Ink jet recording medium and process for producing the ink jet recording medium

A recording medium, inkjet technology, applied in the direction of copying/marking method, printing, coating, etc., can solve the problems of reduced printing density, poor ink absorption and water resistance, poor water resistance, etc., and achieve high printing density , Excellent ink absorption and water resistance, excellent gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

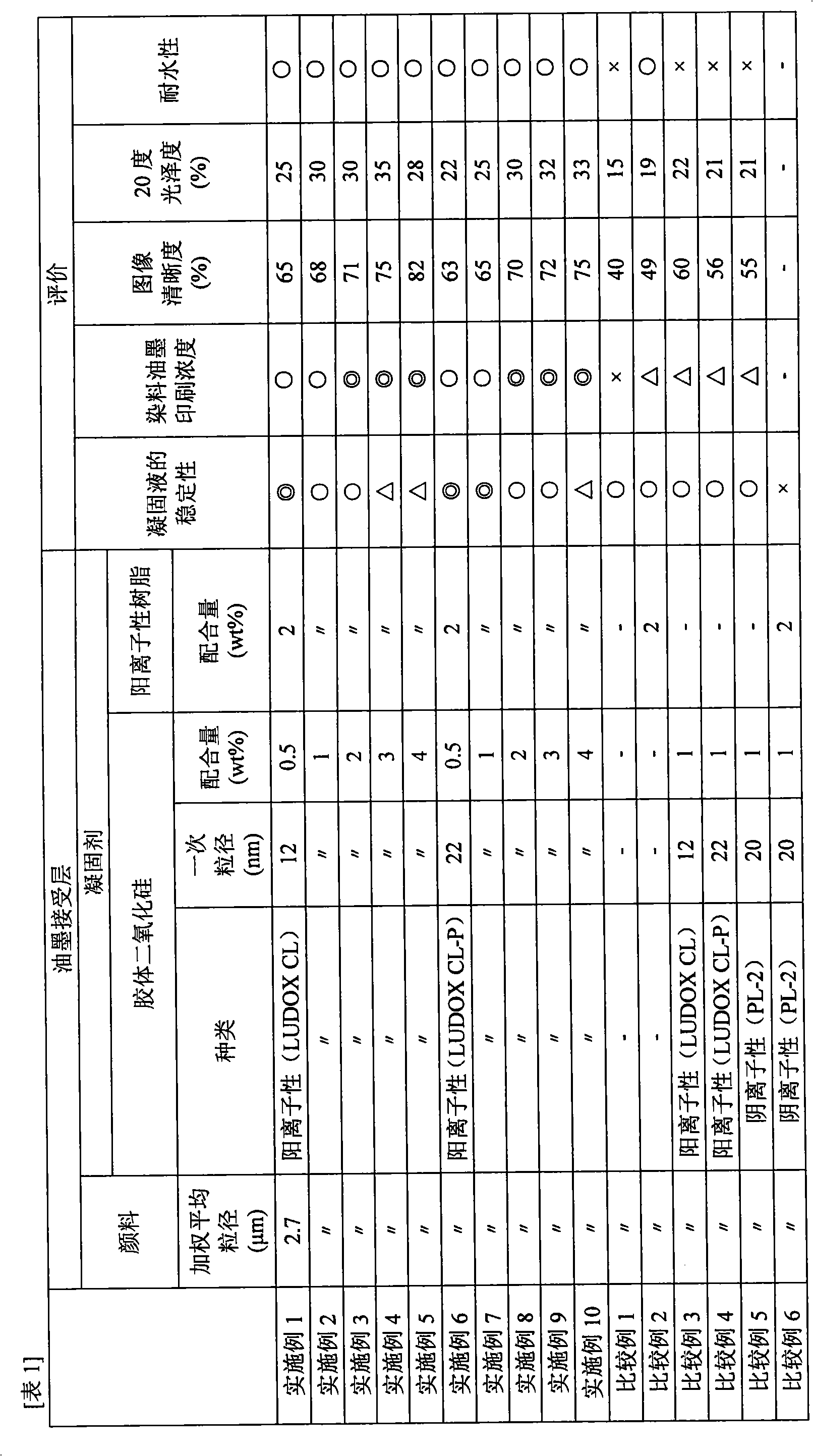

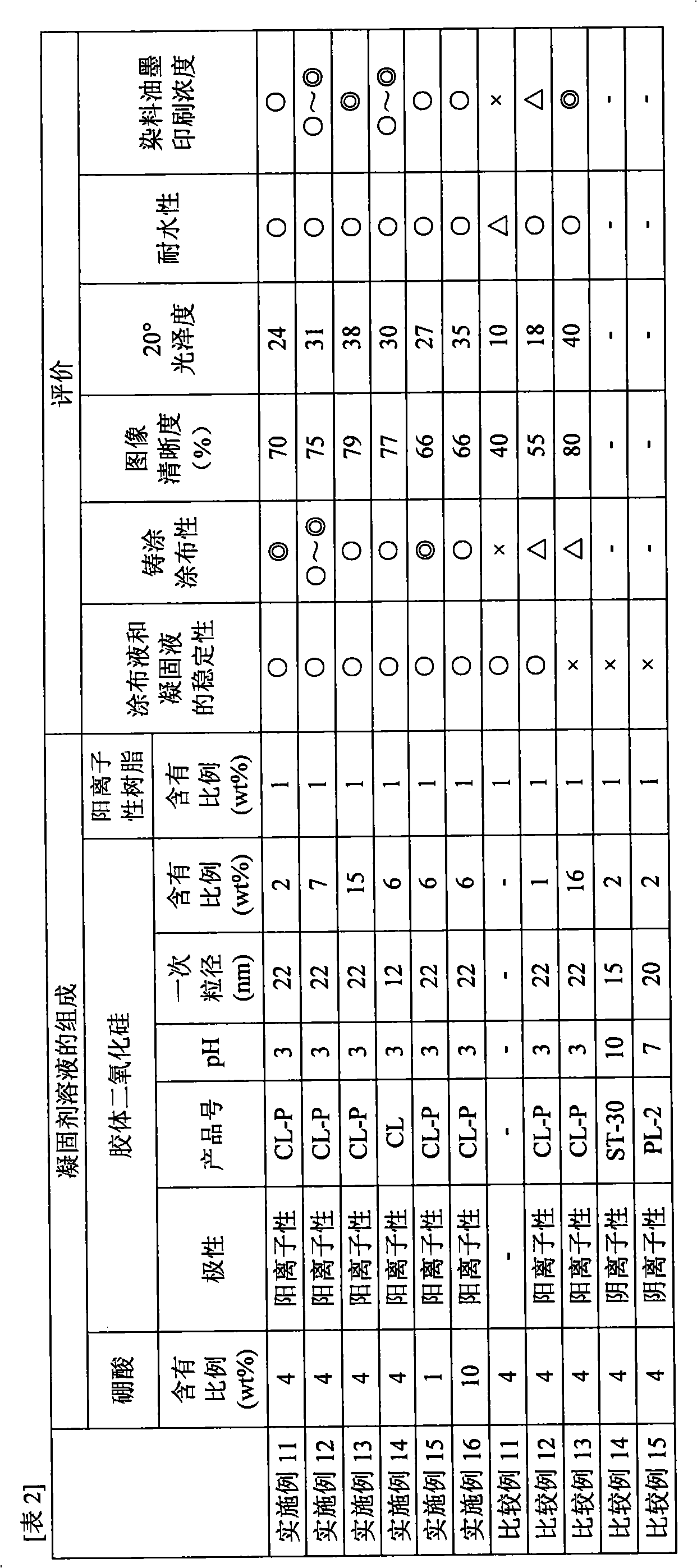

Embodiment 1

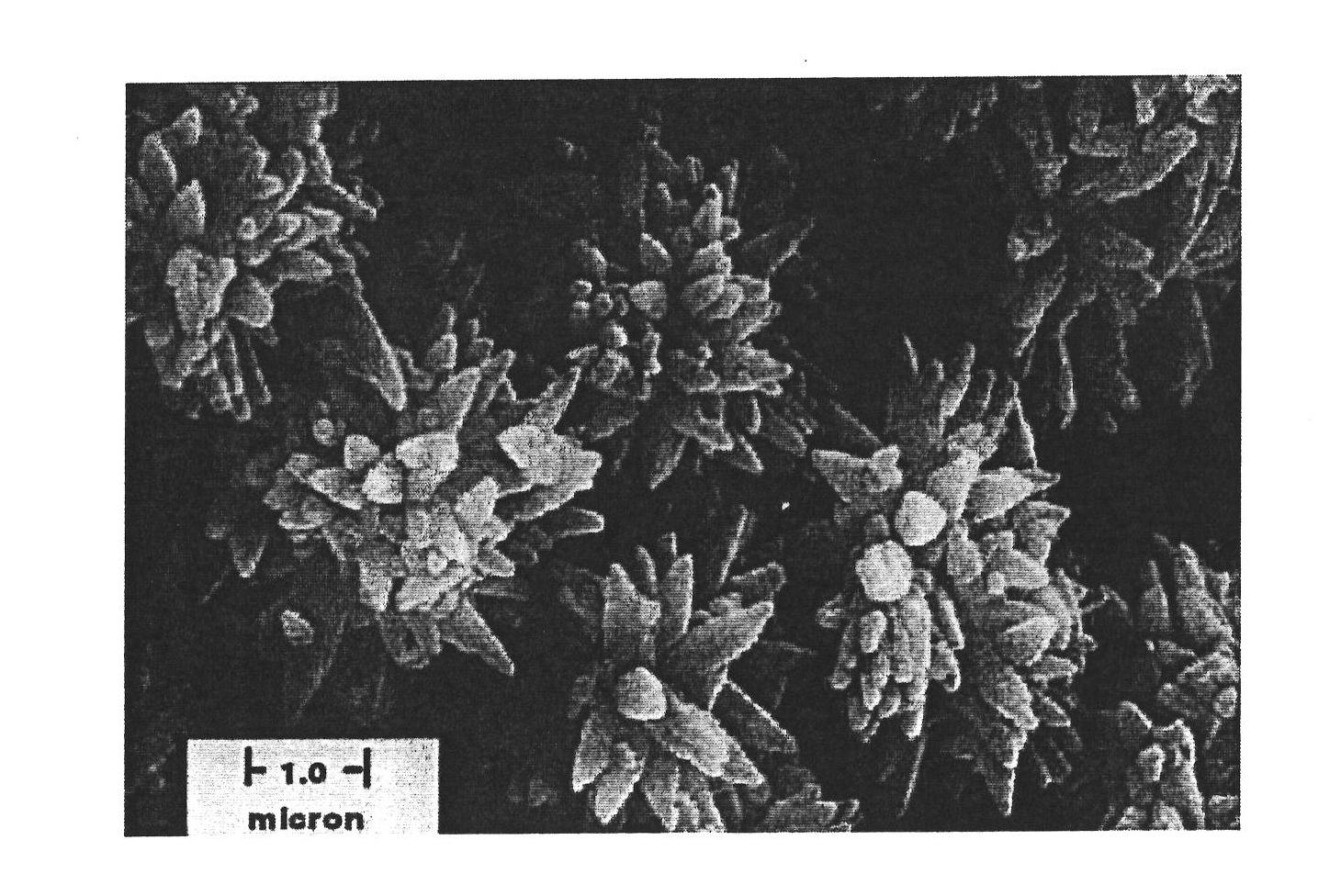

[0090]With respect to the paper pulp slurry whose beating degree is 350ml which is composed of 90 parts of hardwood bleached kraft pulp (L-BKP) and 10 parts of softwood bleached kraft pulp (N-BKP), the petal-shaped light calcium carbonate ( ALBACAR 5970: manufactured by SMI Corporation) so that the ash content would be 20%, 1.0 parts of aluminum sulfate, 0.15 parts of AKD, and 0.05 parts of retention aid were added. Paper was made using this slurry with a paper machine, and at this time, 5% of starch and 0.2% of surface sizing agent (ADK) were applied so that the solid content would be 1.5 g / m 2 , so as to get 180g / m 2 support body.

[0091] Apply 13g / m on the support with a roll coater 2 Coating solution A, apply 2.0g / m while the coating layer is in a wet state 2 coagulant B, and make the coating layer coagulate, and then press it on the heated mirror-finished surface by pressing roll to copy the mirror surface, so as to obtain 195g / m 2 inkjet recording media.

[0092] C...

Embodiment 2

[0096] An inkjet recording medium was obtained in the same manner as in Example 1 except that the compounding amount of coagulant B and cationic colloidal silica (LUDOX CL: manufactured by Grace) was changed to 1%.

Embodiment 3

[0098] An inkjet recording medium was obtained in the same manner as in Example 1, except that the compounding amount of coagulant B and cationic colloidal silica (LUDOX CL: manufactured by Grace) was changed to 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com