Dispersion type integral steel ladle bottom blowing air brick as well as forming process and application method thereof

A kind of breathable brick and integral technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of low service life, uneven ventilation, and small air flow of diffused breathable bricks, and achieve the improvement of inclusions Removal rate, effect of reducing crack problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

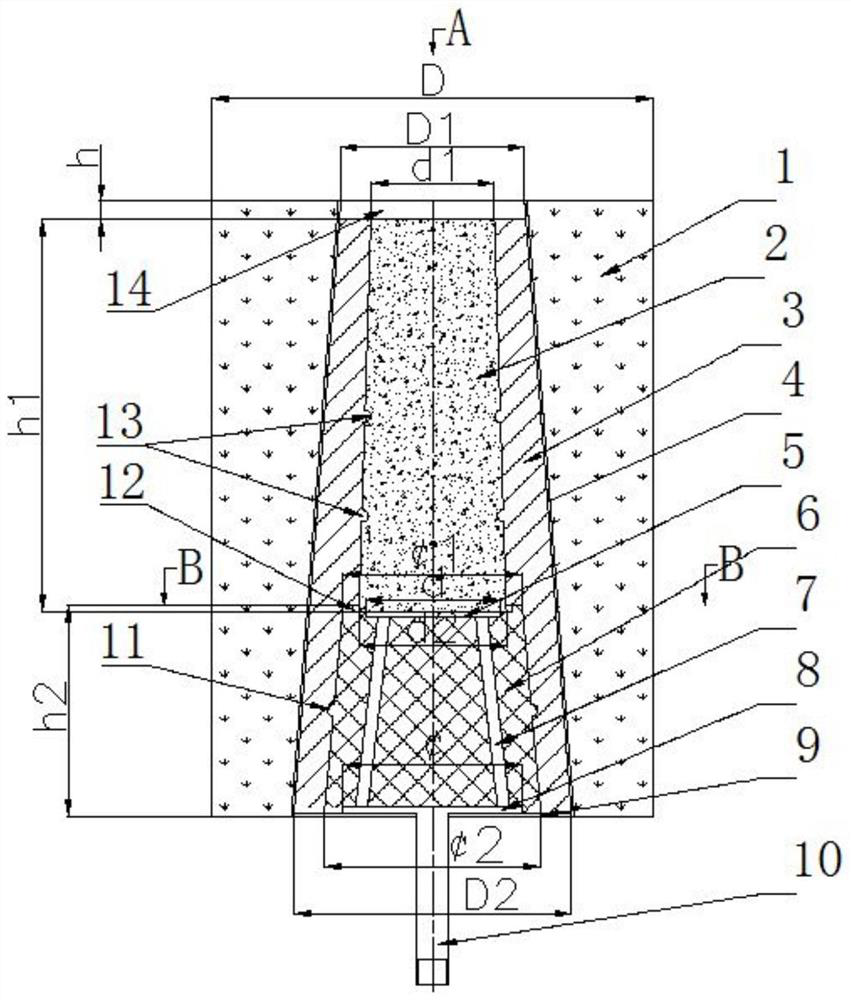

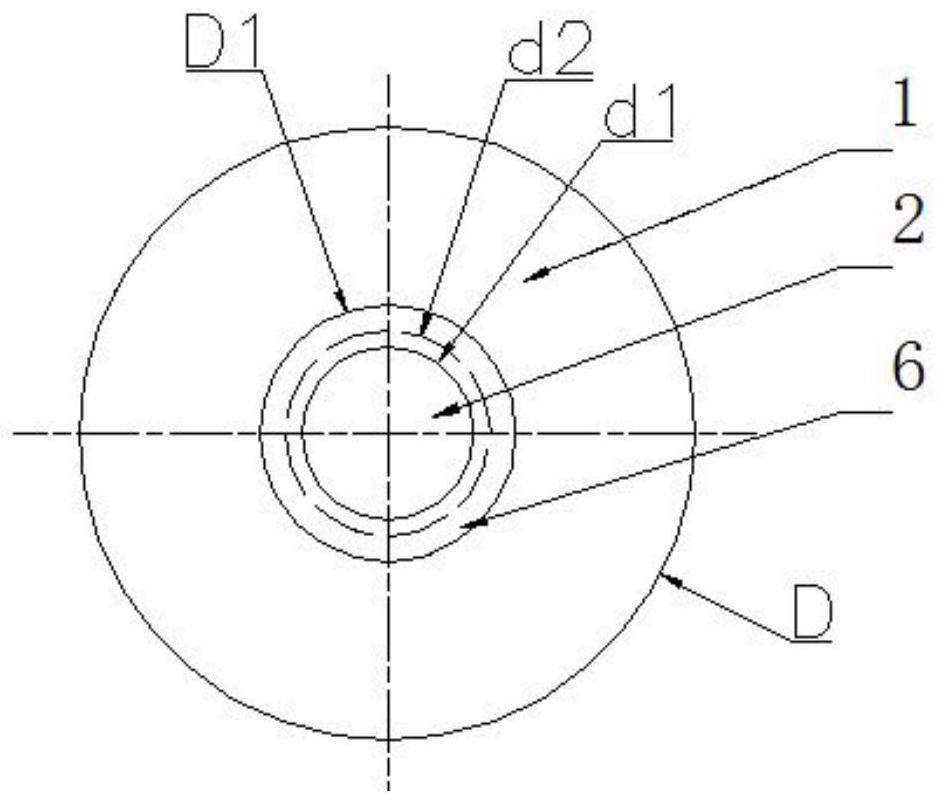

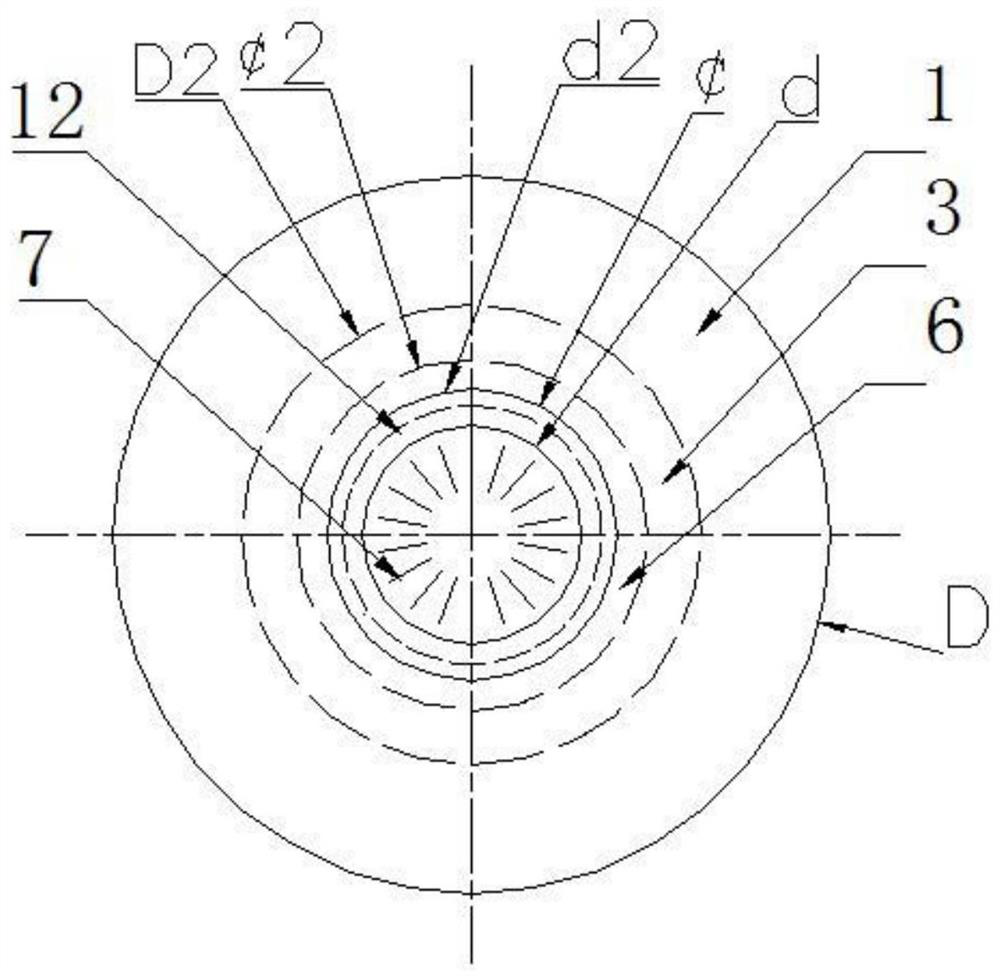

[0042] A kind of diffuse type integral ladle bottom blowing breathable brick, such as Figure 1-Figure 4 As shown, it includes the ladle bottom blowing vent brick body 1, diffuse venting plug 2, protective body 3, steel shell 4, upper air chamber 5, safety warning device 6, slit air passage 7, lower air chamber 8, and bottom cover plate 9. The air intake pipe 10, the lower part of the diffusion-type venting plug 2 is positioned in the positioning groove 12 on the upper part of the safety warning device 6, and the safety warning device 6 is provided with a plurality of slits arranged in a circular cross-section and "eight" in the longitudinal section The air passage 7, the upper end of the slit air passage 7 communicates with the upper air chamber 5, the lower end of the slit air passage 7 communicates with the lower air chamber 8, and the periphery of the diffusion type ventilation plug 2 and the safety warning device 6 is provided with a protective body 3, The outer surface o...

Embodiment 2

[0061] As described in Example 1, the diffuse type integral ladle bottom blowing air brick is different in that:

[0062] The diffusion-type ventilation plug 2 is in the shape of a truncated cone as a whole, the diameter d1 of the upper bottom is 110 mm, and the diameter d2 of the lower bottom is 130 mm. The height h1 of the diffusion-type ventilation plug 2 used for the new working lining of the ladle and the repairing working lining is different, wherein The height h11 for the new working lining of the ladle is 520mm, and the height h12 for the repairing working lining of the ladle is 470mm.

[0063] The safety warning device 6 is in the shape of a truncated cone as a whole, the diameter of the upper bottom ¢1 is 155 mm, the diameter of the lower bottom ¢2 is 185 mm, and the height h2 is 130 mm.

[0064] The upper air chamber 5 is cylindrical, the diameter d of the bottom surface is 115mm, and the height of the cylinder is set according to the required air flow.

[0065] Th...

Embodiment 3

[0077] As described in Example 1, the diffuse type integral ladle bottom blowing air brick is different in that:

[0078] The diffusion-type ventilation plug 2 is in the shape of a truncated cone as a whole, the diameter d1 of the upper bottom is 120 mm, and the diameter d2 of the lower bottom is 140 mm. The height h1 of the diffusion-type ventilation plug 2 used for the new working lining of the ladle and the repairing working lining is different, wherein The height h11 for the new working lining of the ladle is 530mm, and the height h12 for the working lining of the ladle repair is 480mm.

[0079] The safety warning device 6 is in the shape of a truncated cone as a whole, the diameter of the upper bottom ¢1 is 165 mm, the diameter of the lower bottom ¢2 is 195 mm, and the height h2 is 150 mm.

[0080] The upper air chamber 5 is cylindrical, the diameter d of the bottom surface is 120mm, and the height of the cylinder is set according to the required air flow.

[0081] The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com