Patents

Literature

49results about How to "High printing density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

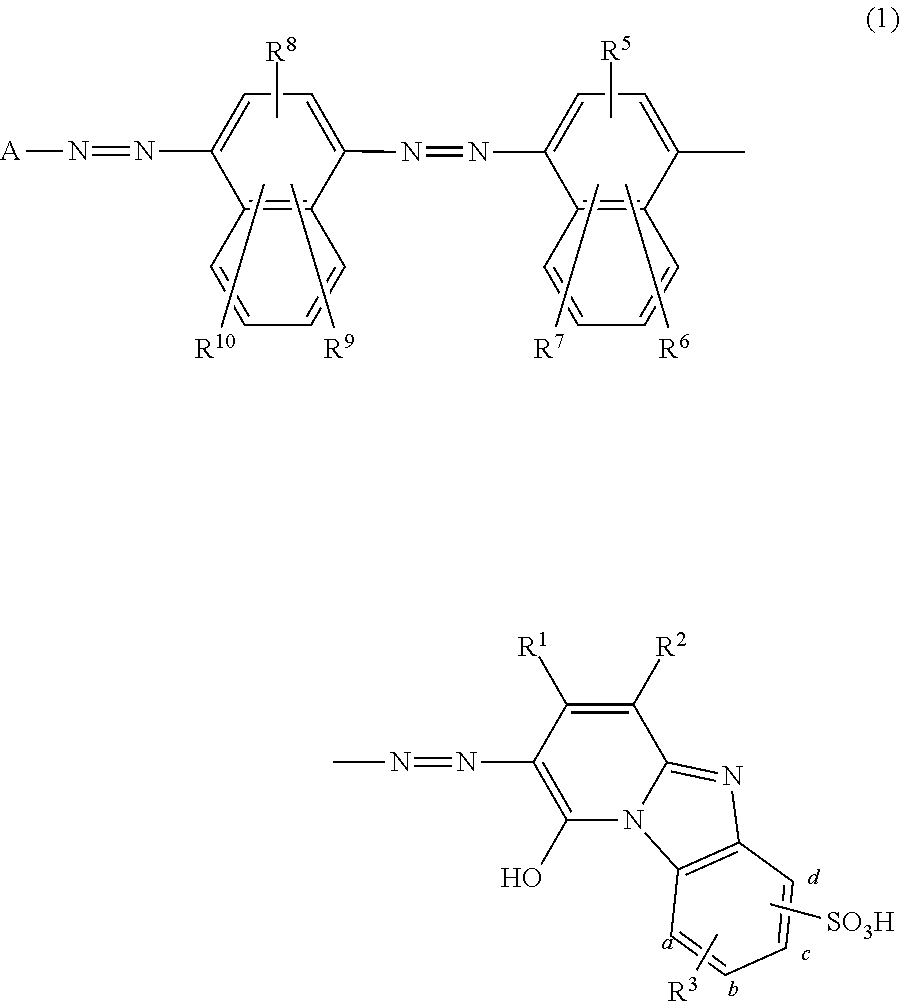

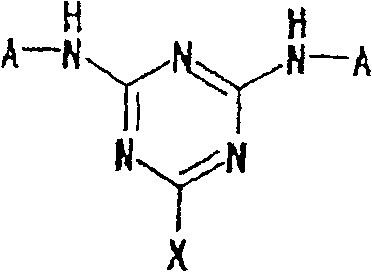

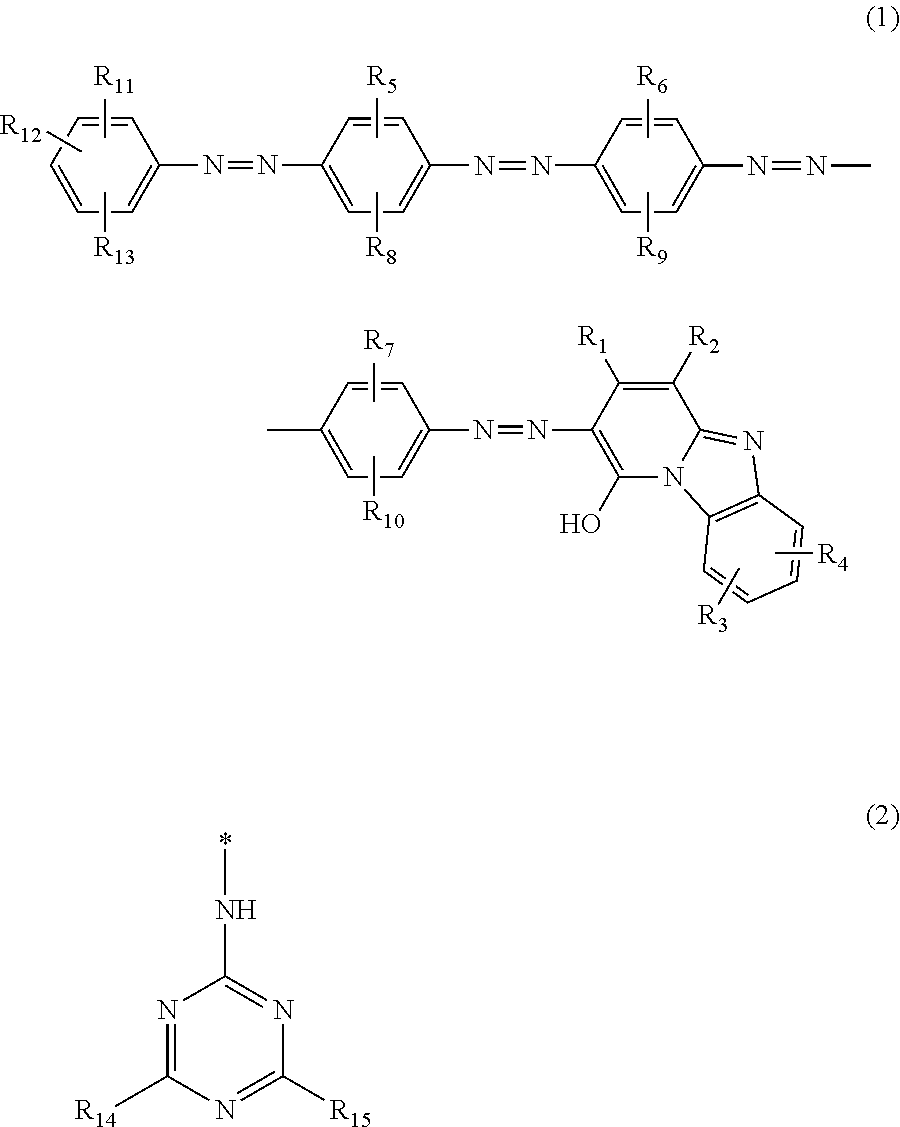

Azo compound, ink composition and colored article

ActiveUS7503967B2Good water solubilityHigh print densityMonoazo dyesOrganic chemistryHydrogen atomAlkoxy group

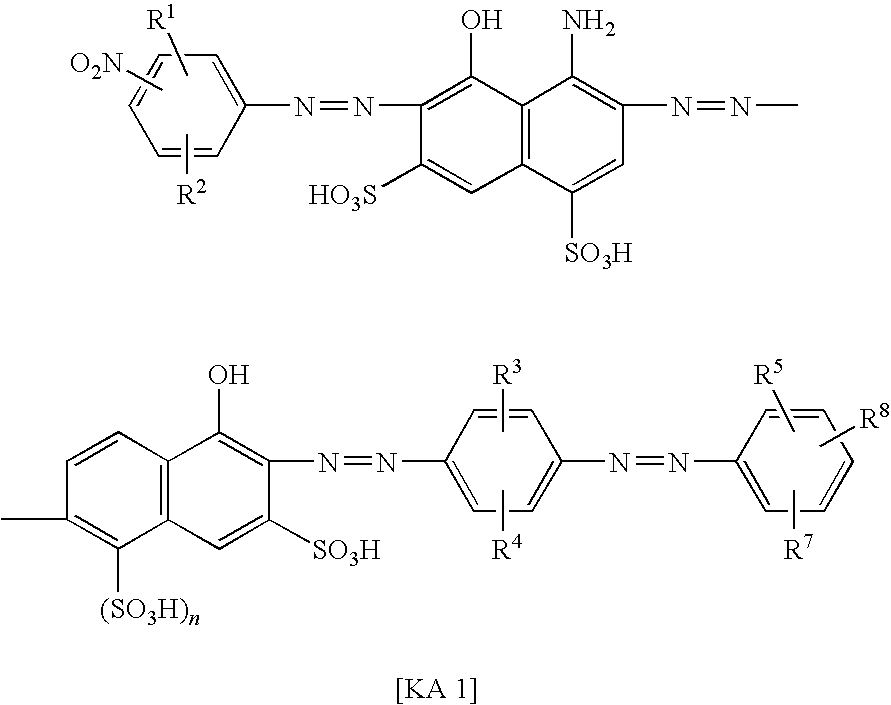

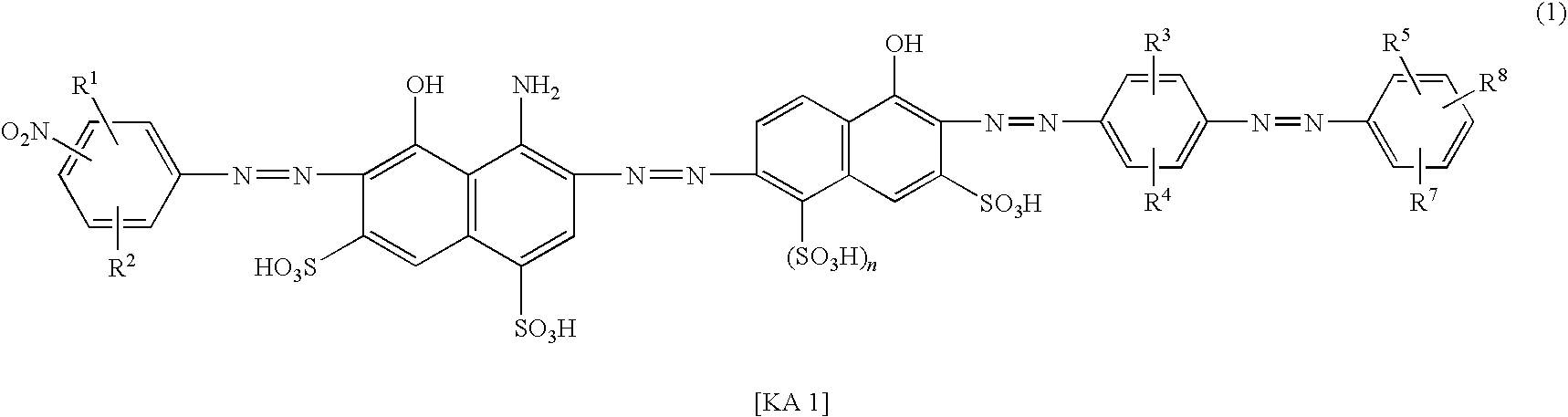

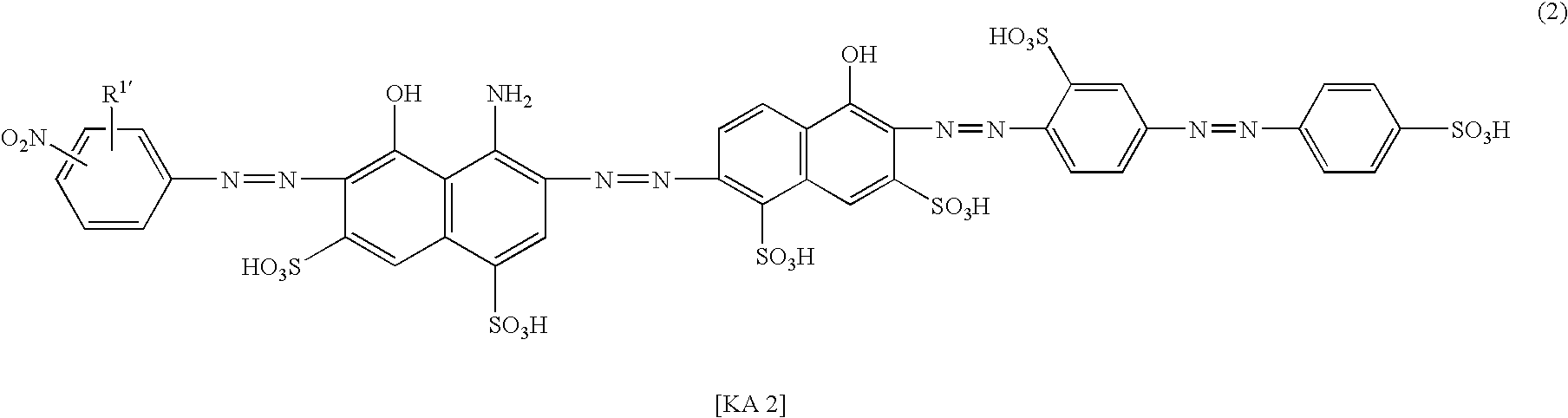

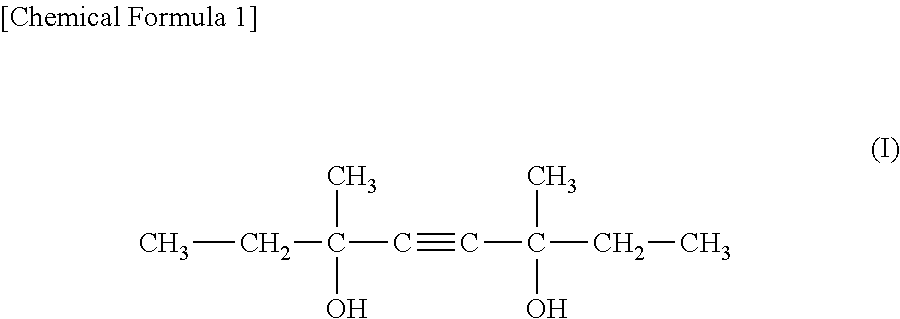

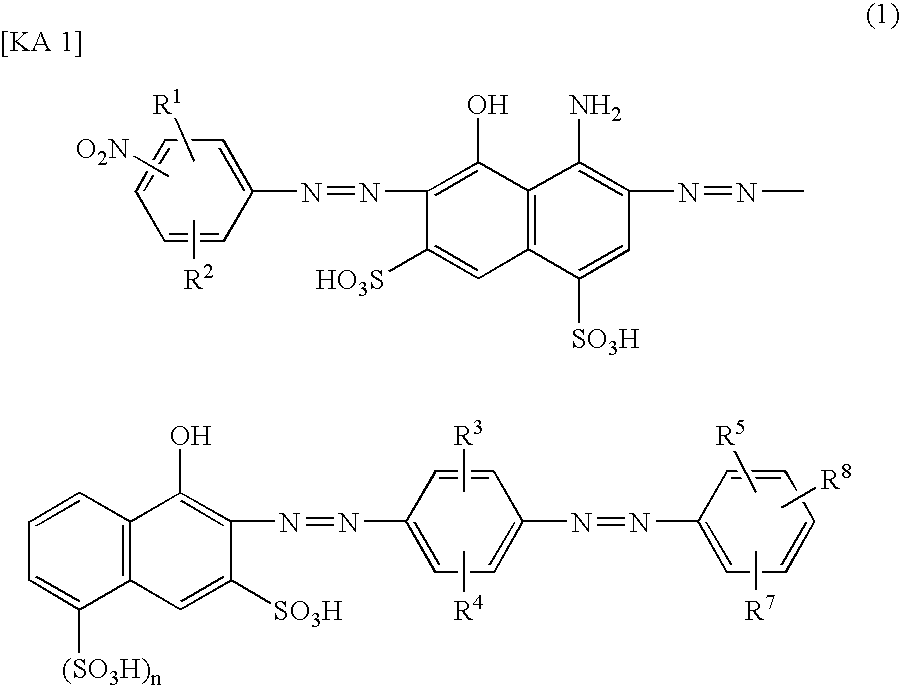

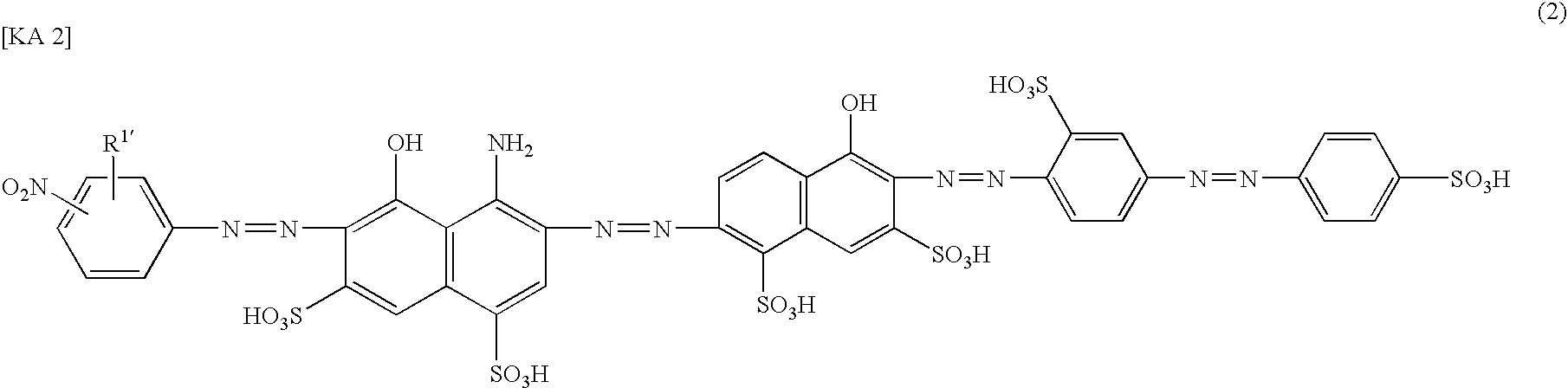

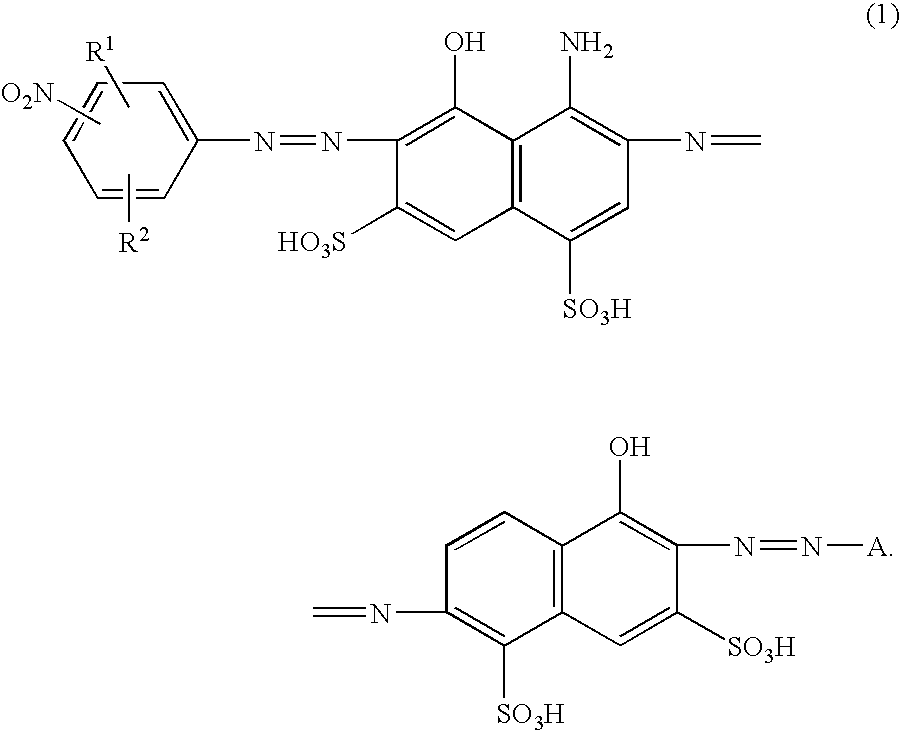

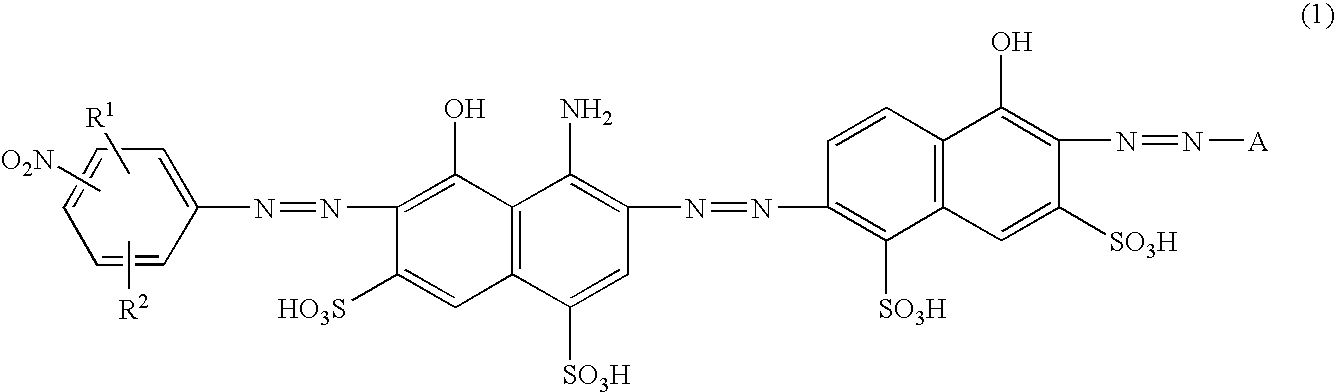

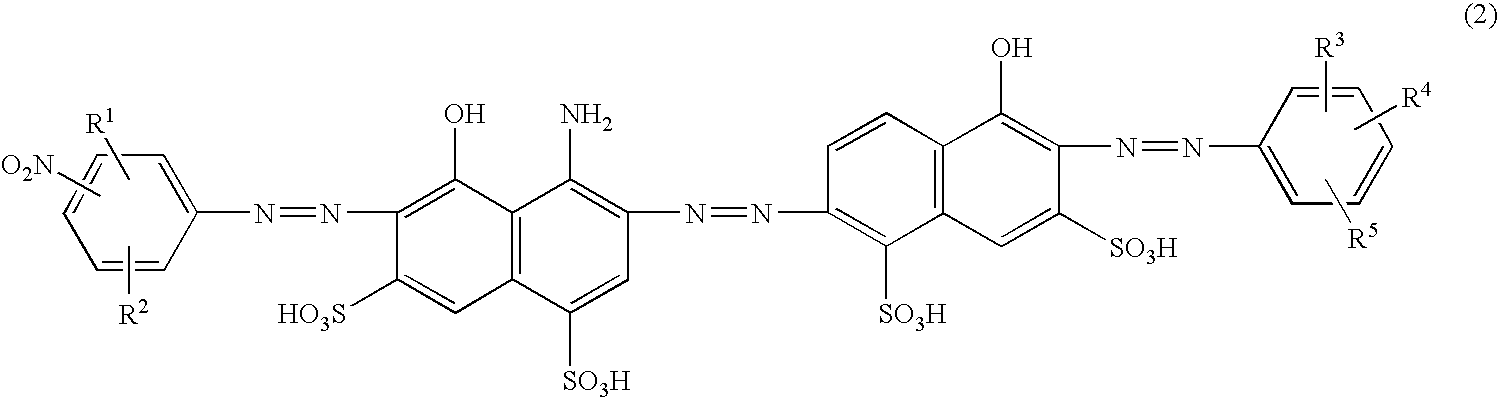

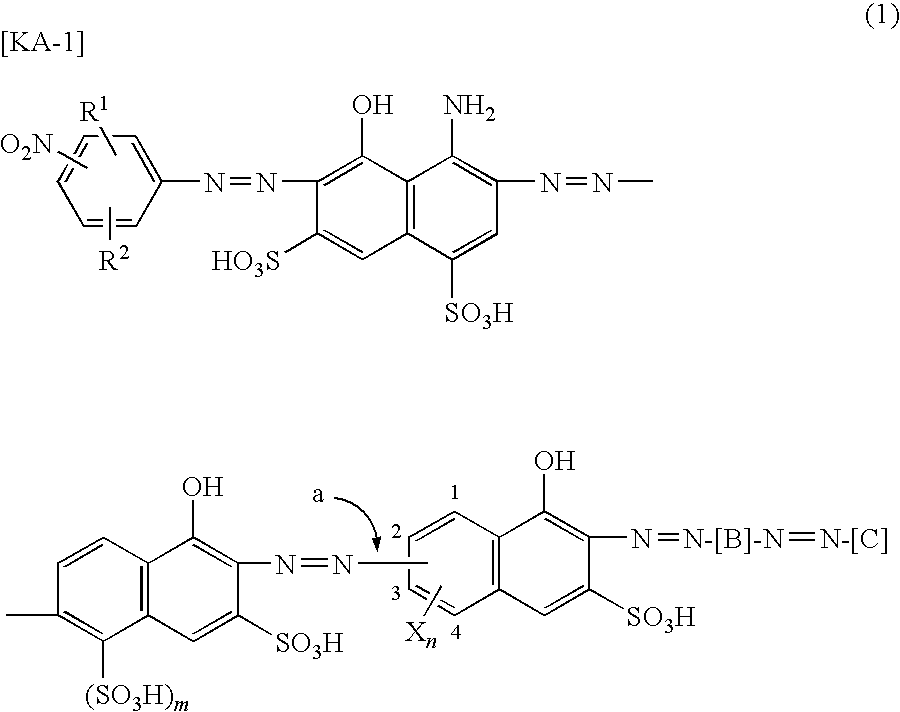

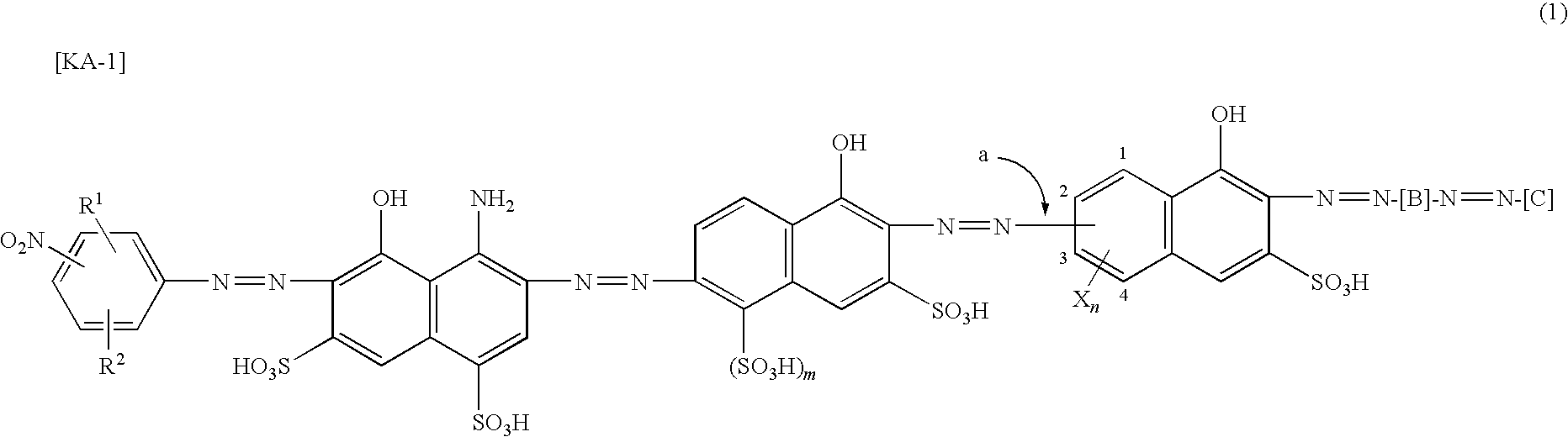

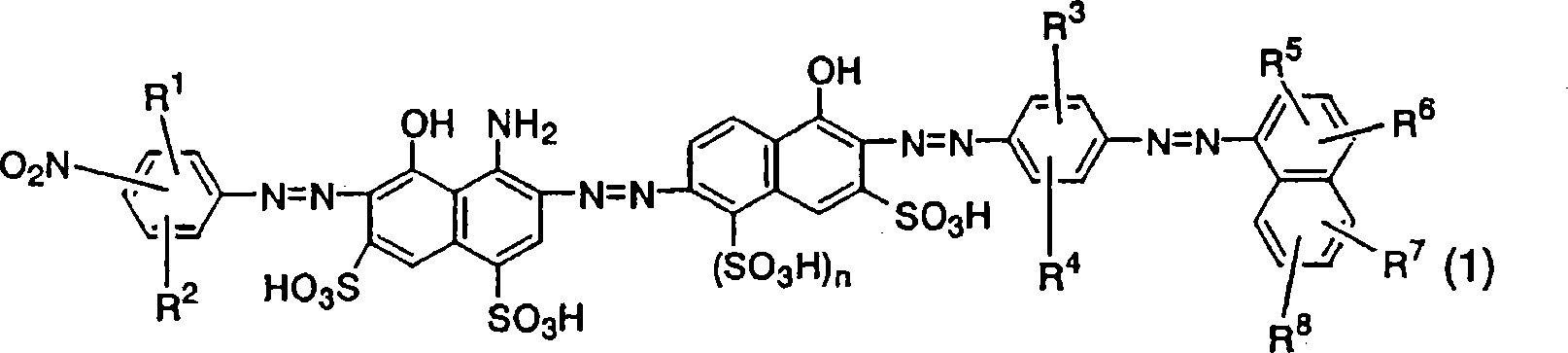

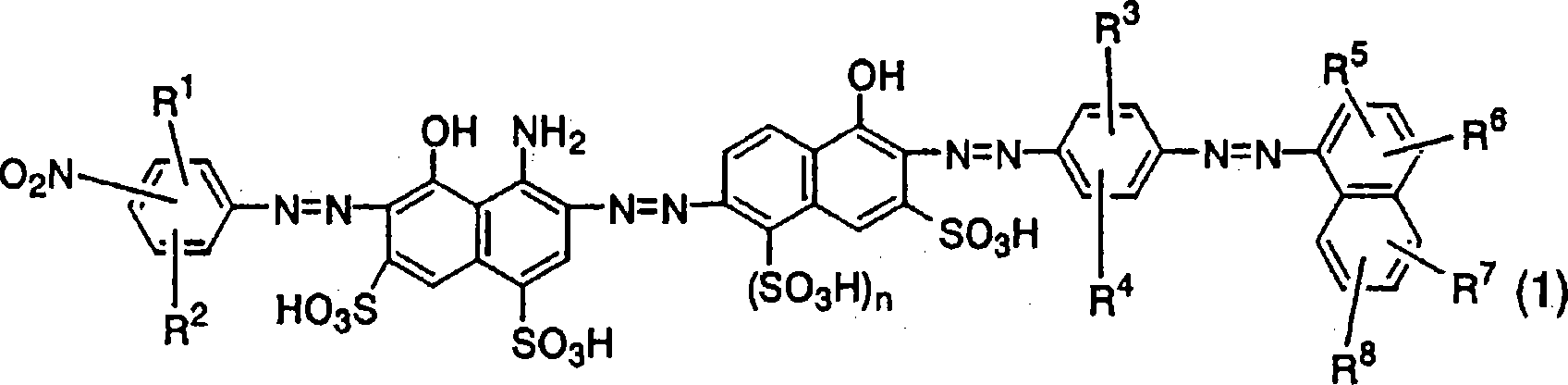

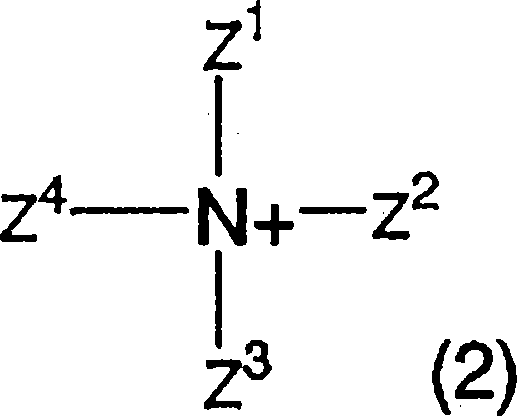

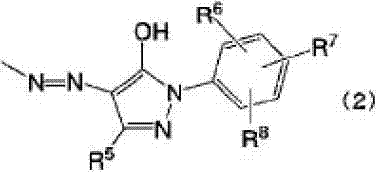

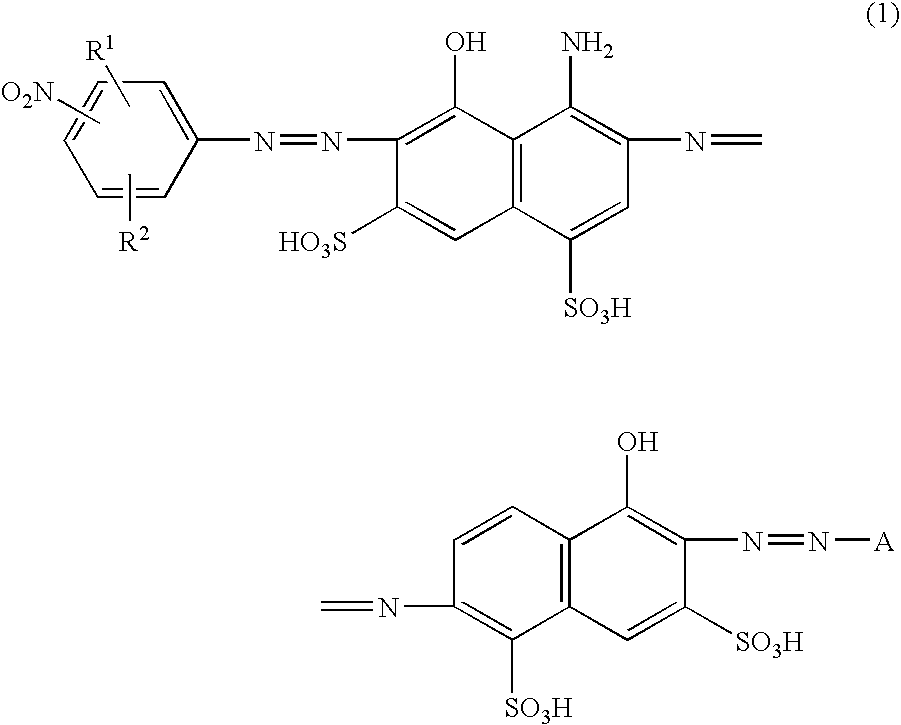

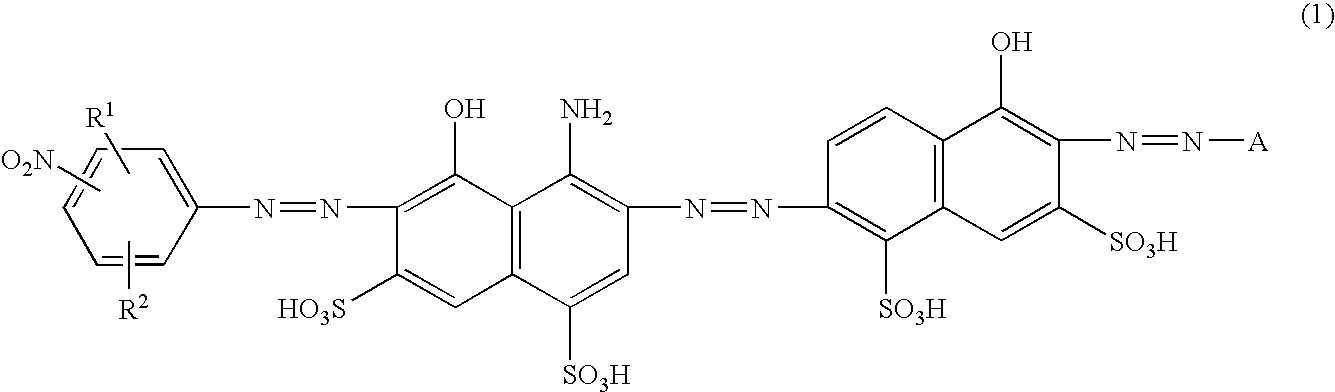

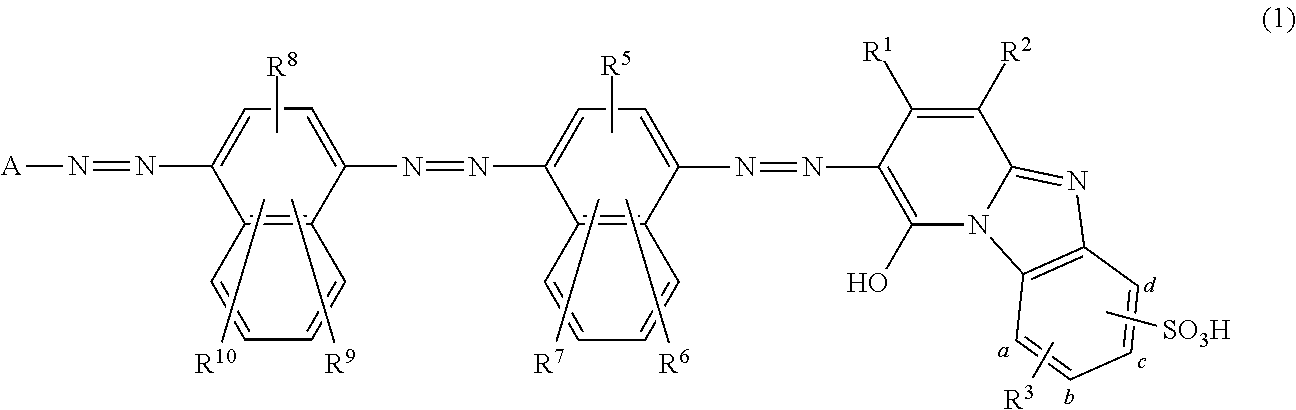

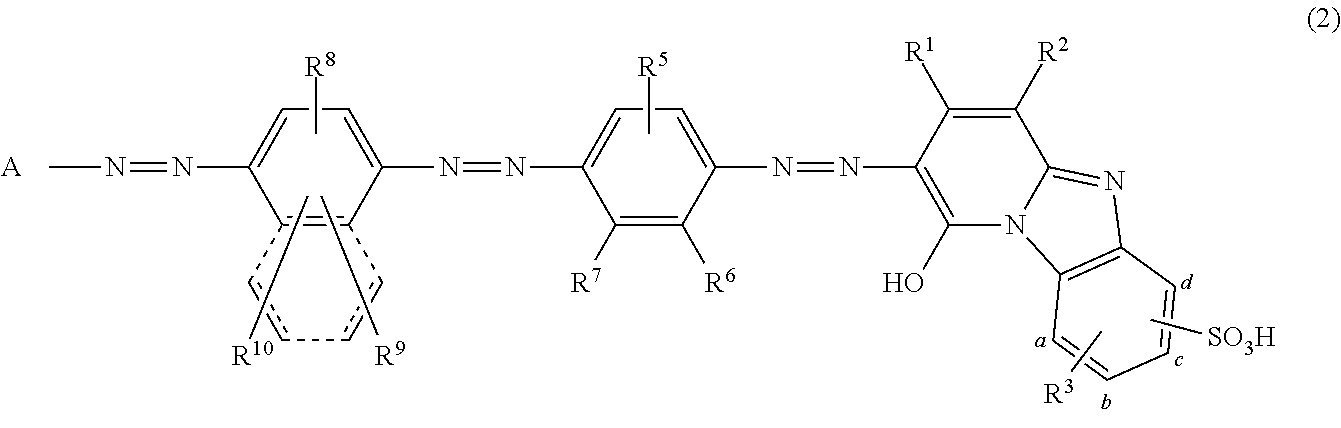

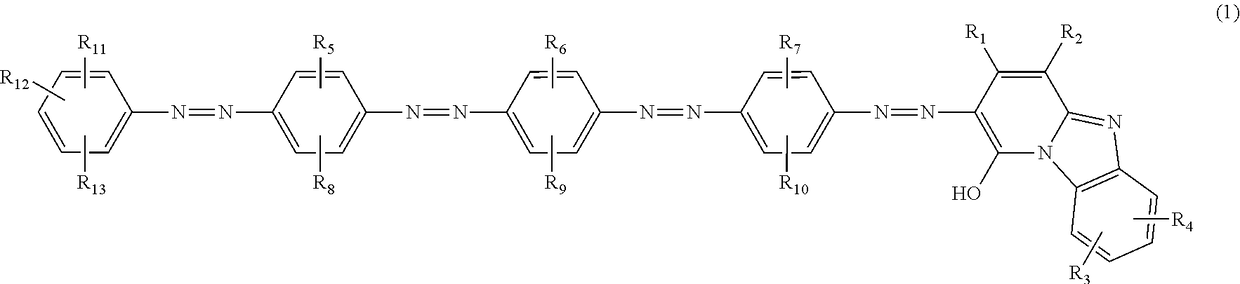

An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

Ink for inkjet textile printing and dyeing method

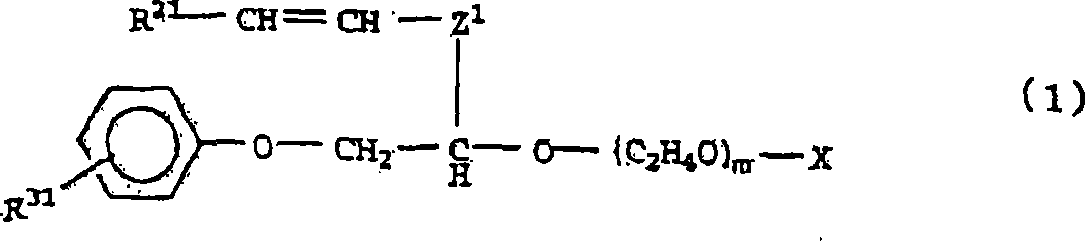

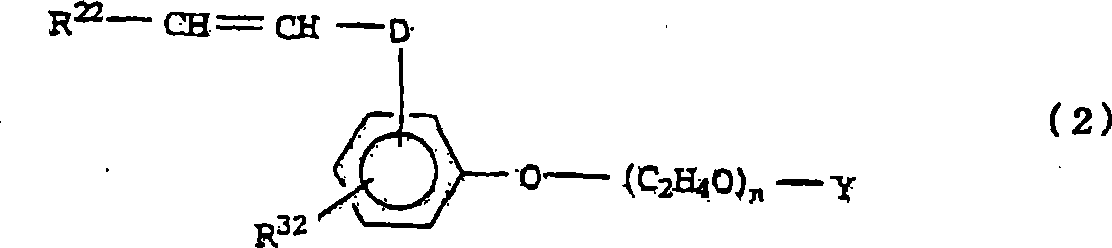

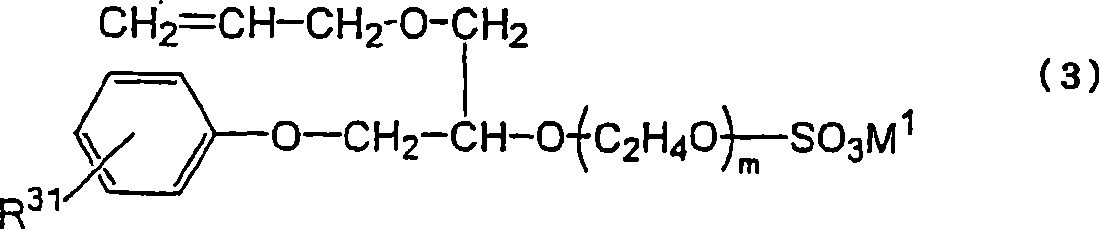

ActiveUS20150116419A1Improve recording performanceHigh print densityInksDyeing processDisperse dyeTextile printer

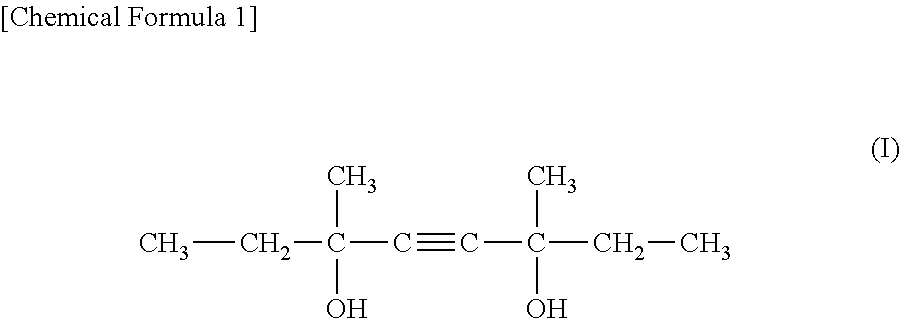

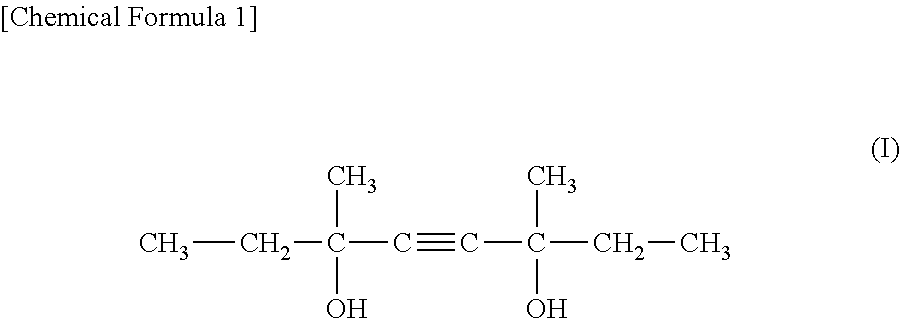

Ink for inkjet textile printing of the present invention contains water, a disperse dye, a water-soluble organic solvent and an anionic high-molecular dispersant. The water-soluble organic solvent is a polyhydric alcohol such as glycerin. The water-soluble organic solvent is contained in an amount of 25 to 50 mass % with respect to the total mass of the ink. The anionic high-molecular dispersant is a styrene-(meth)acrylic acid-based copolymer having an acid value of 160 to 250 mg KOH / g and a weight-average molecular weight of 8,000 to 20,000. The ink for inkjet textile printing further contains an acetylene glycol-based compound expressed by the following Chemical Formula (I) as a penetrant. With this ink for inkjet textile printing, provided is disperse dye-containing ink for inkjet textile printing that has a high-quality and stable recording performance and achieves a high print density on the surface of a fabric while maintaining an ink storage stability, and an inkjet textile printing method using the ink for inkjet textile printing.

Owner:KIWA CHEM IND CO LTD

Azo Compound, Ink Composition and Colored Article

ActiveUS20080193660A1Good water solubilityHigh print densityMonoazo dyesOrganic chemistrySolubilityHydrogen atom

[Problems] A compound of a black ink which has such excellent fastnesses of a recorded article as light fastness, ozone gas fastness and moisture fastness, excellent solubility, and storage stability as a recording liquid, when used for inkjet recording and writing tools, and an ink composition comprising the same are provided.[Method for solving the problems] An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

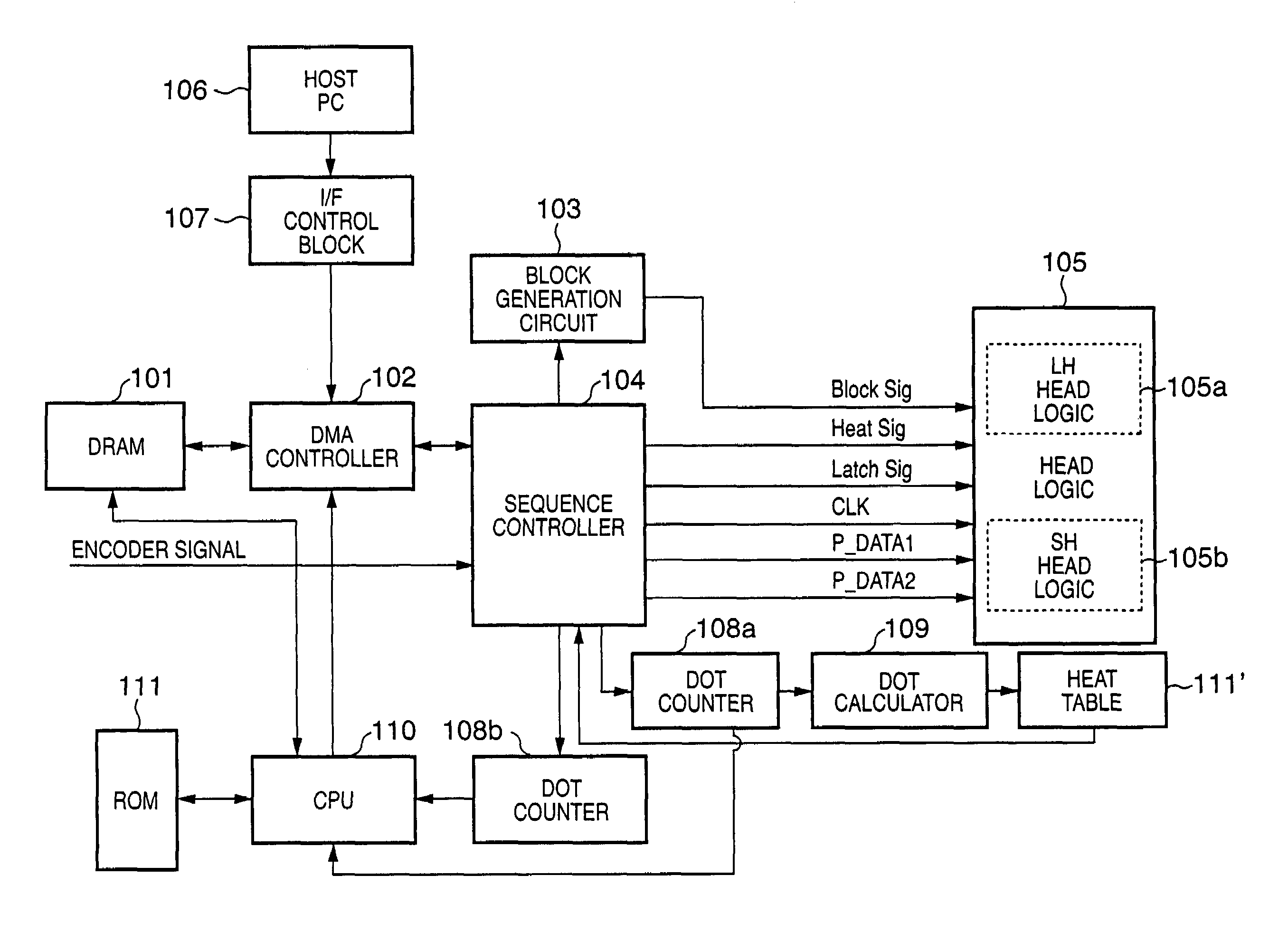

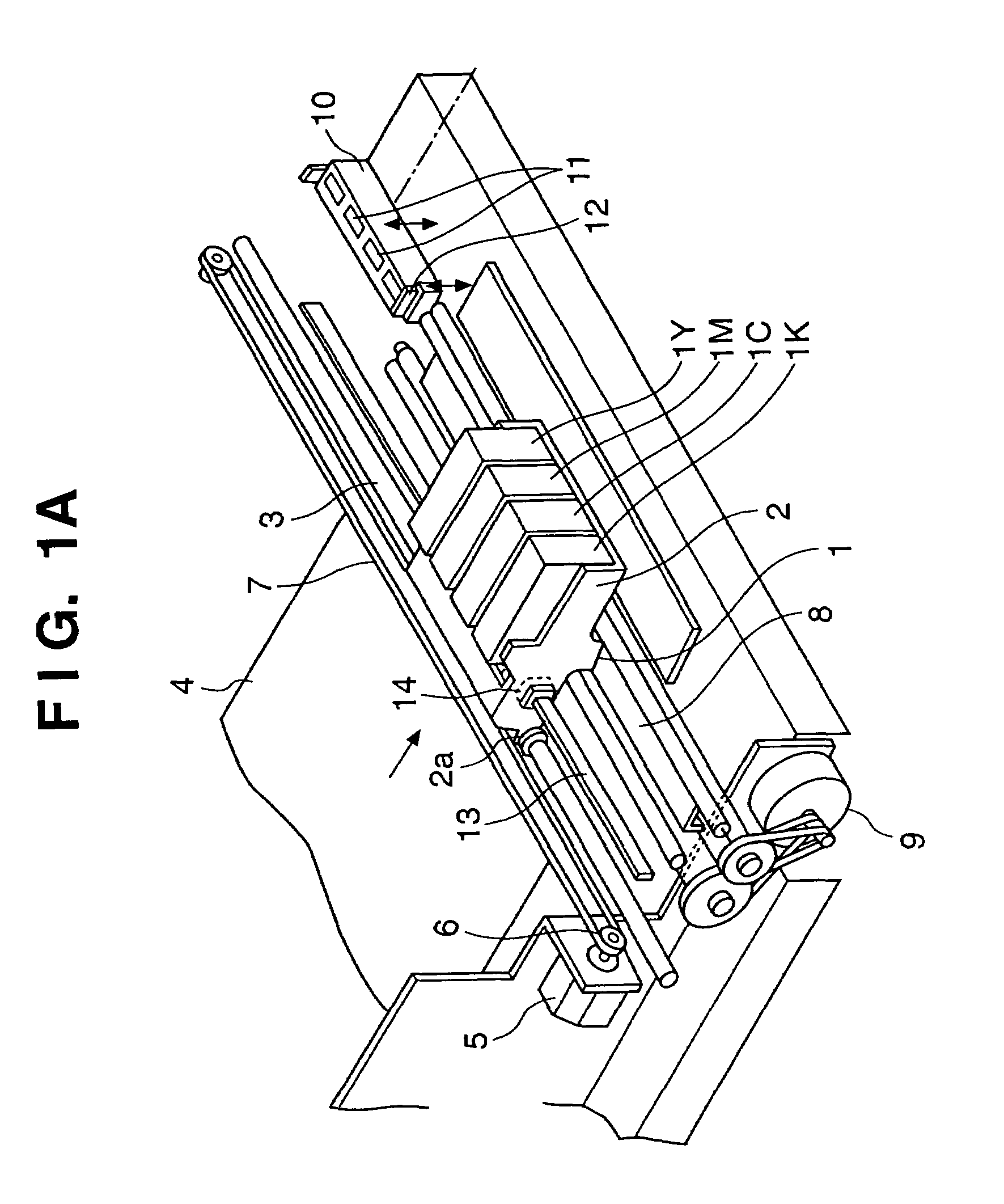

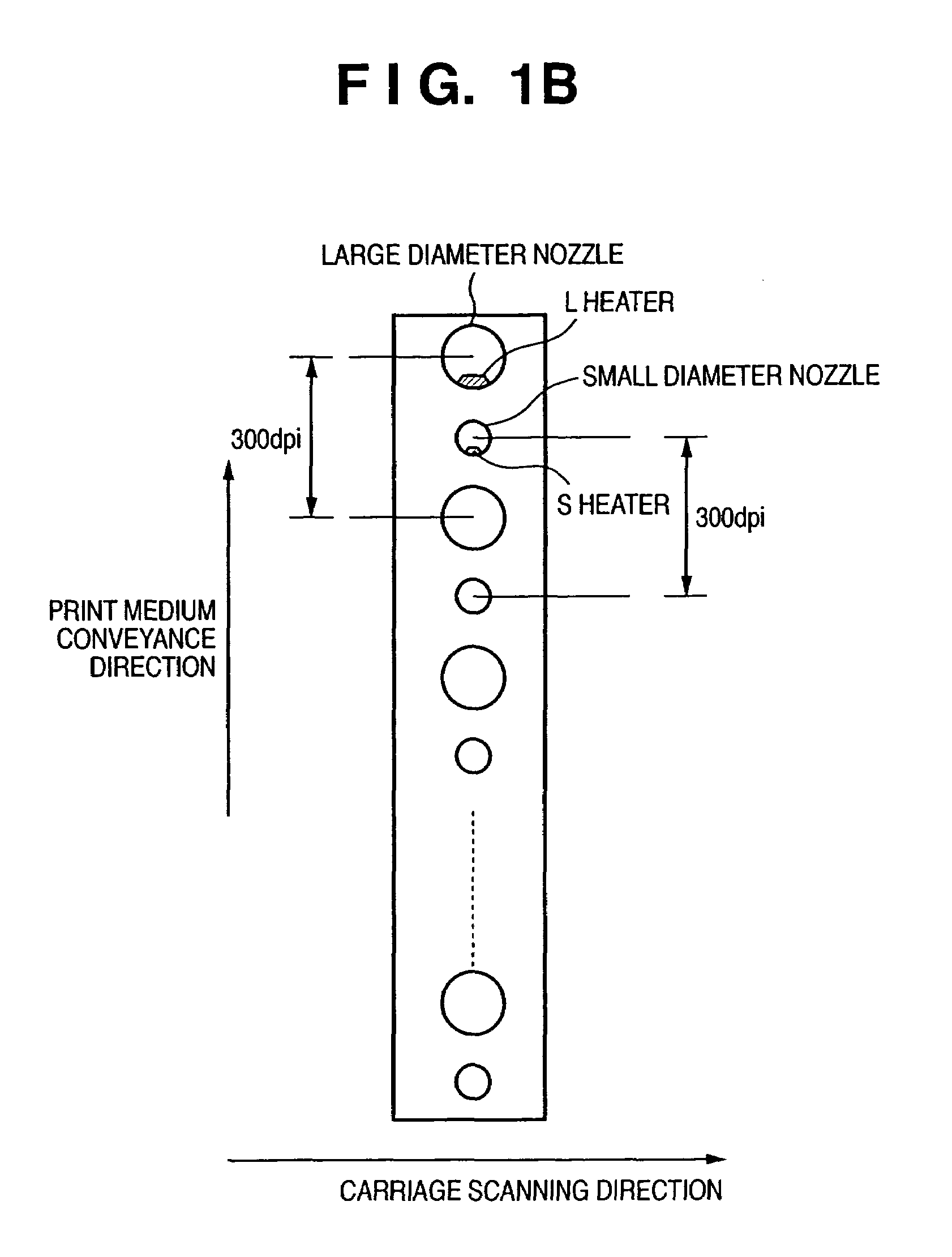

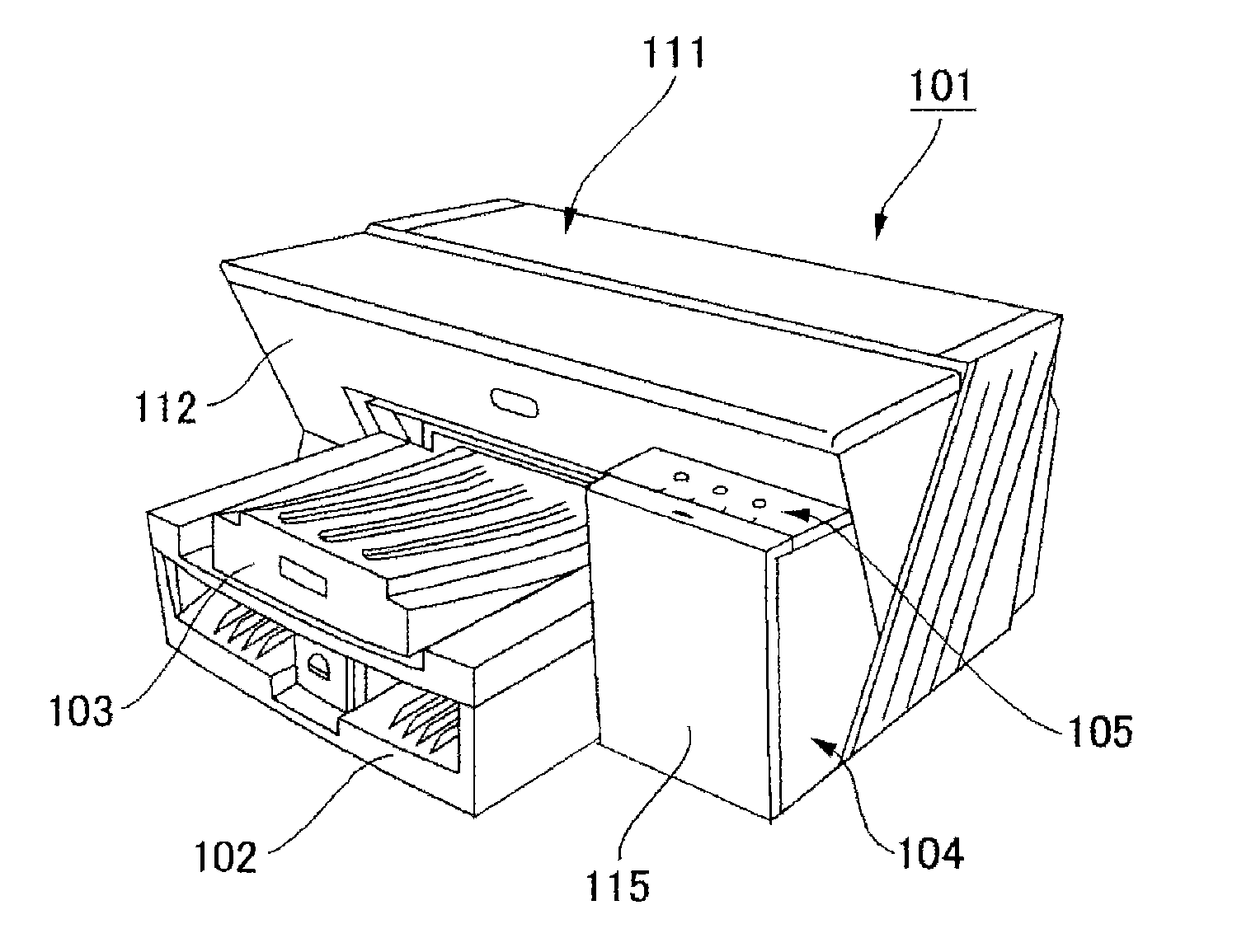

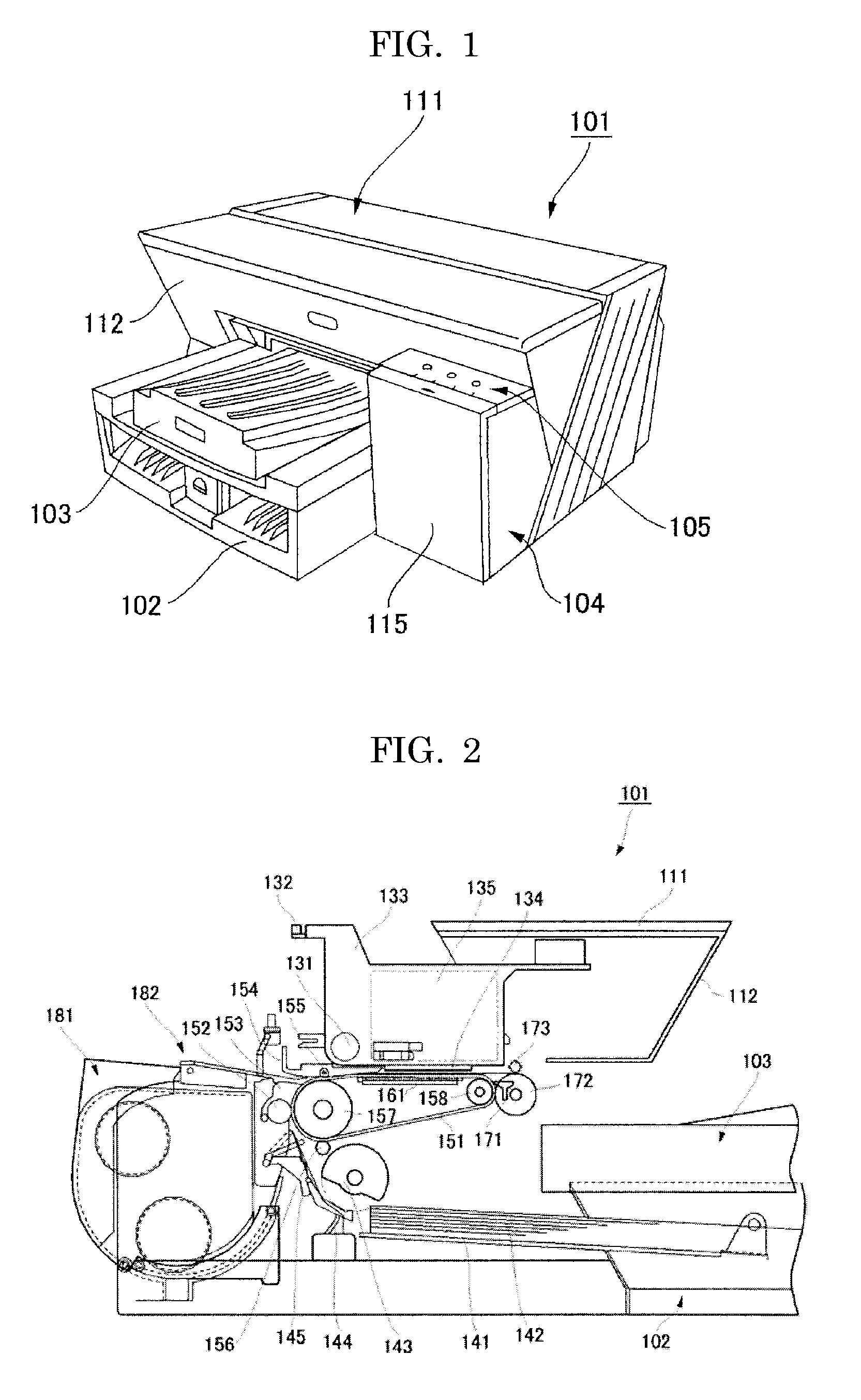

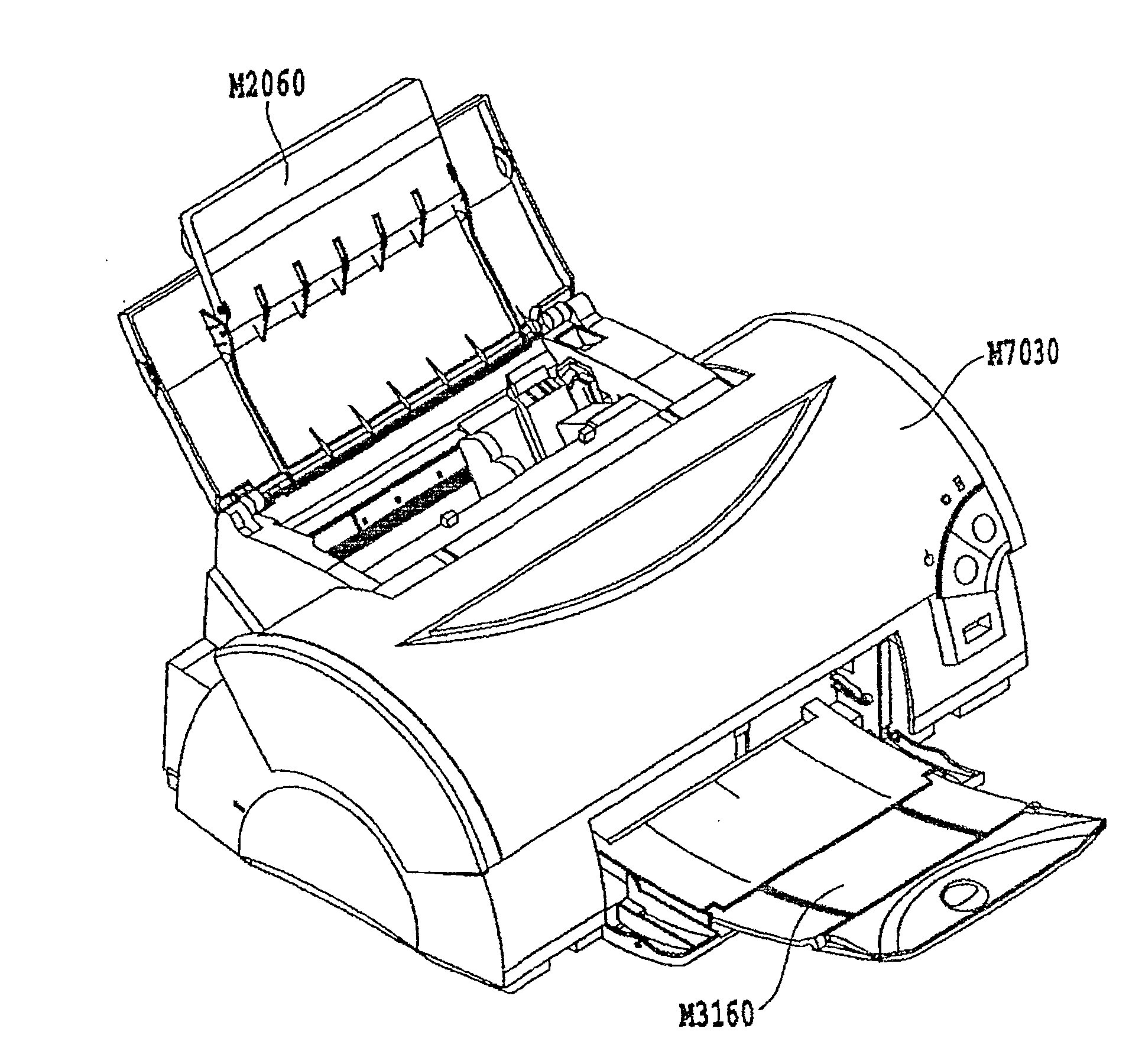

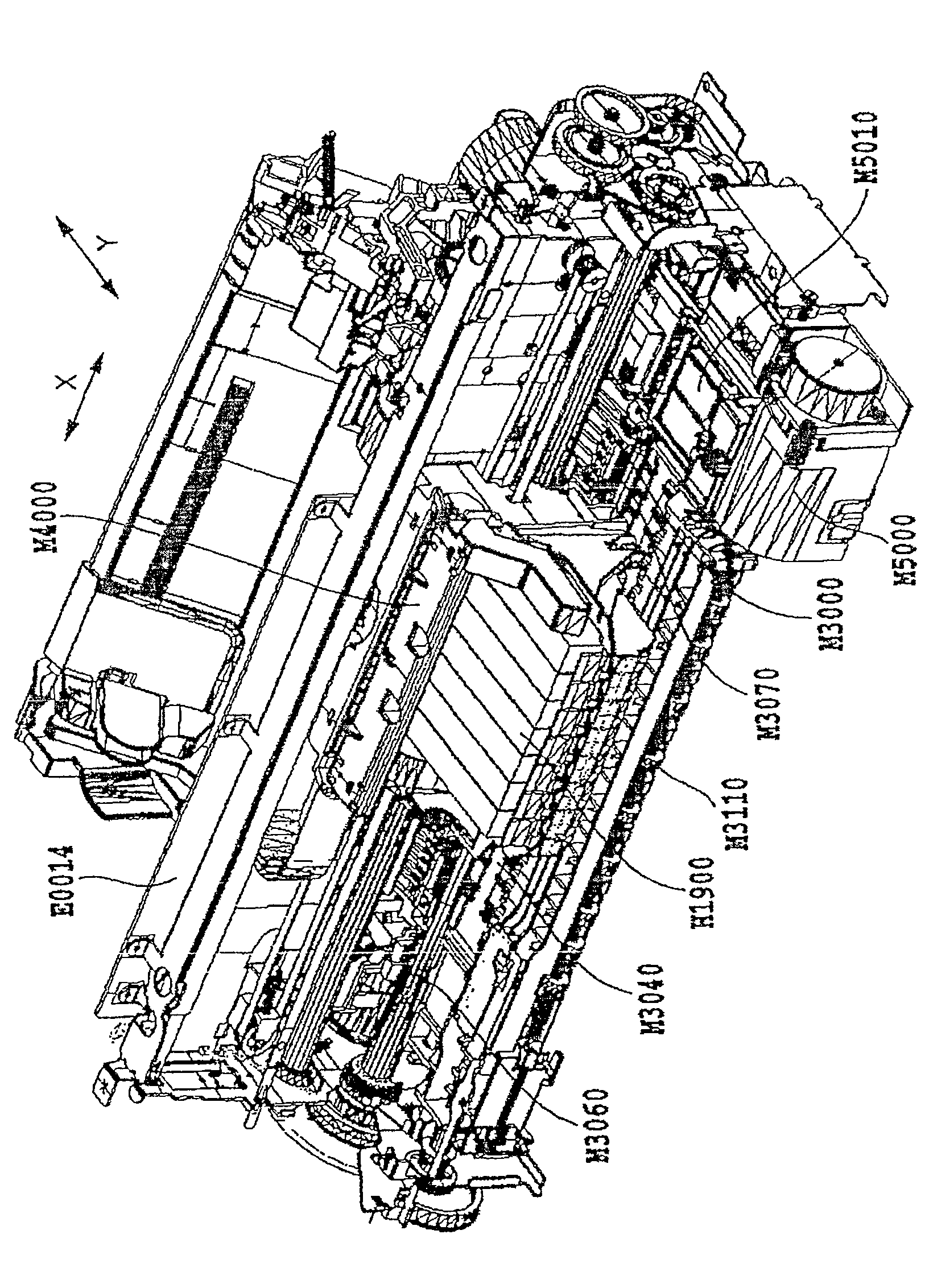

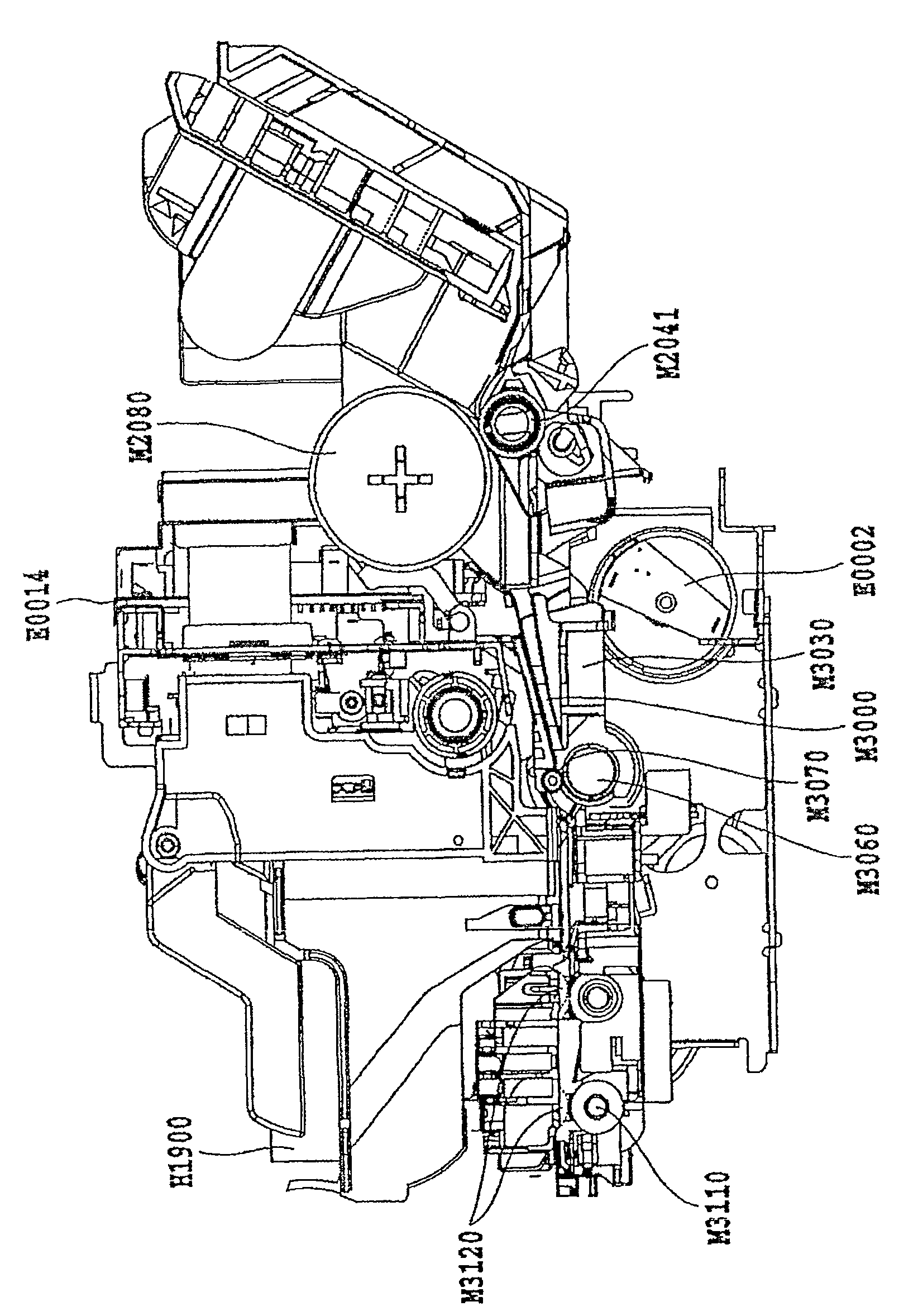

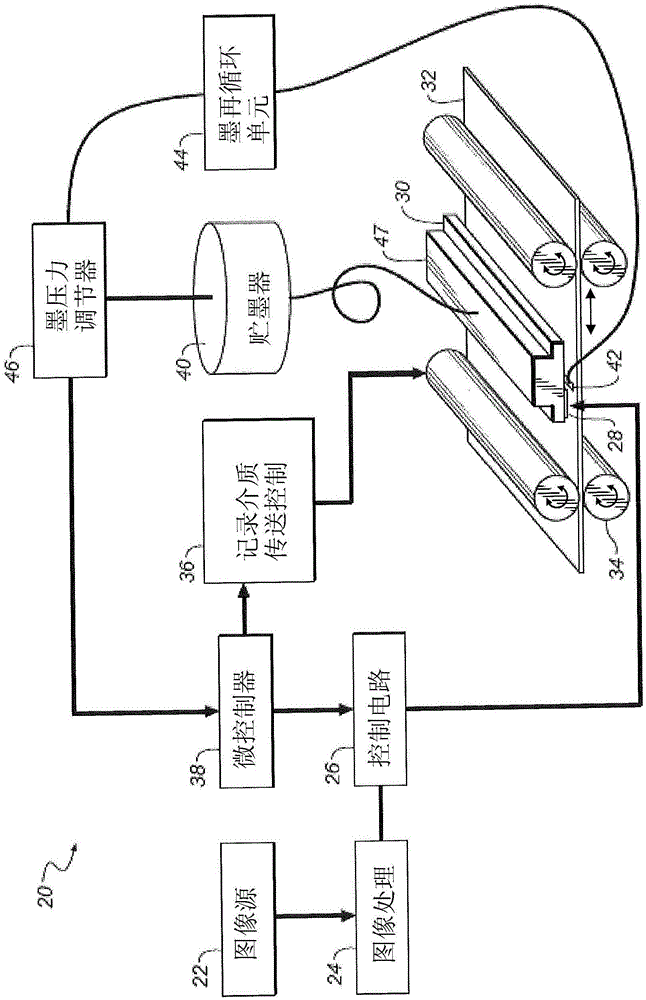

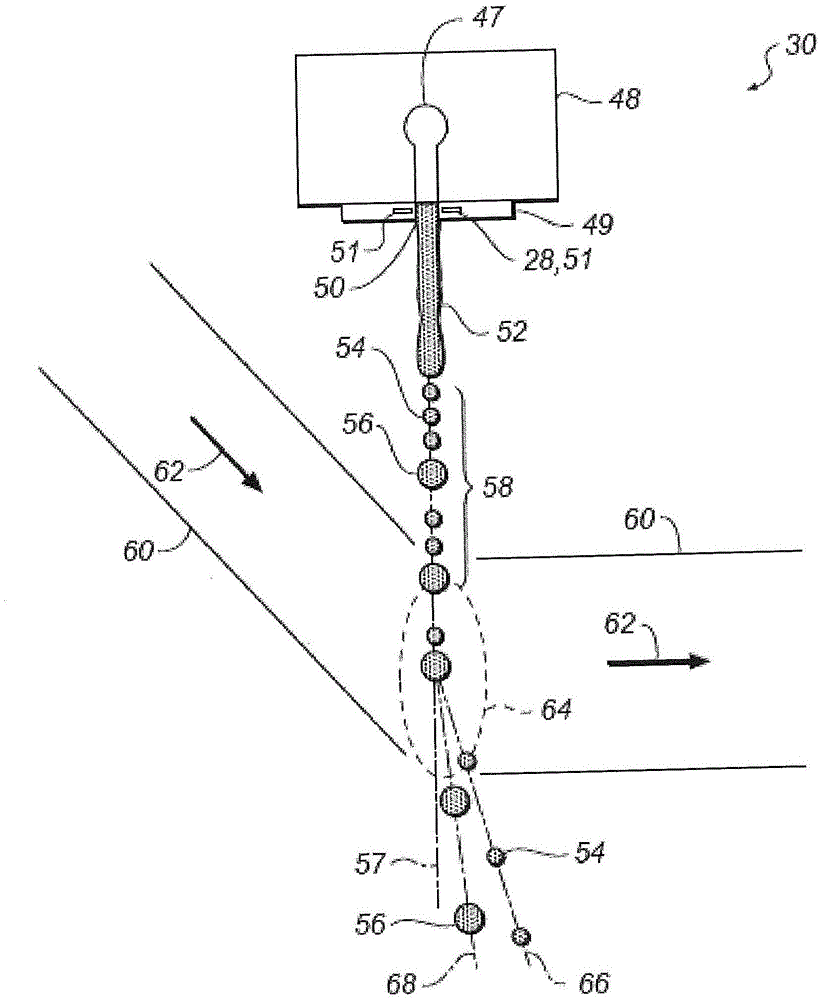

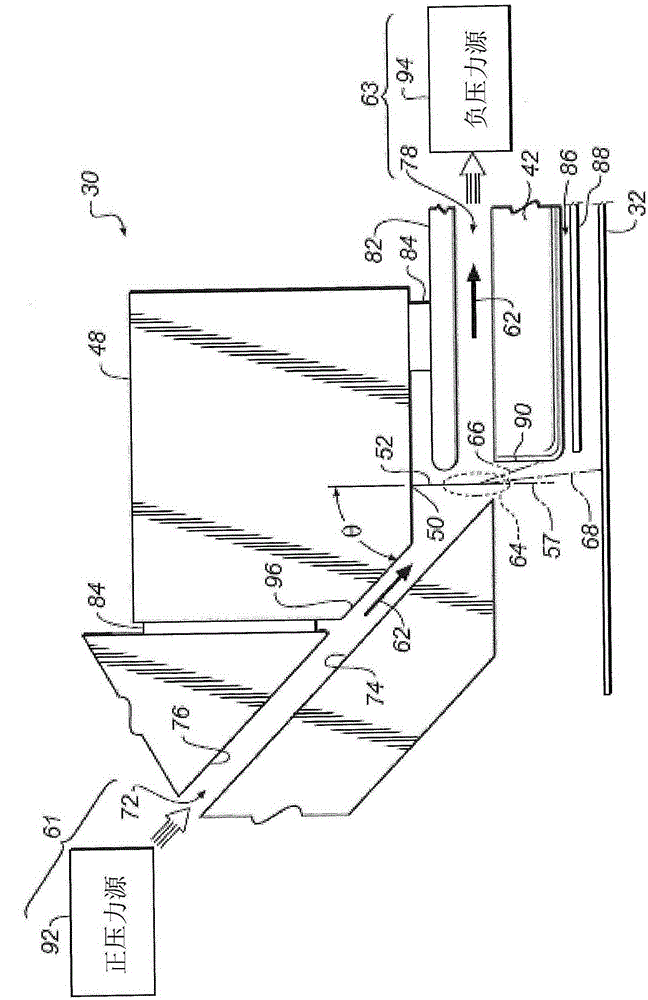

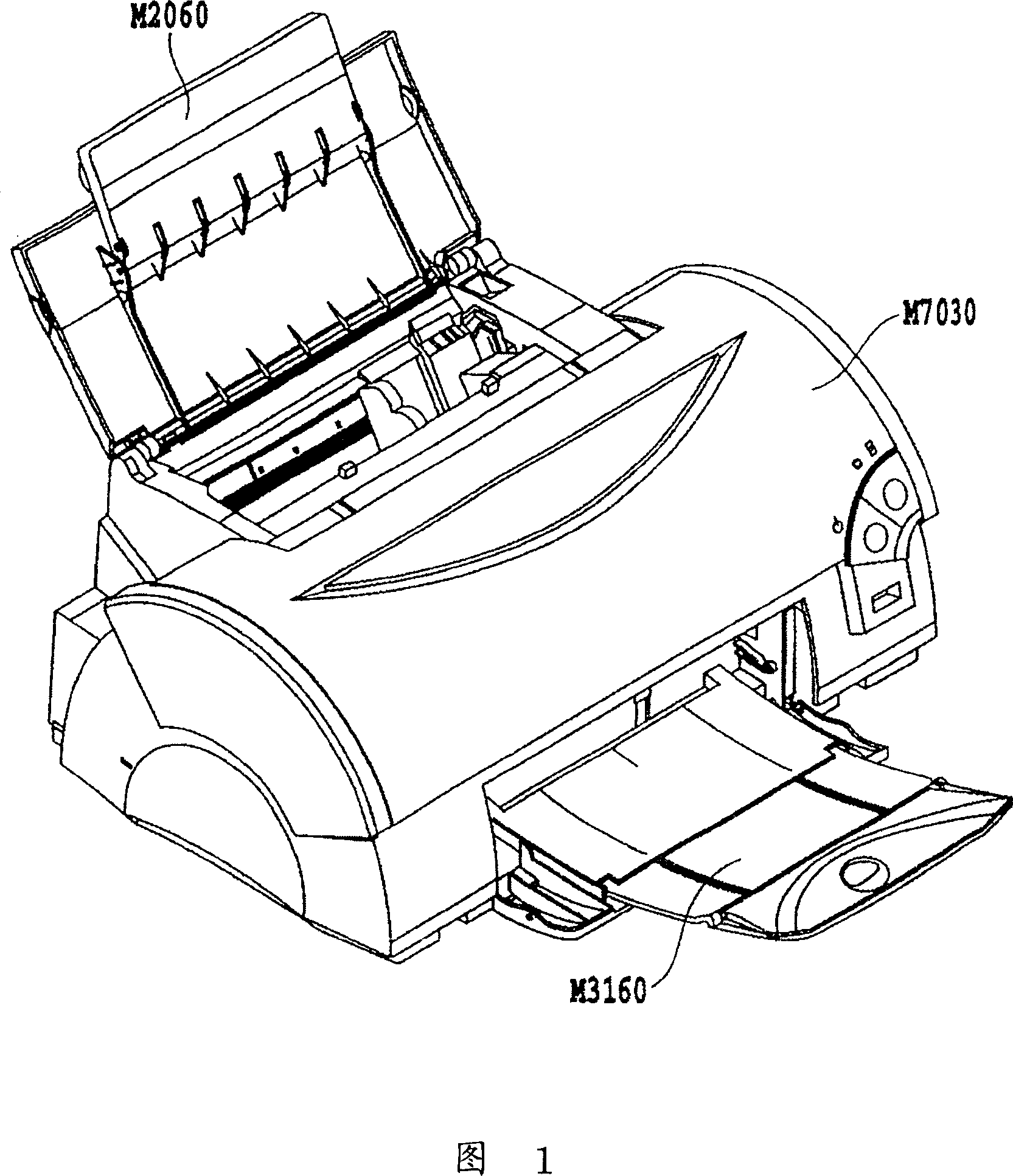

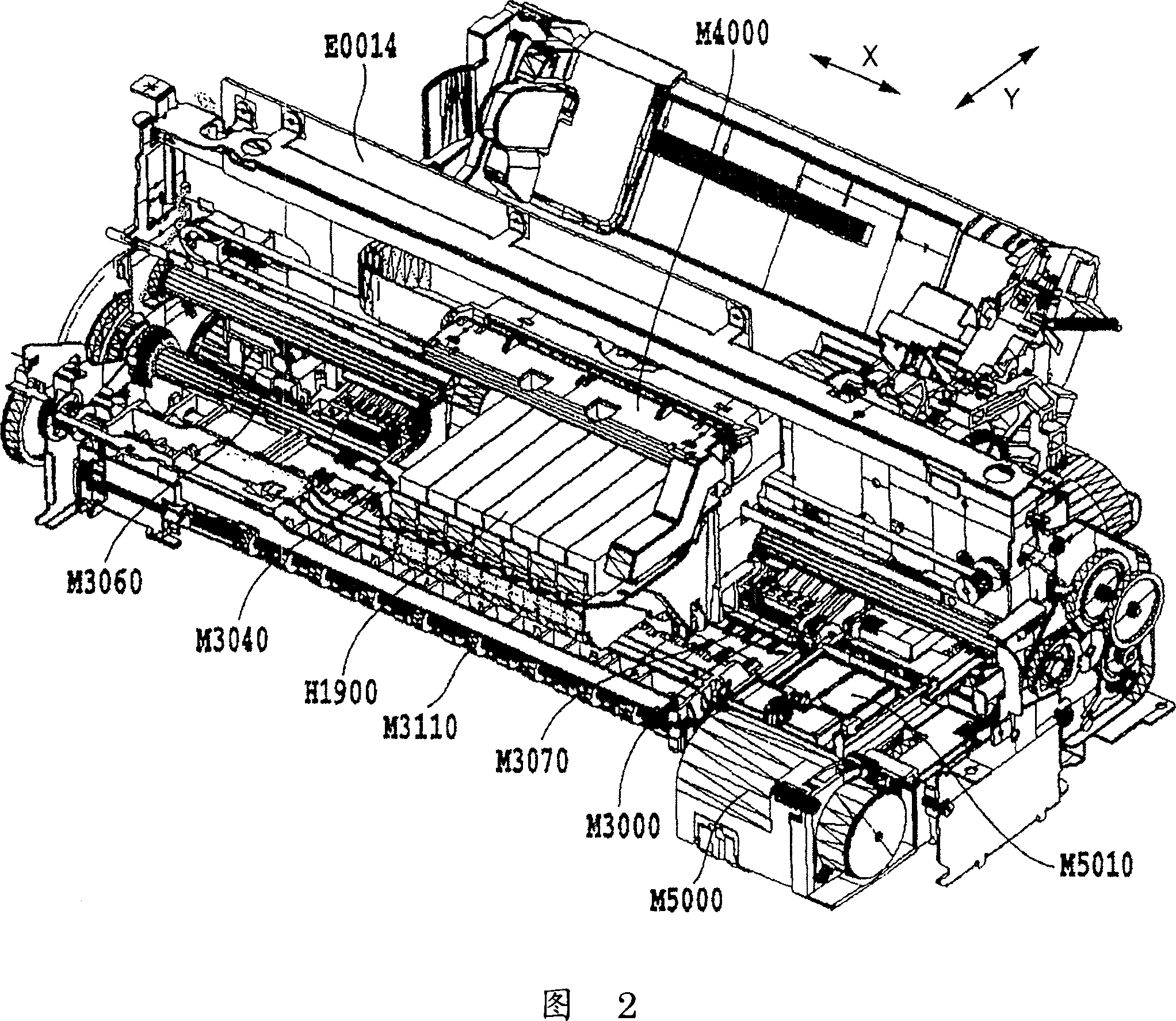

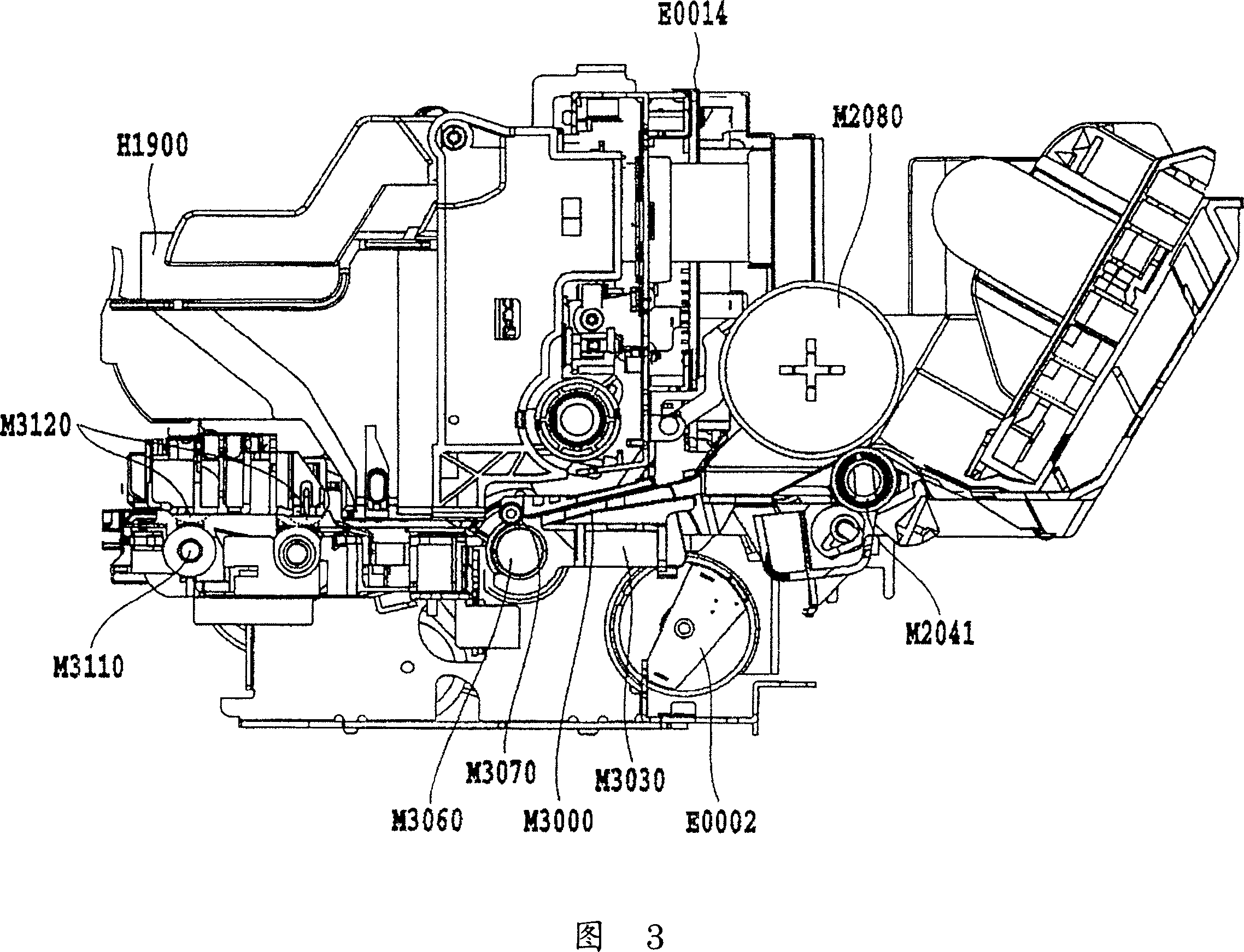

Printing apparatus and print control method

ActiveUS6969155B2High printing densityProlong lifeOther printing apparatusImage formationEngineering

A printing apparatus and a print control method can obtain excellent ink discharge without reducing the life of a printhead for image formation using plural sizes of ink droplets. Unop printing by discharging ink from an ink-jet printhead, having plural printing elements capable of discharging ink droplets in plural sizes, to a print medium, the number of concurrently-driven printing elements is counted corresponding to each respective size of the plural sizes, based on input print data, then a drive pulse applied to the concurrently-driven printing elements corresponding to the respective size of the plural sizes is determined based ont he result of counting, and the drive pulse is applied to the concurrently-driven printing elements.

Owner:CANON KK

Thermal transfer image receiving sheet

InactiveCN101060994ANo crackGood transferabilityDuplicating/marking methodsCoatingsPolyester resinEngineering

Disclosed is a thermal transfer image receiving sheet comprising a substrate sheet and an image-receiving layer formed on at least one side of the substrate sheet and mainly containing a dyeable resin. The image-receiving layer contains a cellulose acetate butyrate and a polyester resin having a number-average molecular weight of not more than 10,000.

Owner:OJI PAPER CO LTD

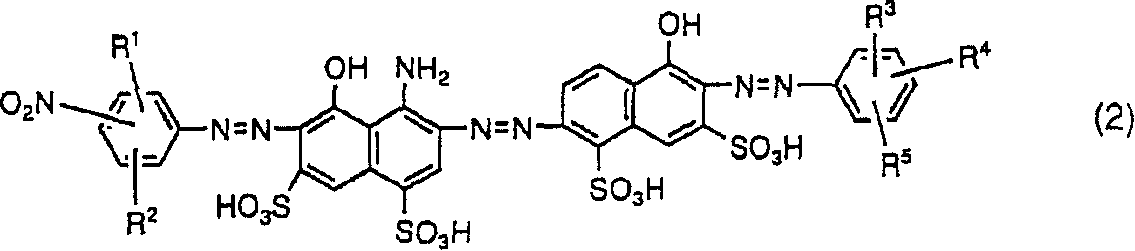

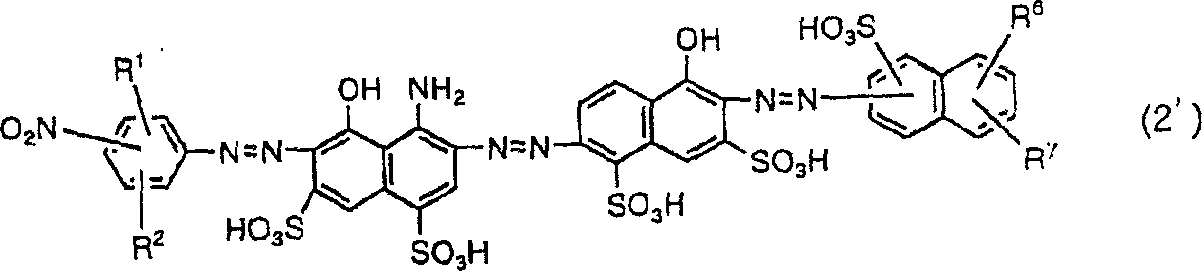

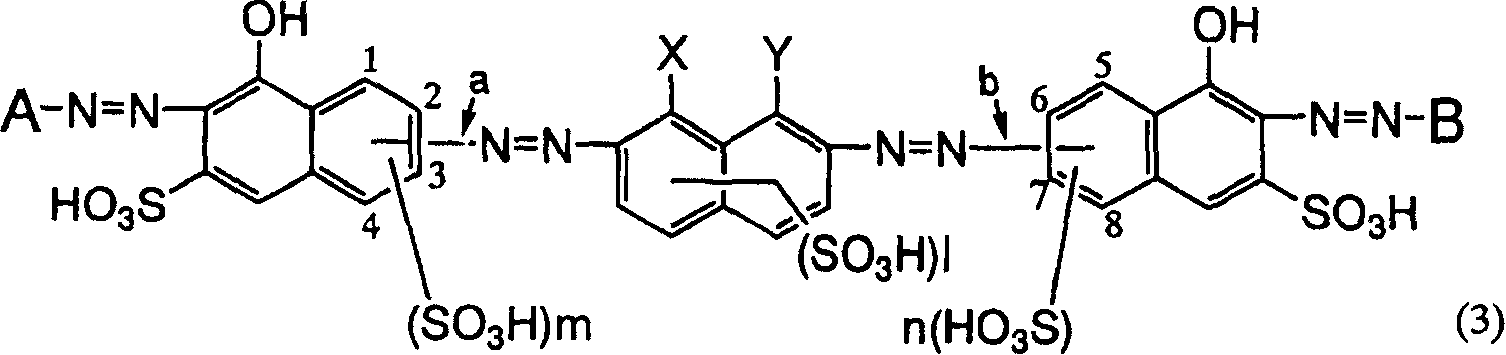

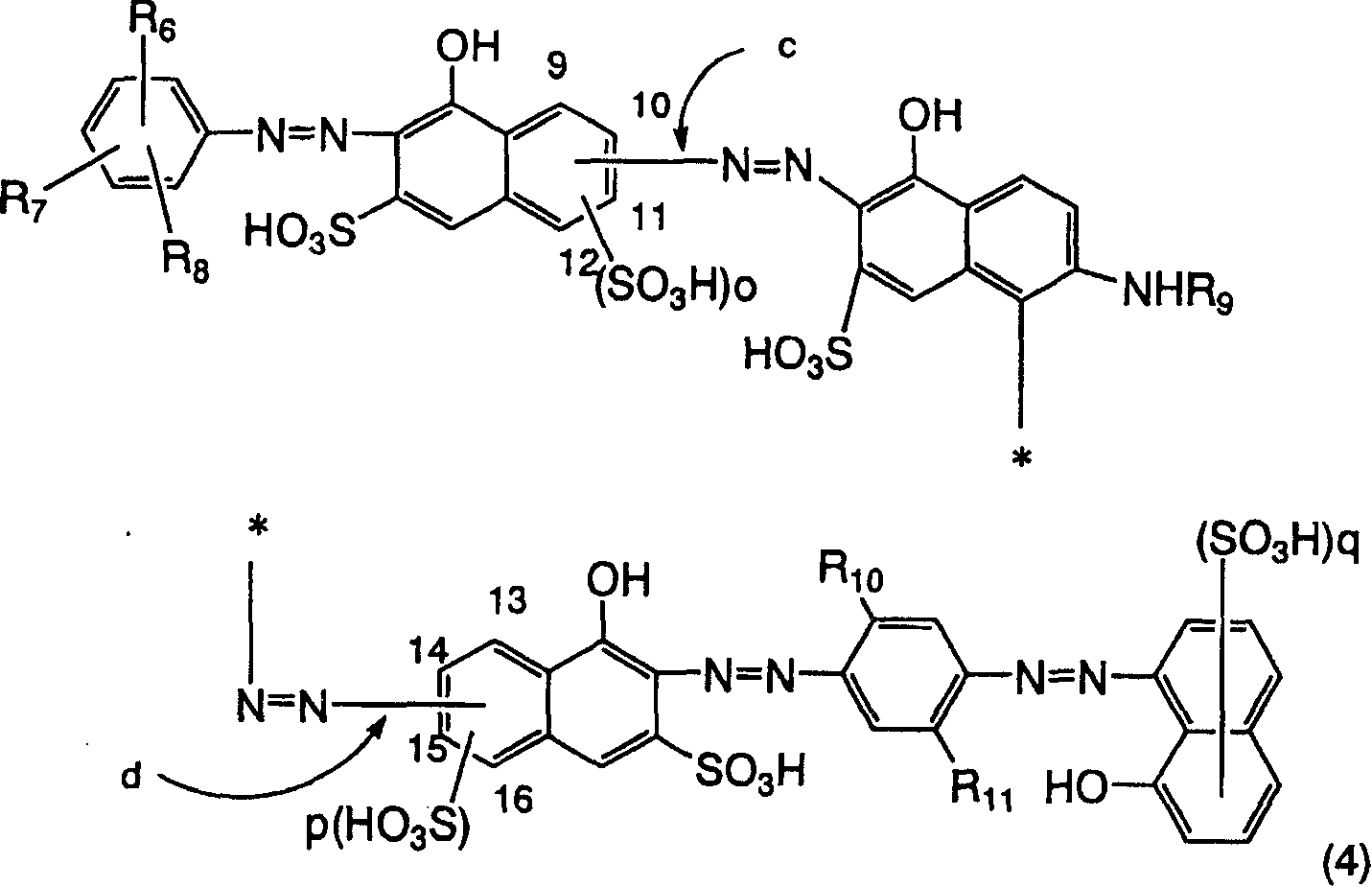

Trisazo compound, ink composition, and colored object

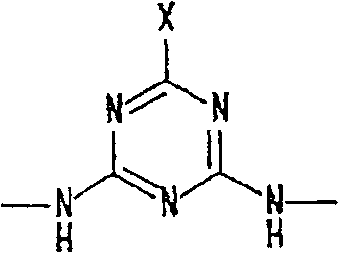

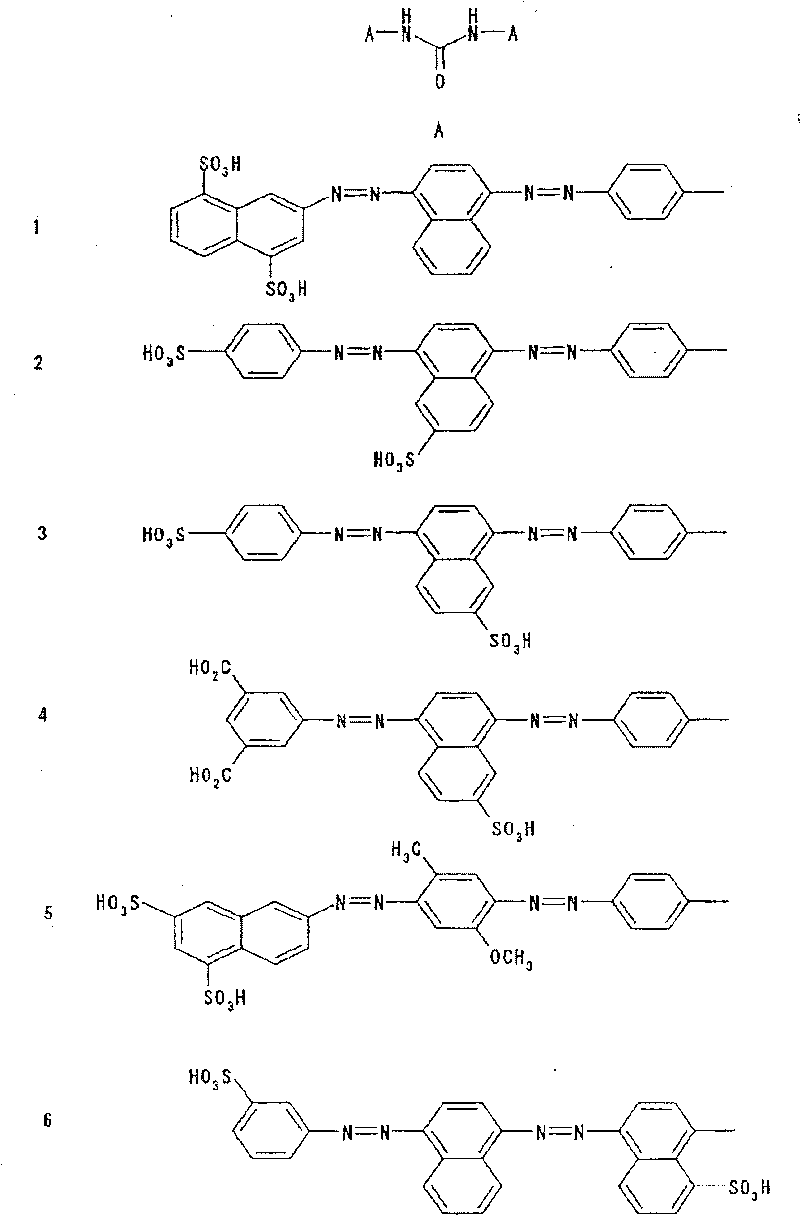

InactiveUS7326288B2Good water solubilityHigh fastnessOrganic chemistryMeasurement apparatus componentsCarboxyl radicalMoisture resistance

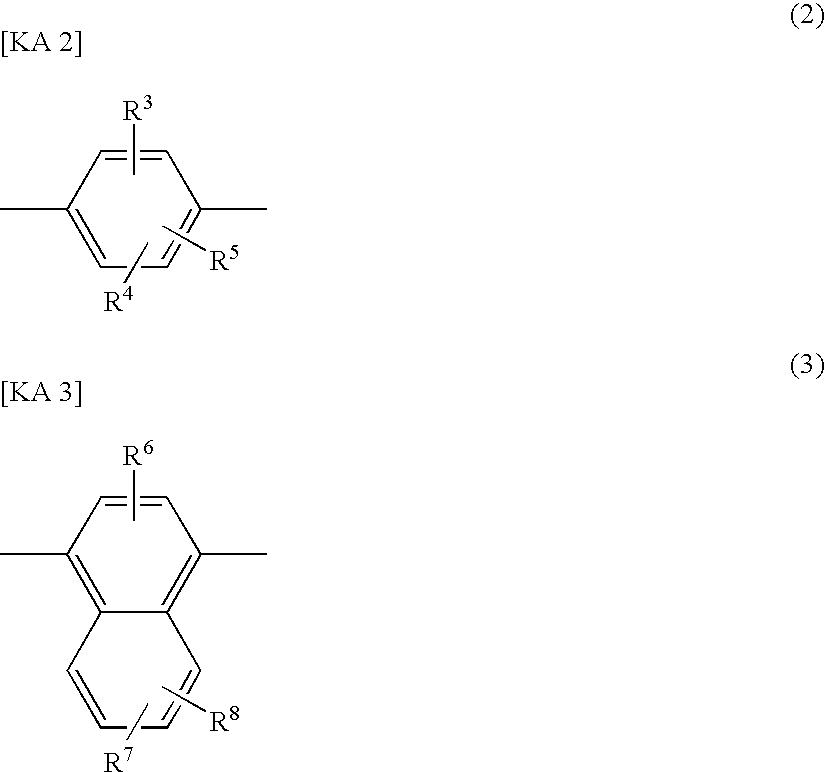

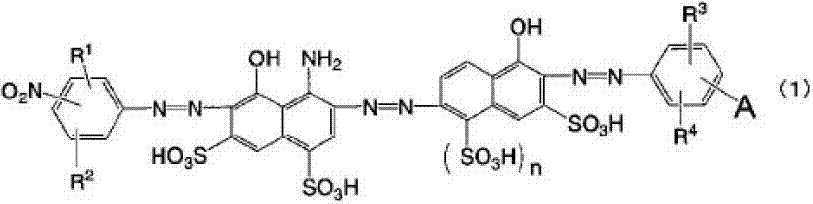

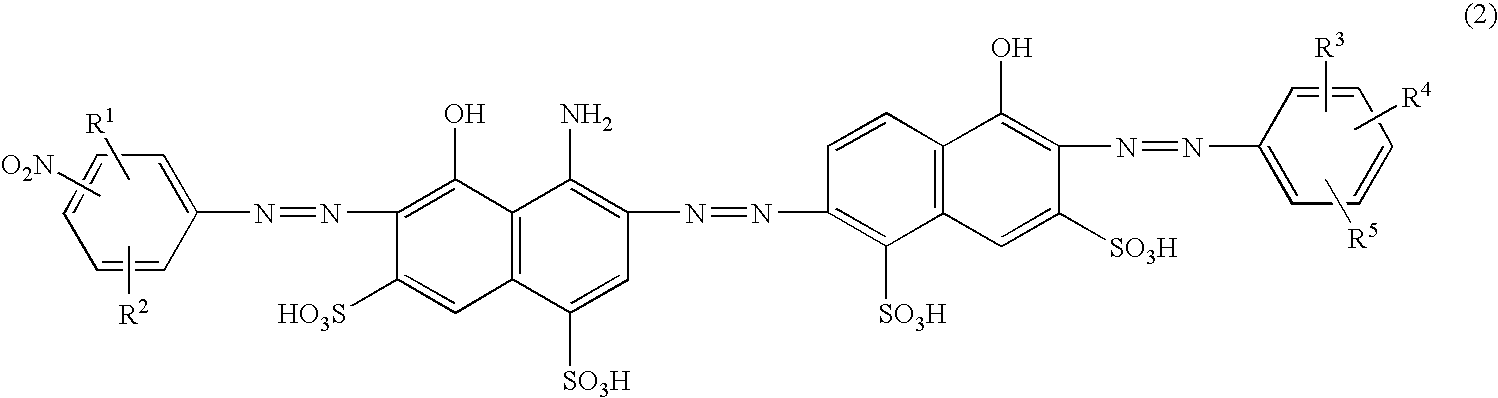

[PROBLEMS] To provide: a black compound which is for use in ink-jet recording or writing utensils, is excellent in ozone resistance, light resistance, moisture resistance, and color rendering, and gives a recording fluid having satisfactory storage stability; and an ink composition containing the compound. [MEANS FOR SOLVING PROBLEMS] The black compound is a trisazo compound represented by the following formula (1) or a salt thereof. (1) [In the formula (1), R1 and R2 each independently represents hydrogen, carboxy, sulfo, hydroxy, a C1-4 alkyl, C1-4 alkoxy, or sulfo group optionally substituted by C1-4 alkoxy, an optionally carboxylated C1-4 alkoxy group, etc.; and A represents phenyl or naphthyl (provided that the phenyl and naphthyl groups may be substituted by halogeno, carboxy, sulfo, sulfamonyl optionally substituted by alkyl or phenyl, nitro, etc.).]

Owner:NIPPON KAYAKU CO LTD

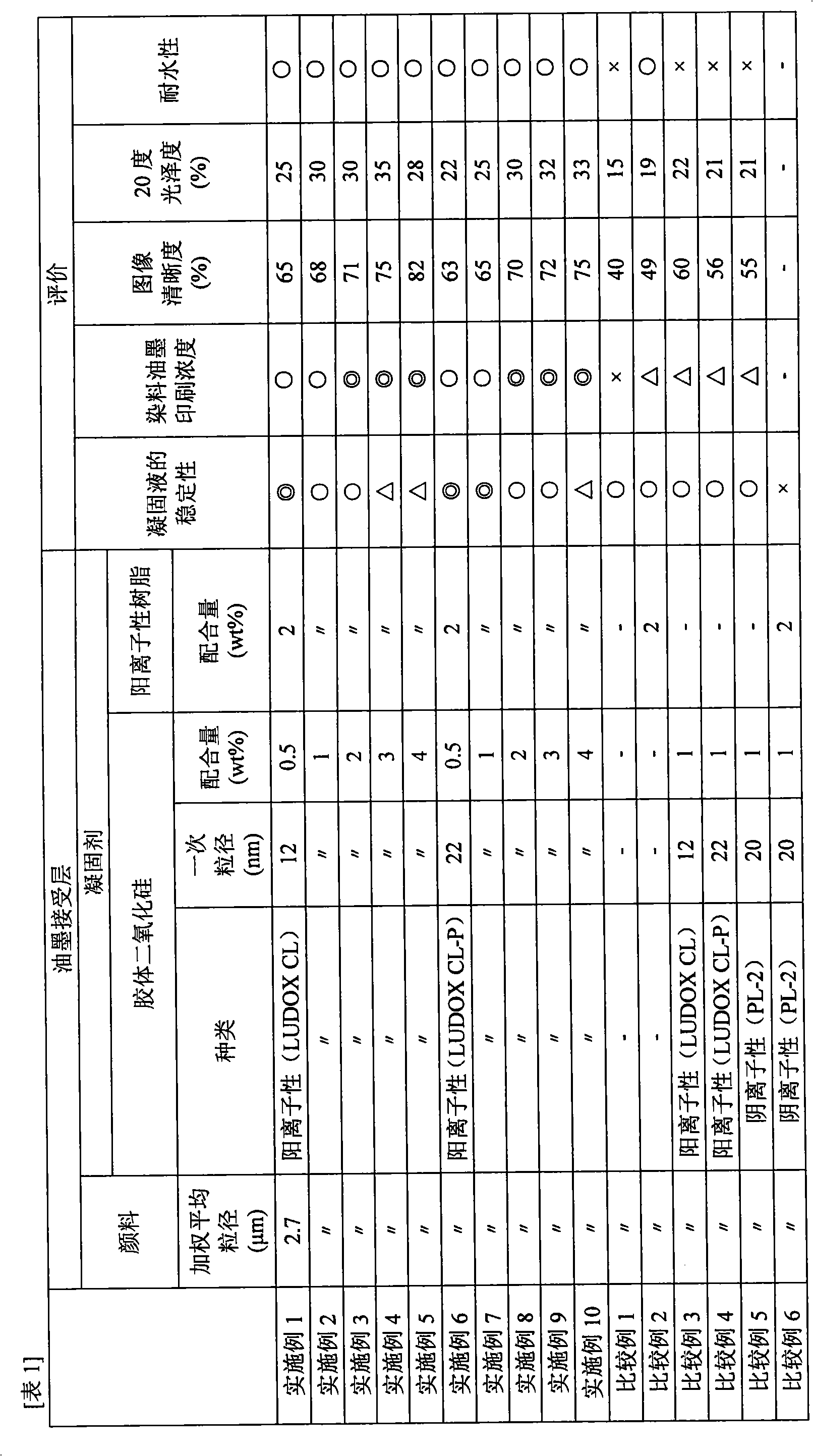

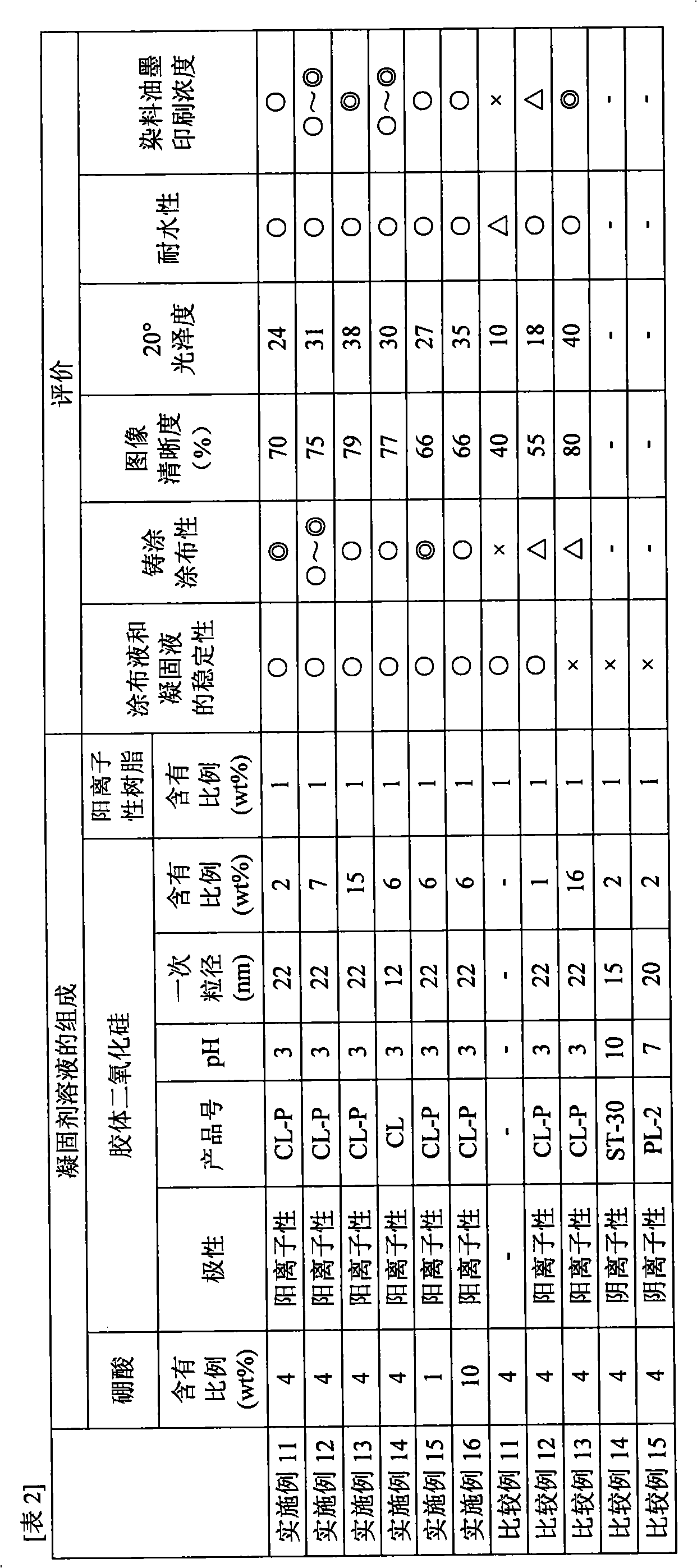

Ink jet recording medium and process for producing the ink jet recording medium

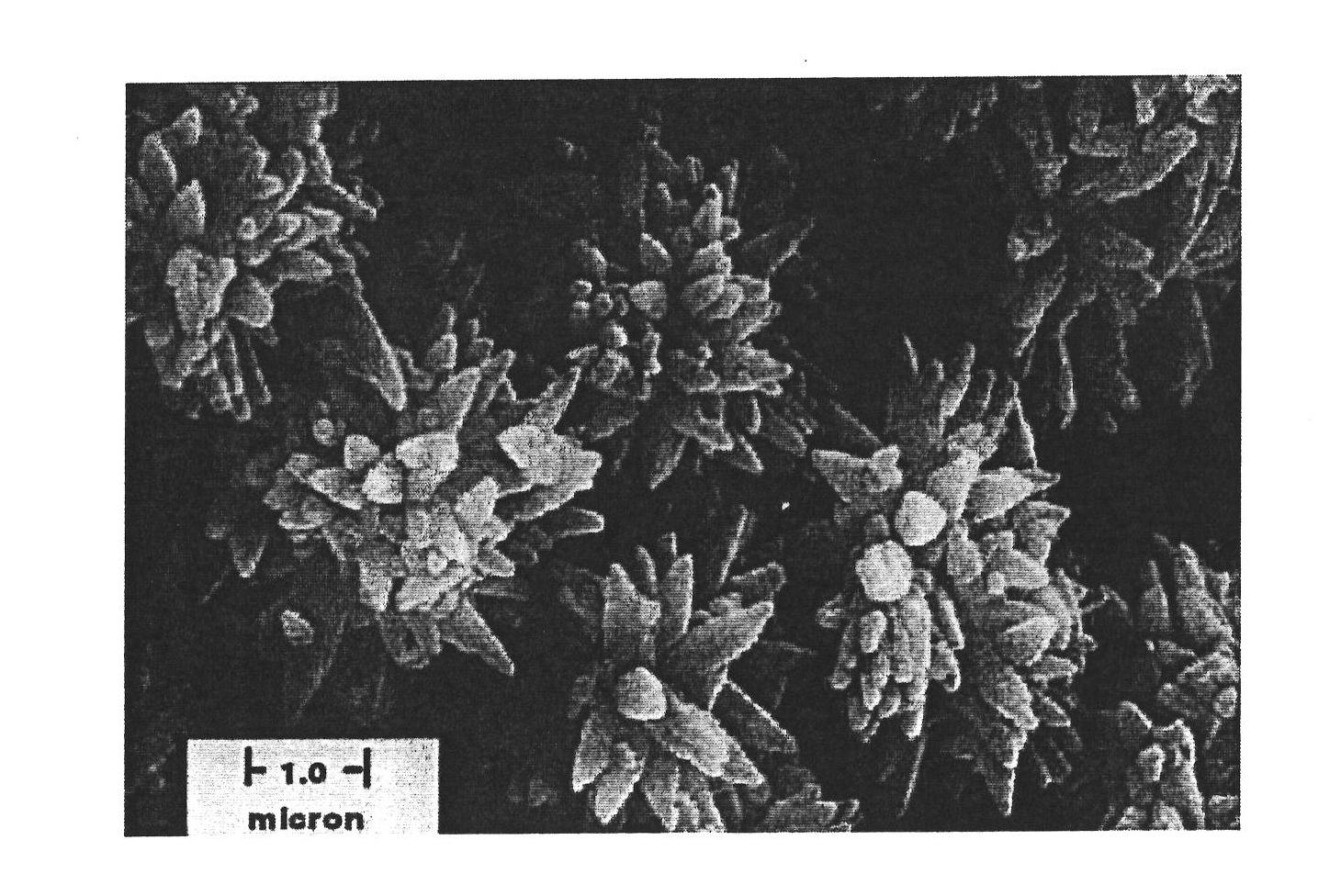

InactiveCN101980872APromote absorptionImprove water resistanceDuplicating/marking methodsCoatingsColloidal silicaSilicon dioxide

Disclosed is an ink jet recording medium that has an excellent glossy impression, has a high print density in ink jet recording using a dye ink, and has excellent ink absorption and waterfastness. The ink jet recording medium is produced by forming a coating layer containing a pigment and a binder on at least one side of an air permeable support and then coating a coagulating agent, which coagulates the binder, onto the surface of the coating layer to provide an ink receptive layer by a coagulation cast coating method. A boron compound, a cationic resin, and a cationic colloidal silica contained in the coagulating agent are present on the surface of the ink receptive layer.

Owner:NIPPON PAPER IND CO LTD

Microencapsulated material, microencapsulated color material, process for production of the material, ink composition, ink-jet recording method, and recorded material

InactiveCN101208395AExcellent ejection stabilityImprove firmnessMaterial nanotechnologyDuplicating/marking methodsDispersion stabilityHydrophilic monomer

The present invention provides microencapsulation for an ink composition that is excellent in dispersion stability, ejection stability, and color rendering, has excellent image fastness and scratch resistance, is less prone to image penetration, and can obtain a recorded matter with high printing density Color material, ink composition using the color material, its production method, inkjet recording method, recorded matter, and microencapsulated product. On the surface of the core substance represented by the color material particles such as pigments, the wall material mainly composed of the following substances is covered to perform microencapsulation. The substances in it are: 1) have ionic groups and hydrophobic groups and 2) a polymer (B) having at least: a first polymerization from an ionic group having a charge opposite to that carried by the polymer, a hydrophobic group, and a polymerizable group A repeating structural unit derived from a surfactant, and from a second polymerizable surfactant having the same or opposite charge to that of the first polymerizable surfactant and / or having a charge similar to that of the polymer Repeating structural units derived from hydrophilic monomers and / or hydrophobic monomers with the same or opposite charges. The aqueous medium contains a color material such as a pigment as a core material and microencapsulates it. As an ink composition, the ink composition is ejected from a nozzle on a recording medium by an inkjet recording method. object, get the record object. By constituting the core material with chemicals, metal powder, ceramics, etc., it becomes possible to perform surface modification of the core material.

Owner:SEIKO EPSON CORP

Inkjet recording apparatus, method for inkjet recording, and ink

ActiveUS8801167B2Improve waterproof performanceImprove discharge stabilityMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceOrganic solvent

An inkjet recording apparatus including an ink; and an ink discharging head configured to discharge the ink, wherein the ink discharging head is provided with a nozzle having a silicone-containing water-repellent film on a surface thereof on which the ink contacts, wherein the ink contains a colorant; water; and a water soluble organic solvent, wherein the colorant contains a carbon black partially coated with a resin, and wherein the ink meets the following expressions (1) and (2): 1.0×104<N×R / 100<1.0×106 (1) 20.0<R≦̸100.0 (2) where R (% by mass) denotes a rate of the mass of the carbon black partially coated with a resin relative to the mass of the colorant, and N denotes the number of coarse particles having a particle diameter of 0.5 μm or more per 5 μL of the ink where the number thereof is determined with a number counting method.

Owner:RICOH KK

Ink jetting record material

InactiveCN1370687APromote absorptionHigh printing densityDuplicating/marking methodsCoatingsPorosityVisibility

An inkjet recording material, in which at least one ink receiving layer is provided on one side of a light-transmitting support, and at least one bottom coating layer is provided on the opposite side, wherein the bottom coating contains primary particles with an average particle diameter of 5 to For 50nm inorganic particles and binders, the porosity is 70% by volume or less. Provided is an inkjet recording material which has high ink absorbency, high printing density, no problem of printer conveyance and back bleeding, and excellent visibility by means of backlighting.

Owner:MITSUBISHI PAPER MILLS LTD

Azo compound, ink composition, recording method and colored article

InactiveUS20090118479A1Good water solubilityImprove stabilityOrganic chemistryInksSolubilityHydrogen atom

The present invention relates to an azo compound represented by the following formula (1)(wherein, each of R1 and R2 independently represents a hydrogen atom, a halogen atom, a cyano group, a carboxyl group, a sulfo group, a sulfamoyl group or the like, each of m and n independently represents 0 or 1, X represents a sulfo group, B represents a substituted p-phenylene group or a substituted p-naphthylene group (these may be substituted by a group selected from the group consisting of a sulfo group, a sulfo C1 to C4 alkoxy group, a C1 to C4 alkyl group and the like), and C represents a substituted phenyl group or a naphthyl group)or a salt thereof, an ink composition containing it, especially a black ink composition. Said pentakis-azo compound is excellent in solubility to medium whose main component is water and suitable for an water-soluble composition (ink composition and the like) for inkjet recording and writing tools; recorded articles recorded using said composition are excellent in fastnesses such as light fastness and ozone gas fastness; bronzing is not generated on the recorded images; and its recording liquids are good in storage stability.

Owner:NIPPON KAYAKU CO LTD

Trisazo compound, ink composition, and colored object

To provide: a black compound which is for use in ink-jet recording or writing utensils, is excellent in ozone resistance, light resistance, moisture resistance, and color rendering, and gives a recording fluid having satisfactory storage stability; and an ink composition containing the compound. The black compound is a trisazo compound represented by the following formula (1) or a salt thereof. (1) [In the formula (1), R<1> and R<2> each independently represents hydrogen, carboxy, sulfo, hydroxy, a C1-4 alkyl, C1-4 alkoxy, or sulfo group optionally substituted by C1-4 alkoxy, an optionally carboxylated C1-4 alkoxy group, etc.; and A represents phenyl or naphthyl (provided that the phenyl and naphthyl groups may be substituted by halogeno, carboxy, sulfo, sulfamonyl optionally substituted by alkyl or phenyl, nitro, etc.)].

Owner:NIPPON KAYAKU CO LTD

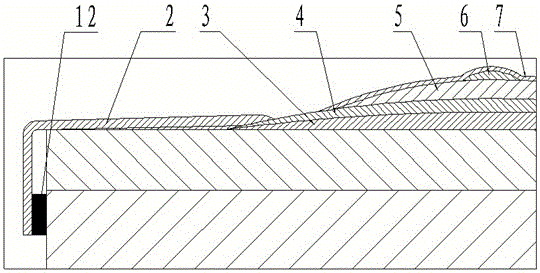

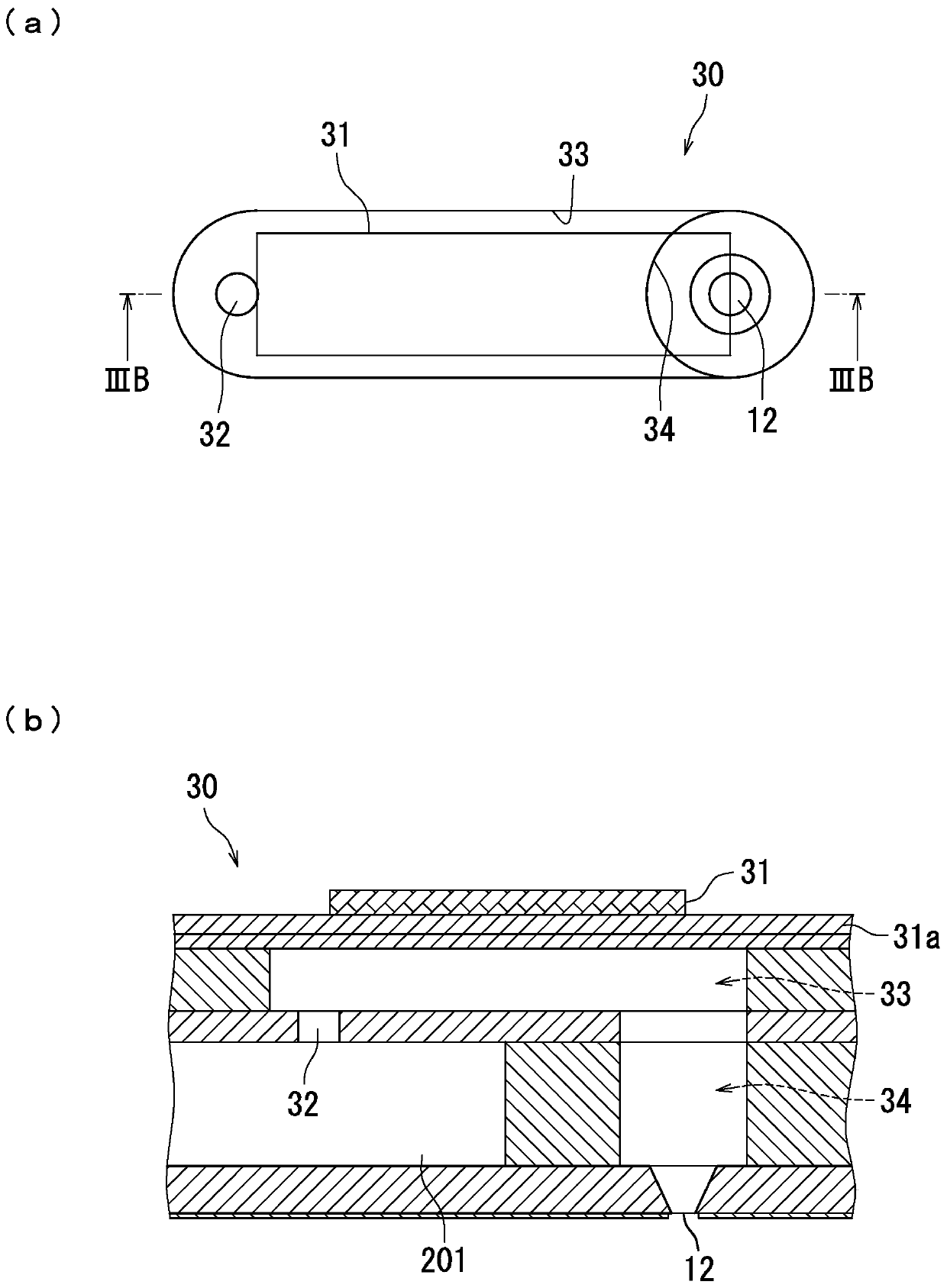

thermal print head

ActiveCN104401135BRaise base temperatureHigh printing densityPrintingThermal conductivityThermal printing

The invention relates to a thermal printing head, in particular to a thermal printing head that a high-heat-conductivity interlayer is added into a base layer. The thermal printing head is characterized in that the high-heat-conductivity interlayer is added into the base layer of a thermal printing head base plate; the heat conductivity of the interlayer is greater than 20W / mK; an external lead is arranged in the interlayer. When the thermal printing head is required to be provided with a rapid heat dissipation property, the lead of the interlayer is connected with a base platform of the thermal printing head, so that the heat dissipation efficiency of the base layer is improved; when the thermal printing head is not required to be provided with the rapid heat dissipation property, the lead is suspended and is not connected, then the heat dissipation velocity of the thermal printing head depends on the heat conductivity of the base layer. The thermal printing head has the advantages that the heat dissipation effect is good, the switching is convenient, and high / low speed product switching requirements can be met.

Owner:SHANDONG HUALING ELECTRONICS

Ink-jet type ink group

An inkjet ink comprising a colorant, a water-soluble ester or amide of pyrrolidin-2-one carboxylic acid, and water. An inkjet printing method is also disclosed.

Owner:EASTMAN KODAK CO

Azo compound, ink composition, recording method, and colored object

InactiveCN101248141AGood water solubilityGood storage stabilityDuplicating/marking methodsInksHydrogenPhotochemistry

Owner:NIPPON KAYAKU CO LTD

Ink composition, inkjet recording method, and colored material

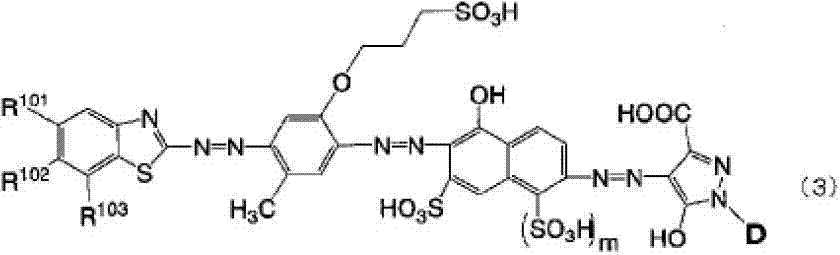

ActiveCN103097471AHas firmnessExcellent ozone resistanceDuplicating/marking methodsInksHydrogen atomCOLORED MATERIAL

Disclosed is an aqueous black ink composition which enables the formation of an excellent black recorded image having extremely high ozone gas resistance and a neutral and achromatic color. The ink composition comprises: a dye (I) which comprises at least one compound represented by specific formula (1) or at least one tautomer or salt of the compound; a dye (II) which comprises at least one compound represented by specific formula (3) or at least one tautomer or salt of the compound; and a dye (III) which comprises at least one compound represented by specific formula (4) or at least one tautomer or salt of the compound. In formula (1), R1 and R2 independently represent a hydrogen atom, a sulfo group or the like; R3 and R4 independently represent a halogen atom, a sulfo group or the like; and n represents 0 or 1. In formula (3), m represents 0 or 1; R101 to R103 independently represent a hydrogen atom, a sulfo group or a C1-C4 alkoxy group; and a group D represents a phenyl or naphthyl group substituted by 1 to 3 sulfo groups. In formula (4), R201 to R204 independently represent a hydrogen atom, or a C1-C4 alkoxy group substituted by a sulfo group.

Owner:NIPPON KAYAKU CO LTD

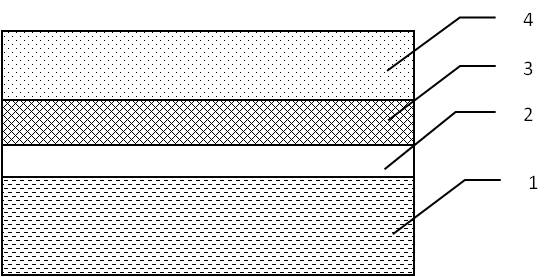

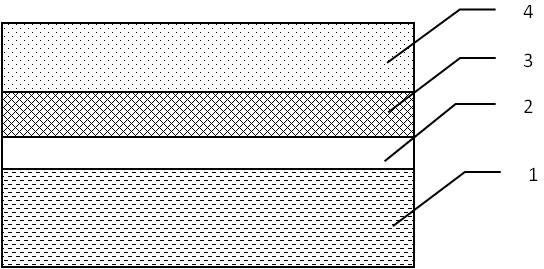

Environment-friendly renewable super-light printing lamp box cloth

The invention relates to environment-friendly renewable super-light printing lamp box cloth which is composed of polyvinyl base cloth, a base painting agent layer 3 and an ink-absorbing painting layer 4, wherein the polyvinyl base cloth is composed of a polyvinyl weaving cloth 1 and a polyvinyl pouring film layer 2 on the front surface of the polyvinyl weaving cloth 1; the base painting agent layer 3 is arranged on the front surface of the polyvinyl base cloth; and the ink-absorbing painting layer 4 is distributed on the base painting agent layer 3. A preparation method comprises the following steps of: (1) adopting polyvinyl plastic grains, drawing, weaving and pouring polyvinyl, thereby obtaining the polyvinyl base cloth; (2) coating base painting agent on the front surface of the base cloth, drying, and then coating the ink-absorbing painting layer; and (3) slitting, rewinding and checking, thereby obtaining an end product. The ink-absorbing painting layer is prepared by adopting pure acrylic emulsion, polrvinyl chloride emulsion, calcium carbonate, bubble-restraining defoamer, silica gel, titanium dioxide, wetting agent, brightening agent, n-butyl alcohol, sodium chloride and multiple parts of ammonia water at a certain weight ratio. The weaving cloth of the environment-friendly renewable super-light printing lamp box cloth provided by the invention is made from polyvinyl and the environment-friendly coatings of pure acrylic emulsion and polrvinyl chloride emulsion are selected for the painting layer, so that the environment-friendly renewable super-light printing lamp box cloth has the advantages of light weight, environmental friendliness, renewability and the like.

Owner:JIANGSU TETRA NEW MATERIAL TECH

Trisazo compound, ink composition, and colored object

InactiveUS20070107628A1Good water solubilityHigh fastnessOrganic chemistryMeasurement apparatus componentsHydrogenMoisture resistance

[PROBLEMS] To provide: a black compound which is for use in ink-jet recording or writing utensils, is excellent in ozone resistance, light resistance, moisture resistance, and color rendering, and gives a recording fluid having satisfactory storage stability; and an ink composition containing the compound. [MEANS FOR SOLVING PROBLEMS] The black compound is a trisazo compound represented by the following formula (1) or a salt thereof. (1) [In the formula (1), R1 and R2 each independently represents hydrogen, carboxy, sulfo, hydroxy, a C1-4 alkyl, C1-4 alkoxy, or sulfo group optionally substituted by C1-4 alkoxy, an optionally carboxylated C1-4 alkoxy group, etc.; and A represents phenyl or naphthyl (provided that the phenyl and naphthyl groups may be substituted by halogeno, carboxy, sulfo, sulfamonyl optionally substituted by alkyl or phenyl, nitro, etc.).]

Owner:NIPPON KAYAKU CO LTD

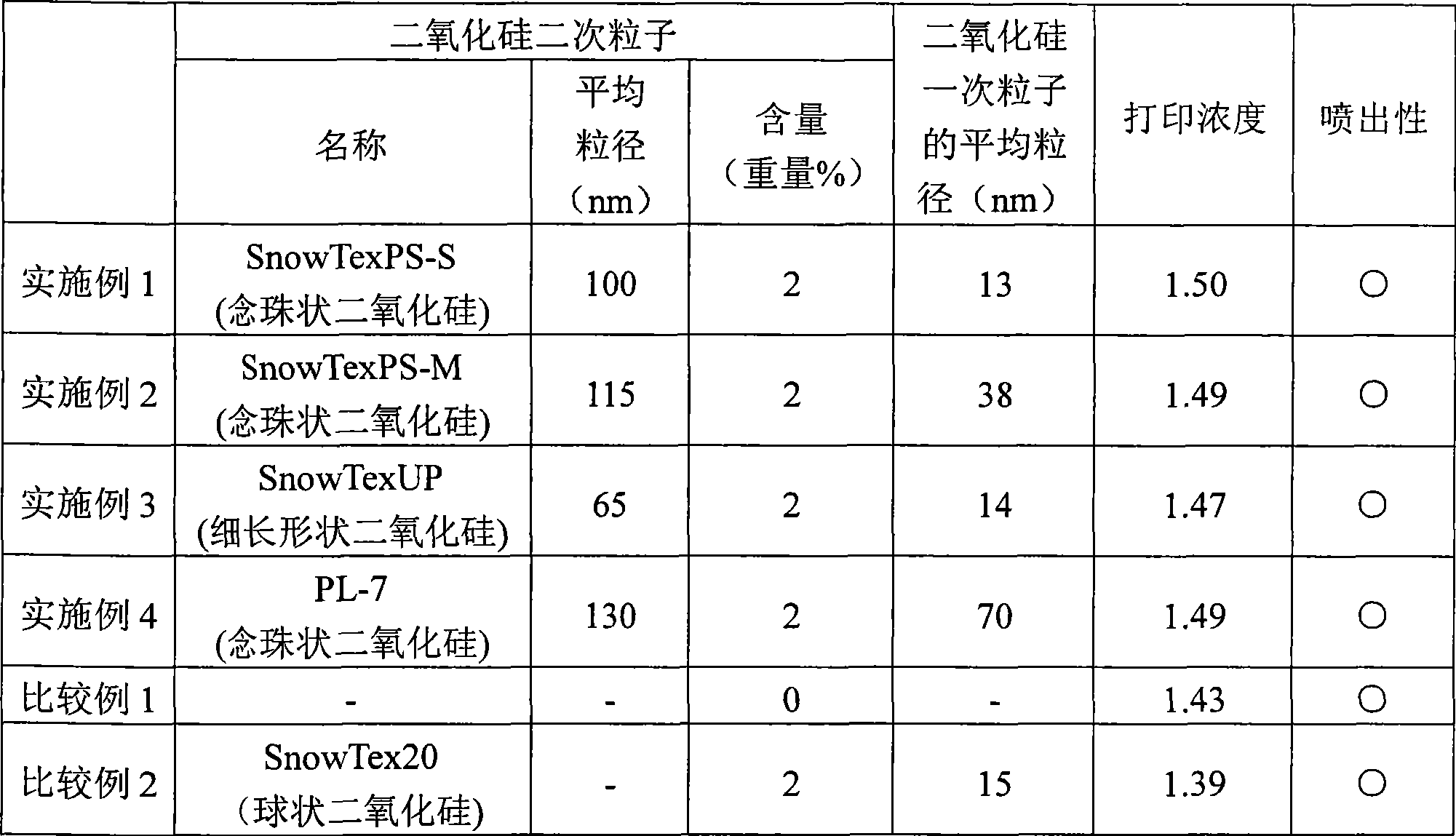

Aqueous ink for inkjet recording

InactiveCN101490184AHigh printing densityDuplicating/marking methodsInksVolumetric Mass DensitySilicon dioxide

Disclosed is an aqueous ink for inkjet recording which is excellent in print density when printed on plane paper and the like. Also disclosed is an aqueous dispersion used for such an ink. Specifically disclosed is an aqueous ink for inkjet recording which is composed of an aqueous dispersion for inkjet recording containing a coloring agent and a metal oxide secondary particle wherein a plurality of primary particles are linked. In this aqueous ink for inkjet recording, the metal oxide is composed of at least one substance selected from the group consisting of silica, titanium oxide and cerium oxide.

Owner:KAO CORP

Inkjet black ink, ink set, inkjet recording method, ink cartridge, recording unit, and inkjet recorder

InactiveCN100545223CFull weather resistanceHigh optical densityDuplicating/marking methodsAzo dyesOrganic solventWater soluble

Owner:CANON KK

Water-base black ink composition and colored material

ActiveCN1756812AGood storage stabilityGood water solubilityDuplicating/marking methodsInksCOLORED MATERIALLightfastness

The present invention relates to a water-based black ink composition comprising a water-soluble black dye (A) exhibiting ozone fastness and a condensate compound (B) of 4,4'-dinitrostilbene-2,2'-disulfonic acid and aminobenzenes or a reduction product (C) thereof. Said ink composition is suitable for use in ink-jet recording, and realizes neutral hue and black color of high printing density. Further, a printed matter obtained is excellent in ozone gas fastness, light fastness, moisture fastness and color rendering properties. Still further, storage stability as a recording liquid is excellent.

Owner:NIPPON KAYAKU CO LTD

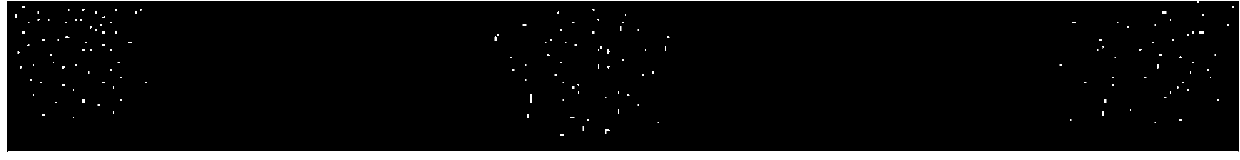

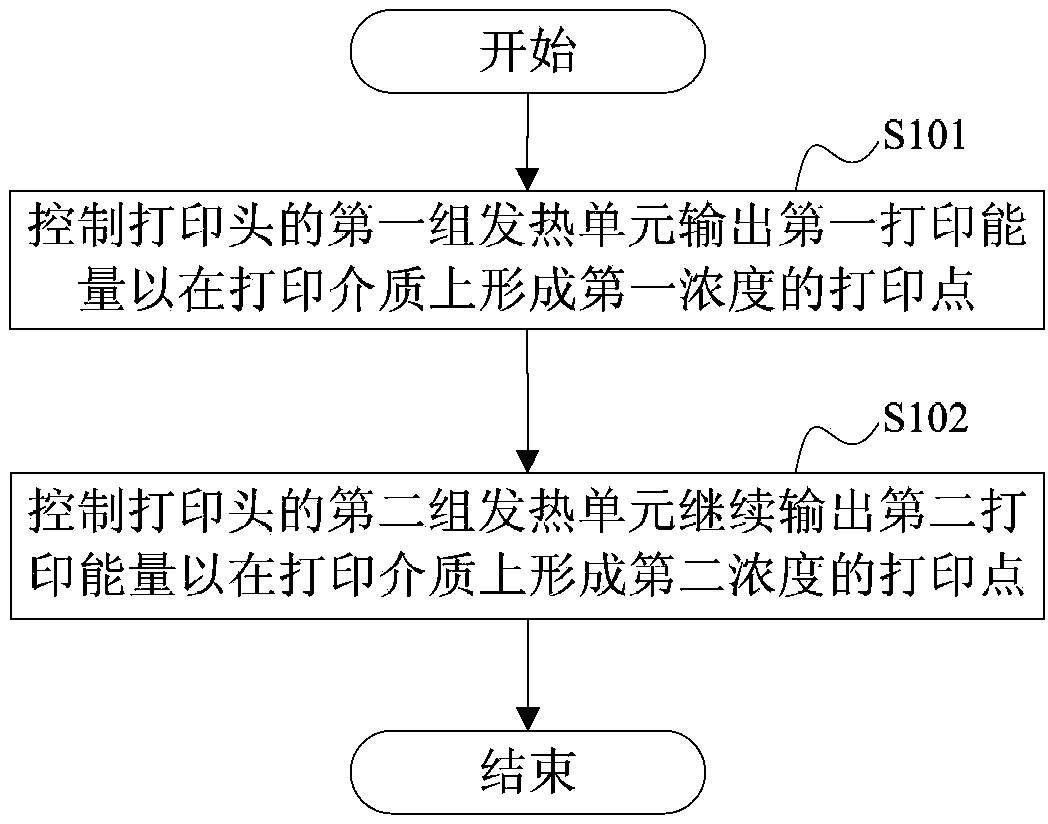

Control method of printing machine and printing machine

ActiveCN103862891AHigh printing densitySolve the problem of uneven printing densityOther printing apparatusComputer engineering

The invention discloses a control method of a printing machine and the printing machine, wherein the control method of the printing machine comprises the following steps that a first group of heating units of a printing head are controlled to output first printing energy for forming printing points at the first concentration on a printing medium; a second group of heating units of the printing head are controlled for continuously outputting second printing energy for forming printing points at second concentration on the printing medium, wherein the second group of heating units consist of heating units requiring printing energy compensation in the first group of heating units. Through the control method and the printing machine provided by the invention, the printing concentration of the heating units requiring the printing energy compensation on the corresponding printing points is improved, and the problem of nonuniform printing concentration of each printing point caused by nonuniform pressure between the printing head and a printing rubber roller can be effectively solved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

A kind of coated matte pp carbon ribbon printing synthetic paper and preparation method thereof

ActiveCN111087639BImprove printing effectHigh printing densityPolyurea/polyurethane coatingsThermographyPolymer scienceInsulation layer

A coated matte PP carbon ribbon printing synthetic paper, the synthetic paper comprises a PP synthetic paper base material and a coating layer coated on the surface of the base material, the coating layer comprises the following raw materials in parts by weight: The solid parts by weight of the layer are taken as the reference parts, the others are measured in parts by solid content, the moisture of the solution property is counted in the parts of water, 100 parts of heat insulation layer, 80-180 parts of adhesive, 0.08- of water-retaining agent 0.15 part, lubricant 0.5-1.0 part, defoamer 0.2-0.8 part, and water 500-1300 part. The thermal insulation layer is used in the coating of the present invention, which effectively reduces the energy transmission loss of the print head, thereby preventing the poor transfer caused by the temperature reduction of the printed carbon ribbon, and reducing the energy level of the print head.

Owner:河北方大新材料股份有限公司

Inkjet printing with large particles

InactiveCN103842914BLow costImprove reliabilityElectrographic process apparatusPulp and paper industryMoisture

Owner:EASTMAN KODAK CO

Coloring matter consisting of trisazo compound, ink compositions, recording method, and colored body

InactiveUS20120120148A1Easy to synthesizeGood water solubilityDuplicating/marking methodsAzo dyesHigh concentrationPolymer science

Provided are a coloring matter for black ink which is highly soluble in water-based media, and ink compositions containing the same. A high-concentration aqueous solution and ink that contain the coloring matter are stable even when have been stored for a long period, and can produce printed images having extremely high density. Even when printing is conducted using the high-concentration aqueous solution, no bronzing occurs in the resulting printed images. The ink compositions can produce black recorded images which exhibit various excellent fastnesses, particularly excellent light fastness and ozone gas fastness. The coloring matter consists of at least one substance selected from among trisazo compounds represented by general formula (1), tautomers thereof, and salts of both. In general formula (1), R1 is unsubstituted C1-4 alkyl or the like; R2 is cyano or the like; R3 is a chlorine atom or the like; R5 to R7 are a hydrogen atom, unsubstituted C1-4 alkyl, sulfo-substituted C1-4 alkoxy, or the like; R8 to R10 are a hydrogen atom, unsubstituted C1-4 alkyl, sulfo-substituted C1-4 alkylthio, or the like; A is sulfo-substituted 2-naphthothiazolyl or the like; and a to d represent the positions at which the ring is substituted with R3 and sulfo.

Owner:NIPPON KAYAKU CO LTD

Inkjet black ink, ink set, inkjet recording method, ink cartridge, recording unit, and inkjet recorder

InactiveCN1977007AFull weather resistanceHigh optical densityDuplicating/marking methodsAzo dyesOrganic solventWater soluble

The present invention aims to provide an ink jet black ink which can improve weatherability, optical density and sticking recovery property of nozzles of a recording head. According to the present invention, an ink jet black ink is provided which comprises at least a coloring-material and a water-soluble organic solvent, wherein the coloring material is a compound represented by the following general formula (I) or a salt thereof, and the water-soluble organic solvent is a water-soluble organic solvent having a relative permittivity of from 30.0 or more to less than 70.0 at 20 DEG C and capable of dissolving the compound represented by the following general formula (I) or a salt thereof, by 1.0 mass % or more at 25 DEG C, and is in a content of 50.0 mass % or more with respect to the total content of all water-soluble organic solvents contained in the ink jet black ink.

Owner:CANON KK

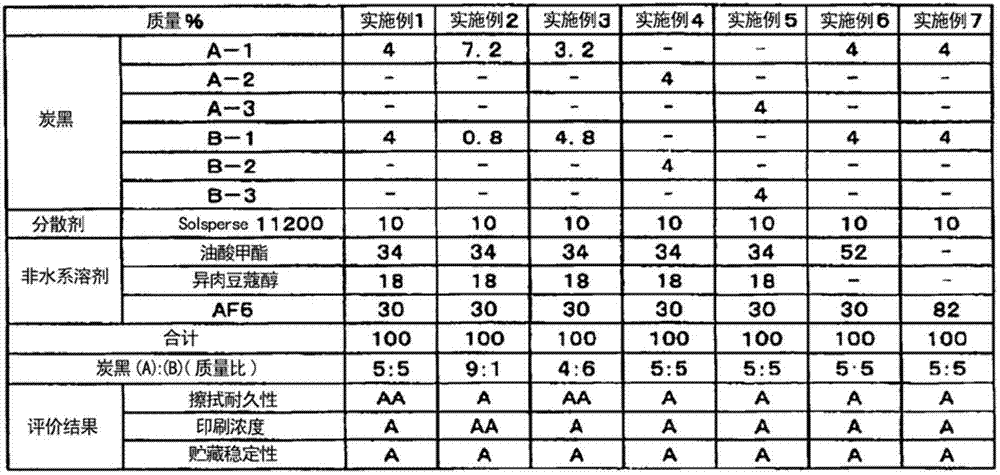

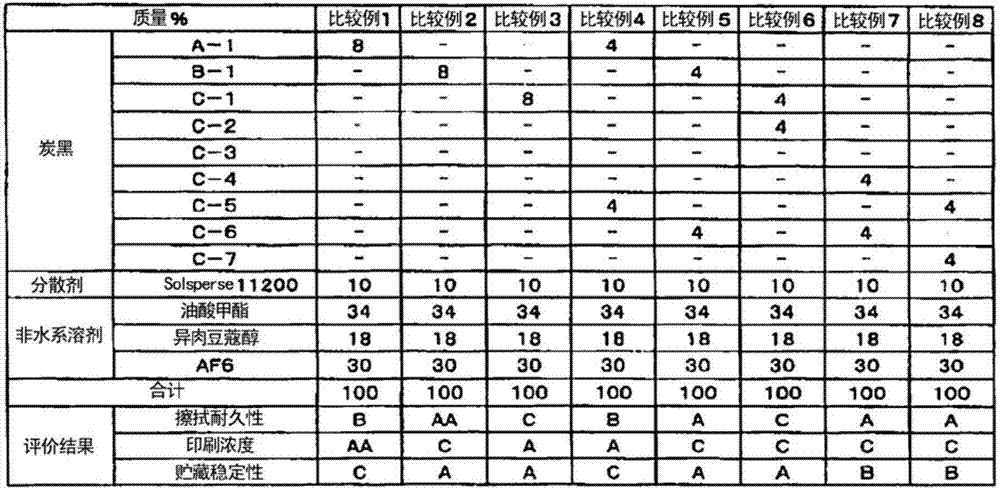

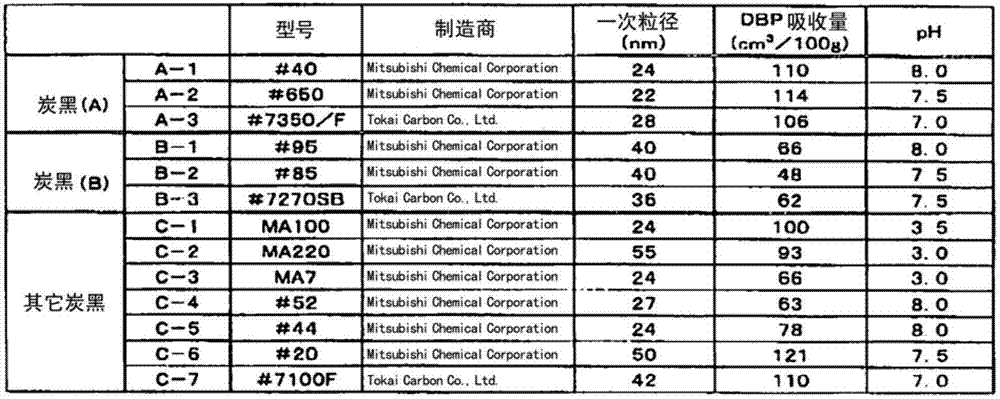

Non-aqueous ink and method of producing same

ActiveCN102952427AIncreased durabilityGood storage stabilityDuplicating/marking methodsInksPhysical chemistrySolvent

The invention provides non-aqueous ink for a nozzle plate which has excellent wiping durability and storage stability and high printing concentration and a method of producing same. The non-aqueous ink comprising a carbon black and a non-aqueous solvent is provided, wherein the carbon black comprises: a carbon black (A) having a primary particle size of at least 18 nm but less than 30 nm, a DBP absorption of at least 80 cm3 / 100 g but not more than 130 cm3 / 100 g and a pH of at least 6.0 but not more than 9.0, and a carbon black (B) having a primary particle size of at least 30 nm but not more than 50 nm, a DBP absorption of at least 40 cm3 / 100 g but less than 80 cm3 / 100 g and a pH of at least 6.0 but not more than 9.0.

Owner:RISO KAGAKU CORP

Black ink composition, ink set containing the same and inkjet recording method

InactiveCN1997714BHigh fastnessReduce bleedingDuplicating/marking methodsInksOrganic solventWater soluble

Black ink compositions are provided. First embodiment contains a water-soluble long-wavelength dye L and a water-soluble short-wavelength dye S, in which the water-soluble short-wavelength dye S has 3or more azo groups per molecule and a naphthalene skeleton. Second embodiment contains a water-soluble short-wavelength dye S whose absorption spectrum in aqueous solvent has a maximum between 440 nmand 540 nm and a half-band width of 90 to 200 nm and a water-soluble long-wavelength dye L whose absorption spectrum in aqueous solvent has a maximum between 550 nm and 700 nm and a half-band width of 100 nm or more. Third embodiment contains water, a water-miscible organic solvent, and a coloring material, in which C. I. Direct Red 84 is contained as a water-soluble short-wavelength dye S.

Owner:FUJIFILM CORP

Azo compound, ink composition, ink jet recording method, and colored article

ActiveUS20180319988A1Good storage stabilityGood colorDuplicating/marking methodsInksAlkoxy groupPhotochemistry

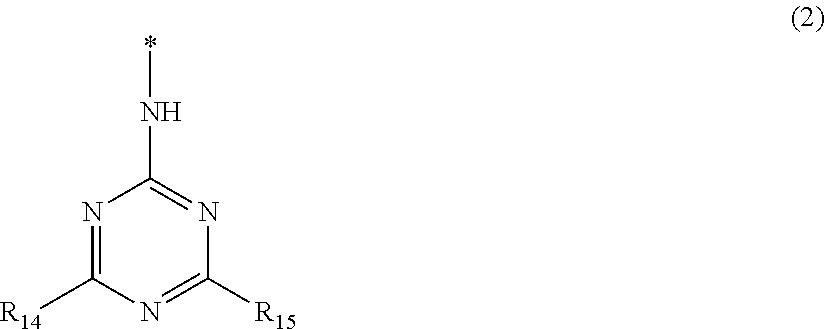

An azo compound and an ink composition containing the azo compound are used as inks for ink jet recording and have excellent gas (ozone) resistance when recording is done on special ink jet paper. The azo compound is represented by formula (1) or a tautomer thereof, or a salt of these. In formula (1), R1 represents a C1-C4 alkyl group, R2 represents a cyano group, R3 and R4 each independently represent a C1-C4 alkoxy, R5-R10 each independently represent a group represented by formula (2), and R11-R13 each independently represent a nitro group. In formula (2), R14 is an anilino group, and R15 is a mono- or di-C1-C6 alkylamino group

Owner:NIPPON KAYAKU CO LTD

Inkjet ink and inkjet recording system

ActiveCN110698918AHigh printing densityExcellent ejection stabilityDuplicating/marking methodsInksPolymer scienceMethacrylate methyl

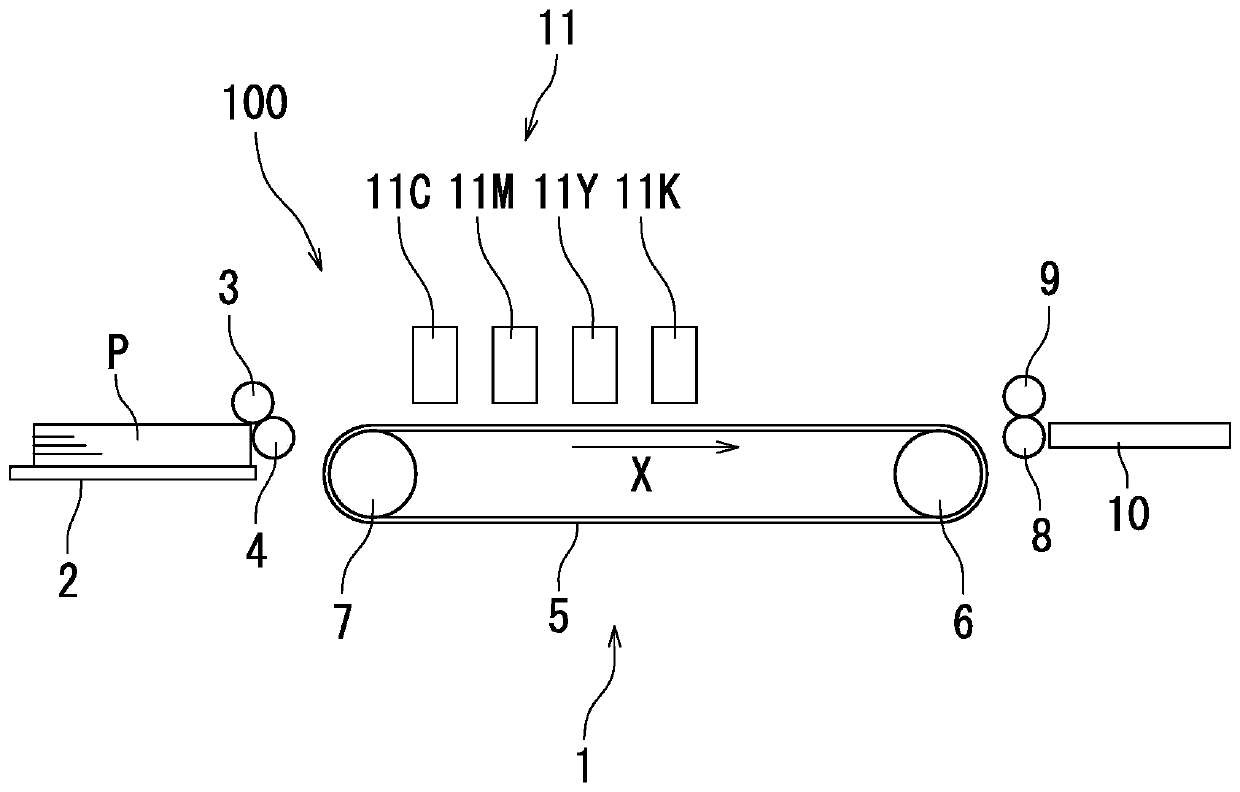

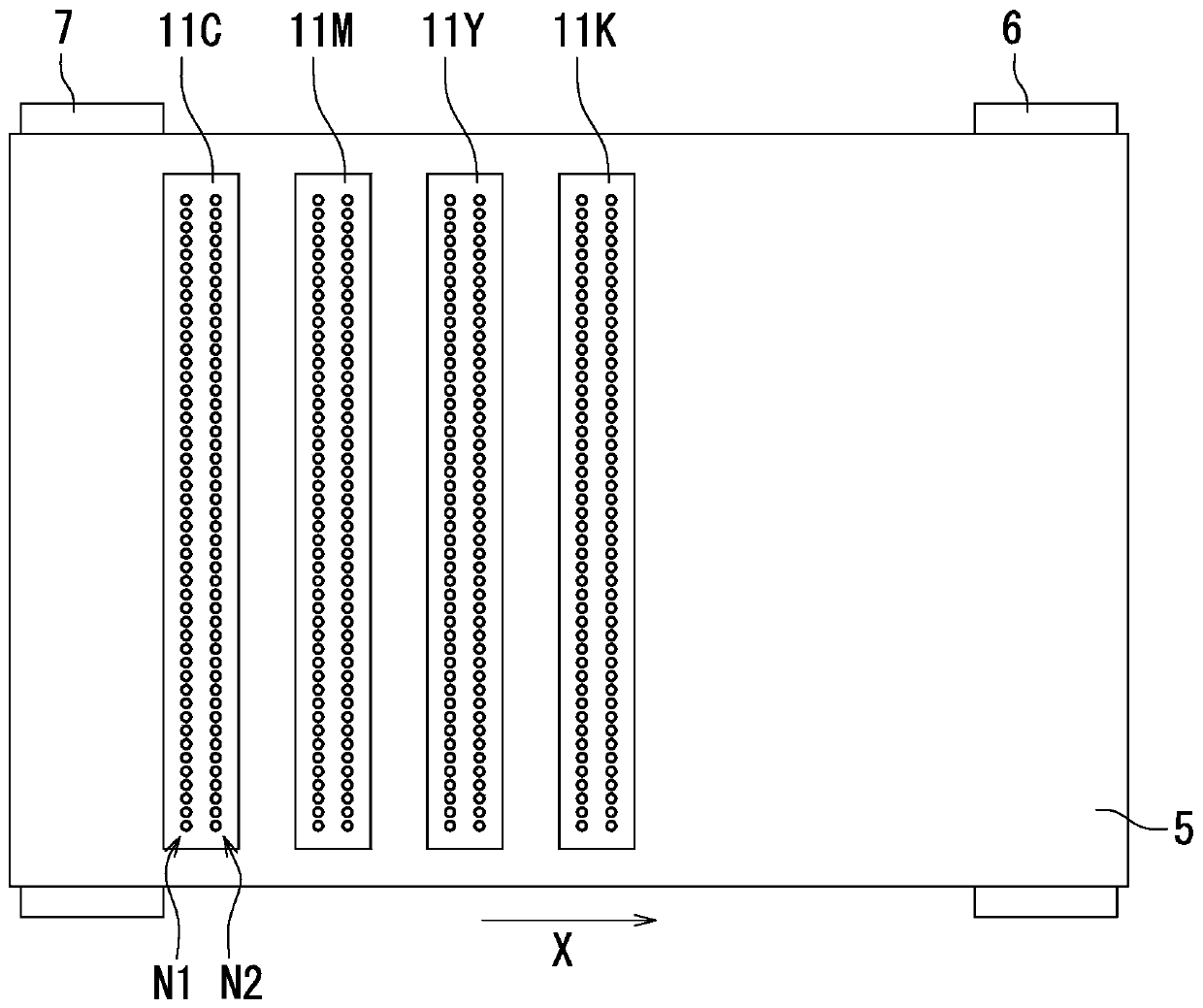

The invention provides inkjet ink and an inkjet recording system. The inkjet ink includes a pigment, first particles containing a first resin, second particles containing a second resin, and a moisturizing agent. The first resin includes a repeating unit derived from methyl methacrylate at a content percentage of at least 30% by mass and no greater than 70% by mass relative to all repeating unitsincluded in the first resin. The second resin has a content percentage of the repeating unit derived from methyl methacrylate of less than 30% by mass relative all repeating units included in the second resin. The moisturizing agent includes an alpha, omega-alkanediol. In the inkjet recording system (100), a plurality of nozzles eject the inkjet ink to form dots on a recording medium conveyed by the conveyance section.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com