Composition for inkjet and recording material

A composition and inkjet technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of inability to give full play to the metallic luster, composition stability (deterioration of storage stability, decline of ejection stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

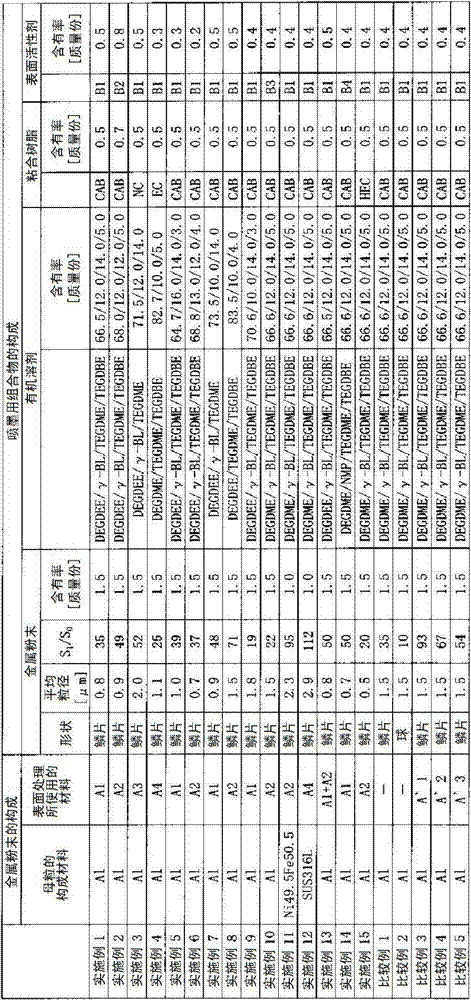

Embodiment 1

[0134] First, a polyethylene terephthalate film with a smooth surface (surface roughness Ra of 0.02 μm or less) was prepared.

[0135] Next, silicone oil was coated on the entire surface of one side of the film.

[0136] Next, a film made of Al was formed by a vapor deposition method on the surface side on which the silicone oil was applied.

[0137] Next, the polyethylene terephthalate film (base material) on which the Al film was formed was placed in a liquid composed of diethylene glycol diethyl ether, and ultrasonic vibration was applied. In this way, scaly Al particles (particles that should serve as master batches) were obtained.

[0138] Next, by putting the particles made of Al obtained in the above manner into CF which is a fluorophosphate 3 (CF 2 ) 4 (CH 2 ) 2 O-PO(OH) 2 1% by mass of propanol solution, and stirred for 10 seconds, so that the surface treatment by fluorophosphate ester was carried out, and the metal powder was obtained.

[0139] The average pa...

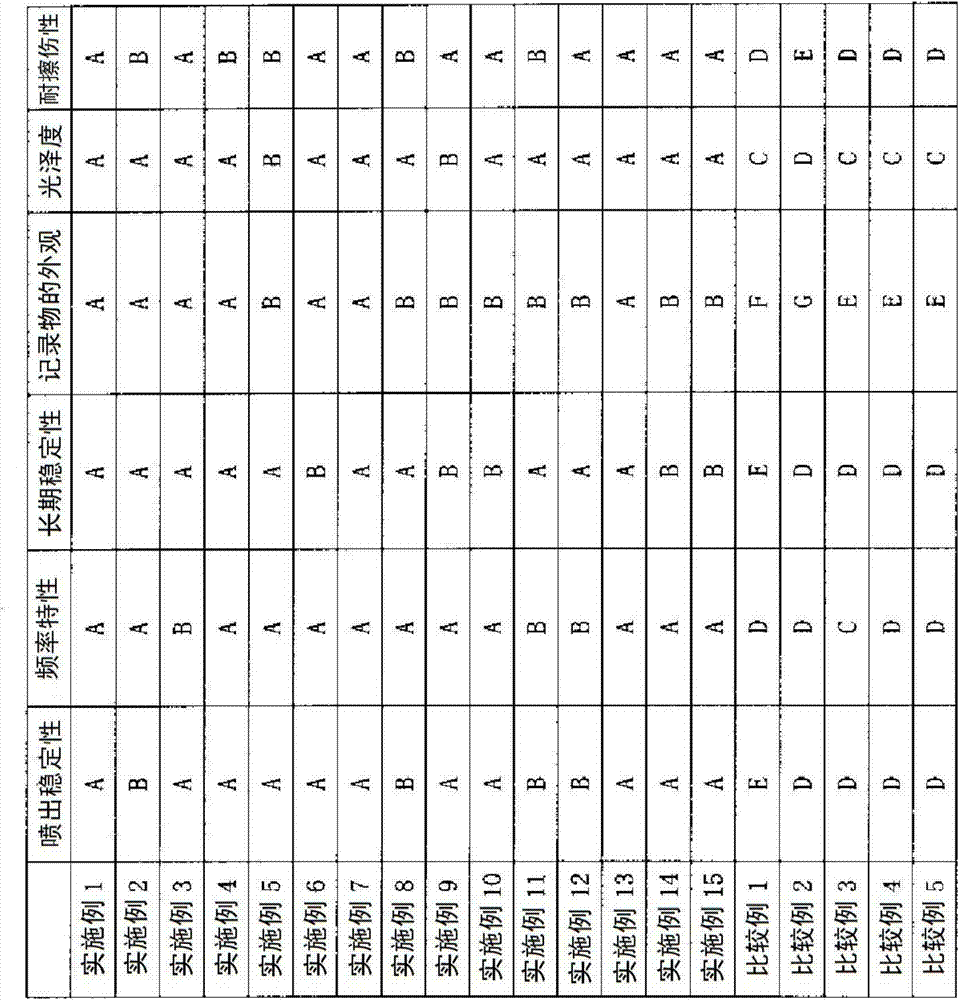

Embodiment 2~15

[0142] As shown in Table 1, the composition of the metal particles (the composition of the master batch and the type of compound (fluorine-based compound) used for surface treatment) was set, and the type of raw materials used for the preparation of the inkjet composition Or the ratio was changed so that the composition shown in Table 1 was obtained, and an inkjet composition was produced in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com