Patents

Literature

31results about How to "Delicate glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

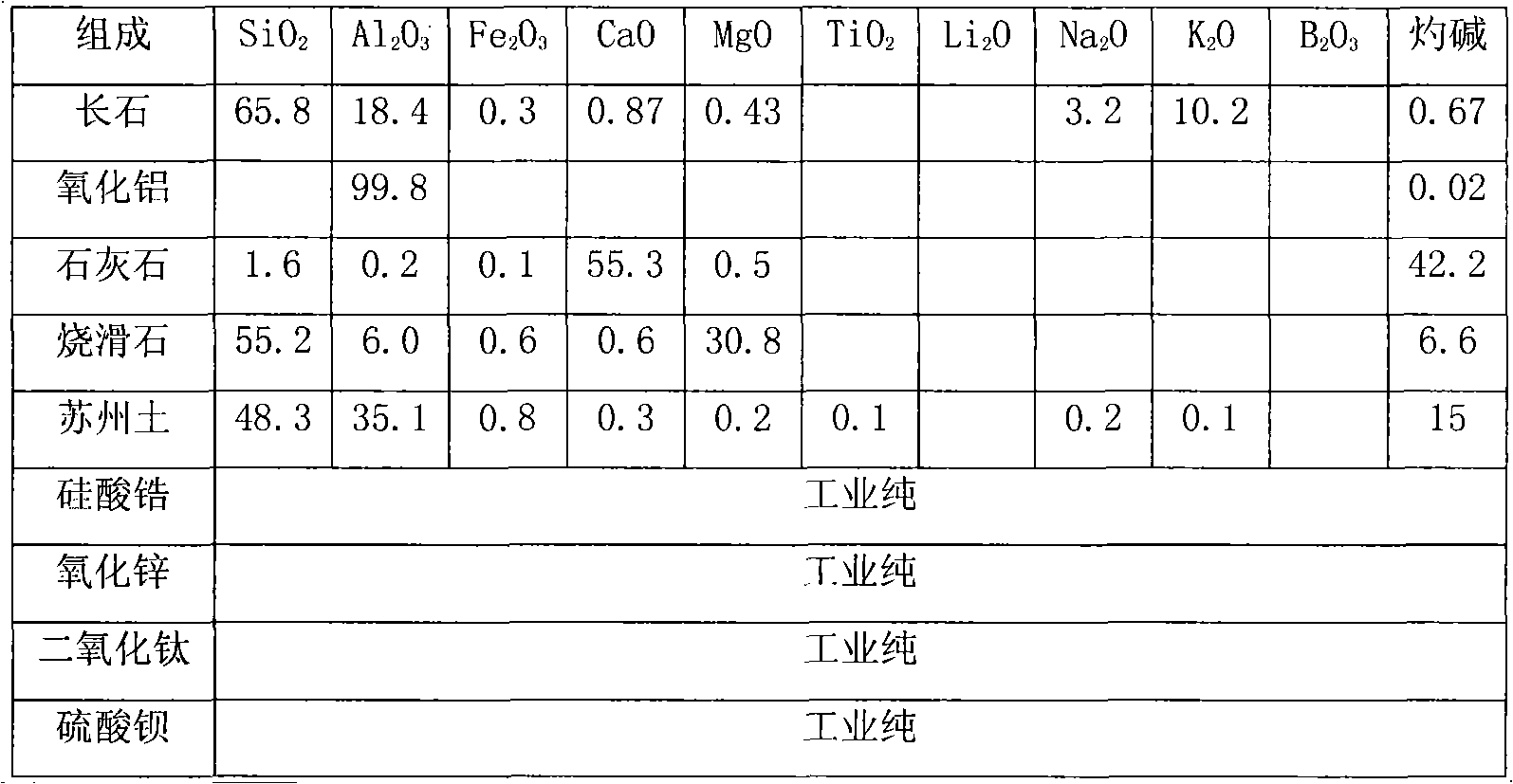

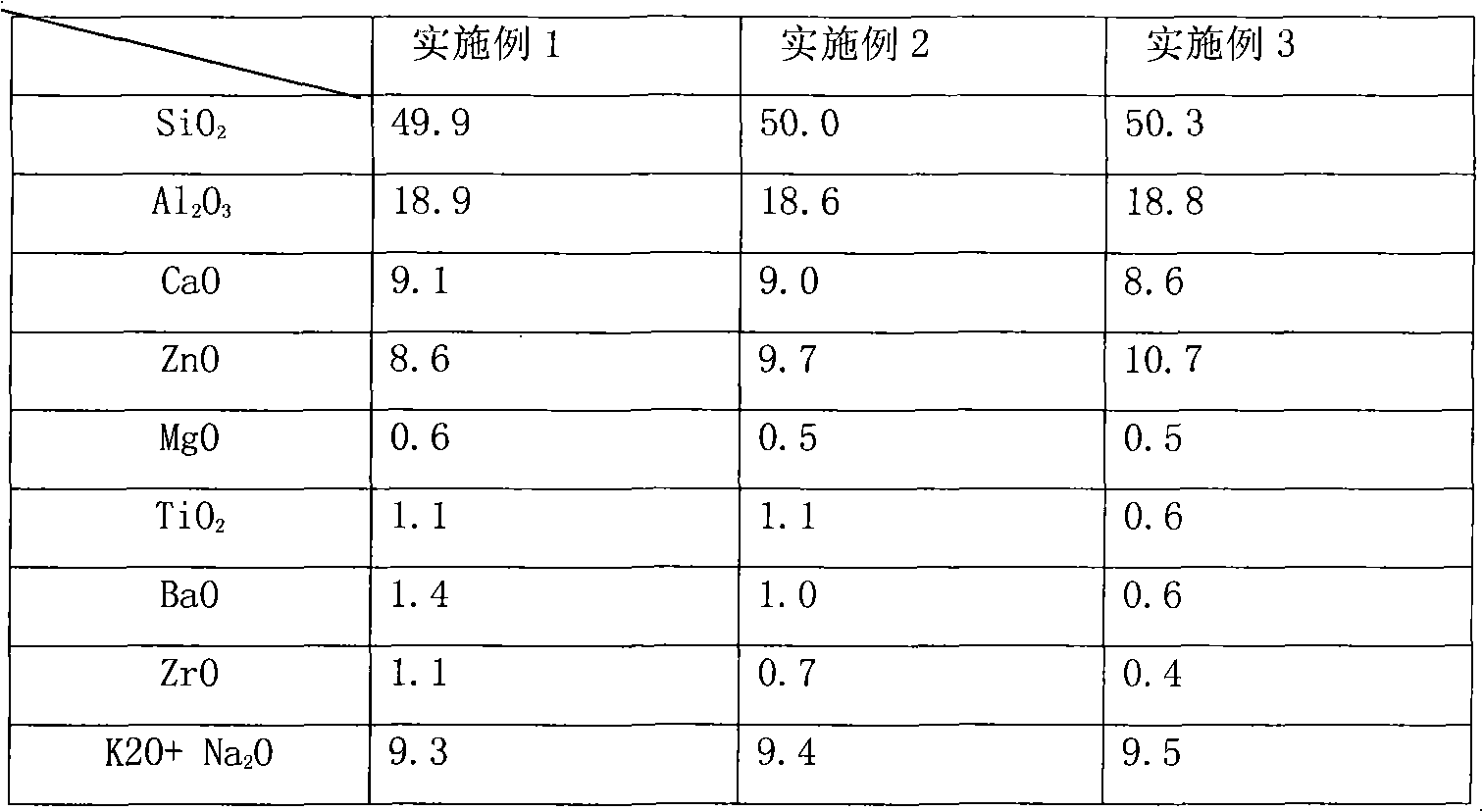

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

Bone matte glaze and method for manufacturing bone china product by using same

The invention relates to bone matte glaze. The bone matte glaze comprises, by weight, 100 parts of frits, 3-8 parts of clay, 2-12 parts of aedelforsite, 3-6 parts of aluminum oxide, 6-15 parts of zinc oxide and 6 parts of stannic oxide. The frits comprise, by weight, 16-24 parts of quartz, 28-38 parts of potash feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 0-10 parts of zinc oxide, 0-3 parts of talcum, 0-12 parts of calcite and 0-0.5 part of zirconium silicate. The glaze surface of a product using the glaze is fine, smooth, resistant to pollution, resistant to acid and alkali, easy to wash and suitable for the decoration means such as decal. The invention further provides a method for manufacturing the bone china product by using the bone matte glaze. The method is simple in firing process, stable in production and good in benefit.

Owner:GUANGDONG SONGFA CERAMICS

Green domestic porcelain

InactiveCN101555126AIncrease the amount addedGood light transmissionClaywaresLithiumSodium Bentonite

The invention provides green domestic porcelain, a porcelain body of which comprises the following components in terms of weight percentage: 18-22% of Hunan feldspar, 9-13% of riped quartz, 8-12% of Zijin silica, 3-5% of bentonite, 18-24% of kaolin braying and 33-37% of weathering potash feldspar; porcelain glaze thereof comprises the following components in terms of weight percentage: 21-23% of waste porcelain powder, 9-11% of Hunan feldspar, 4-6% of lithium porcelain stone powder, 24-26% of quartz, 9-11% of kaoline, 4-6% of zinc oxide, 10-12% of dolomite and 11-13% of calcite. The green domestic porcelain has subtle glaze, crystal and transparent texture and white and green color, and presents the impression of glass colors. The green domestic porcelain adds assortment of the domestic porcelains, solves the problem of dull coloring and conforms to the consumption concept of consumers.

Owner:CHAOZHOU XINYUE CERAMICS MFG

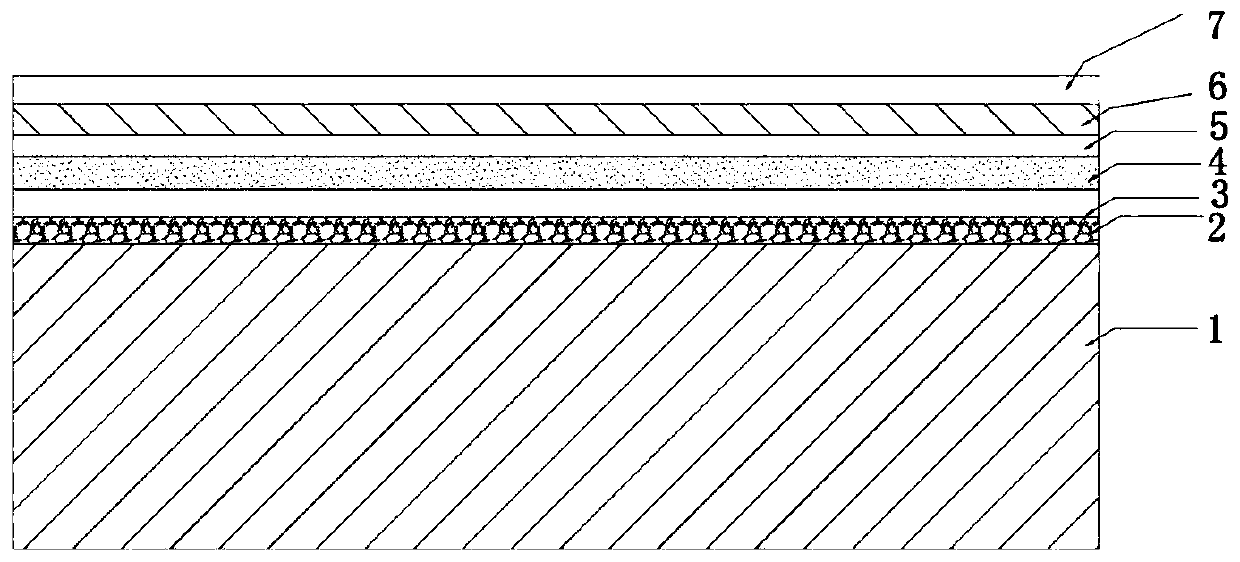

Luxurious stone glaze ceramic tile and production method thereof

The invention relates to a luxurious stone glaze ceramic tile and a production method thereof. The method comprises the steps that engobe, ground glaze, ink permeation resistant oil, a pattern layer,an isolation layer and a protective glaze layer are sprayed to the surface of a green body layer in sequence, then the ceramic tile obtained in the above steps is subjected to high-temperature firingto prepare the luxurious stone glaze ceramic tile, wherein the thickness of the glaze layer in the stone glaze ceramic tile is 0.5-1.0 mm; in the ceramic tile, permeation and diffusion of ink are controlled through a special glaze formula in combination with the ink permeation-resistant layer and the isolation layer, which have an isolation effect, so that a fine and high-definition glazed ceramictile is obtained, and the smooth texture and effect are introduced into a ceramic tile product. The luxurious ceramic tile is smooth and fine in glaze surface, is pure in color development, has clearlines, has antifouling and wear-resisting properties, and is a ceramic tile product with great practical value.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

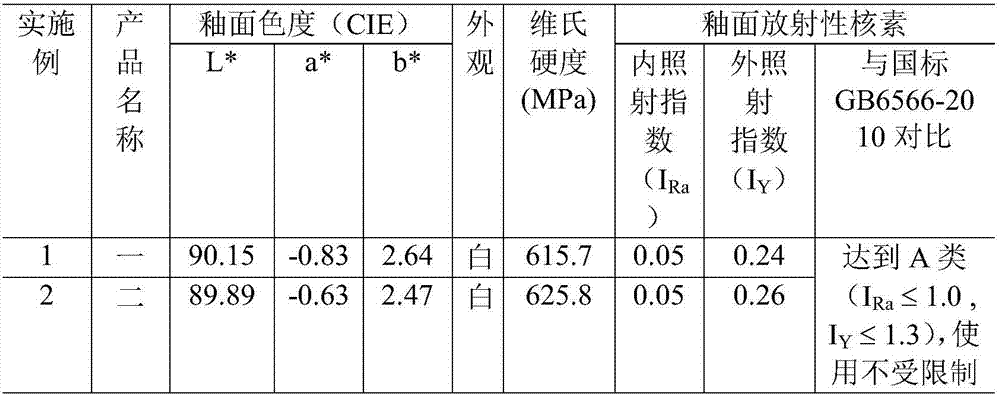

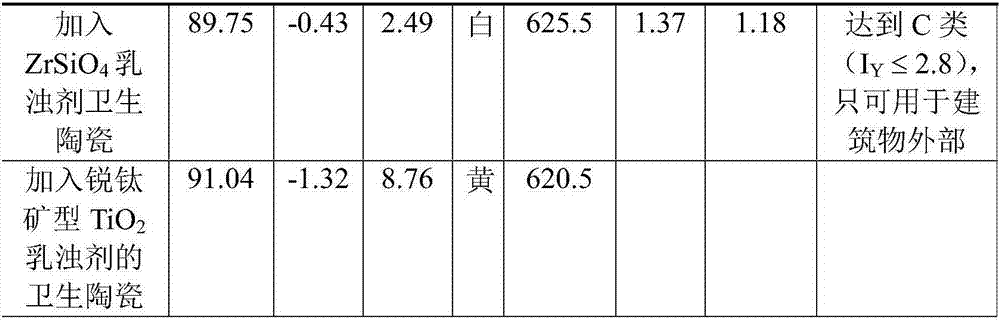

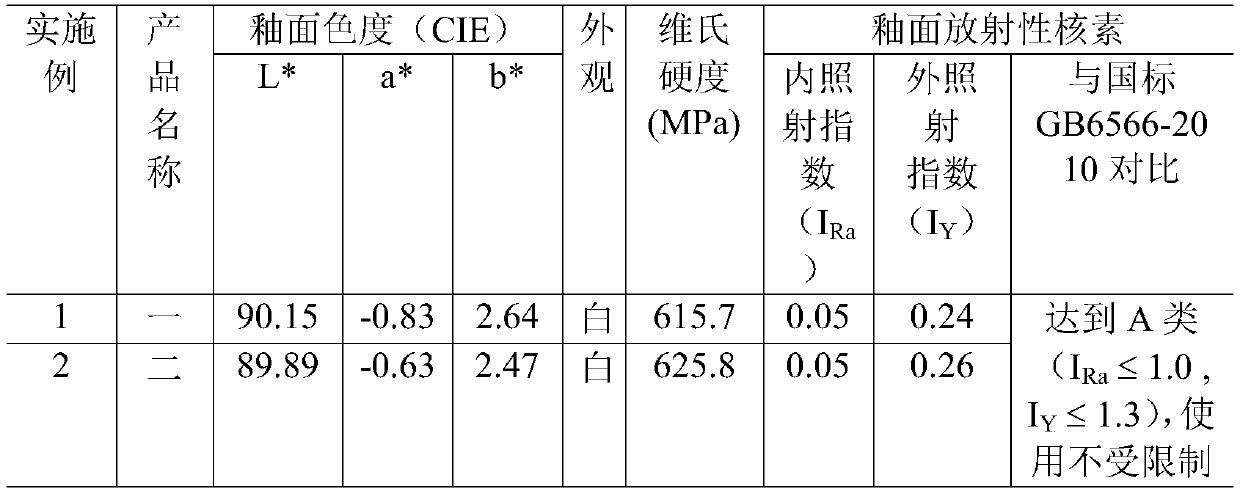

Technique of sanitary ceramic using composite titanium dioxide opacifier

The invention provides a technique of sanitary ceramic using a composite titanium dioxide opacifier in glaze slurry. The technique adopts the composite titanium dioxide opacifier, phosphate, potash feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaoline and a frit as raw materials for preparing opalescent glaze of the ceramic. The sanitary ceramic prepared by the technique has the advantages that: (1) a glaze layer of the prepared sanitary ceramic is tightly combined with a green body; a glaze surface has a good opacifying effect, and is high in whiteness, strong in luster sensation and delicate; (2) the composite titanium dioxide opacifier glaze and the glaze layer of the sanitary ceramic are free from radioactive substances and radioactive radiation and has effects of safety and protection of user health; and (3) the composite titanium dioxide opacifier is lower in cost and price; and phosphate is added into the glaze at the same time to further reduce the use amount of the composite titanium dioxide opacifier, so that the cost of the sanitary ceramic is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Cover glaze and preparation method thereof

The invention discloses a cover glaze which is characterized in that: the constituents of the cover glaze are as follows by weight percentage: 90-96 percent of matte fusion cake, 4-6 percent of gas knife soil, 0.08-0.2 percent of sodium carboxymethylcellulose, 0.03-0.36 percent of industrial sodium tripolyphosphate, and 0.20-0.26 percent of ceramic dispergator, and water accounting for 20-26 percent of total proportion of the raw materials. The preparation process flows of the cover glaze are as follows: raw material incoming inspection--batching--ball milling--detection--deironing and sieving--decaying--warehousing and being sieved by 250 meshes of deironing oscillating screen. The ball milling time is 7-10 hours, and ball-milling glazeslip specific gravity is 1.4-1.9g / cm<3>, and the fineness is 0.6-1.0mm; the flowing speed of the ball-milling glazeslip is controlled above 55s. The cover glaze has the advantages of transparent and smooth performance, bright color and luster and wide market prospect.

Owner:李建平

Corrosion reaction glaze and preparation method thereof

The invention discloses a corrosion reaction glaze and a preparation method thereof and belongs to the field of preparation of reaction glazes. The reaction glaze comprises a priming glaze and a finishing glaze; the priming glaze is prepared from the following components in percentage by mass: 18-23% of potash feldspar, 6-13% of soda feldspar, 7-12% of calcite, 3-8% of Guizhou soil, 15-25% of frit, 6-12% of quartz, 6-15% of zinc oxide and 12-19% of zirconium silicate; the finishing glaze is prepared from the following components in percentage by mass: 15-25% of potash feldspar, 8-12% of soda feldspar, 11-16% of quartz, 5-10% of calcite, 5-10% of Guizhou soil, 24-35% of frit, 0.5-3% of zirconium silicate, 2-5% of zinc oxide, 2-6% of silver grey and 0.2-0.5% of cobalt black. A designed pattern surface can be generated by adjusting raw material components of the priming glaze and the finishing glaze, corroding an oil silk screen on a glaze blank to print patterns and reacting under the high-temperature condition. Lines on the pattern surface of ceramic products produced by corrosion reaction are relatively clear, vivid, natural and dense, and have strong stereoscopic effects; and the effect is colorful and bright.

Owner:醴陵市恒辉瓷厂

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperature range is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

Fluorescent glaze for artistic porcelain

The invention discloses florescent glaze for artistic porcelain. The florescent glaze for the artistic porcelain is prepared from the following components in part by weight: 20 to 30 parts of potash feldspar, 5 to 10 parts of soda feldspar, 6 to 10 parts of red lead, 5 to 10 parts of boric acid, 3 to 8 parts of spodumene, 20 to 30 parts of quartz, 2 to 6 parts of calcite, 3 to 8 parts of barium carbonate, 2 to 5 parts of talc, 2 to 5 parts of zinc oxide, 2 to 5 parts of bone ash, 0.5 to 1.0 part of zirconium silicate, 0.5 to 1.0 part of vanadium pentoxide, 1.0 to 2.0 parts of copper oxide, 1.0 to 2.0 parts of ferric oxide, and 3 to 8 parts of manganese oxide. The florescent glaze for the artistic porcelain is simple in formula, and reasonable in proportioning; the florescent glaze which is prepared according to the formula has the characteristics of long luminescence duration, and fine and smooth glaze; and meanwhile, the phenomenon that luminescent powder is not oxidized at high temperature during firing of the glaze is avoided in a production process, and production is easy to control.

Owner:陈新基

Ceramic cover glaze with luminous effect and preparation method and application of ceramic cover glaze

The invention discloses a ceramic cover glaze with luminous effect and a preparation method and application of the ceramic cover glaze. The ceramic cover glaze is prepared from, by weight, 15-40% of transparent frit powder, 15-40% of luminescent powder, 3-5% of Suzhou kaolin, 3-7% of feldspar, 4-8% of glass powder, 3-5% of zirconite powder, 50-70% of stamp-pad ink, 0.1-0.2% of sodium tripolyphosphate, 0.05-0.15% of aluminium-magnesium silicate and 0.2-0.6% of sodium carboxymethylcellulose. The cover glaze is prepared by adjusting the selection of raw material components, optimizing the proportion of the raw material components and using environment-friendly nonradiative materials, the cover glaze is excellent in chemical resistance and has energy-storing and luminous functions, after the cover glaze absorbs light energy, self-Illumination is achieved in the dark, and the decorative art effect of ceramic preparation is enriched in lack of brightness; meanwhile, the glaze surface is fine and smooth and good in texture, it is ensured that the texture of decorative patterns is clear, and the ceramic cover glaze is suitable for design patterns in different styles. The preparation technology is simple, the production efficiency is high, no other devices are added, the firing curve is matched with an existing firing schedule of a furnace, and adjustment is not needed.

Owner:FOSHAN OCEANO CERAMICS

High-temperature glisten glaze and preparation method thereof

The invention discloses a high-temperature glisten glaze and a preparation method thereof. The glaze comprises, by mass, 1-16% of Al2O3, 50-75% of SiO2, 0.5-5% of CaO, 0-2% of MgO, 2-9% of K2O, 0-2% of Na2O, 2-16% of ZnO, 0-2% of PbO, 3-9% of ZrO2, 3-10% of CeO2 and 0.5-8% of B2O3. The glisten glaze is wide in application range, good in firing performance and high in stability and glisten strength; and the preparation method is reasonable and simple in technology.

Owner:威远县大禾陶瓷原料有限公司

Lead-free opalescent frit

The invention discloses lead-free opalescent frit for ceramics preparation, which is prepared from the following raw materials in part by weight: 50-60 parts of SiO2, 5-10 parts of Al2O3, 5-10 parts of CaO, 5-10 parts of ZnO, 10-20 parts of B2O3, 10-20 parts of ZrO2 and 5-10 parts of alkali metal. The lead-free opalescent frit for ceramics preparation disclosed by the invention has the advantages of no added poisonous lead element, environment friendliness, safety, uniform opalescence and wide application scope.

Owner:CARLOBBIA GLAZE KUNSHAN

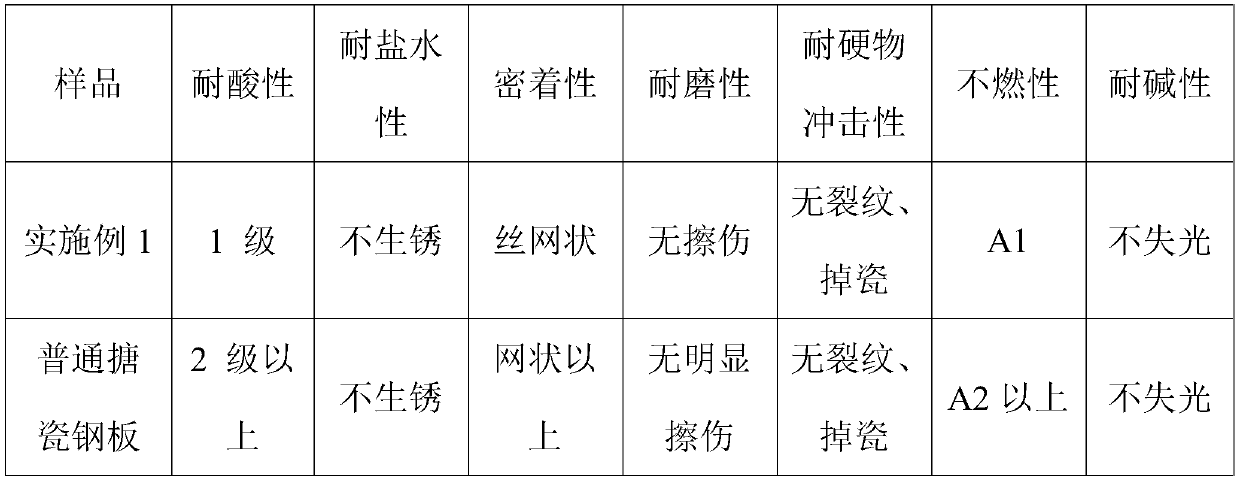

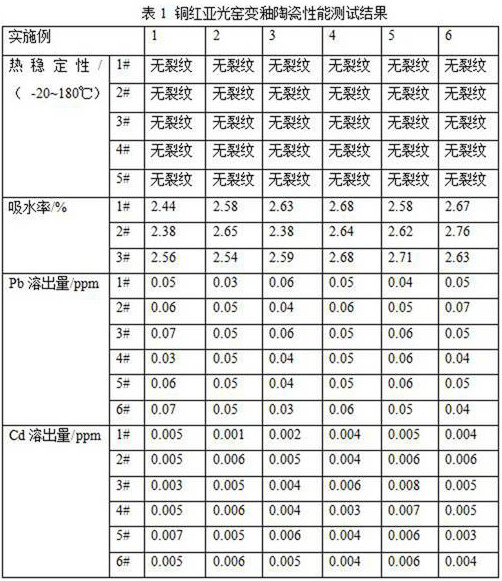

Mahua stone imitated enamel decorative plate and preparation method thereof

ActiveCN110027269ASimple processEasy to implementLaminationLamination apparatusWeather resistanceSubway station

The invention discloses a preparation method of a Mahua stone imitated enamel decorative plate. The method comprises the following steps: pre-treating a steel plate special for enamel, spraying groundglaze and surface glaze, conducting sintering, preparing Mahua stone ground color glaze, conducting spraying and sintering, preparing Mahua stone glaze, and conducting spraying and sintering to obtain the product. The Mahua stone ground color glaze and the Mahua stone glaze are sequentially sprayed on an enamel steel plate base plate, the glaze and the base plate are better fused through sintering, the technology is simplified, implementation is easy, and industrial production is facilitated. The invention further provides the Mahua stone imitated enamel decorative plate which is prepared bythe method. The Mahua stone imitated enamel decorative plate has the characteristics of smooth and attractive Mahua glaze layer, fine and smooth glaze surface, wear resistance, corrosion resistance, weather resistance and easiness in cleaning, and can be applied to subway stations, underground passages, tunnels, outer walls and the like as a decorative material.

Owner:HANGZHOU FANTASY PORCELAIN PROD

Construction waste recycling method

InactiveCN106747305AAchieve recyclingGood benefitCeramic materials productionClaywaresSludgeEconomic benefits

The invention discloses a construction waste recycling method. According to the method, ceramic is prepared from construction wastes and municipal sludge adopted as main raw materials, so that the construction wastes are recycled, and good economic benefits and environment-friendly effects are achieved.

Owner:广州科恩科技有限公司

Transmutation overglaze and preparation method thereof, and porcelain

The invention discloses a transmutation overglaze. The overglaze comprises the following components in percentage by mass: 70%-75% of frit, 5%-8% of kaolin, 4.5%-6.5% of zinc oxide, 1.2%-2.5% of barium carbonate, 4.5%-6% of titanium dioxide, 2.5%-4.5% of bone meal, 1%-2% of ferric oxide and 1%-2% of cobalt oxide. The invention further discloses a preparation method of the transmutation overglaze and porcelain. According to the transmutation overglaze and the preparation method thereof and the porcelain in the invention, the preparation method of the transmutation overglaze is simple in production process and low in environmental pollution; a unique overglaze formula is adopted, and through mutual cooperation and combined action of all the components and the content of the components, the overglaze is transparent and smooth in surface, good in glaze slip performance and good in firing performance; and an overglaze porcelain product is good in decorative effect, fine and smooth in glazesurface and good in texture. The invention belongs to the technical field of ceramics.

Owner:潮州市荣嘉陶瓷有限公司

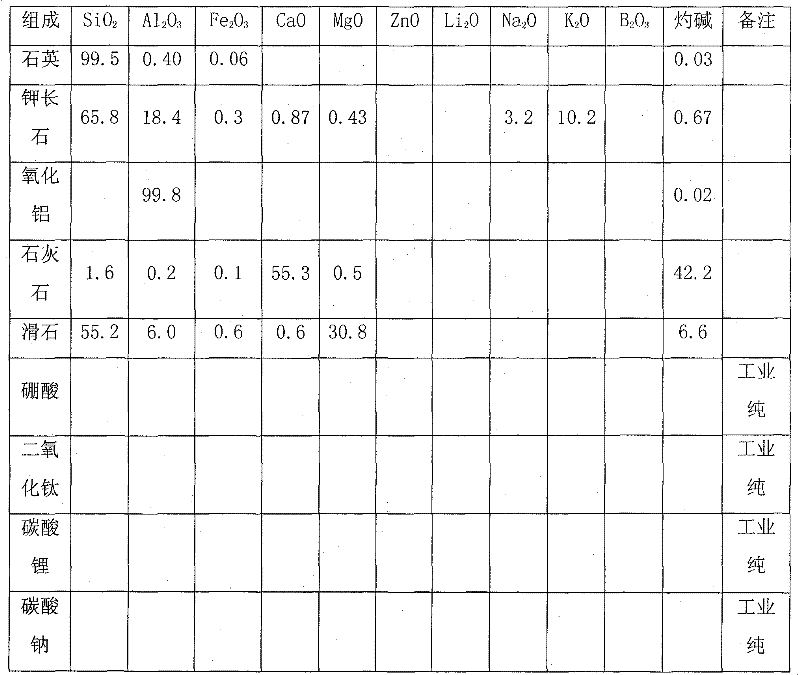

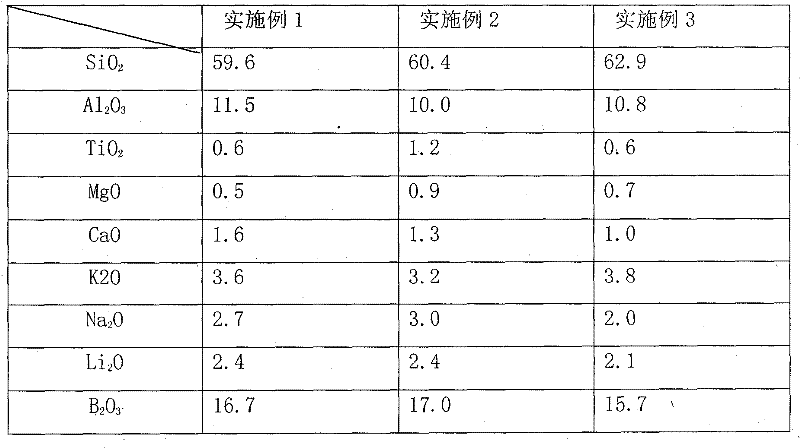

High acid and alkali resistance lead-free cadmium frit glaze for bone china

The invention relates to a ceramic glaze, in particular to a high acid-resistant and alkali-resistant lead-free frit glaze for bone china used for producing high-quality lead-free bone china products. The chemical weight percentage of the high acid and alkali resistant lead-free frit glaze is as follows: SiO 2 58.0-66.0%, Al 2O 3 10.0-15.0%, TiO 2 0.0-1.0%, CaO 0.5-2.0, MgO 0.0-1.0%, K 2O 2.0-6.0%, Na 2O 2.0-6.0%, Li 2O 2.0-6.0%, B 2O 3 15.0-25.0%. The high acid and alkali resistant lead-free frit glaze of the present invention does not contain any lead, cadmium, zinc, barium, bismuth and other heavy metal element components in its raw material composition, and a certain amount of alkali metal oxides, TiO2 and boric acid are added. The composition is simple, scientific and reasonable, and easy to implement; the blank glaze has good adaptability, especially suitable for the characteristics of large temperature differences in domestic kilns; the finished porcelain glaze surface after firing is fine, smooth, smooth, and good gloss; the glaze surface has strong corrosion resistance , not easy to lose gloss, no fouling, easy to clean; good adaptability to decal printing paper, high mechanical strength, good thermal shock stability, after testing, the thermal shock stability reaches 180°C-20°C water heat exchange 5 pieces at a time It is especially suitable for use in tableware dishwashers; the content of lead, cadmium, zinc, barium, bismuth and other heavy metals in the enamel is zero, which completely solves the problem of poor acid and alkali resistance and heavy metals such as lead and cadmium in high-grade bone china .

Owner:张垠

A kind of technological method of sanitary ceramics using composite titanium dioxide opacifying agent

The invention provides a technique of sanitary ceramic using a composite titanium dioxide opacifier in glaze slurry. The technique adopts the composite titanium dioxide opacifier, phosphate, potash feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaoline and a frit as raw materials for preparing opalescent glaze of the ceramic. The sanitary ceramic prepared by the technique has the advantages that: (1) a glaze layer of the prepared sanitary ceramic is tightly combined with a green body; a glaze surface has a good opacifying effect, and is high in whiteness, strong in luster sensation and delicate; (2) the composite titanium dioxide opacifier glaze and the glaze layer of the sanitary ceramic are free from radioactive substances and radioactive radiation and has effects of safety and protection of user health; and (3) the composite titanium dioxide opacifier is lower in cost and price; and phosphate is added into the glaze at the same time to further reduce the use amount of the composite titanium dioxide opacifier, so that the cost of the sanitary ceramic is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High-temperature glisten glaze and preparation method thereof

The invention discloses a high-temperature glisten glaze and a preparation method thereof. The glaze comprises, by mass, 1-16% of Al2O3, 50-75% of SiO2, 0.5-5% of CaO, 0-2% of MgO, 2-9% of K2O, 0-2% of Na2O, 2-16% of ZnO, 0-2% of PbO, 3-9% of ZrO2, 3-10% of CeO2 and 0.5-8% of B2O3. The glisten glaze is wide in application range, good in firing performance and high in stability and glisten strength; and the preparation method is reasonable and simple in technology.

Owner:威远县大禾陶瓷原料有限公司

Method for preparing underglaze bone china

Owner:李永生 +1

Raw material for low-temperature firing of Longquan celadon and firing method

The invention relates to a firing technology for low-temperature firing of celadon and aims to provide a raw material for low-temperature firing of Longquan celadon and a firing method. According to the invention, as for a blank body and glaze, a raw mineral material and a chemical raw material which are generally used by the Longquan celadon are adopted for matching, and nano calcium carbonate and zinc borosilicate glass powder are also contained; the nano particle high-specific external surface activity and various additives are combined with a cooling down mechanism, so as to allow the Longquan celadon to be fired under 1,150-11,800 DEG C, and the problems that the Longquan celadon is high in sintering temperature and high in energy consumption are solved. The product has the characteristics of high finished product ratio, good porcelain quality, high strength and the like, and has a wide application prospect.

Owner:ZHEJIANG TIANFENG CERAMIC

Imitation iron porcelain prepared from waste gray bricks and its preparation method

ActiveCN105801086BDelicate glazeMeet the requirements of sustainable developmentCeramic materials productionClaywaresBrickRutile

The invention relates to the technical field of ceramics, in particular to iron-like porcelain prepared from waste gray bricks and a preparation method thereof. The raw material of the imitation ironware ceramics prepared from waste gray bricks is prepared from waste gray brick powder, Siban clay, low temperature stone, pyrophyllite, iron oxide, rutile, and lapis lazuli; the glaze is made of feldspar, waste gray brick powder, Quartz, plant ash, iron oxide, zirconium silicate, double fly powder, cobalt oxide, manganese dioxide. This kind of iron-like ceramics has a taupe surface similar to that of wrought iron. The glaze is smooth and delicate, and can reflect colorful spots under different lights. It has a rough and simple artistic effect and can be directly used in production. Use or artistic ceramics; the ceramic material of the present invention can solve the problem of continuous increase in the cost of ceramic production and the homogeneity of ceramic products, and it is easy to popularize in places where ceramics are produced, providing a new way to solve construction waste, which is in line with sustainable development requirements.

Owner:DEHUA DEHUA CERAMICS CO LTD

A bone matt glaze and method for making bone china products using the glaze

The invention relates to bone matte glaze. The bone matte glaze comprises, by weight, 100 parts of frits, 3-8 parts of clay, 2-12 parts of aedelforsite, 3-6 parts of aluminum oxide, 6-15 parts of zinc oxide and 6 parts of stannic oxide. The frits comprise, by weight, 16-24 parts of quartz, 28-38 parts of potash feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 0-10 parts of zinc oxide, 0-3 parts of talcum, 0-12 parts of calcite and 0-0.5 part of zirconium silicate. The glaze surface of a product using the glaze is fine, smooth, resistant to pollution, resistant to acid and alkali, easy to wash and suitable for the decoration means such as decal. The invention further provides a method for manufacturing the bone china product by using the bone matte glaze. The method is simple in firing process, stable in production and good in benefit.

Owner:GUANGDONG SONGFA CERAMICS

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperaturerange is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

Ceramic wine bottle color glaze and spray glaze method

The invention discloses a glaze spraying method for water-repellent ceramic wine bottle colored glaze. The ceramic wine bottle colored glaze is characterized in that the glaze material is prepared from the following materials in parts by weight: 10-12 parts of bauxite, 3-4 parts of dolomite, 5-6 parts of zinc sulfate, 2-3 parts of magnesium sulfate, 3-4 parts of cobalt acetate, 9-12 parts of CaO, 2-3 parts of MgO, 3-4 parts of BaO, 2-3 parts of silicon carbide, 1-2 parts of graphite, 3-4 parts of SnO2, 1-2 parts of Sc2O3, 13-14 parts of binder and a proper amount of water. The ceramic wine bottle glaze disclosed by the invention is smooth and fine in glaze, extremely good in hand feeling, has very good hydrophobicity, can prevent water from gathering on the glaze, can keep the glaze dry, and therefore, the ceramic wine bottle colored glaze has very good waterproof and moisture-resistant performances.

Owner:ANHUI YICAI GLASSWARE

Brown opaque glaze and method for making vase with the same

The invention discloses a brown non-transparent glaze. The glaze comprises, by weight, 49 parts of frit, 7-9 parts of feldspar, 13-14 parts of quartz, 8-9 parts of kaolin, 3.5-4.5 parts of calcite, 2-3 parts of dolomite, 8-10 parts of calcined talcum, 3-4 parts of calcined tin oxide, 0.5-1 part of a black pigment, and 1-2 parts of a red brown pigment. The glaze has the advantages of strong coloring property, uniform color, fine glaze surface, good hardness, good staining resistance and good acid and alkali resistance. The invention also discloses an environmentally-friendly simple-process method for making a vase by using the glaze.

Owner:景德镇皇窑陶瓷有限公司

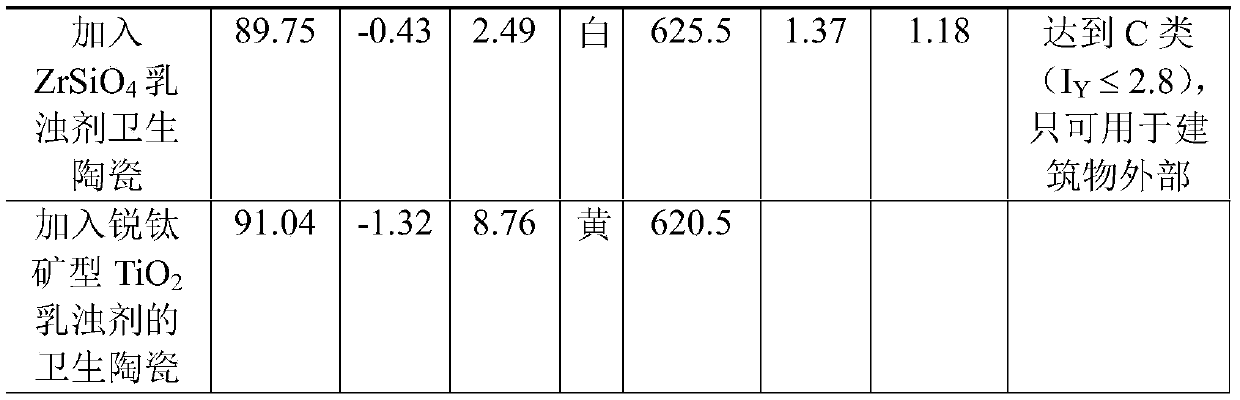

A kind of copper red matt kiln changing glaze and preparation method thereof

The invention relates to the technical field of ceramic glazes, in particular to a copper red matt kiln-changing glaze and a preparation method thereof. The copper-red matt kiln glaze is composed of a bottom glaze and a top glaze. The bottom glaze includes refined potassium feldspar, animal bone ash, refined quartz, lime, talc, refined cordierite, silicon carbonate, copper oxide, tin oxide, zinc oxide, Alumina, barium carbonate, and boron; topcoats include refined potassium feldspar, refined quartz, talc, zirconium phosphate, titanium oxide, tin oxide, frit, refined dolomite, zinc oxide, and copper oxide. The preparation method comprises: preparing the bottom glaze slurry; preparing the top glaze slurry; preparing the bottom glaze; and preparing the top glaze. The invention solves the problems of high difficulty in making kiln-transformed glaze and poor kiln-transformed effect in the prior art, and the prepared kiln-transformed glaze has excellent performance, and the thermal stability, water absorption rate and dissolution of lead and cadmium of the product can meet the requirements of daily-use ceramic products. related standards.

Owner:福建省德化县哈维陶瓷有限公司

Dehua snow white porcelain and its preparation method

Owner:福建省德化县臻晖陶瓷有限公司

A kind of surface glaze and preparation method thereof

The invention discloses a surface glaze, which is characterized in that the component weight ratio of the surface glaze is: 90-96% of matte frit, 4-6% of air knife soil, and 0.08-0.2% of sodium carboxymethyl cellulose , 0.30-0.36% of industrial sodium tripolyphosphate, 0.20-0.26% of ceramic debonding agent; and 30-36% of water in the total proportion of the above-mentioned raw materials. The preparation process of the surface glaze is as follows: raw materials entering the factory for inspection—batching—ball milling—testing—iron removal and sieving—staleness—passing through a 250-mesh iron removal vibrating screen for use. The ball milling time is 7-10 hours, the specific gravity of the ball-milling glaze slurry is 1.4-1.9 g / cm 3 , and the fineness is 0.6-1.0 mm; the flow rate of the ball-milling glaze slurry is controlled to be above 55 s. The product of the invention has the advantages of transparency and smoothness, bright color, wide market prospect and the like.

Owner:李建平

A kind of green light daily-use porcelain

InactiveCN101555126BIncrease the amount addedGood light transmissionClaywaresLithiumSodium Bentonite

A kind of green-light daily-use porcelain, the raw material of the porcelain blank includes the following components by weight percentage: 18-22% of Hunan feldspar, 9-13% of cooked quartz, 8-12% of purple gold silica, 3-5% of bentonite, kaolin wash Mud 18-24% and weathered potassium feldspar washing mud 33-37%; its enamel raw materials include the following components by weight percentage: waste porcelain powder 21-23%, Hunan feldspar 9-11%, lithium porcelain stone powder 4-6 %, quartz 24-26%, kaolin 9-11%, zinc oxide 4-6%, dolomite 10-12% and calcite 11-13%. The green-light daily-use porcelain of the present invention has fine and smooth glaze surface, crystal clear and transparent texture, white and green color, and presents the appearance of glass color. The present invention adds designs and varieties of daily-use porcelain, solves the problem of monotonous colors, and conforms to consumers' consumption concepts.

Owner:CHAOZHOU XINYUE CERAMICS MFG

A kind of imitation twisted stone enamel decorative plate and its preparation method

ActiveCN110027269BSimple processEasy to implementLaminationLamination apparatusWeather resistanceGlaze

Owner:HANGZHOU FANTASY PORCELAIN PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com