High-energy-density lithium-ion battery and preparation method thereof

A lithium-ion battery and energy technology, which is used in secondary batteries, battery electrodes, battery pack components, etc. Large gas volume and other problems, to achieve good electrical conductivity, good electrical conductivity, and the effect of reducing the expansion of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

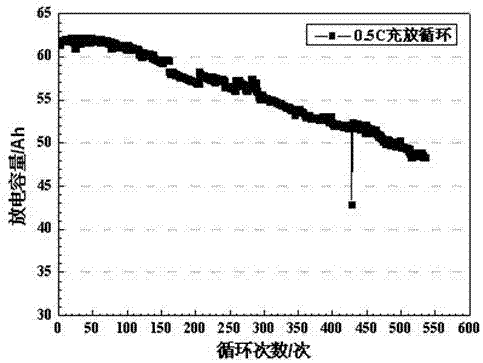

[0025] 100140200-60Ah-3.7V high specific energy lithium-ion battery preparation, first 80kg positive electrode active material nickel cobalt lithium aluminate (LiNi 0.88 co 0.08 al 0.04 o 2 ), 18.9kg lithium iron manganese phosphate (LiFe 0.4 mn 0.6 PO 4 ), 25kg of single-armed carbon nanotube conductive liquid (the solvent is N-methylpyrrolidone NMP single-armed carbon nanotube solution with a solid content of 0.4%), 1kg of binder polyvinylidene fluoride (PVDF), 30kg of N-methylpyrrolidone (NMP ) into a 100L mixer to mix and disperse evenly, and coat on a (12±1) μm thick aluminum foil current collector, and coat both sides with a density of (500±4) g / m 2 , the thickness of the roll is (155±3) μm, and cut to obtain a positive electrode sheet with a length*width of the material area of 180mm*134mm. Then carry out the preparation of high specific energy lithium-ion battery negative plate, 4.9kg nano-silicon (Si), 44.1kg artificial graphite (C), 25kg single-armed carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com