High-end aluminium alloy material MH-03 and preparation method thereof

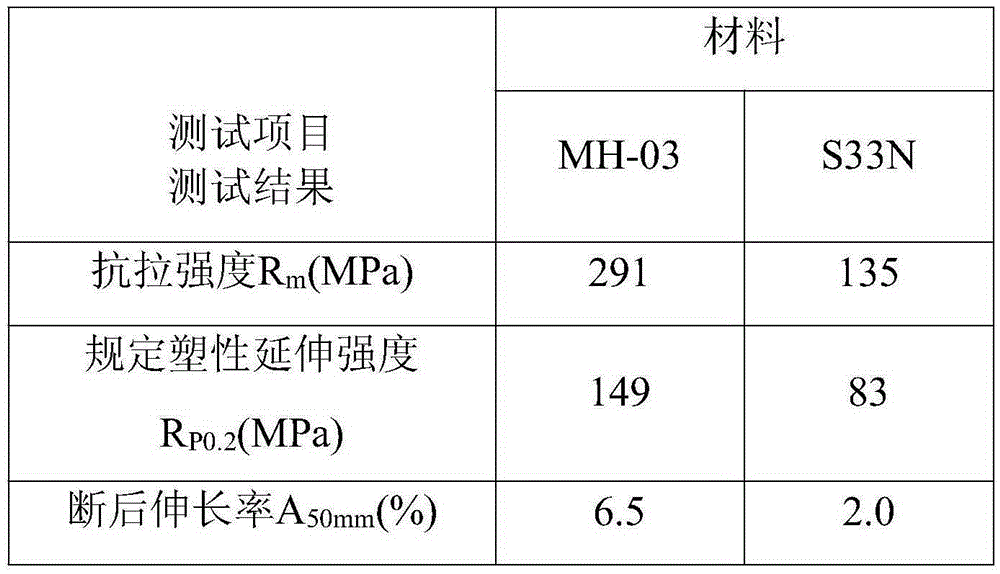

An aluminum alloy material, MH-03 technology, applied in the field of high-end aluminum alloy materials and its preparation, can solve the problems of tensile strength, hardness, elongation after fracture, elastic modulus, etc., and achieve low harmful substance content and high toughness Strong, to solve the effect of insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 aluminum alloy material MH-03 and preparation method thereof

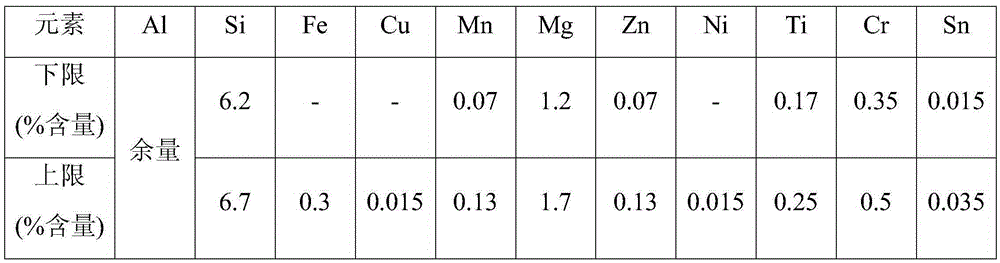

[0028] An aluminum alloy material in this embodiment is prepared from the following components in weight percentage: Al90.2649%, Si2.26%, Fe0.276%, Cu0.0465%, Mn0.737%, Mg6.1 %, Cr0.135%, Ni0.0035%, Zn0.0783%, Ti0.0712%, Bi0.0045%, Ca0.0012%, Cd<0.001%, Sn0.0070%, Zr0.0017%, Pb0.0132 %.

[0029] The preparation method of the aluminum alloy material of this embodiment comprises the following steps:

[0030] 1. Loading

[0031] During smelting, the order and method of charging the charge not only affect the smelting time, metal burning loss, and heat energy consumption, but also affect the quality of the metal melt and the service life of the furnace. The principles of loading are:

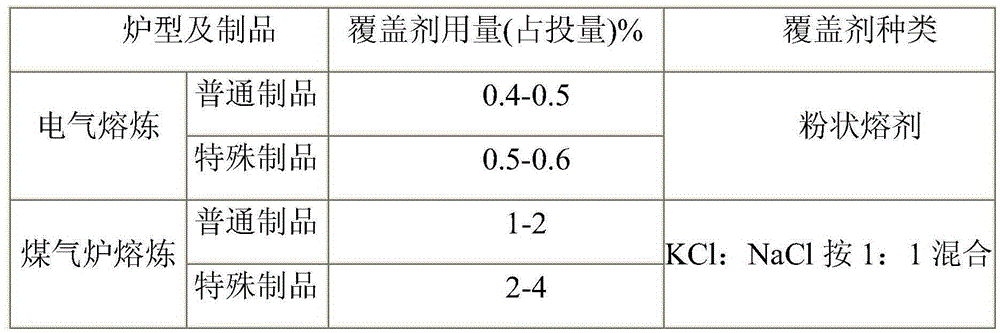

[0032] a. The order of charging the furnace materials should be reasonable. The correct charge depends on the nature and state of the charged charge, and should also take into account the fastest melting speed, ...

Embodiment 2

[0072] Example 2 Aluminum alloy material MH-03 and its preparation method

[0073] An aluminum alloy material in this embodiment is prepared from the following components in weight percentage: Al90.2669%, Si2.27%, Fe0.275%, Cu0.0461%, Mn0.737%, Mg6.09 %, Cr0.135%, Ni0.0033%, Zn0.0780%, Ti0.0719%, Bi0.0044%, Ca0.0011%, Cd<0.001%, Sn0.0063%, Zr0.0017%, Pb0.0133 %.

[0074] The preparation method of the aluminum alloy material of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0075] Example 3 Aluminum alloy material MH-03 and its preparation method

[0076] An aluminum alloy material in this embodiment is prepared from the following components in weight percentage: Al90.0838%, Si2.26%, Fe0.272%, Cu0.0455%, Mn0.741%, Mg6.17 %, Cr0.135%, Ni0.0033%, Zn0.0779%, Ti0.0720%, Bi0.0043%, Ca0.0011%, Cd<0.001%, Sn0.0064%, Zr0.0017%, Pb0.0126 %.

[0077] The preparation method of the aluminum alloy material of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com