Luxurious stone glaze ceramic tile and production method thereof

A production method and a technology for perfecting stone glaze are applied in the field of architectural decoration materials, which can solve the problems of large amount of ink and glaze, low definition, and reduction of dark ceramic tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

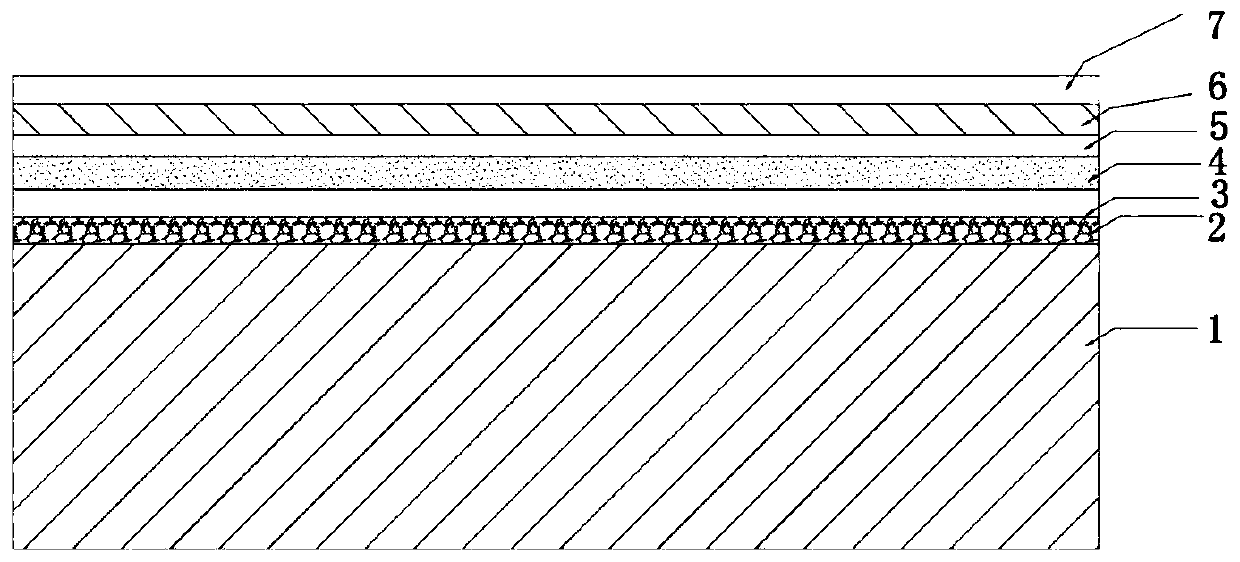

[0024] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of a stone-glazed ceramic tile proposed according to the present invention are described in detail as follows.

[0025] Such as figure 1 As shown, the production method of a kind of stone-glazed ceramic tile according to the present invention comprises the following steps.

[0026] (1) Sprinkle make-up soil on the surface of the green body layer to form a make-up soil layer.

[0027] (2) Drizzle the bottom glaze on the make-up soil layer to form a bottom glaze layer.

[0028] (3) Spray anti-ink penetration oil on the surface of the bottom glaze layer to form an anti-ink penetration layer.

[0029] (4) Ink-jet printing on the surface of the anti-ink penetration layer to form a pattern layer.

[0030] (5) Print the printing paste on the surface of the pattern layer with a roller to form an isolation layer.

[0031] (6) Spray pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com