Inkjet printing with large particles

A printing and ink particle technology, applied in the field of digital control printing system, can solve the problems of low capacity, low speed, etc., achieve the effect of cost reduction, reliability improvement and image quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

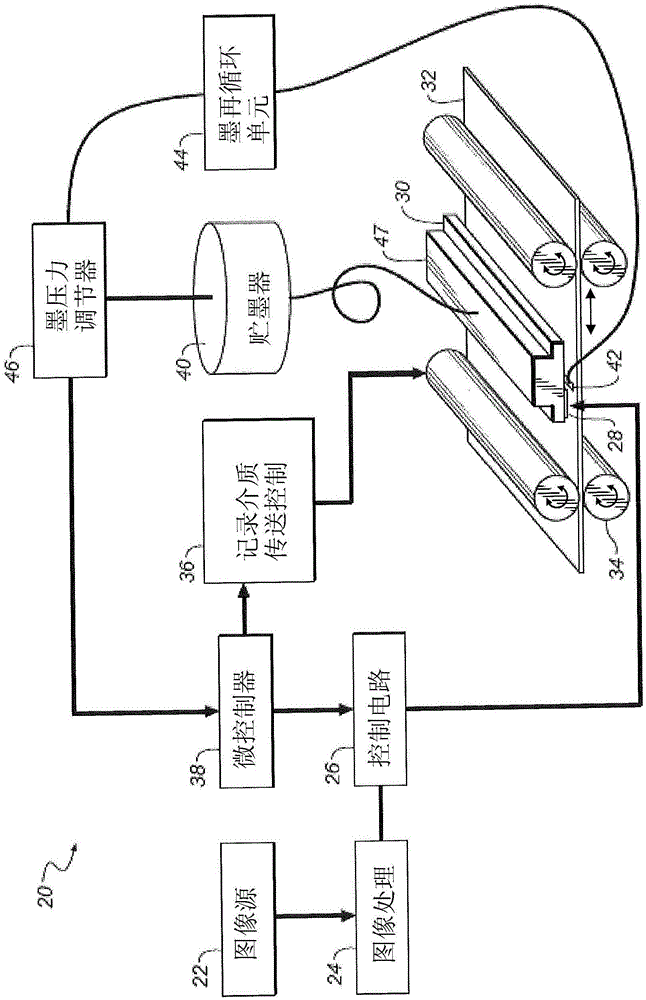

AI Technical Summary

Problems solved by technology

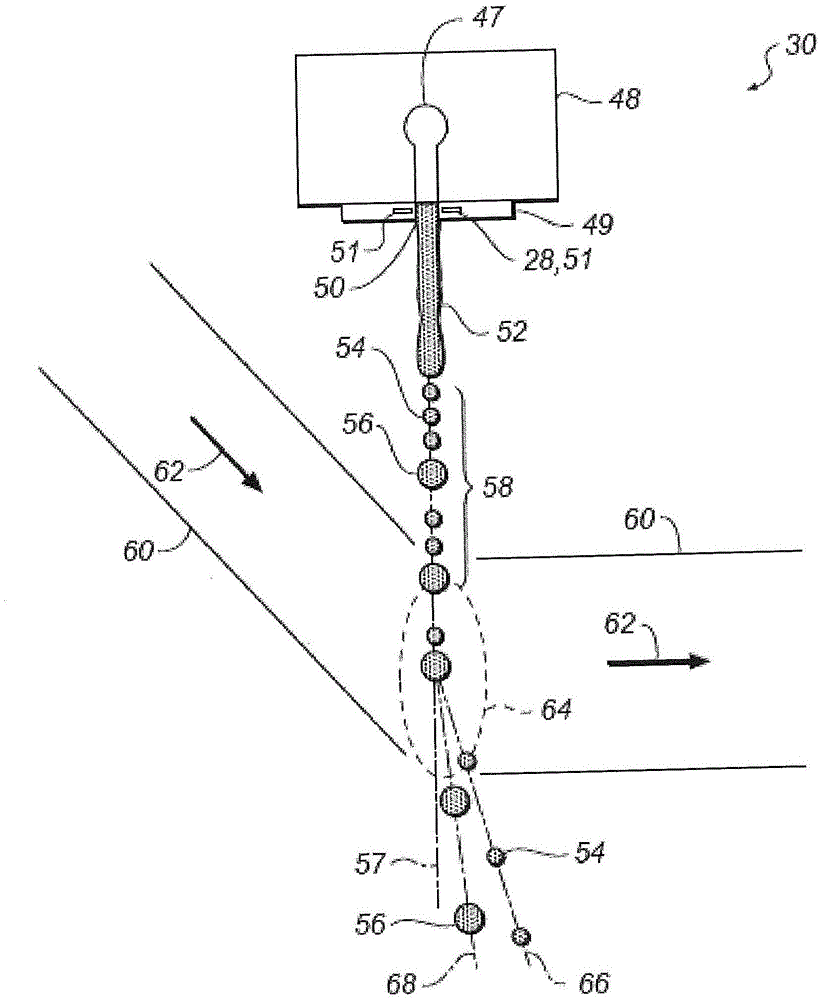

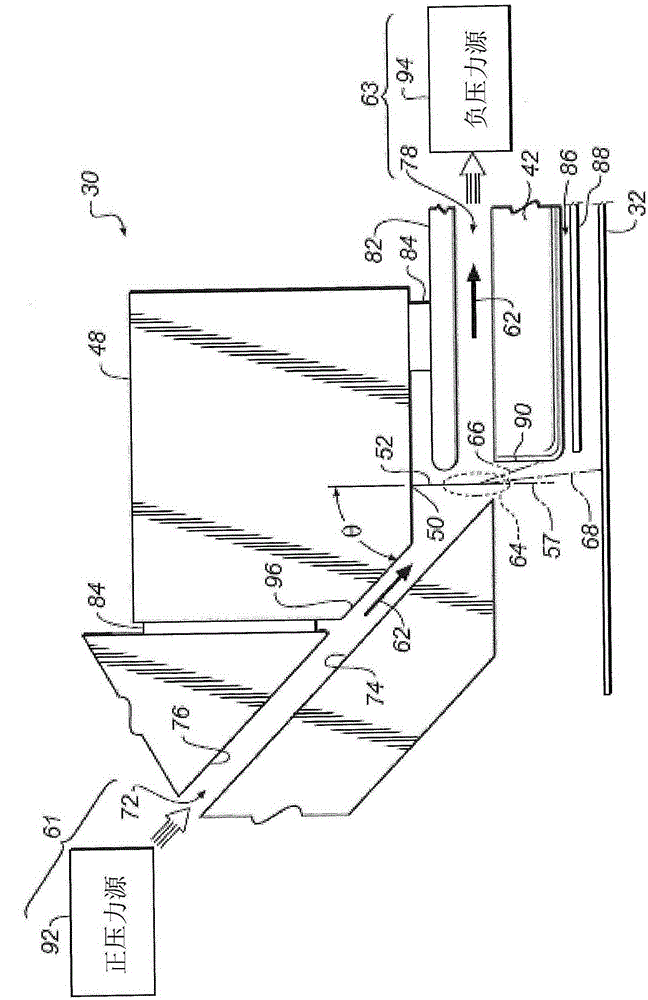

Method used

Image

Examples

Embodiment Construction

[0037] The terms "toner" and "dry ink" are used interchangeably herein.

[0038] As used herein, the term "paper" refers to a material generally made by pressing together damp fibers or fibers of a fabric. Paper comprises fibers derived from cellulose pulp derived from wood, chips or grass, and they are dried into flexible sheets or rolls. Paper generally contains moisture, which remains after drying or is absorbed by exposure to air. Thus, the term "paper" as used herein includes conventional materials marketed as paper and other materials with corresponding characteristics, such as canvas.

[0039] As used herein, oliophilic and hydrophobic liquids are defined as organic liquids that are immiscible or only slightly miscible with water. These include aliphatic and aromatic hydrocarbons. Hydrophilic and oliophobic are defined as liquids that are wholly or substantially miscible with water. These include water-based solutions and suspensions, such as inkjet inks containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com