Filling fire clay for assembling tundish upper water gate iron shell and preparation method thereof

An iron shell and fire clay technology is applied in the field of filling fire clay for assembling the iron shell of the tundish nozzle and its preparation, and can solve the problems of large equipment accidents, damage to the mechanism, and steel seepage in the gap between the nozzle and the seat brick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

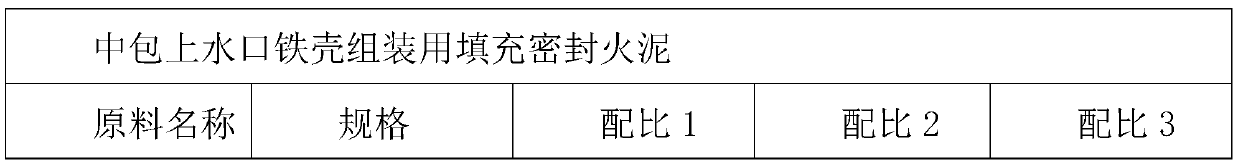

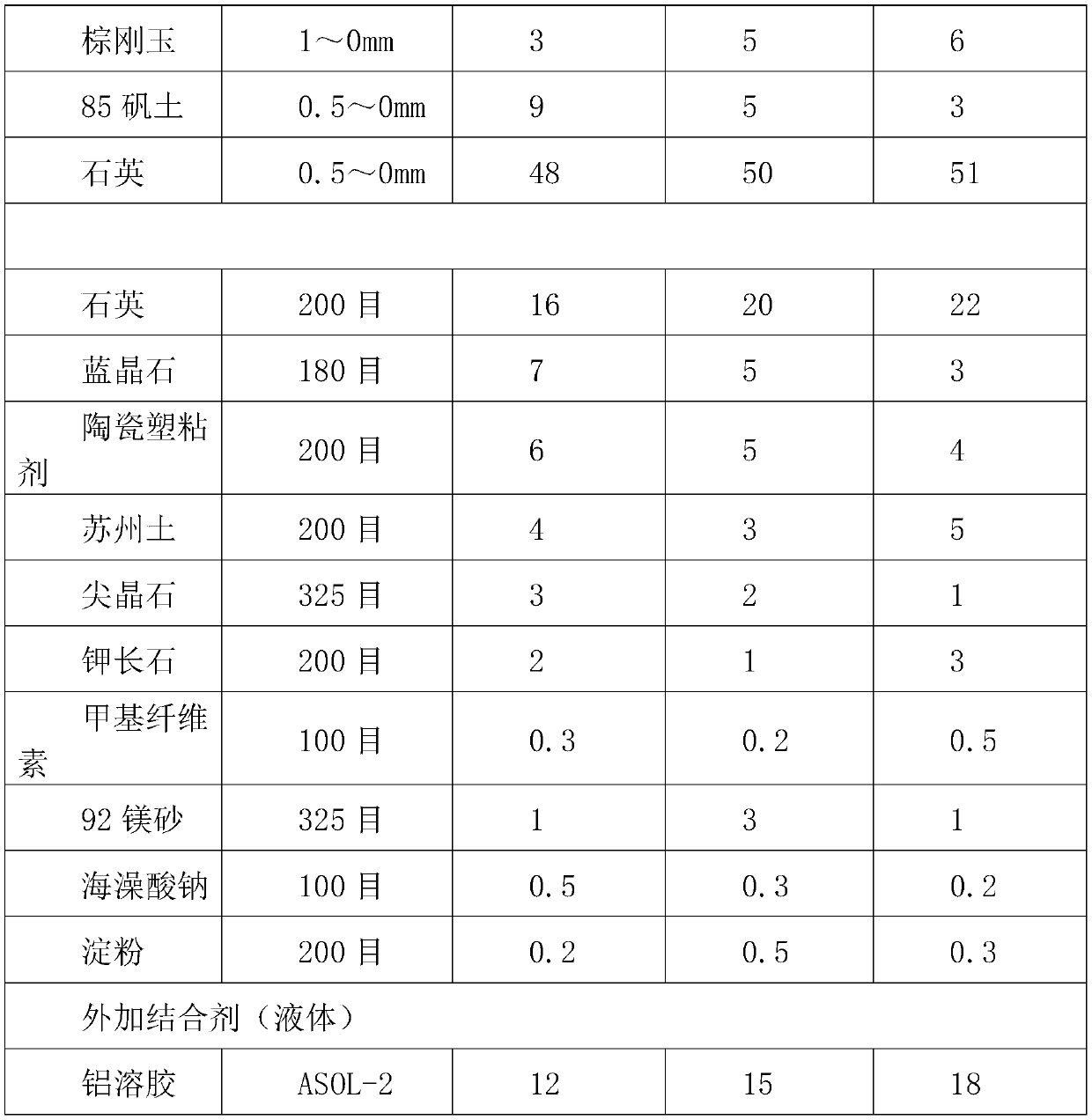

[0022] Filling fire clay for tundish upper nozzle iron shell assembly, containing the following components: brown corundum, 85 bauxite, quartz, kyanite, ceramic plastic adhesive, Suzhou soil, spinel, potassium feldspar, methyl cellulose , 92 magnesia, sodium sea bath, starch, aluminum sol; the weight percentage of each component: brown corundum 3~7%, 85 bauxite 3~7%, quartz 65~75%, kyanite 3~7%, ceramic plastic adhesive 3~7%, Suzhou soil 2~5%, spinel 1~3%, potassium feldspar 1~2%, methyl cellulose 0.1~0.3%, 92 magnesia 2 ~ 5%, sodium sea bath 0.2 ~ 0.5%, starch 0.3 ~ 0.7%, aluminum sol 12 ~ 18%.

[0023] Brown corundum: Al2O3 content ≥95.0%, Fe2O3 content <1%, SiO2 content ≤1.20%, TiO2 content <3.8%, bulk density ≥3.8g / m3;

[0024] 85 Bauxite: Al2O3 content ≥85.0%, Fe2O3 content <1.8%, TiO2 content <4.0%, bulk density ≥3.15g / m3;

[0025] Quartz: SiO2 content ≥97%, Fe2O3 content <0.5%, kyanite Al2O3 content ≥55.0%, Fe2O3 content <1.5%, TiO2 content ≤2%;

[0026] Bulk density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com