Patents

Literature

194results about How to "Strong gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

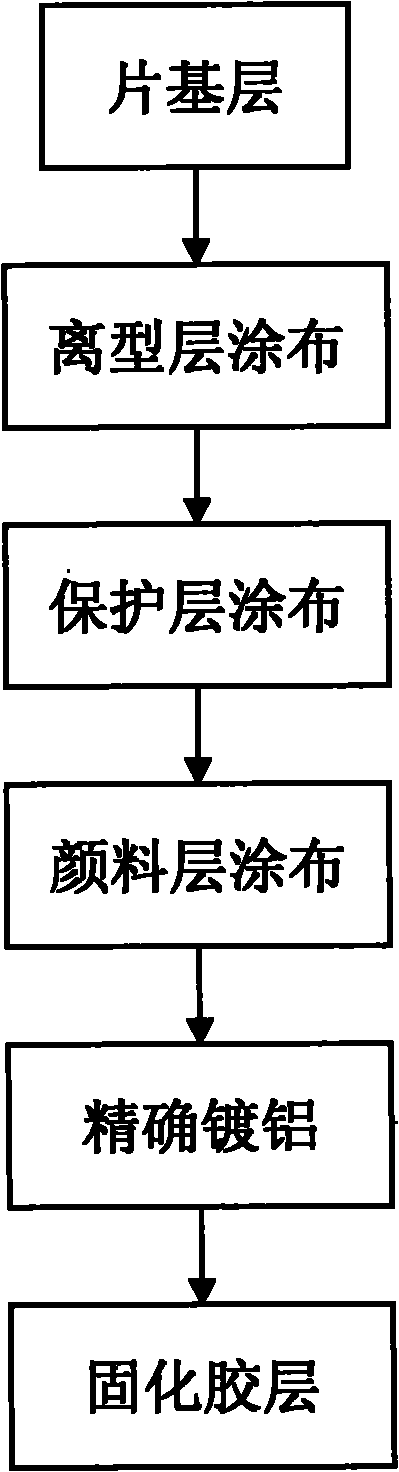

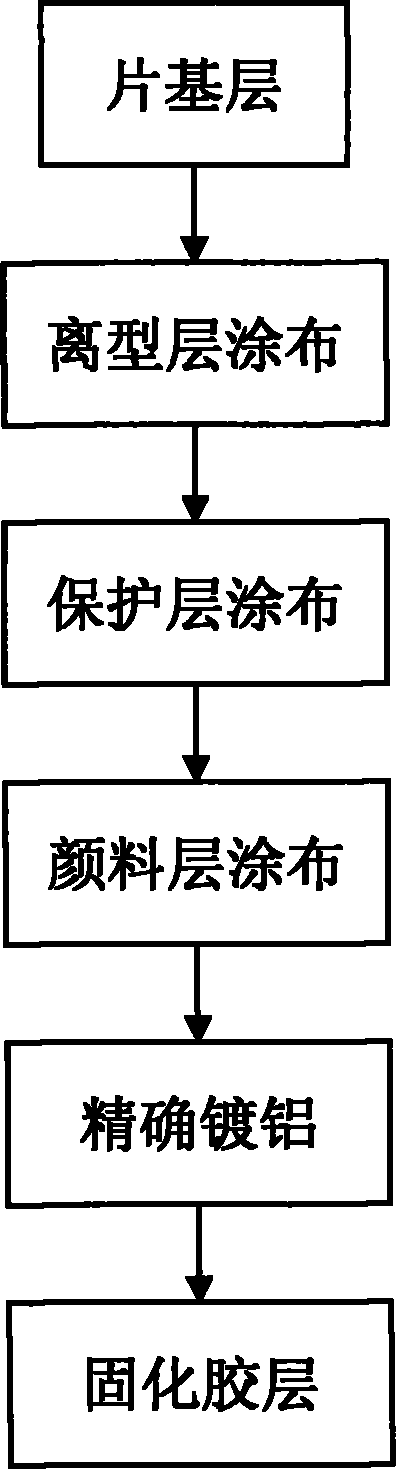

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

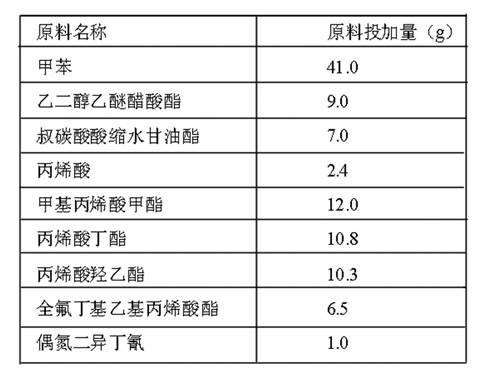

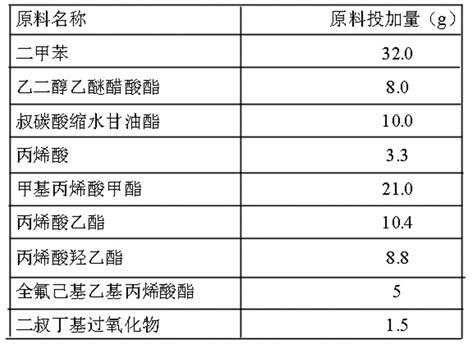

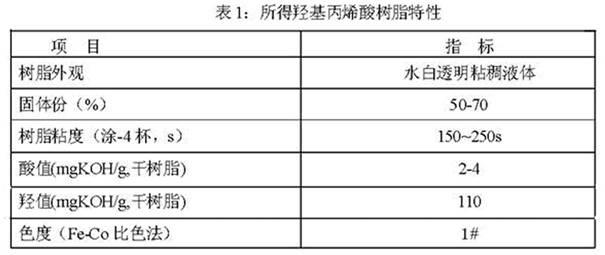

Hydroxylated acrylic resin as well as preparation method and application thereof

The invention relates to hydroxylated acrylic resin as well as preparation method and application thereof. The hydroxylated acrylic resin has a structural formula, wherein n is equal to 4, the sum of C number in 6, 8, R1 and R2 is 9, and the molecular weight is 10,000-20,000; the preparation method comprises the steps of: adding solvent and reactive solvent into a reaction vessel under protectionof nitrogen gas environment, and increasing temperature to 150-160 DEG C; evenly mixing acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate and perfluoroalkylethyl acrylate monomer with initiator, and carrying out dropwise addition for 3-4 hours; carrying out heat insulation for 1.5-2 hours; and reducing temperature to 40-70 DEG C for discharging, thus obtaining hydroxylated acrylic resin. A paint film formed by the hydroxylated acrylic resin and a curing agent has properties of both acrylic polyurethane and fluorocarbon coating. The prepared hydroxylated acrylic resin can carry out reaction smoothly at normal temperature and normal pressure, has low production cost, can be cured at normal temperature and be applied in the fields of ships, containers, drilling platforms, anticorrosion of steel structures, outer wall coating of high-rise buildings and the like.

Owner:JINZHOU DPF TH CHEM CO LTD

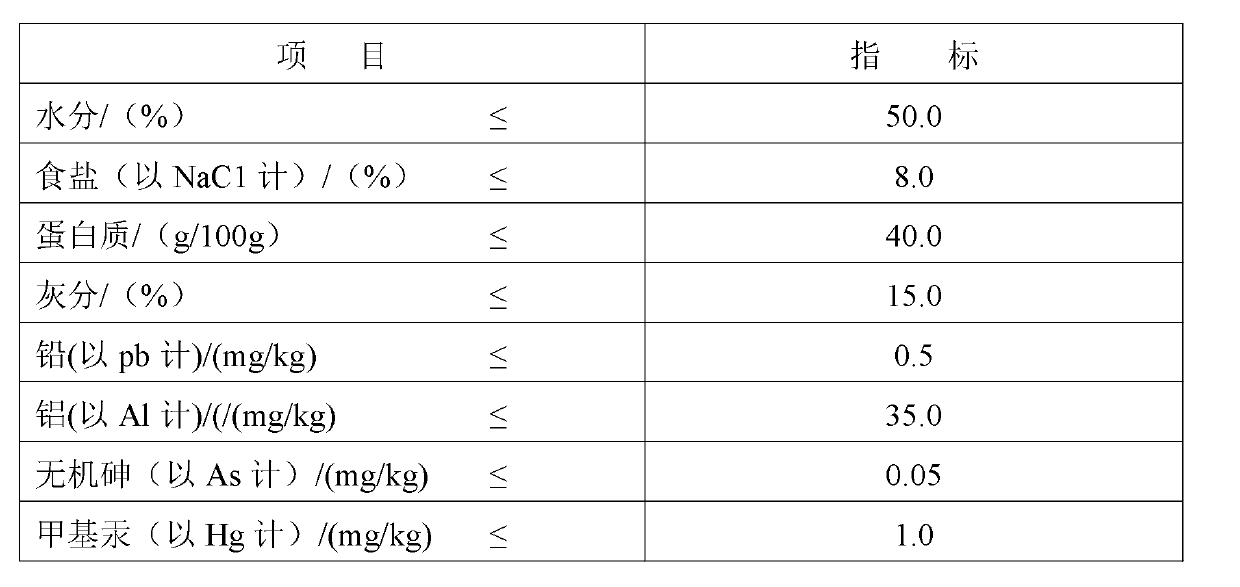

Preparation method of convenient and instant flavory grilled fish

The invention discloses a preparation method of convenient and instant flavory grilled fish. The preparation method is characterized in that a modern processing process is adopted for preparing fresh water fish into the convenient and instant flavory grilled fish which is convenient to eat and adaptable to fast pace of life in the society. The prepared fish is fresh in taste, unique in flavor, and chewable with certain elasticity and rigidity. In addition, fish thorns and fishbone tissues are completely softened, so that the convenient and instant flavory grilled fish can be directly eaten, and the problem that a user can be choked up by fishbone of most fresh water fish is solved.

Owner:SICHUAN UNIV

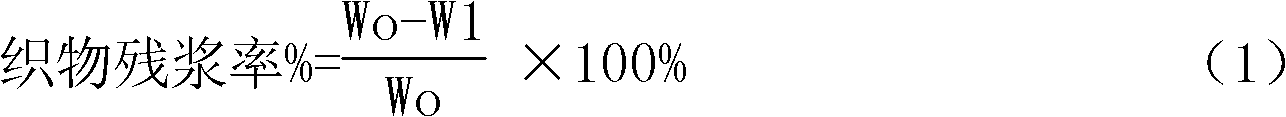

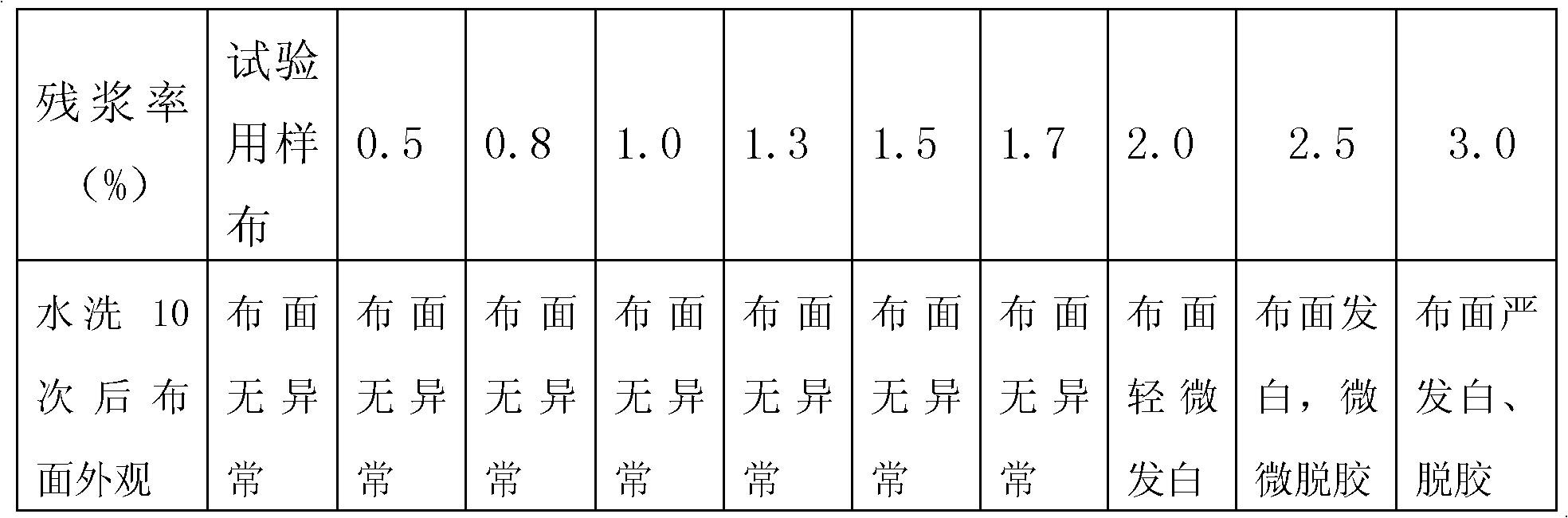

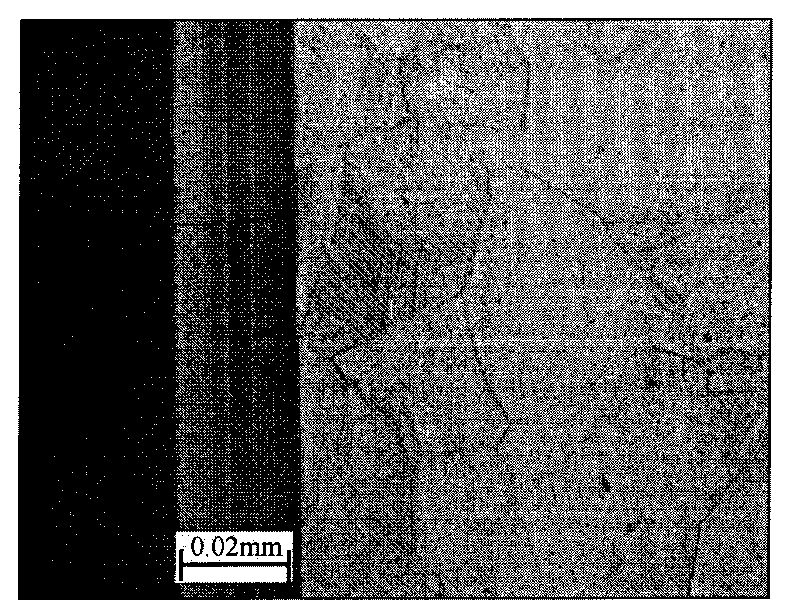

Post-treatment method of chinlon superfine denier fiber fabric

ActiveCN102505488AImprove tear resistanceOvercome the rough feelFibre typesDry-cleaning apparatus for textilesFiberHydrostatic pressure

The invention aims at the shortages that chinlon superfine denier fiber fabric of the prior art is easy in adhesive failure, low in hydrostatic pressure resistance, non-washable, low in tearing strength, , easy in impregnation of adhesive and inverse adhesion in the coating process, and the clothes made of the fabric is not stiff and smooth enough. Provided is a post-treatment method of the chinlon superfine denier fiber fabric. The method comprises three steps including desizing, calendering treatment and coating finishing, wherein, in the coating finishing step, one surface of the fabric is coated with a finishing agent A which is composed of components by weight part as follows: 86-90 parts of polyurethane resin, 4-8 parts of solvent A, 3-6 parts of bridging agent, 1-2 parts of promoter and 2-4 parts of titanium dioxide; the other surface of the fabric is coated with a finishing agent B which is composed of components by weight part as follows: 81.5-92.5 parts of silicone resin, 3-11 parts of solvent B, 2-5 parts of cross-linking agent and 2-5 parts of cross-linking catalyst. The fabric treated by the method disclosed by the invention is obviously improved in anti-tearing performance, anti-ultraviolet ray performance, static pressure resistance, stiffness and smoothness.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Medical coating powder containing nano material

InactiveCN1616105AOvercome the defects that the quality is difficult to guarantee, etc.Simple and fast operationPharmaceutical non-active ingredientsDrageesUltimate tensile strengthMaterials science

The medicinal coating powder containing nanometer material consists of hydromellose 55-65 wt%, copolymer of vinyl pyrrolidone and vinyl acetate 8 wt%, glycerin 15 wt%, Span 8 wt%, coloring agent 2-4 wt%, and nanometer titania 2-10 wt%. The medicinal coating powder containing nanometer material has simple production process, wide application, high performance / cost ratio, no physiological toxicity and many other advantages, and may meet the requirement of coating various solid Chinese medicine preparation.

Owner:GUANGDONG GUOFANG MEDICAL TECH

Fabric stiffening adhesive paste, preparation method thereof and forming cloth

ActiveCN104830255AGood water solubilityHigh viscosityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesHazardous substanceDouble bond

The invention discloses fabric stiffening adhesive paste, a preparation method thereof and forming cloth. The fabric stiffening adhesive paste comprises the following raw materials: vinyl acetate, organosilicone monomers containing unsaturated double bonds, butyl acrylate, polyvinyl alcohol, a silane coupling agent, a sodium salt chelating agent, a defoaming agent, deionized water, an initiator and a preservative. The finished fabric stiffening adhesive paste does not contain hazardous substances such as formaldehyde, heavy metal and the like, is free of toxicity and off-odor, is safe and reliable, has very strong adhesive force to multiple chemical fabrics, and is applicable to cotton cloth, chemical fabrics, linen, wool fabrics, silk and blended fabrics; the glossiness, hardness and hand feeling are improved without changing colored light of cloth, and the processed cloth does not easily absorb moisture and ease back and has storability.

Owner:佛山永恒达新型建材有限公司

LED photocured inkjet ink suitable for high-speed ink jetting

InactiveCN104845451AImprove anti-aging propertiesImprove adsorption fastnessInksUltraviolet lightsEngineering

The invention discloses and provides LED photocured inkjet ink suitable for high-speed ink jetting, which does not evaporate a solvent, can reduce energy consumption, can reduce environmental pollution and is suitable for cold light source LEDs. The inkjet ink comprises the following components in parts by weight: 1-10 parts of a nanoscale pigment, 2-5 parts of an ultraviolet light absorber, 1-10 parts of a super dispersion agent, 2-10 parts of a quick initiator, 2-20 parts of a macromolecular prepolymer, 0.1-2 parts of a wetting and leveling agent, 0.1-1 part of a defoaming agent, 0.1-10 parts of an adhesion promoter, 5-10 parts of a combined monomer and 30-70 parts of a UV active diluent. According to the formula of the ink, the viscosity of the ink can be reduced, a spray head of a printer cannot be blocked, ultraviolet lights can be absorbed, curing energy can reach 130 mj / cm<2>, the curing speed of the ink can be increased, the curing time can be controlled within 5-20 seconds, and meanwhile, the transfer rate of printing pattern is improved; the LED photocured inkjet ink has long-acting antioxidative and anti-yellowing performances, high luster sensation and marresistance.

Owner:珠海欣威科技有限公司

Surface treatment method for improving wear resistance and corrosion resistance of austenitic stainless steel shell

InactiveCN101709463AContent controlImprove bindingLiquid/solution decomposition chemical coatingChemical platingSand-paper

The invention discloses a surface treatment method for improving wear resistance and corrosion resistance of an austenitic stainless steel shell, which comprises the following steps: sanding the austenitic stainless steel shell with sand paper; deoiling, and washing with water to remove residual deoiling solution; and washing with acid to remove the film, activating the surface, washing with cold water and preheating, putting the austenitic stainless steel shell in a prepared plating solution to carry out plating for 1-2 hours, taking out, washing with hot water and cold water alternately to remove the residual plating solution on the sample surface, and finally drying to obtain the plating. The invention adopts the chemical plating technique to obtain the good-quality amorphous Ni-W-P ternary alloy plating on the surface of the austenitic stainless steel shell, thereby obviously improving the wear resistance of the product on the premise that the original silvery color and favorable glossiness of stainless steel are ensured.

Owner:SOUTH CHINA UNIV OF TECH

Protection method for outdoor willow furniture product

ActiveCN106221446AImprove adhesionEnhanced weather resistance and stabilityFireproof paintsAntifouling/underwater paintsCorrosion preventionPre treatment

The invention discloses a protection method for an outdoor willow furniture product. The protection method comprises the following steps: (1) preparation of a protection paint; (2) pretreatment of a willow product; (3) protection treatment. The protection paint in the protection method has an excellent use characteristic, the adsorbability of the protection paint and the willow product is further improved through a reasonable spraying method, and the protection paint on the surface of the willow product does not fall off or degrade even under the weather with bad environmental change. According to the outdoor willow furniture product treated by the method, the characteristics of inflaming retarding, smoke inhibition, corrosion prevention, mould prevention, insect prevention, antisepsis and loss resistance are well strengthened, the surface of the outdoor willow furniture product is smooth and has no wrinkle, the bending strength is improved by 20-30%, the compressive strength is improved by 15-20%, and the protection method has a high use value.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Ink-jet printing dyestuff ink

InactiveCN101186770AIncreased reflection densityStability has no effectInksPrintingDrying timePolymer chemistry

Disclosed is pigment ink for ink-jet printing, which is composed by mixing color paste, resin, pH regulating agents and de-ionized water and is characterized in that the weight percent of the color paste is 10-50%, the weight percent of the resin is 0.1-3%, the weight percent of the pH regulating agents is 0.1-2%, and the rest is the de-ionized water. The advantages and technical effects of the invention are in that satisfied scuff resistance can be achieved by changing the added resin, fingers can smear on the surface of printed materials without leaving any marks after printing is finished, strong luster sensation is achieved together with the scuff resistance, and stability and drying time of the ink can not be influenced after the resin is added.

Owner:天津兆阳纳米科技有限公司

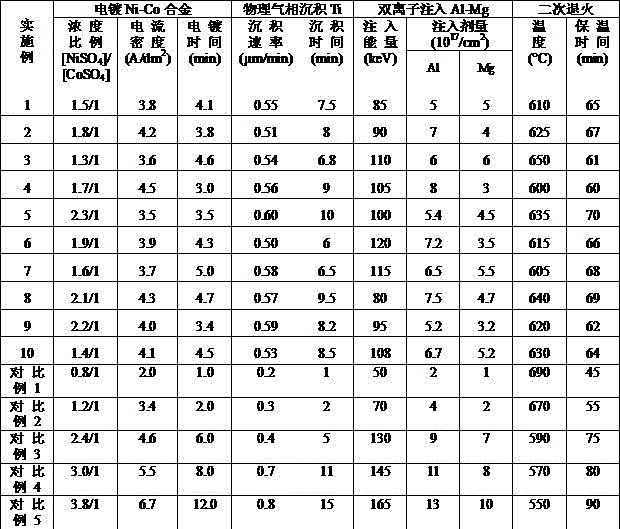

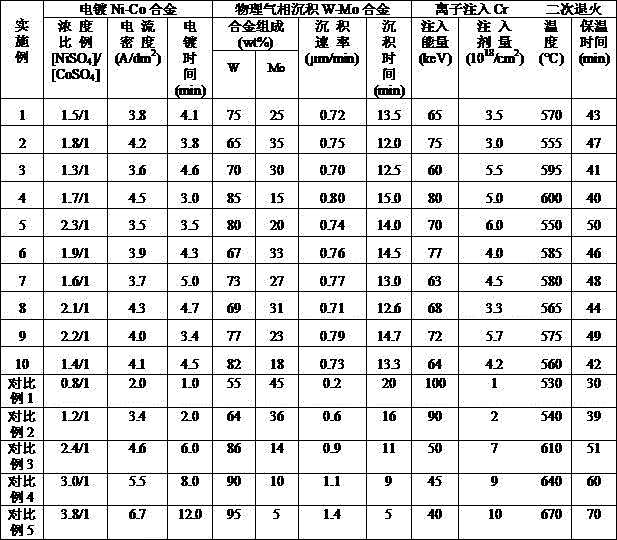

Production method of plating steel belt for household gas wares

InactiveCN105887146AImprove performanceTo meet the needs of the production of household gas appliancesVacuum evaporation coatingSputtering coatingAlloyChemical vapor deposition

Provided is a production method of a plating steel belt for household gas wares. The method comprises the steps that a DC03 hot-rolled pickling coil serves as a raw material, repeated cold rolling is conducted, and then degreasing is conducted; primary annealing is conducted; belt making is conducted, specifically, uncoiling and striping are conducted and burrs are removed; an Ni-Co alloy is electroplated; conventional washing and drying are conducted; physical vapor deposition is conducted; ion implantation is conducted; secondary annealing is conducted; and the plating steel belt is obtained by winding after being naturally cooled to the room temperature. The tensile strength of the steel belt is 500-550 MPa, ductility is 34-38%, the surface roughness is 0.04-0.07 micrometer, the specular reflectance is 99.2-99.7%, and the gloss loss is not more than 0.2% after the steel belt is exposed for 4000 days at the indoor atmosphere environment; and for the steel belt needed by a gas ware panel, the tensile strength is 400-450 MPa, ductility is 42-47%, the surface roughness is 0.02-0.05 micrometer, the specular reflectance is 99.55-99.95%, and the gloss loss is not more than 0.3% after the steel belt is exposed for 3600 days at the indoor atmosphere environment.

Owner:武汉钢铁有限公司

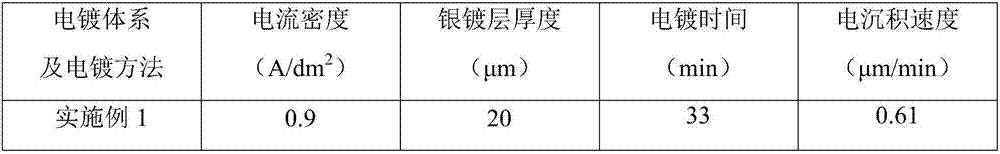

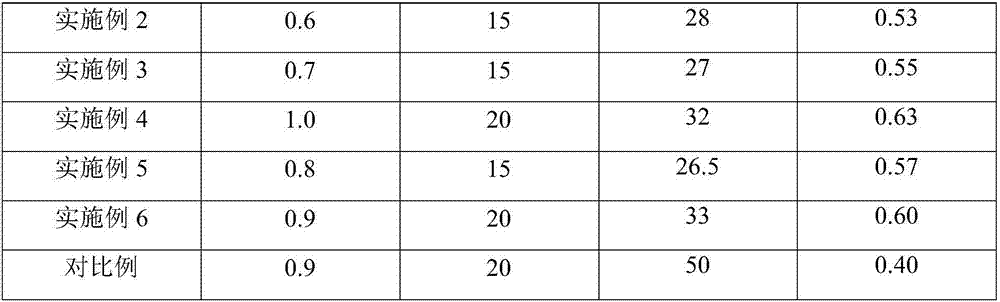

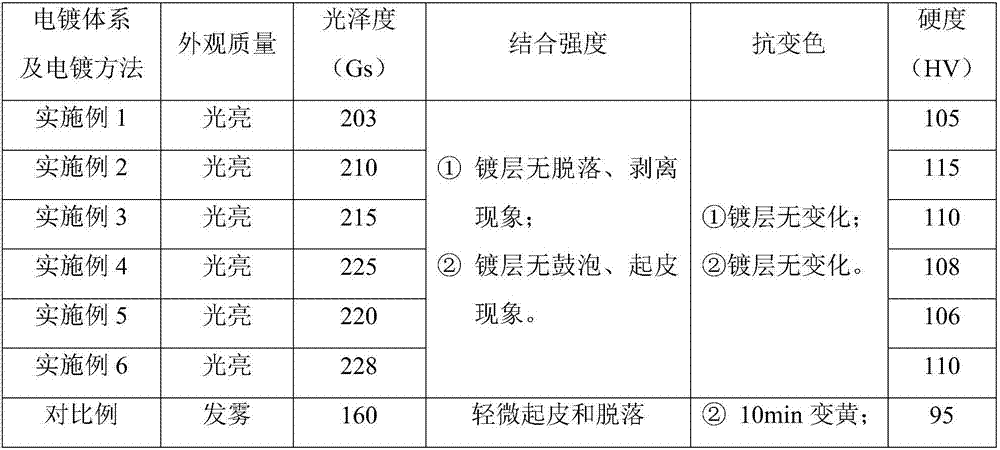

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

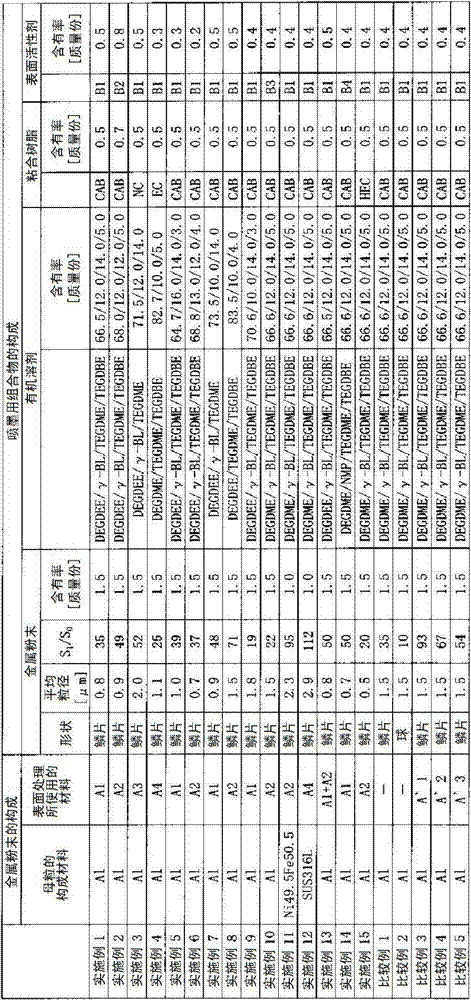

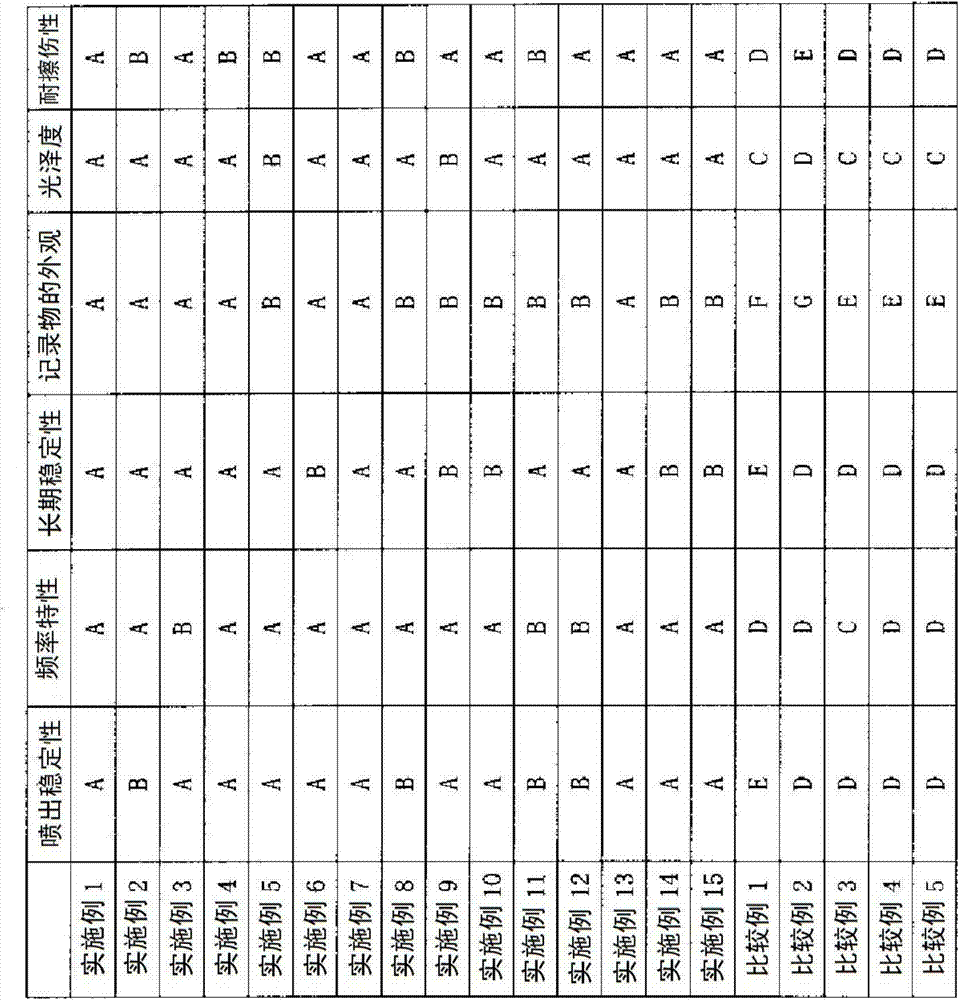

Composition for inkjet and recording material

The present invention provides a composition for inkjet and a recording material. The composition for inkjet has excellent discharge stability and excellent storage stability and can be appropriately used to form a pattern (printing part) with excellent glossy appearance. The recording material has a pattern with excellent glossy appearance by using the ultraviolet-curable composition for inkjet. A composition adapted to be discharged by an inkjet method includes a metal powder, an organic solvent, and a binder resin. The metal powder is treated by surface preparation with a fluorinated silane compound and / or a fluorinated phosphate ester as a surface preparation agent.

Owner:SEIKO EPSON CORP

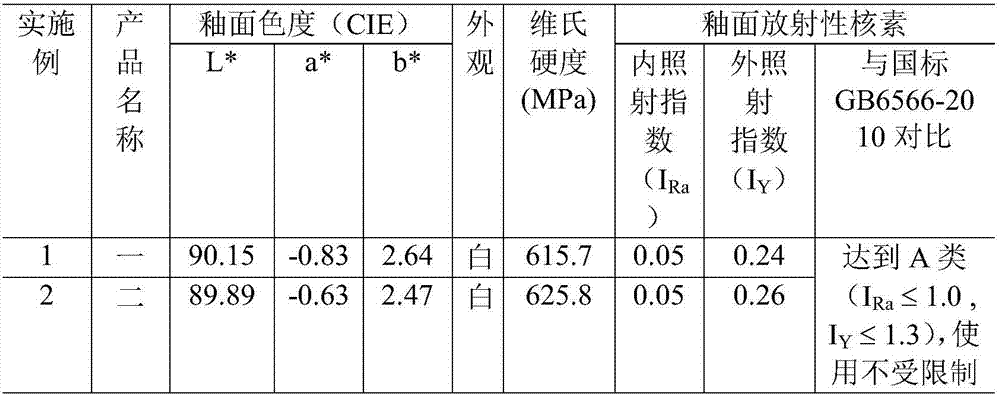

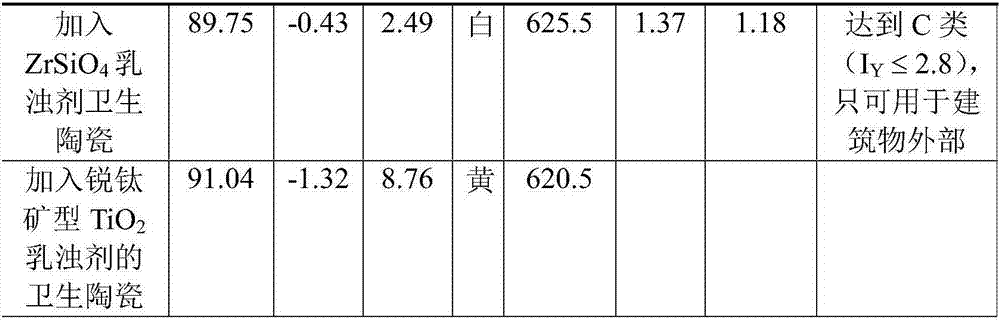

Technique of sanitary ceramic using composite titanium dioxide opacifier

The invention provides a technique of sanitary ceramic using a composite titanium dioxide opacifier in glaze slurry. The technique adopts the composite titanium dioxide opacifier, phosphate, potash feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaoline and a frit as raw materials for preparing opalescent glaze of the ceramic. The sanitary ceramic prepared by the technique has the advantages that: (1) a glaze layer of the prepared sanitary ceramic is tightly combined with a green body; a glaze surface has a good opacifying effect, and is high in whiteness, strong in luster sensation and delicate; (2) the composite titanium dioxide opacifier glaze and the glaze layer of the sanitary ceramic are free from radioactive substances and radioactive radiation and has effects of safety and protection of user health; and (3) the composite titanium dioxide opacifier is lower in cost and price; and phosphate is added into the glaze at the same time to further reduce the use amount of the composite titanium dioxide opacifier, so that the cost of the sanitary ceramic is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for manufacturing polystyrene torsion film

InactiveCN101096129AExcellent mechanical propertiesHigh glossSynthetic resin layered productsFlat articlesEngineeringHigh intensity

The invention discloses a producing method for no-rebound polystyrene torsion film used for food package. Polystyrene resin, high impact polystyrene resin or modified polystyrene resin is mixed with toughening agent and so on in plasticization. The mixture is melted and extruded out to form single-layer or multiple-layer film. The film is drawn in horizontal and vertical direction to become finished product. The torsion film is provided with better mechanical characteristic, high intensity, big rigidity, no rebound elasticity. The torsion film is a better torsion film and can take the place of PVC torsion film, glass paper or PET torsion film as packaging material.

Owner:GUANGDONG HUAYE PACKING MATERIAL

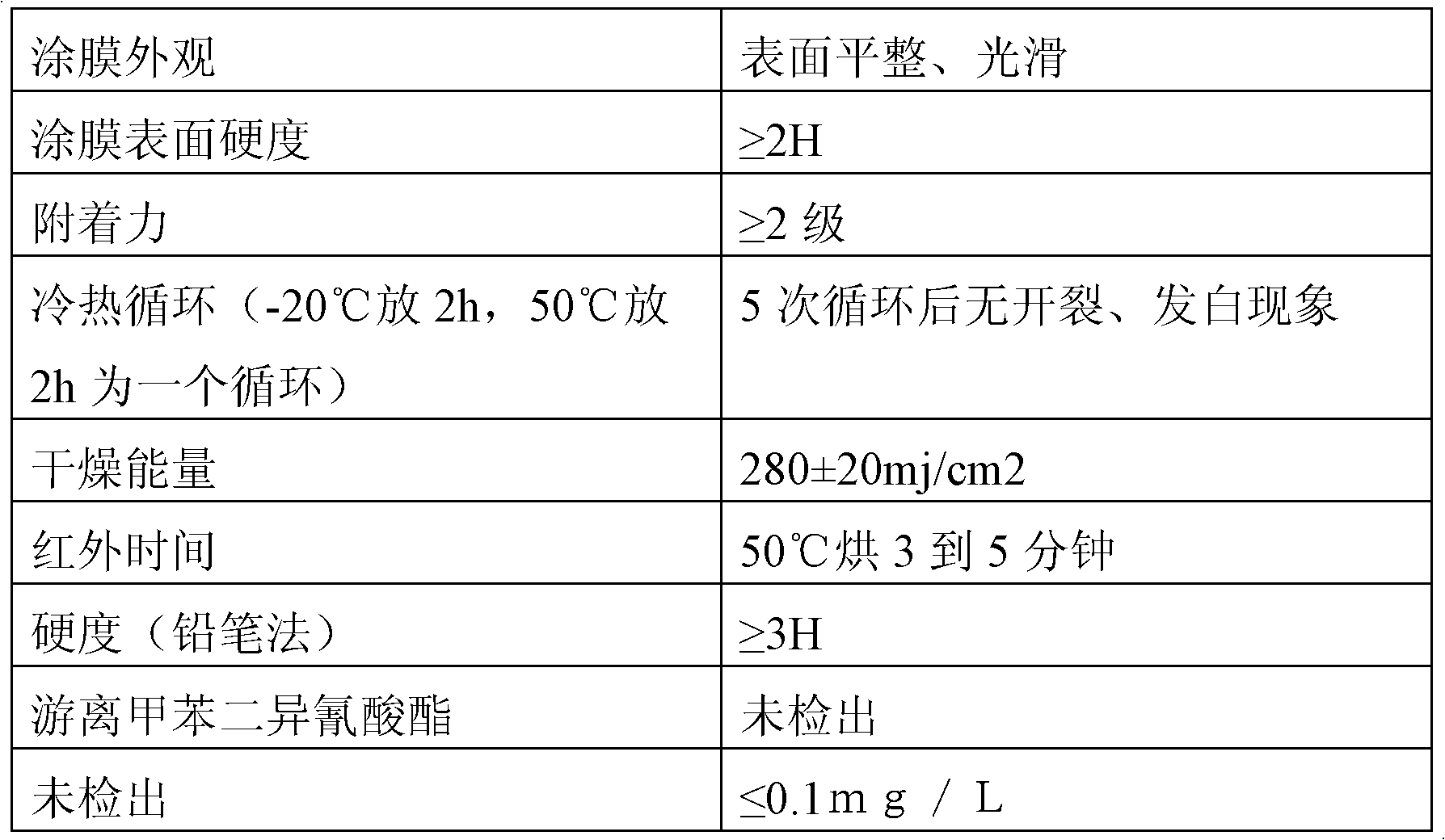

Ultraviolet solidified yellowing resistant and glossy woodenware paint and application technology thereof

InactiveCN102220070AScratch resistantStrong glossPretreated surfacesPolyurea/polyurethane coatingsPolyesterButyl acetate

The invention relates to an ultraviolet solidified yellowing resistant and glossy woodenware paint, which comprises components of A and B. Wherein, component A is composed of epoxy acrylate (EA), polyurethane acrylate (PUA), polyester acrylate (PEA), an active diluent, an antifoaming agent, a levelling agent, a dispersant and a photoinitiator, while component B is composed of butyl acetate, B fat and xylene. According to the application technology, component A and component B are mixed at a proportion of 100:20-50 and then used for application. The paint of the invention has the advantages of strong glossiness, high hardness, scratch resistance, yellowing resistance, good fullness of color, fast drying speed and simple application.

Owner:上海展辰涂料有限公司

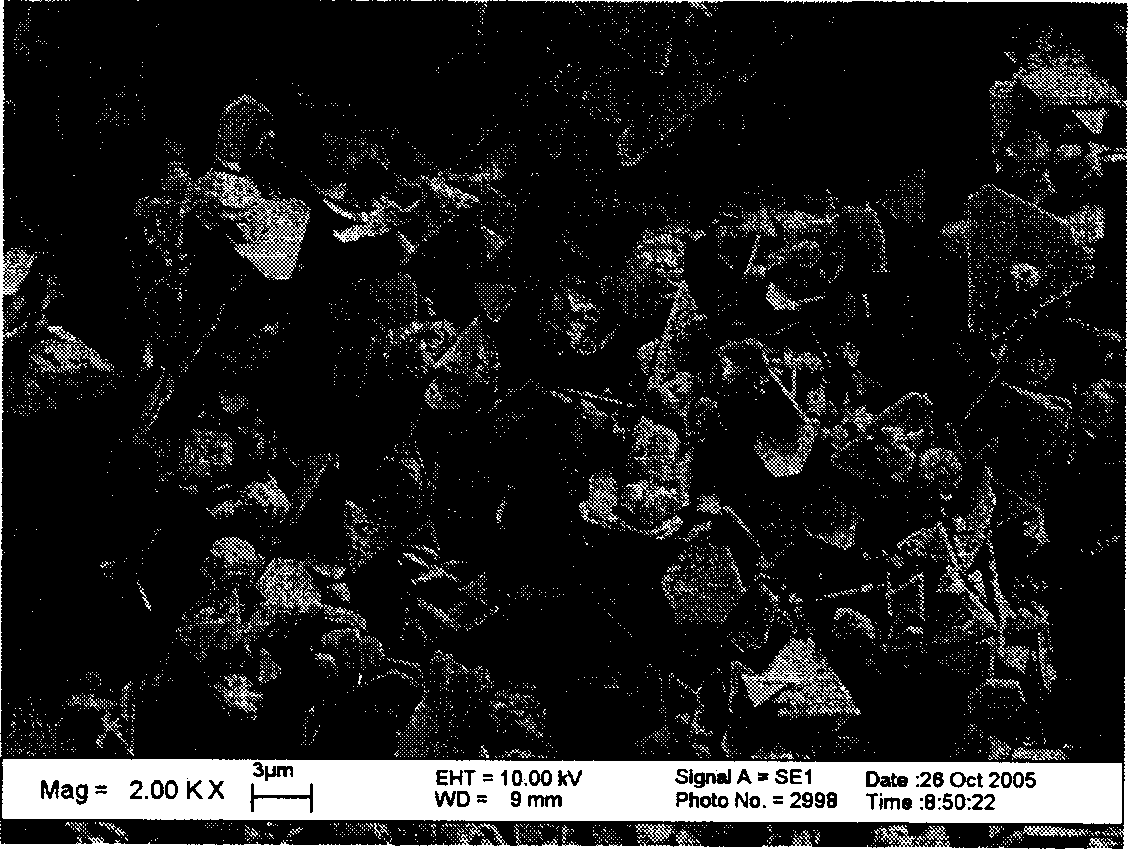

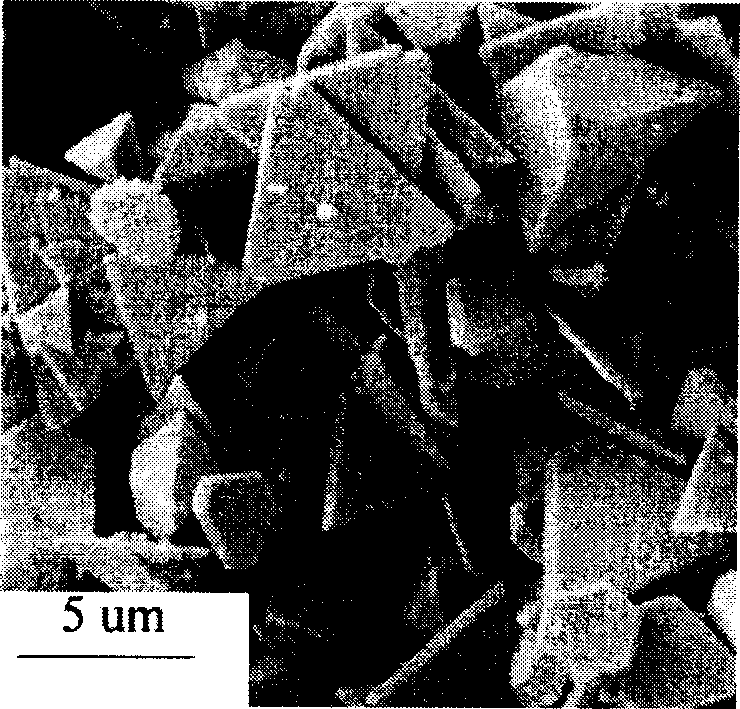

Sheet crystal cupper powder and liquid phase chemical preparation process thereof

A liquid-phase chemic method for preparing the flaky-crystal cupper powder from cuprous oxide powder, amino acetic acid or amino propionic acid as promoter and ammonium hexadecane trimethylbromide as disperser through dissolving promoter and disperser in deionized water, adding cuprous oxide powder, stirring, regulating the pH value of reducer (hydrazine) solution, adding it to the dispersed cuprous oxide solution, reaction, separation, washing and drying.

Owner:SOUTH CHINA UNIV OF TECH

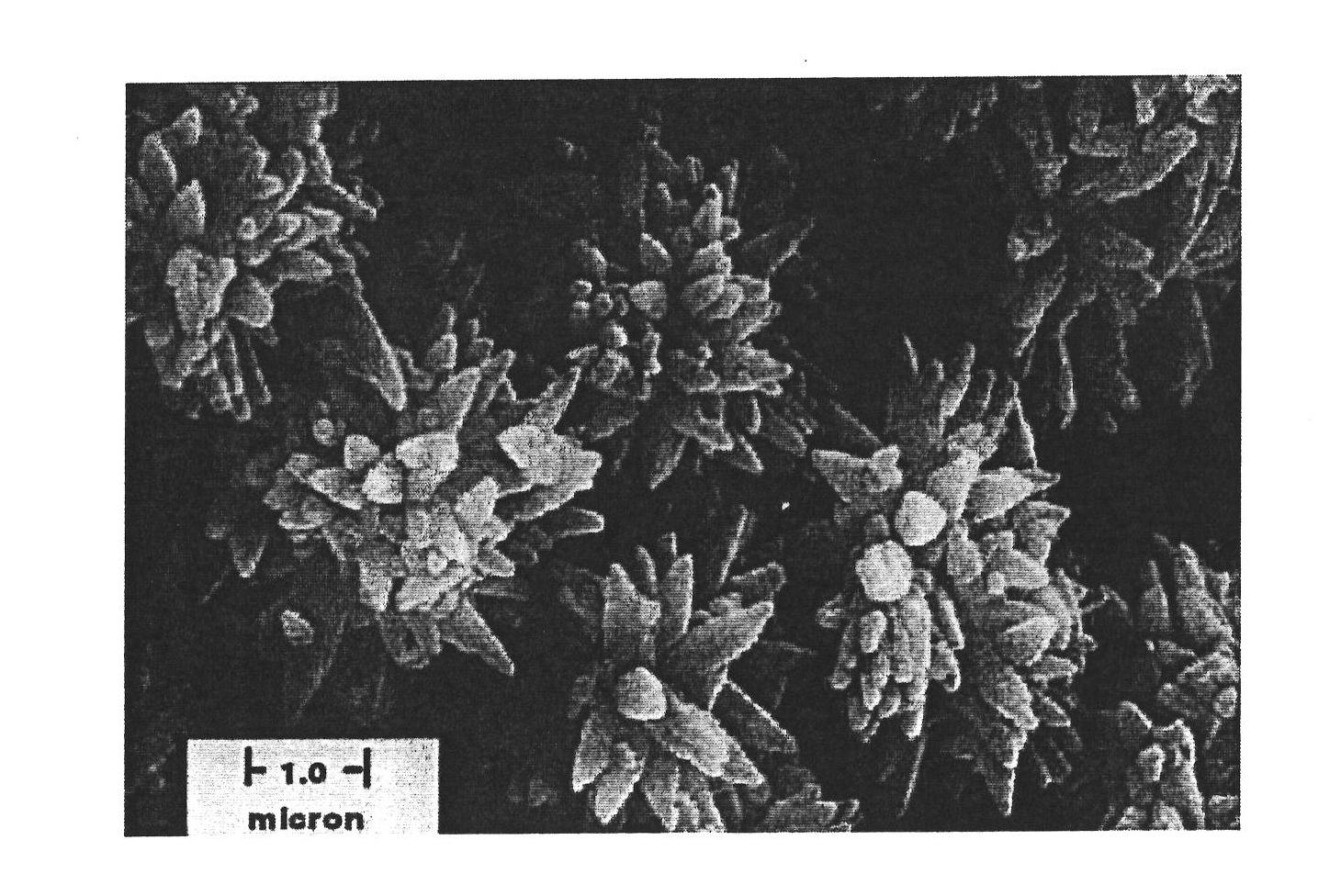

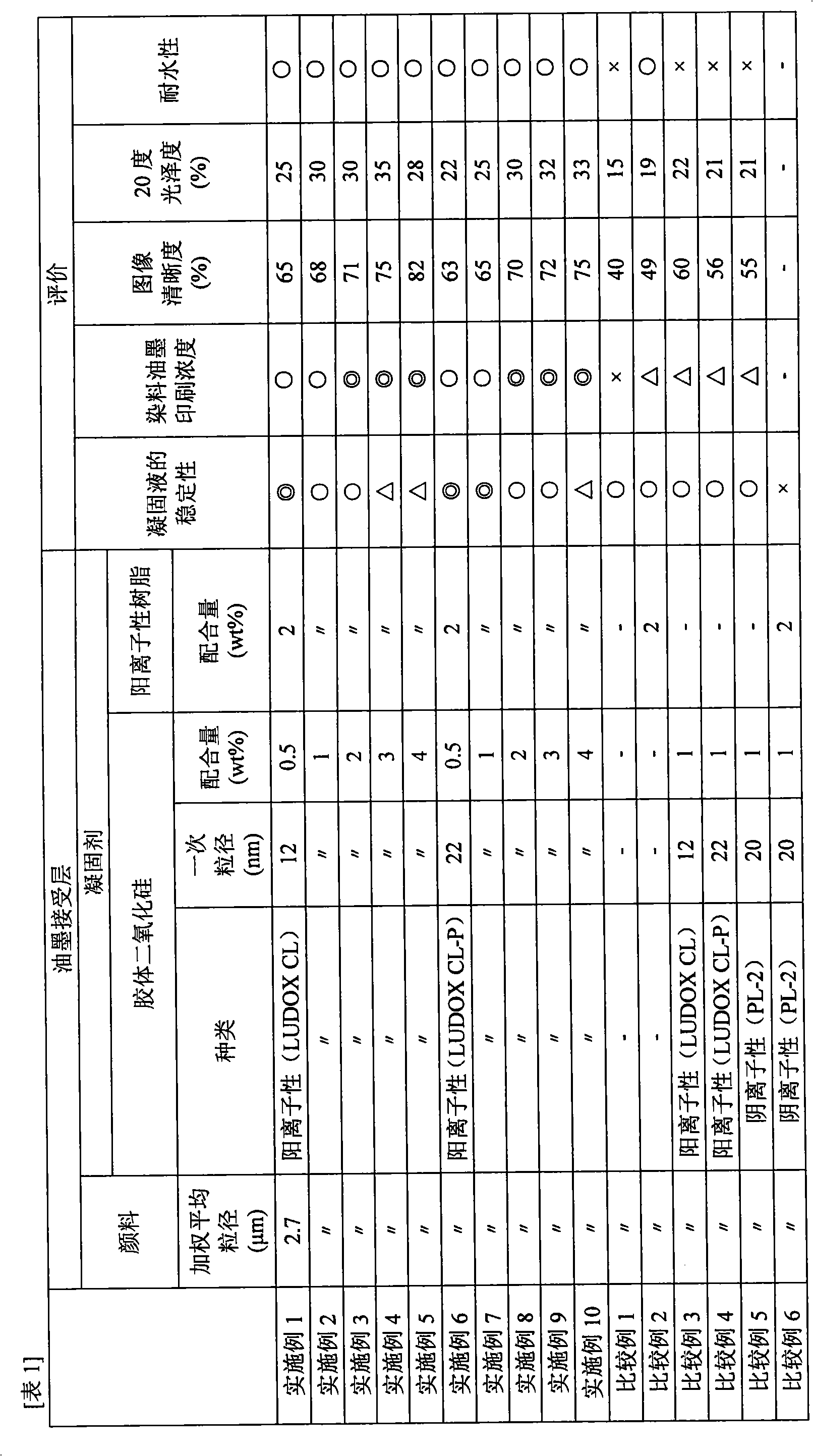

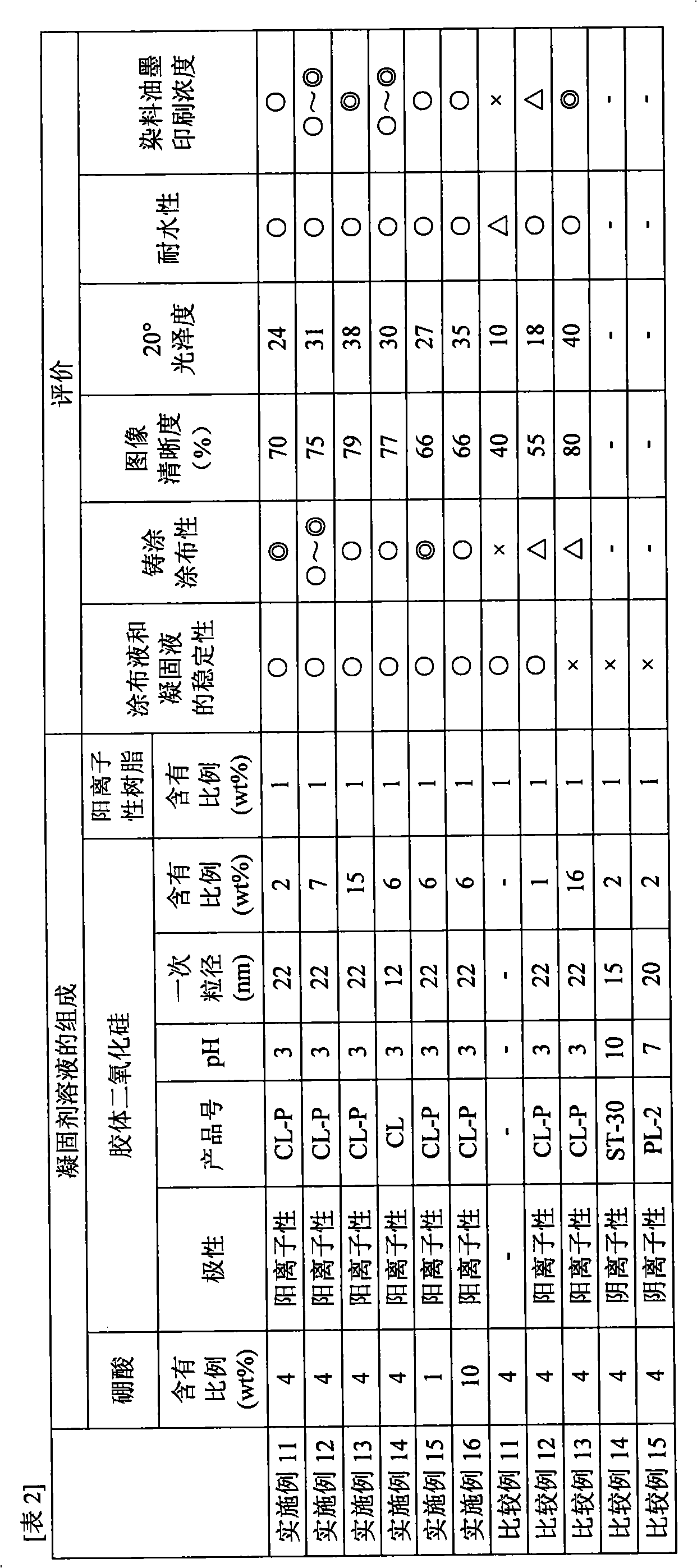

Ink jet recording medium and process for producing the ink jet recording medium

InactiveCN101980872APromote absorptionImprove water resistanceDuplicating/marking methodsCoatingsColloidal silicaSilicon dioxide

Disclosed is an ink jet recording medium that has an excellent glossy impression, has a high print density in ink jet recording using a dye ink, and has excellent ink absorption and waterfastness. The ink jet recording medium is produced by forming a coating layer containing a pigment and a binder on at least one side of an air permeable support and then coating a coagulating agent, which coagulates the binder, onto the surface of the coating layer to provide an ink receptive layer by a coagulation cast coating method. A boron compound, a cationic resin, and a cationic colloidal silica contained in the coagulating agent are present on the surface of the ink receptive layer.

Owner:NIPPON PAPER IND CO LTD

Double-sided color electric aluminum hot stamping foil and production method thereof

InactiveCN105500853AAccurate overprintStrong glossSynthetic resin layered productsMetal layered productsHot stampingComposite film

The present invention provides a double-sided color electric aluminum hot stamping foil and a production method thereof. According to the present invention, after the double-sided color electric aluminum hot stamping foil is subjected to hot stamping on a transparent material, the front surface and the back surface of the stamped material can display the same or different colors; after the double-sided color electric aluminum hot stamping foil is used for plastic composite film printing, the hot stamping picture-text can be lined while the printing on the back surface, and the precise chromatograph edition of the hot stamping pattern and the ink printing picture-text can be achieved; and after the product is compounded, the printing layer and the hot stamping layer are positioned on the inner surface of the printed film, the gloss is strong, and the scratch caused by external force cannot be generated.

Owner:KUNSHAN SHENGLI PACKAGING MATERIALS

Production method of transferring form packing paper

InactiveCN101012630AStrong glossStructuredFlexible coversWrappersPrinting inkPulp and paper industry

The invention relates to a manufacturing method of cigarette packing material, which is the improvement to prior technology and relates to a manufacturing method to tipping paper of transferring paper type. The tipping paper produced in the invention is that after original paper with 32g is compounded with transferring film, the matrix film is eliminated so as to make the brushing face of original paper high smoothness and strong luster sensation; if it is compounded with laser transferring film, there are every kinds of luxurious patterns and reflecting seven-colored gloss. The tipping paper can produce brand cigarette product and when the tipping paper of cigarette is touched with people's mouth directly, there is no harm for human body. The invention is the improvement for prior technology. The transferring paper is printed by semitransparent special printing ink. After bronzing, the tipping paper is provided with very strong gloss, clear level and beautiful pattern. The transferring tipping paper adopts a great deal of original material with environmental protection so as to make cigarette more environmental protection. There in no pollution to circumstance in the producing process and it can be used to produce brand cigarette. The invention is more reasonable manufacturing method for transferring tipping paper and can be widened.

Owner:GANSU TOBACCO IND

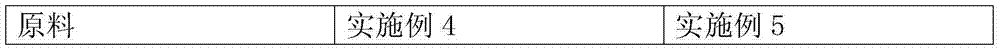

Environmental-protection interior wall latex paint

The present invention provides an environmental-protection interior wall latex paint, which comprises a dispersing agent, a preservative, a bactericidal agent, an insecticide, essence, active carbon, a pigment filler, a film-forming additive, a defoamer, an elastic emulsion, a multi-function auxiliary agent, and water.

Owner:TIANJIN YICHENG SHUOSHEN ENVIRONMENTAL PROTECTIONDEV CO LTD

Luminescent nylon-real silk fabric

The invention discloses a luminescent nylon-real silk fabric which is in a composite structure which is formed by a nylon yarn layer, a real silk layer and a luminescent coating layer, wherein real silks are natural silks, the luminescent coating layer is an outer fabric layer, the nylon yarn layer is a middle fabric layer, and the real silk layer is an inner fabric layer which is contacted with a human body; the luminescent coating layer is fluorescent powder or reflection materials; and the thickness ratio of the luminescent coating layer to the nylon yarn layer to the real silk layer is 1:4:5, and the nylon yarn layer is a bright nylon yarn layer. Through the mode, the outer fabric layer of the product is the luminescent coating and can illuminate at night, and the middle layer adopts the nylon yarn layer, is bright in color, and has high color fastness, wear resistance, strong glossiness and better gloss compared with that of the natural silk; and the inner layer adopts the real silks, and has strong moisture absorption and good air permeability. When the fabric is made into clothes, the natural silks are the parts of the clothes, which are contacted with the human body, the clothes are soft and smooth, comfortable to wear, and also have the antibacterial function. The fabric can be widely applied to various T-shirts, gym suits, home textiles and the like.

Owner:江苏红运果服饰有限公司

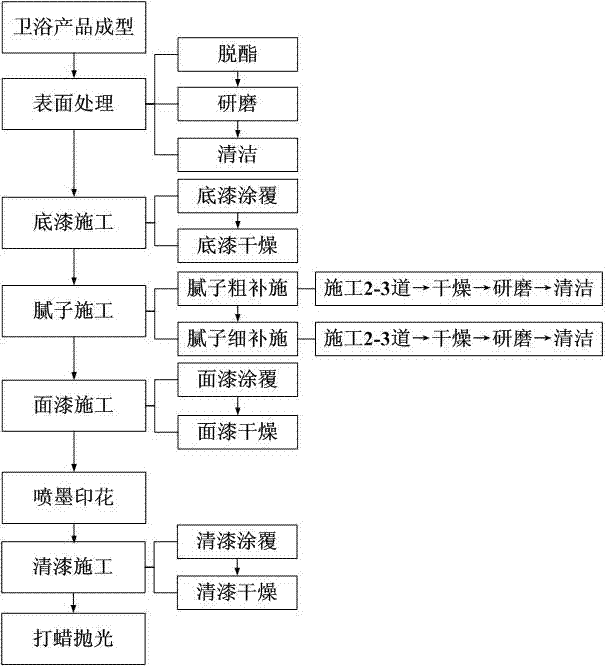

Ink-jet printing method of bathroom product

ActiveCN102862408AHigh hardnessImprove corrosion resistanceDuplicating/marking methodsPrinting after-treatmentScreen printingSurface cleaning

The invention discloses an ink-jet printing method of a bathroom product. According to sequence, the ink-jet printing method of the bathroom product includes: adopting the processes of cabinet plate shaping, surface cleaning, base coat construction, finish paint construction, ink-jet printing, varnish construction, polishing and waxing. The ink-jet printing method of the bathroom product adopts an advanced ink-jet printing technology, exquisite printing patterns are output by a computer directly, no film and no plate making are needed, printing efficiency is high, high definition fine printing is performed, picture quality is high clear, no film screen printing point exists, image color is beautiful, vivid, surface is smooth, and color is even. Furthermore, waterproof printing ink is adopted in the ink-jet printing process, and the fine printing patterns are waterproof, sun-proof, abrasion-resistant and not prone to fade and drop.

Owner:广东吉立屋集成房屋科技有限公司

Light and thin wrinkle nylon fabric and production method thereof

The invention discloses light and thin wrinkle nylon fabric and a production method thereof. Yarns accounting for 60 wt percent of the fabric are hollow nylon yarns with the fineness in the range of 10-75 denier, the tearing strength of the fabric in the warp and weft direction is in the range of 10-15 N, and the venting quality is less than 1.5 cc / cm<2>.sec. According to the light and thin wrinkle nylon fabric and the production method thereof, the technique is simple, the cost is low, the natural wrinkle effect is durable, and the nylon fabric also can have glossiness after being subjected to high-temperature calendaring. The light and thin wrinkle nylon fabric and the production method thereof can be applicable to down wear, down jackets, sleeping bags, fashion and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

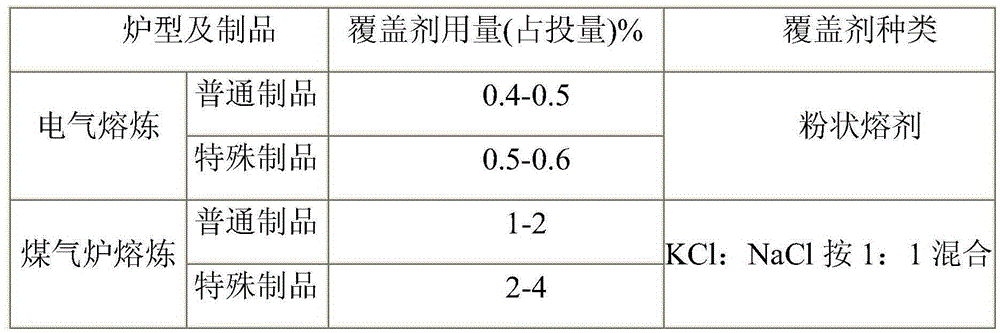

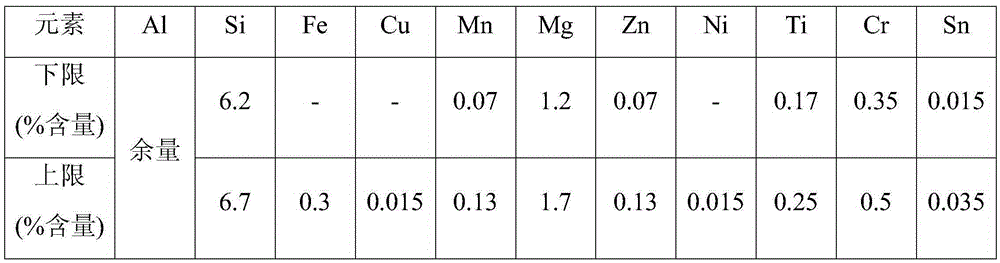

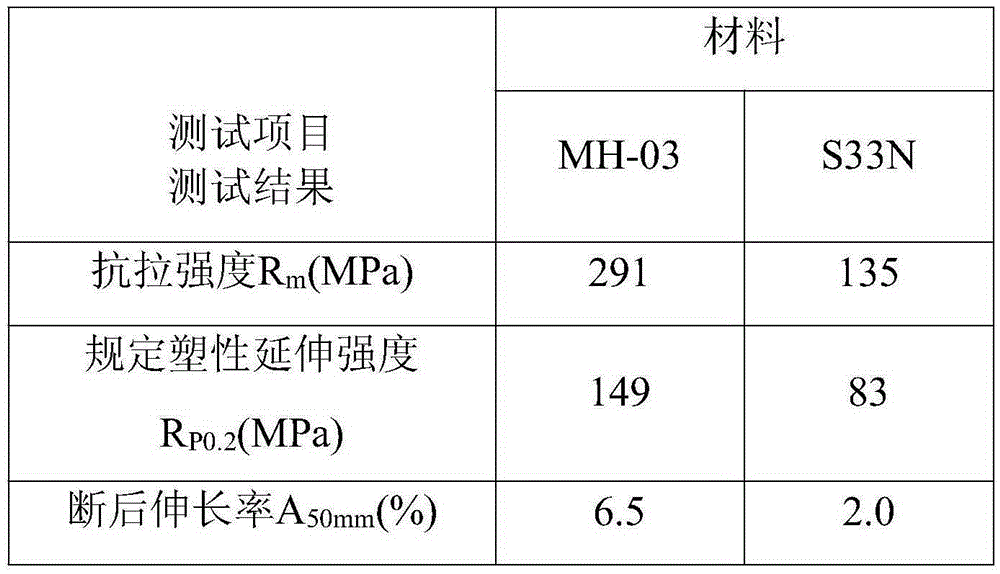

High-end aluminium alloy material MH-03 and preparation method thereof

The invention discloses a high-end aluminium alloy material MH-03. The high-end aluminium alloy material MH-03 comprises the following components: 89.0-91.0% of Al, 1.8-3.5% of Si, less than 0.50% of Fe, less than 0.2% of Cu, 0.55-1.0% of Mn, 4.8-6.5% of Mg, less than 0.3% of Cr, less than 0.07% of Ni, 0.05-0.1% of Zn, less than 0.2% of Ti, less than 0.005% of Bi, less than 0.002% of Ca, less than 0.1% of Pb, less than 0.05% of Sn, less than 0.005% of Bi, and less than 0.001% of Cd. The high-end aluminium alloy material MH-03 disclosed by the invention has higher tensile strength, specified plastic extension strength, percentage elongation after fracture, elasticity modulus and Brown hardness; the content of harmful substances is extremely low, and far lower than the limit value of 2001 / 65 / EU instructions; and the high-end aluminium alloy material MH-03 is simple in preparation process, and suitable for mass production.

Owner:深圳市鑫雅豪智能科技股份有限公司 +1

Aqueous paint and preparation method thereof

The invention discloses aqueous paint. The aqueous paint comprises the following materials in parts by weight: 80-90 parts of aqueous acrylic emulsion, 15-20 parts of light calcium carbonate, 8-10 parts of hydroxypropyl methyl cellulose, 2-3 parts of dibutyl phthalate, 2-4 parts of glycerol, 1-2 parts of glycol ether, 1-2 parts of sodium polyacrylate, 1-2 parts of buthyl polyacrylate, 2-3 parts of hydrotalcite, 0.2-0.4 part of dimethyl silicon oil, 1-3 parts of diphenylamine, 10-20 parts of deionized water, 0.8-1 part of N-(beta-aminoethyl)-gamma-aminopropyl trimethoxy silane and 10-15 parts of composite mosifying agent. The paint film produced by the preparation method disclosed by the invention is firm, good in glossiness, strong in impact resistance, unlikely to crack, soft in texture, strong in decoration, high in weather resistance, washing-resistant, strong in adhesive force, long in service life, free of special smell, free of heavy metals including mercury, lead and the like, free of formaldehyde volatile matter and capable of satisfying the technical requirements of environmentally-friendly paint. The conventional titanium dioxide is replaced by the added composite modifying agent, so that the surface gloss of the paint film is improved and the production cost is saved; moreover, the paint film has better washing resistance and weather resistance, and therefore, the quality of the paint film is strengthened.

Owner:ANHUI ZHENXIN PAINT

Ink composition, recording method using the same, and recorded matter

InactiveCN101151334AStrong glossImprove scratch resistanceDuplicating/marking methodsInksCross-linkPolymer science

PROBLEM TO BE SOLVED: To provide an ink composition capable of obtaining an image having an excellent glossy feeling for various recording media, especially the recording media having gloss, showing less bronze phenomenon and having a good fixing property and abrasion resistance such as a gloss change, etc. SOLUTION: This ink composition at least containing a coloring agent covered by a water insoluble polymer and resin particles is characterized in that the water insoluble polymer is a polymer obtained by polymerization using at least a polymerizable unsaturated monomer and a polymerization initiator by a solution polymerization method, the coloring agent covered with the water insoluble polymer is the coloring agent obtained by a phase inversion emulsification of dissolving the water insoluble polymer with an organic solvent, adding at least the coloring agent and water, mixing and then removing the organic solvent to disperse in an aqueous medium, and the resin particles are made of at least a polymer obtained by a polymerization by emulsion polymerization method using a cross-linking agent. COPYRIGHT: (C)2007,JPO&INPIT

Owner:SEIKO EPSON CORP

Production method and device for special crystal cotton fiber

The invention discloses a production method and device for special crystal cotton fiber. The invention is aimed at providing a production method for special crystal cotton fiber. The glazed flat POY raw silk is used as raw material, and the raw silk is introduced into a tow raw silk tube through the silk frame hanging wire device at the same time so that the tow directly enter into a first roller through a silk guider; compressed air network is performed before entering into the first roller; the tow enters into the an upper heating box for low-temperature tensile deformation; then the tow enters into a cooling plate to be stretched, cooled and sized and enters into a false twister for false twisting so that the tow has a good bulkiness; then the tow enters into a lower heating box for sizing; the sized tow is sent out through a third roller and then fully oiled on an oil wheel through a silk guider, and then the tow enters into a spindle derivation friction roller for winding formation. By means of the production method and device, the special crystal cotton fiber with the characteristics of strong fabric gloss, soft and comfortable surface, good post-hair style and good hair straightness, anti-pilling, stain resistance and rigidity is produced.

Owner:桐乡市中洲化纤有限责任公司

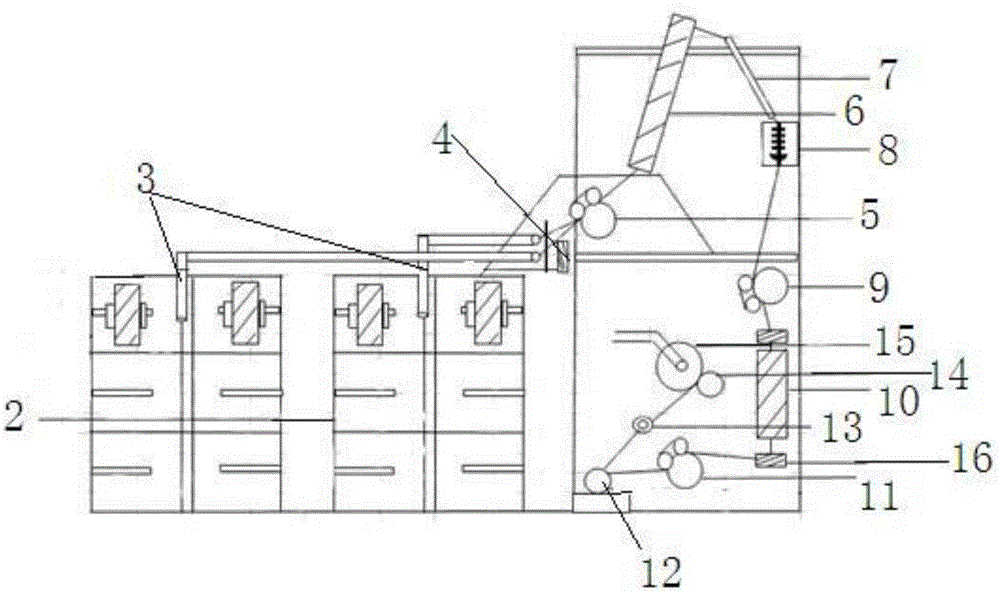

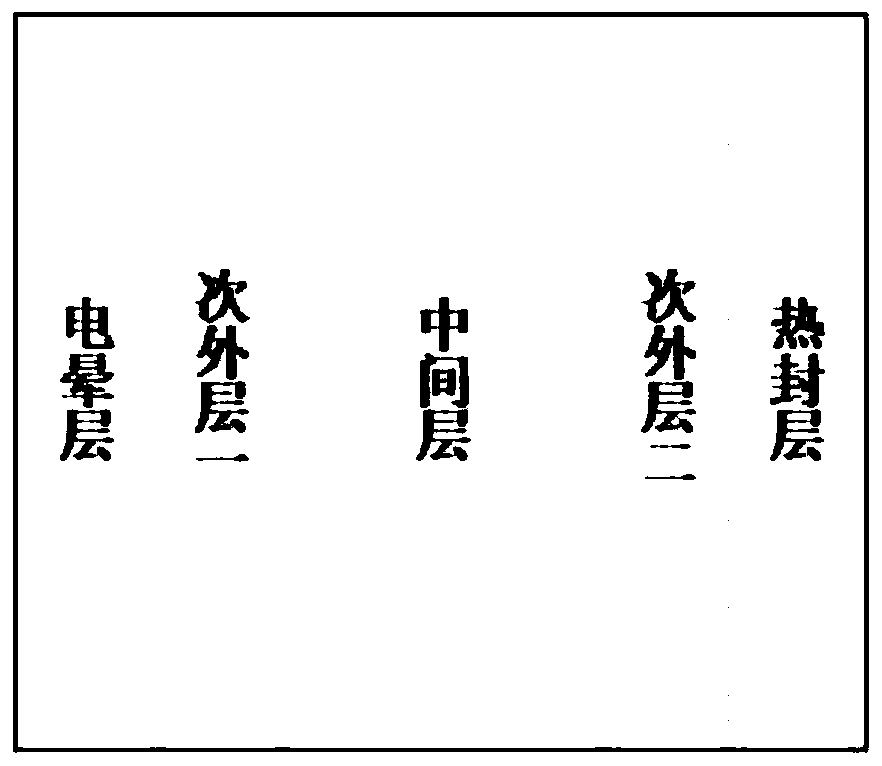

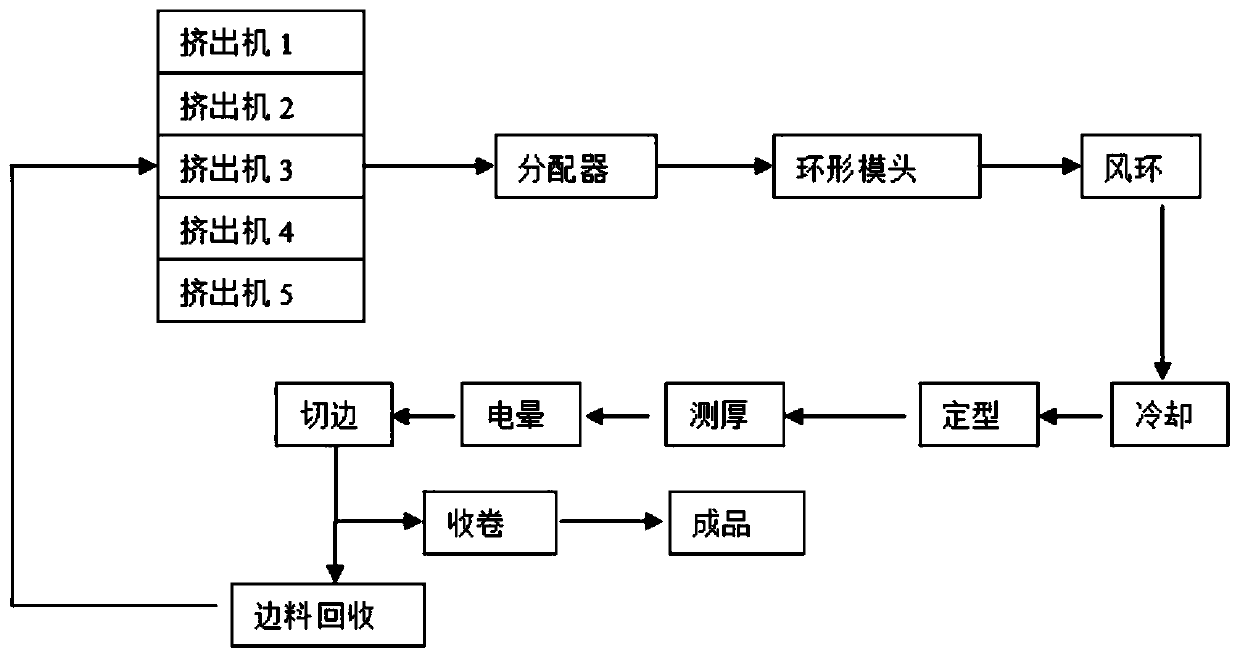

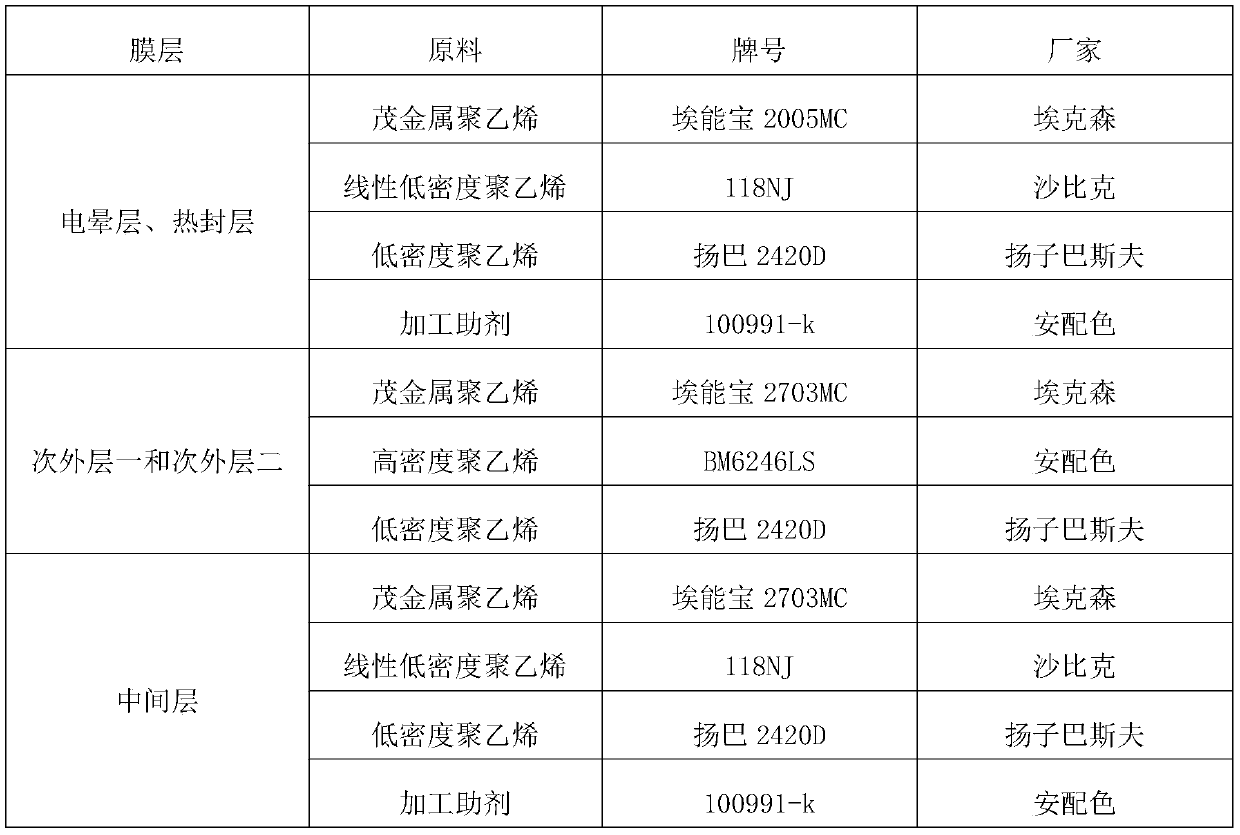

High-light low-haze PE heat shrinkable film and preparation method thereof

ActiveCN110216960AFlat forceIncrease productivitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-light low-haze PE heat shrinkable film and a preparation method thereof. A film layer structure of the PE heat shrinkable film successively comprises a corona layer, afirst sub-outer layer, an intermediate layer, a second sub-outer layer and a heat sealing layer; the corona layer, the intermediate layer and the heat sealing layer separately comprise metallocene polyethylene, linear low-density polyethylene, low-density polyethylene and a processing aid in a mass ratio of (28-32):(8-12):(58-62):(0.1-0.3); and the first sub-outer layer and the second sub-outer layer separately comprise metallocene polyethylene, high-density polyethylene and low-density polyethylene in a mass ratio of (28-32):(28-32):(38-42). The PE heat shrinkable film has high shrinkage rate, powerful shrinkage memory function, large tensile strength, powerful puncture resistance and anisotropic tearing resistance, and has the characteristics of low haze, high transparency and high gloss, the friction coefficient is moderate and stable, thickness uniformity and flatness are good, and printing adaptability is good.

Owner:HUANGSHAN NOVEL

Walnut shell skin cleaning and moistening scrubbing cream and preparation method thereof

InactiveCN104958229AKeep MoisturizedKeep the glossCosmetic preparationsToilet preparationsBiotechnologyCutin

The invention discloses a walnut shell skin cleaning and moistening scrubbing cream and a preparation method thereof. The scrubbing cream is prepared from the following raw materials in parts by weight: 0.2-0.6 part of walnut shell flour, 0.4-0.8 part of Carbomer, 1-5 parts of honey, 1-5 parts of brown sugar, 0.5-2.5 parts of Jojoba oil, 0.5-2.5 parts of coconut oil, 0.3-1 part of rose essential oil, 0.1-0.4 part of diazolidinyl urea, a proper amount of triethanolamine and a proper amount of water. According to the walnut shell skin cleaning and moistening scrubbing cream disclosed by the invention, since natural ingredients are used as a scrubbing agent, a mild effect is realized, cutin can be removed, and the skin is cleaned, moistened and smooth. The walnut shell skin cleaning and moistening scrubbing cream is non-irritant and suitable for all skin types.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com