Production method and device for special crystal cotton fiber

A production method and technology of crystal cotton, applied in the field of polyester fiber production, can solve the problems of lack of production capacity and product effect, and achieve the effects of good rigidity, guaranteed stability and strong fabric luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

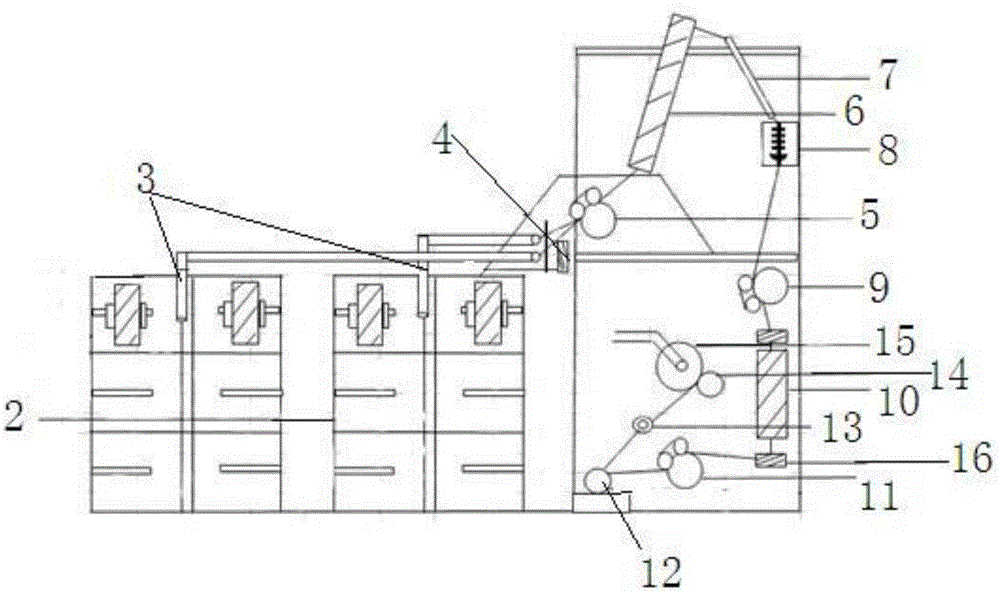

[0010] Below in conjunction with accompanying drawing, the present invention will be further described with regard to specific embodiment:

[0011] A production method of special crystal cotton fiber, which adopts glossy flat POY raw silk as raw material, and simultaneously introduces the raw silk into the tow raw silk tube through the wire frame hanging device, so that the tow directly enters the first roller through the yarn guide, Compressed air network is performed before the first roller, and then enters the upper hot box for low-temperature stretching and deformation, and then enters the cooling plate for stretching, cooling and shaping, and enters the false twister for false twisting, so that the tow has good bulkiness. Enter the lower hot box for shaping, and the shaped tow is sent out through the third roller, and then through the yarn guide, and finally fully oiled on the oil tanker, and then wound to the friction roller of the spindle position for winding and forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com