Method for preparing nanospherical ferrosilicon red-coated pigment by microwave hydrothermal method

A technology of microwave hydrothermal method and encapsulation of color materials, which is applied in the field of ceramic color materials, can solve the problems of unsuitable for high efficiency and environmental protection, large product particle size, long heat preservation time, etc., achieve low synthesis temperature, simple process, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

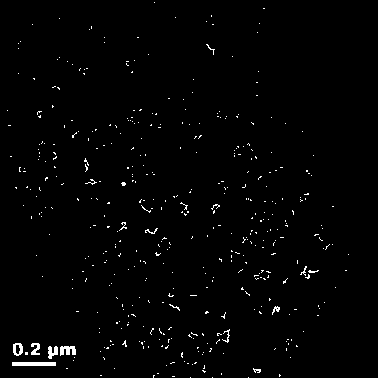

Embodiment 1

[0024] Step 1: Measure 30 ml of deionized water into a beaker, add 0.29 g of ferric chloride (FeCl 3 ·6H 2 0), stirring at room temperature with a constant temperature magnetic stirrer makes it dissolve completely;

[0025] Step 2: Add 0.18g of borax to the solution in the previous step, and continue stirring for 10 min;

[0026] Step 3: Mix 5.71 g tetraethyl orthosilicate (as SiO 2 content ≥ 28.4%) was added dropwise to the solution obtained in the previous step, then NaOH solution with a concentration of 3 mol / L was added dropwise to adjust the pH to 9, the temperature of the magnetic stirrer was set to 40 °C, and the stirring was continued for 120 min;

[0027] The fourth step: transfer the obtained mixed solution to a reaction kettle with a volume of 100 ml, add deionized water dropwise, so that the total volume of the solution is 50 ml, put it into a microwave hydrothermal reaction kettle for reaction, and the reaction temperature is 180℃, holding time is 90 minutes; ...

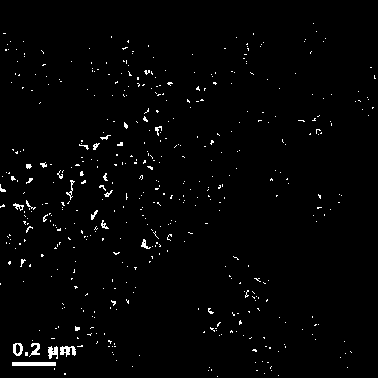

Embodiment 2

[0030] Step 1: Measure 35 ml of deionized water into a beaker, add 0.46 g of ferric chloride (FeCl 3 ·6H 2 0), stirring at room temperature with a constant temperature magnetic stirrer makes it dissolve completely;

[0031] Step 2: Add 0.18 g of borax to the solution in the previous step, and continue stirring for 10 min;

[0032] Step 3: Mix 5.54 g tetraethyl orthosilicate (as SiO 2 content ≥ 28.4%) was added dropwise to the solution obtained in the previous step, then NaOH solution with a concentration of 3 mol / L was added dropwise to adjust the pH to 7, the temperature of the magnetic stirrer was set to 40 °C, and the stirring was continued for 120 min;

[0033] The fourth step: transfer the obtained mixed solution to a reaction kettle with a volume of 100 ml, add deionized water dropwise, so that the total volume of the solution is 50 ml, put it into a microwave hydrothermal reaction kettle for reaction, and the reaction temperature is 200℃, holding time is 90 minutes; ...

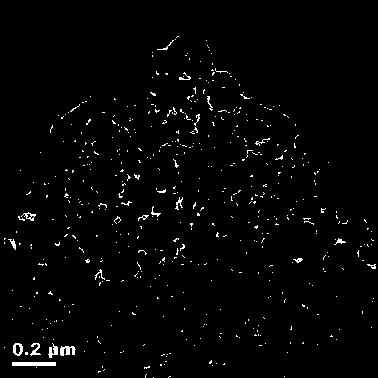

Embodiment 3

[0036] Step 1: Measure 33 ml of deionized water into a beaker, add 0.86 g of ferric chloride (FeCl 3 ·6H 2 0), stirring at room temperature with a constant temperature magnetic stirrer makes it dissolve completely;

[0037] Step 2: Add 0.18 g of borax to the solution in the previous step, and continue stirring for 10 min;

[0038] The third step: add 5.14 g tetraethyl orthosilicate (as SiO 2 content ≥ 28.4%) was added dropwise to the solution obtained in the previous step, then NaOH solution with a concentration of 3 mol / L was added dropwise to adjust the pH to 11, the temperature of the magnetic stirrer was set to 40 °C, and stirring was continued for 120 min;

[0039] The fourth step: transfer the obtained mixed solution to a reaction kettle with a volume of 100 ml, add deionized water dropwise, so that the total volume of the solution is 50 ml, put it into a microwave hydrothermal reaction kettle for reaction, and the reaction temperature is 210°C, the holding time is 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com