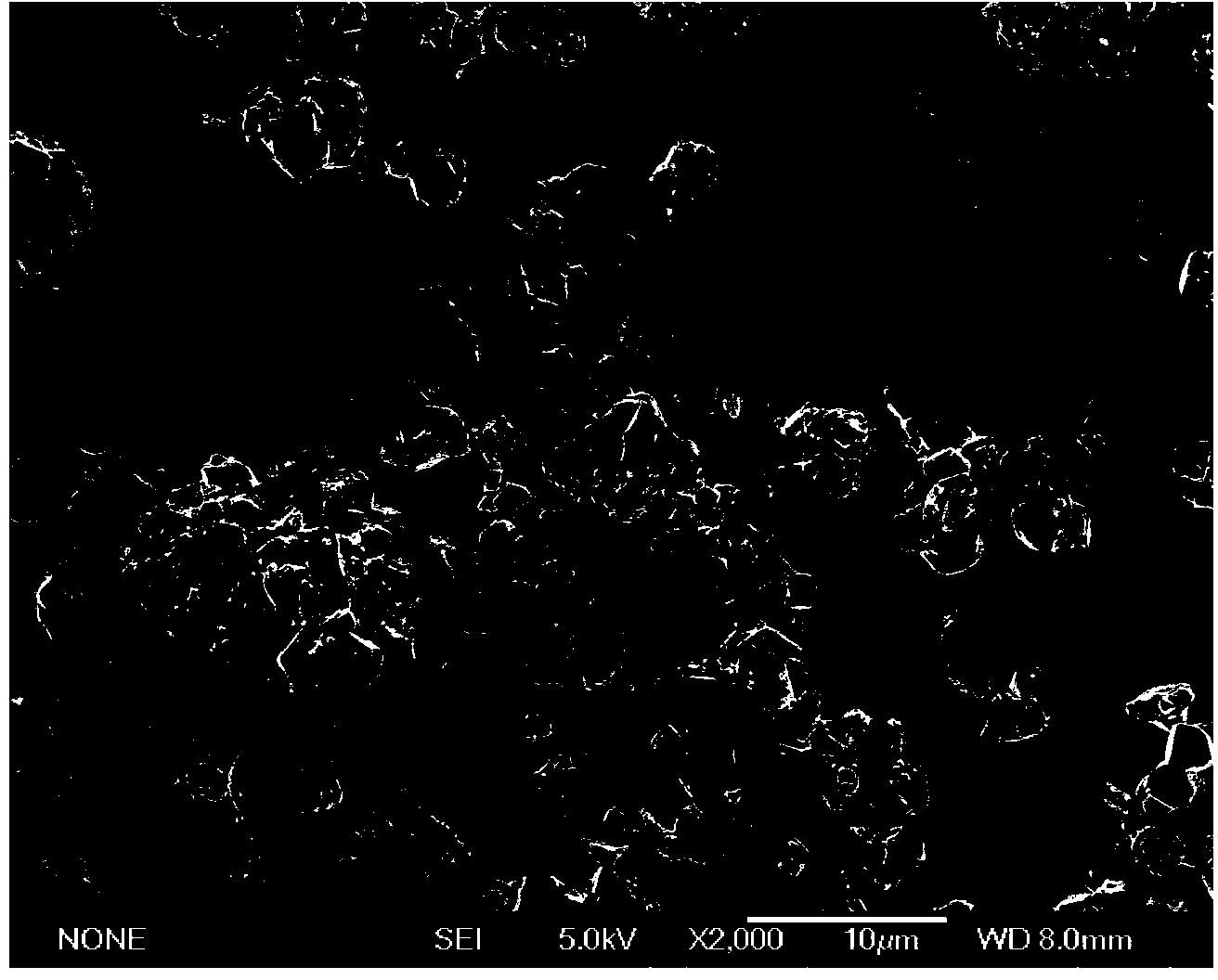

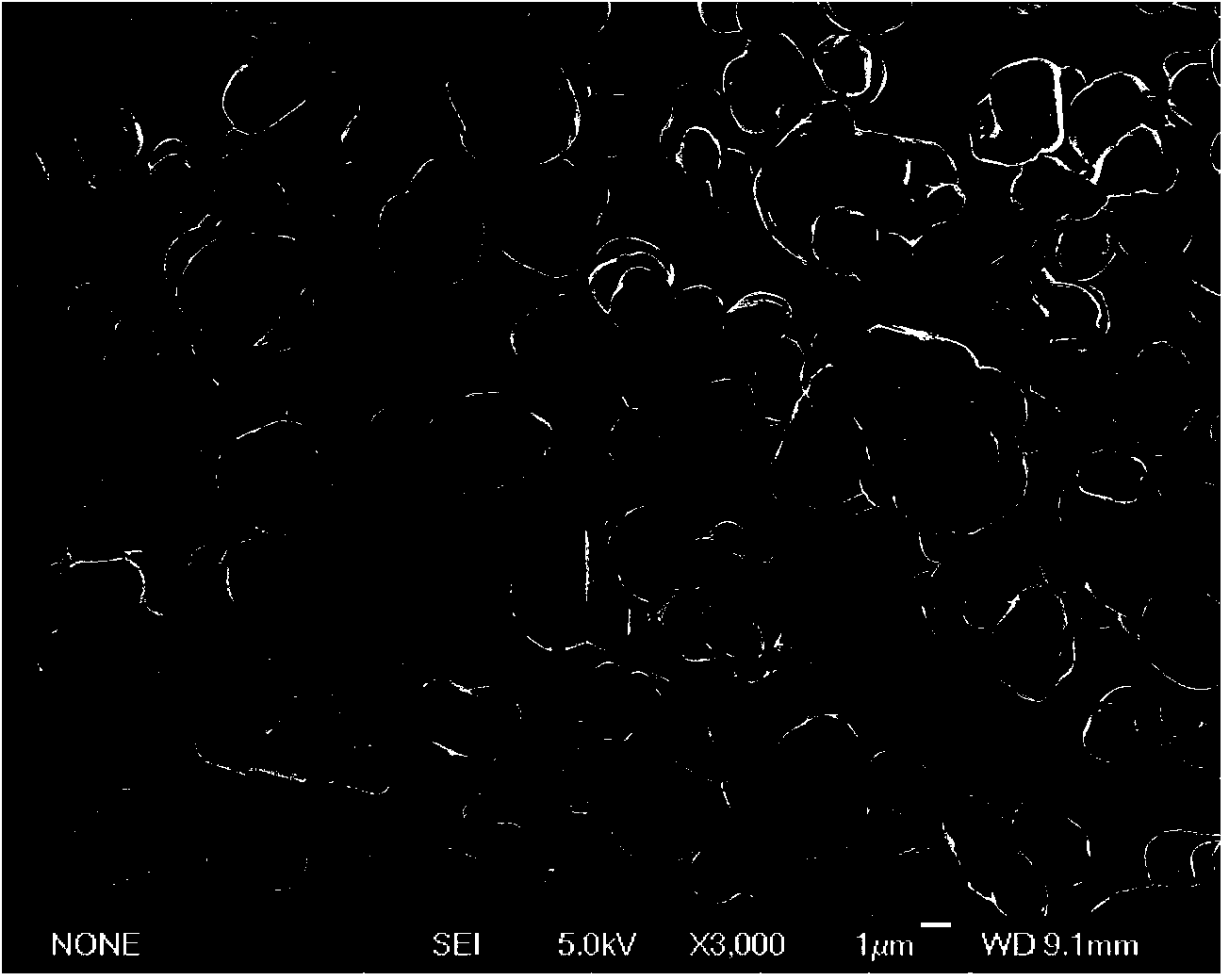

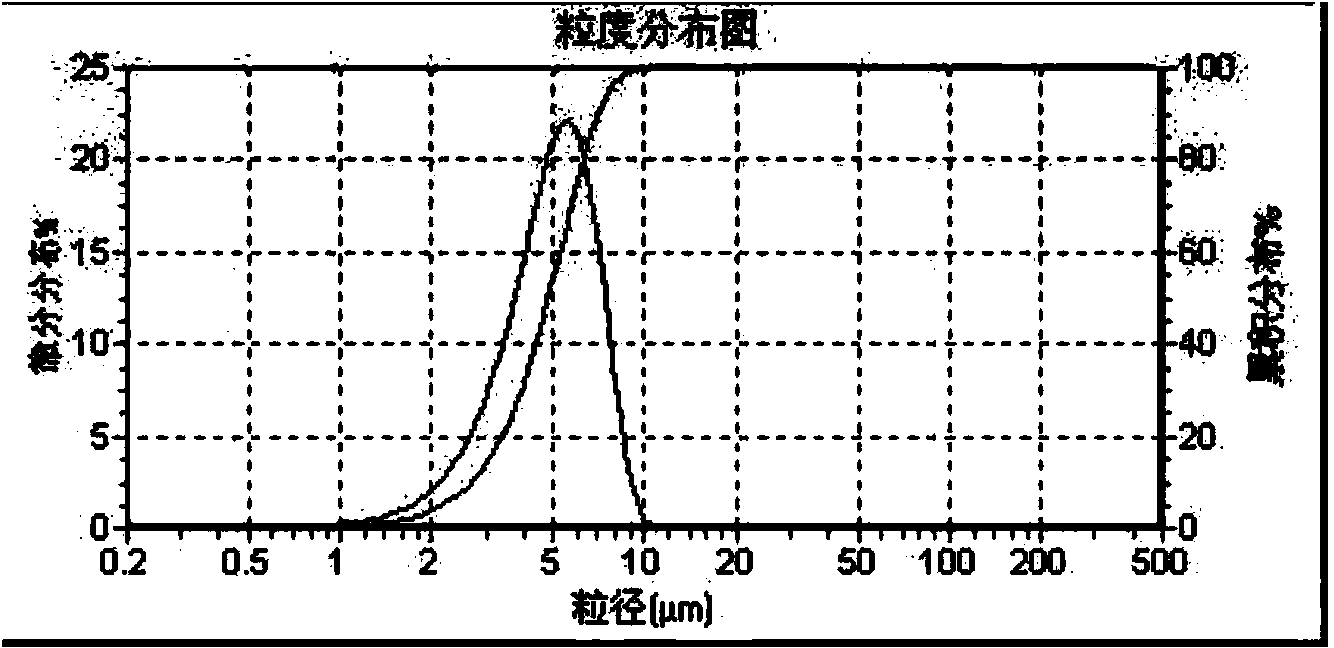

Image

Examples

Embodiment 1

[0028] A surface modification technology for lithium-ion battery cathode materials, completed by the following steps:

[0029] (1) adding nickel cobalt lithium manganese oxide and its doped modified derivatives into diethyl carbonate according to the weight ratio of 1:4 and stirring for 30min;

[0030] (2) filtering the solid-liquid mixture until obtaining a solid filter cake with an organic solvent content of 10%;

[0031] (3) The filter cake was heat-treated at 500° C. for 4 hours to obtain the desired product.

Embodiment 2

[0033] A surface modification technology for lithium-ion battery cathode materials, completed by the following steps:

[0034] (1) Nickel cobalt lithium manganese oxide was added into the mixture of ethyl methyl carbonate and dimethyl carbonate according to the weight ratio of 1:5 and stirred for 70min;

[0035] (2) filtering the solid-liquid mixture until obtaining a solid filter cake with an organic solvent content of 8.5%;

[0036] (3) The filter cake was heat-treated at 650° C. for 4.5 hours to obtain the desired product.

Embodiment 3

[0038] A surface modification technology for lithium-ion battery cathode materials, completed by the following steps:

[0039] (1) Lithium cobaltate is added to the mixture of ethylene carbonate and dimethyl carbonate according to the weight ratio of 1:2 and stirred for 60min;

[0040] (2) filtering the solid-liquid mixture until obtaining a solid filter cake with an organic solvent content of 15%;

[0041] (3) The filter cake is heat-treated at 100° C. for 5 hours to obtain the desired product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com