Technique of sanitary ceramic using composite titanium dioxide opacifier

A technology of titanium dioxide and sanitary ceramics, which is applied in the production of sanitary ceramics, can solve the problems of high cost, yellowing of sanitary ceramic glazes, and radioactive radiation in glazed surfaces, and achieve reduced dosage, low cost and price, and opacified glazed surfaces good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

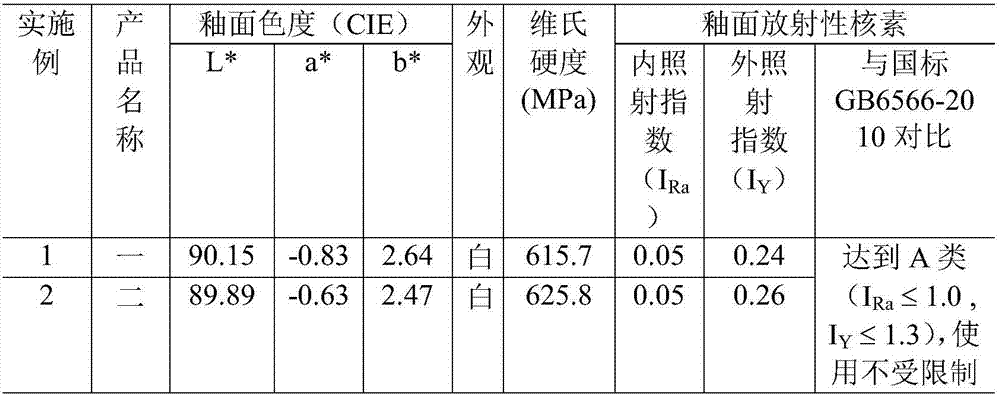

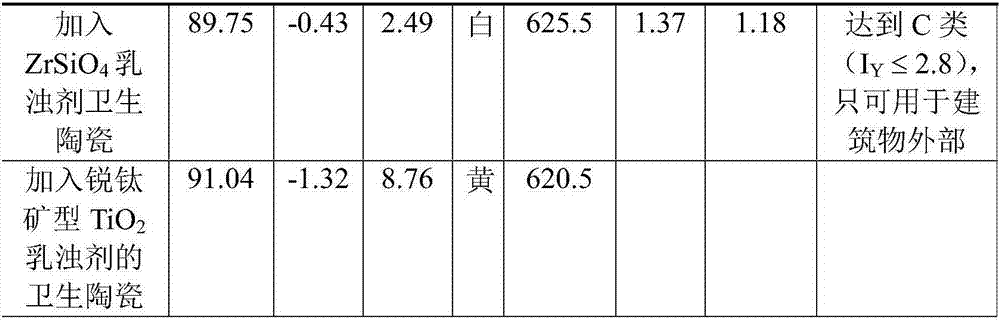

Examples

Embodiment 1

[0020] 1. Selection of raw materials for sanitary ceramic glazes

[0021] Calcite mineral and anatase TiO 2 Composite titanium dioxide opacifier, tricalcium phosphate, potassium feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaolin, and frit that are prepared by compounding particles through the interface of each other are raw materials for opacified glazes, among which calcite The particle size of the composite titanium dioxide opacifier is the median diameter d 50 0.35μm, butt end particle size d 90 1.,0μm; glaze slurry performance adjuster is used as auxiliary agent for wet grinding opacified glaze to prepare glaze slurry; particle size distribution of tricalcium phosphate: 82% of particles less than 2μm, median diameter d 50 1.8 μm; potassium feldspar, quartz, calcite, dolomite, zinc oxide, alumina, kaolin are ground powders with a maximum particle size of less than 74 μm, and the purity is not less than 95%;

[0022] 2. The ratio of glaze raw material...

Embodiment 2

[0028] 1. Selection of raw materials for sanitary ceramic glazes

[0029] Wollastonite mineral and anatase TiO 2 Composite titanium dioxide opacifier, apatite, potassium feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaolin, and frit, which are prepared by compounding particles at the interface with each other, are the raw materials for the opacified glaze. Among them, the particle size of the wollastonite composite titanium dioxide opacifier is the median diameter d 50 0.45μm, butt end particle size d 90 1., 4μm; glaze slurry performance modifier is used as an auxiliary agent for wet grinding opacified glaze to prepare glaze slurry; the particle size distribution of apatite is: the content of particles less than 2μm is 81%, and the median diameter is d 50 2.4 μm; potassium feldspar, quartz, calcite, dolomite, zinc oxide, alumina, kaolin are ground powders with a maximum particle size of less than 74 μm, and the purity is not less than 95%;

[0030] 2. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com