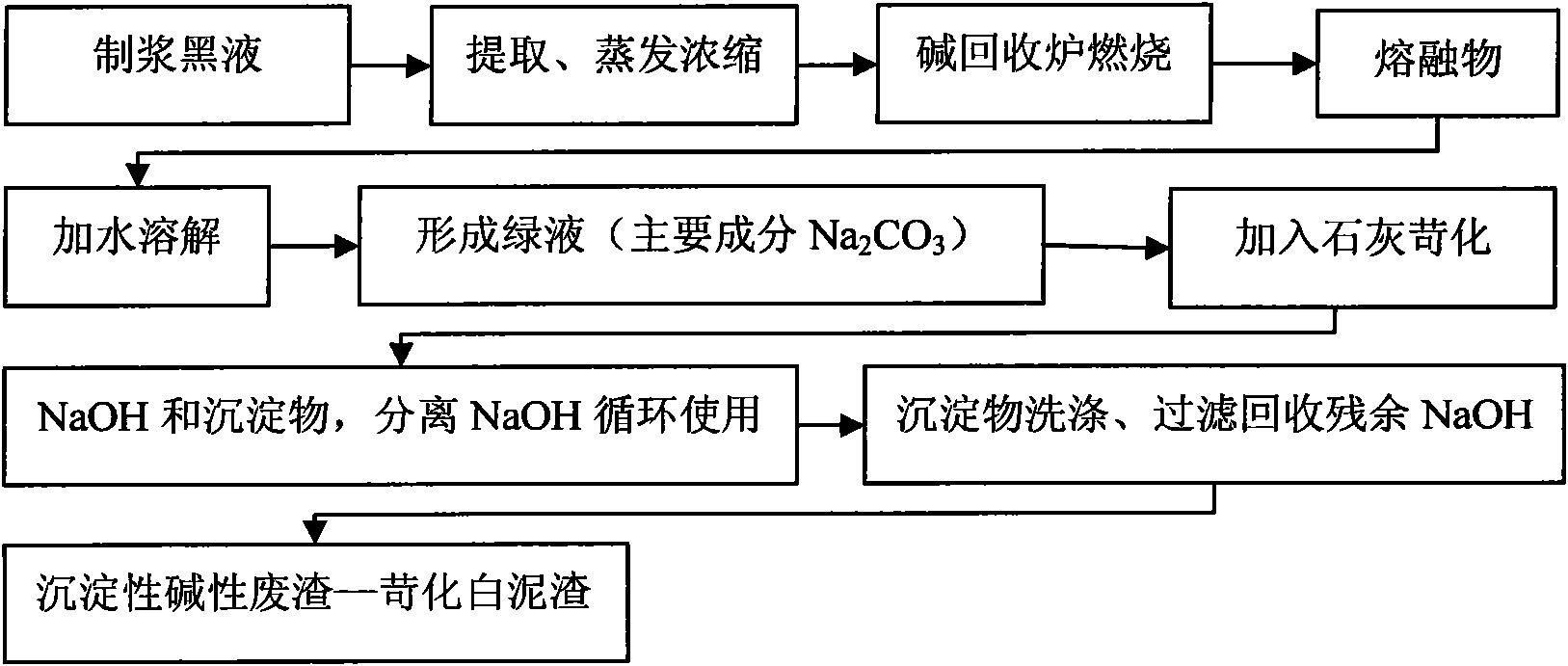

Method for preparing high-strength ceramic wall material from papermaking causticized white mud residues

A technology of causticizing white mud and wall materials, which is applied in the field of preparing new building wall materials, can solve the problems of scarce patent discussion and difficulty in popularization, and achieve saving of cultivated land resources, reduction of burning heat consumption and production costs, and significant application The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

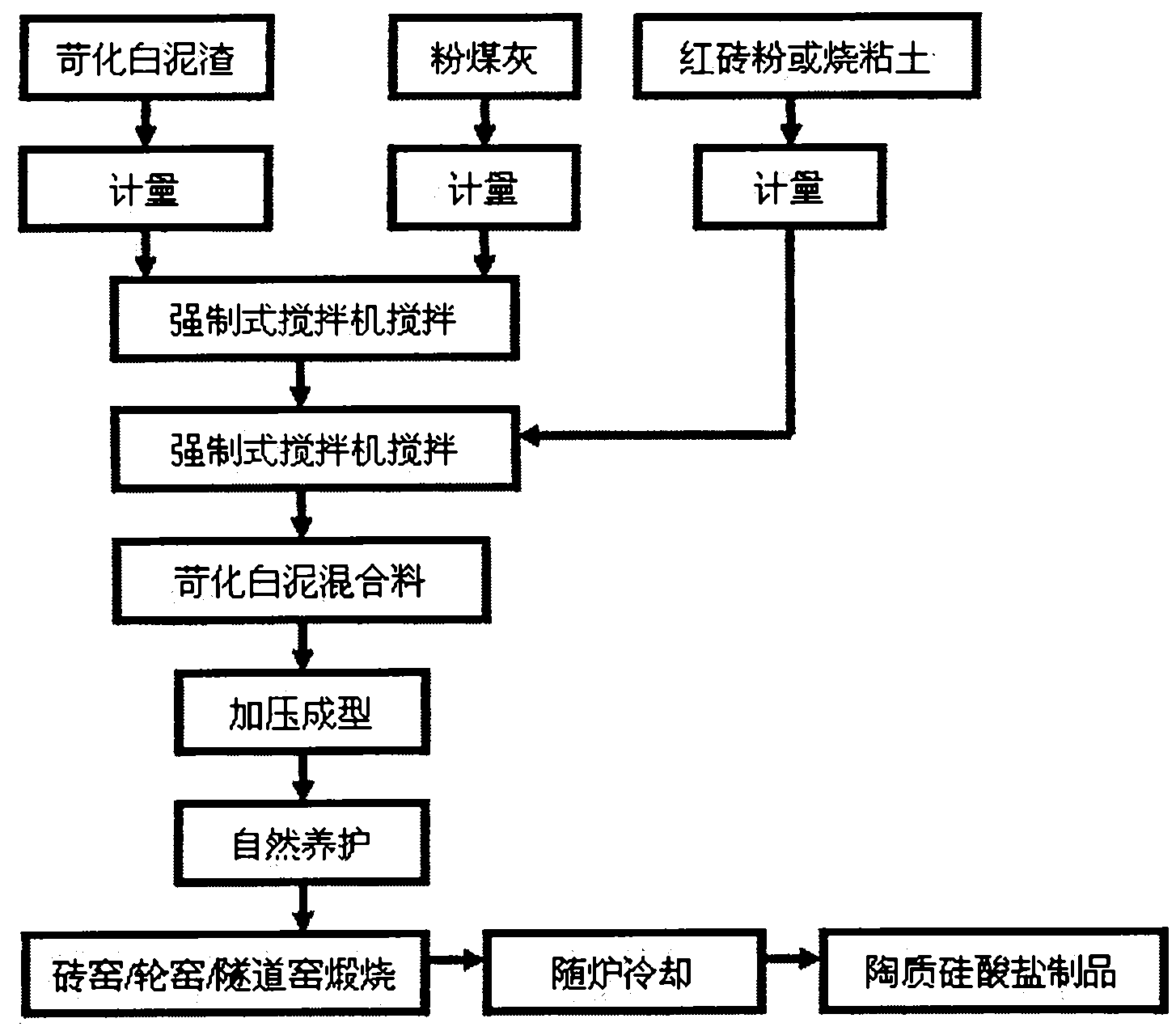

[0046] to combine figure 2 , the method for preparing high-strength ceramic wall material from papermaking causticizing white mud slag of the present invention, the steps are as follows:

[0047] Step 1: Put 500kg of wet causticizing white mud slag and 75kg of fly ash into the mixer and stir for 4 minutes. When the mixture is in a uniform state, add 75kg of red brick powder and continue stirring for 3 to 4 minutes. When the mixture is uniformly mixed;

[0048] The second step: put the causticized white mud mixture obtained in the first step directly into the mold of the brick forming machine, pressurize at 10MPa, and obtain a shaped brick with a standard brick size of 240*115*53mm;

[0049] Step 3: Stack the adobe formed in the second step in a well-ventilated yard for about 7 days, until the adobe no longer loses weight and has an initial compressive strength above 1MPa, and can be transported into the kiln for calcination;

[0050] Step 4: Put the adobe obtained in Step 3...

Embodiment 2

[0052] to combine figure 2 , the method for preparing high-strength ceramic wall material from papermaking causticizing white mud slag of the present invention, the steps are as follows:

[0053] Step 1: Put 500kg of wet causticizing white mud slag and 150kg of fly ash into the mixer and stir for 8 minutes. When the mixture is in a uniform state, add 150kg of red brick powder and continue stirring for 4 minutes. The mixture is uniformly mixed;

[0054] The second step: put the causticized white mud mixture obtained in the first step directly into the mold of the brick forming machine, pressurize at 20MPa, and obtain a shaped brick with a standard brick size of 240*115*53mm;

[0055] Step 3: Stack the adobe formed in the second step in a well-ventilated yard for about 7 days, until the adobe no longer loses weight and has an initial compressive strength above 1MPa, and can be transported into the kiln for calcination;

[0056] Step 4: Put the adobe obtained in the third step...

Embodiment 3

[0058] to combine figure 2 , the method for preparing high-strength ceramic wall material from papermaking causticizing white mud slag of the present invention, the steps are as follows:

[0059] Step 1: Put 500kg of wet causticizing white mud slag and 75kg of fly ash into the mixer and stir for 4 minutes. When the mixture is in a uniform state, add 75kg of burnt clay and continue stirring for 3 minutes. At this time, mix The material is uniformly mixed;

[0060] The second step: put the causticized white mud mixture obtained in the first step directly into the mold of the brick forming machine, pressurize at 15MPa, and obtain a shaped brick with a standard brick size of 240*115*53mm;

[0061]Step 3: Stack the adobe formed in the second step in a well-ventilated yard for about 7 days, until the adobe is no longer reduced in weight and has an initial compressive strength above 1MPa, and can be transported into the kiln for calcination;

[0062] Step 4: Send the adobe obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com