Sheet crystal cupper powder and liquid phase chemical preparation process thereof

A technology of flaky crystal and copper powder, which is applied in the field of thin flaky crystalline copper powder and its liquid phase chemical preparation, can solve the problems of low proportion of flaky particles and poor thixotropy of slurry, etc., and achieve metal strength and smooth surface , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

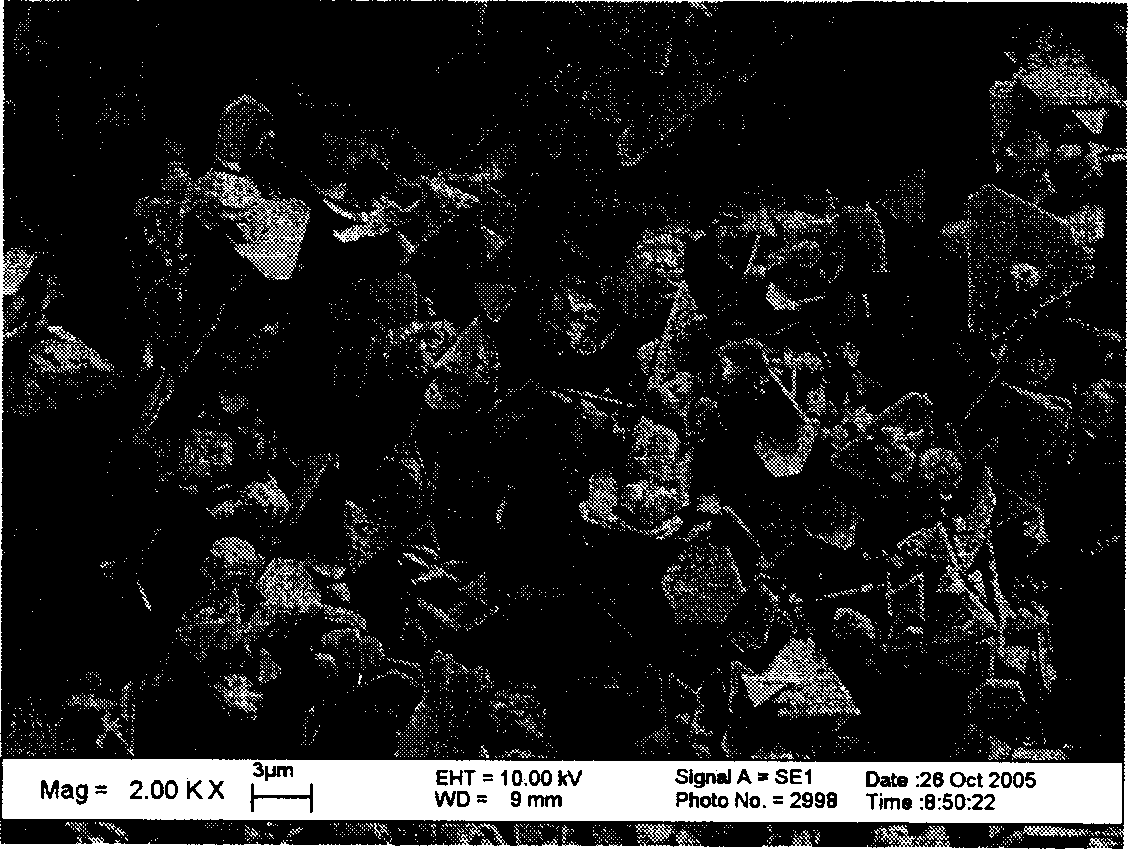

[0020] Dissolve 0.57 g of glycine and 1.64 g of tetradecyltrimethylammonium bromide in 50 ml of water, add 3.67 g of cuprous oxide, stir evenly, and raise the temperature to 65°C. Dissolve 6.3 g of citric acid and 1.26 g of potassium hydroxide in 11 ml of deionized water to form a buffer solution, add 4.1 ml of 80% hydrazine hydrate solution to the buffer solution, and mix well. The hydrazine hydrate reducing solution was added dropwise into the cuprous oxide dispersion for reaction. After 3 hours of reaction, the copper powder was centrifuged, washed repeatedly with deionized water and then with ethanol, and finally vacuum-dried at 60°C. The obtained copper powder is bright pink and shows obvious metallic luster. The scanning electron microscope observed its appearance as figure 1 As shown, most of the particles are in the shape of triangular, pentagonal and hexagonal flakes, the particle diameter is 1.5-6.5 μm, the width is 0.2-0.4 μm, and the particle aspect ratio is betwe...

Embodiment 2

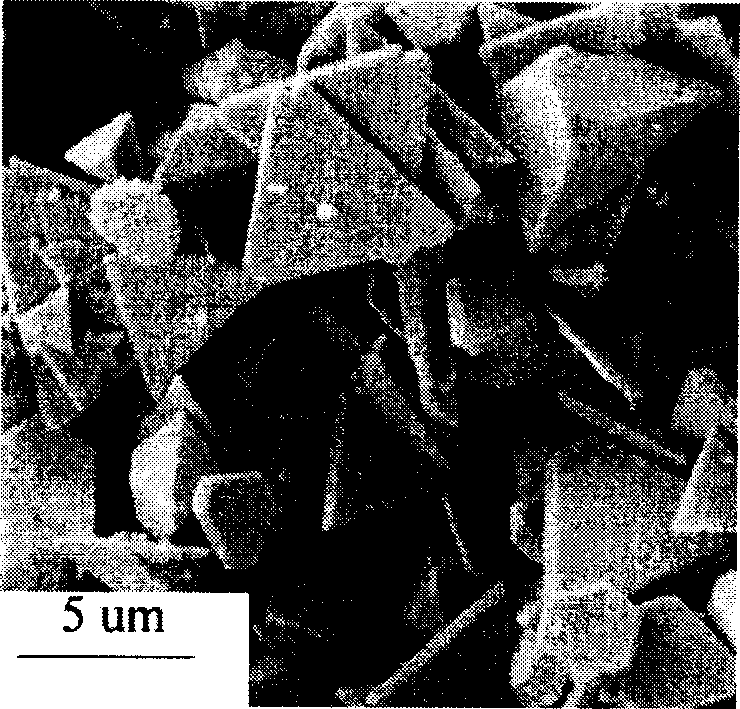

[0022] Glycine 0.76g and cetyltrimethylammonium bromide 1.78g were dissolved in 50ml of water, and cuprous oxide 3.65g was added to disperse evenly, and the temperature was raised to 55°C. 4 ml of 80% hydrazine hydrate was added to 10 ml of deionized water, and the resulting hydrazine solution was adjusted to pH 8.5 with 1M citric acid / water solution. The reducing solution was added dropwise into the cuprous oxide dispersion at a rate of 0.2 ml / min for reaction. After reacting for 2 hours, the copper powder was centrifuged, washed repeatedly with deionized water and then with ethanol, and finally vacuum-dried at 60°C. The obtained copper powder is bright pink and shows obvious metallic luster. The scanning electron microscope observed its appearance as figure 2 As shown, it can be seen that triangular, pentagonal and flake-shaped particles account for the vast majority, and a small number of polyhedral or spherical particles are mixed. The flake-like particles have a diame...

Embodiment 3

[0024] Glycine 0.91g and dodecyltrimethylammonium chloride 2.64g were dissolved in 50ml of water, 7.10g of cuprous oxide was added to disperse evenly, and the temperature was raised to 60°C. Mix 10ml of 80% hydrazine hydrate with 20ml of 1M citric acid / water solution. Add the reducing solution dropwise into the cuprous oxide dispersion to react for 3 hours. The obtained copper powder is bright pink and shows obvious metallic luster. Observing its morphology with a scanning electron microscope, it can be seen that the diameter of flake particles is 4.0-15 μm, the width is 0.6-1.4 μm, and the aspect ratio of particles is between 6-18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com