Yellow sintered landscape brick and production method thereof

A production method and landscape technology, applied in the field of building materials, can solve the problems of low compressive and flexural strength, limited scale use, long maintenance period, etc., and achieve good slag resistance, improved sintering performance, and improved wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

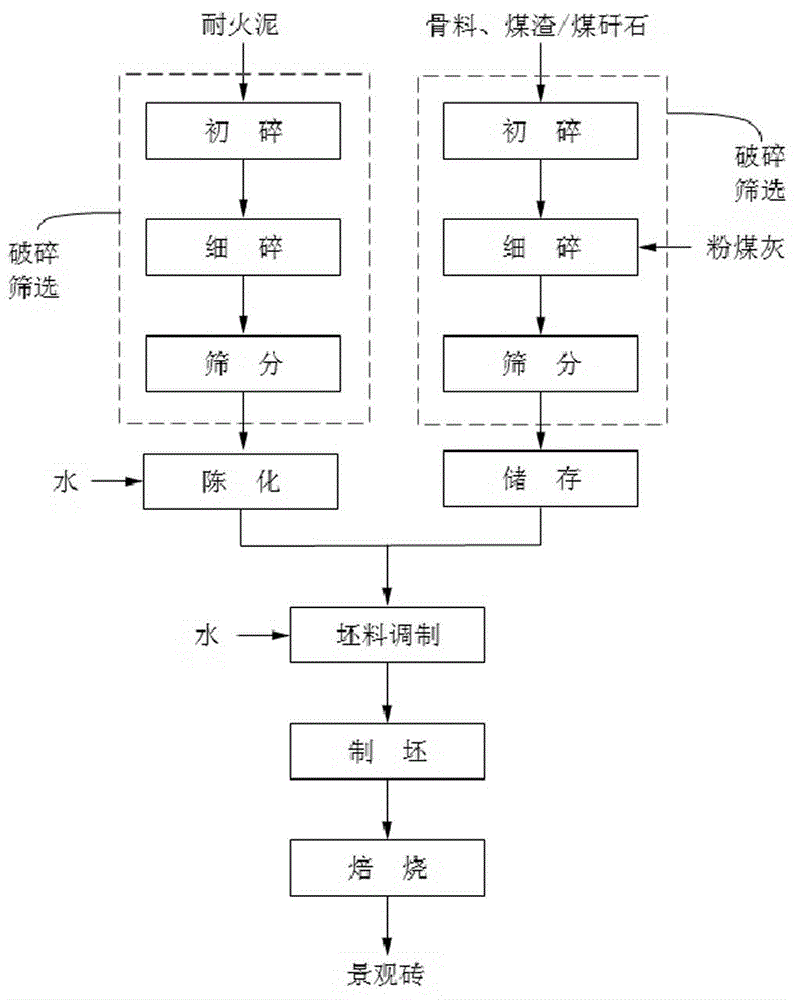

Method used

Image

Examples

Embodiment 1

[0036] Pour the mined refractory mud into the crusher silo, the refractory mud and quartz sand after the initial crushing of the crusher are respectively transported by the belt conveyor to the sanding machine for further fine crushing, and then transported by the belt conveyor to the screen for 9 purposes Drum screening, the part that leaks is the particle size that meets the requirements, the refractory mud is transported by the belt conveyor to the silo for aging and storage, and the quartz sand is transported to the silo for storage; the part that is not leaked is the part that does not meet the required particle size. It is transported back to the sanding machine by a belt conveyor to be finely crushed. Take the 3200kg refractory mud and 4800kg quartz sand obtained by crushing and screening and send it to the mixer, add water and mix evenly to obtain a billet with a moisture content of 6%; the billet is pressed by a press to obtain a solid landscape brick; the landscape bri...

Embodiment 2

[0038] Pour the hard refractory mud, quartz ore, and chromium slag obtained by mining into the crusher silo. The hard refractory mud, quartz ore, and chromium slag are respectively transported by the belt conveyor to the sanding machine after being crushed by the crusher. It is finely crushed, and then transported by a belt conveyor to a screen for 12-mesh vibrating screening. The leakage part is the required particle size. The hard refractory mud is transported by the belt conveyor to the silo for aging and storage, quartz ore, chromium slag They are transported to the silo for storage; the part that is not missed is the part that does not meet the required particle size, and is transported back to the sander by the belt conveyor to be finely crushed. Take the crushed and screened 2100kg hard refractory mud, 2100kg quartz ore and 2800kg chromium slag and send it to the mixer, add water and mix evenly to obtain a billet with a moisture content of 7%; the billet is pressed by a p...

Embodiment 3

[0040] Pour the semi-hard refractory mud, waste clay bricks and coal gangue obtained from the excavation into the crusher silo. The hard refractory mud, waste clay bricks and coal gangue are respectively transported to the crusher by the crusher. The sanding machine is further finely crushed, and then transported by the belt conveyor to the screen for vibrating screening with 10 meshes. The leakage part is the required particle size. The semi-hard refractory mud is transported by the belt conveyor to the silo for aging and storage. The waste clay bricks and coal gangue are transported to the silo for storage; the part that does not leak is the part that does not meet the required particle size, and is transported back to the sand blower by the belt conveyor to be finely broken. Take the 2100kg of this hard refractory clay, 3000kg waste clay bricks and 900kg coal gangue obtained by crushing and screening, and send them to the mixer, add water and mix uniformly to obtain a billet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com