Non-aqueous ink and method of producing same

A manufacturing method, non-aqueous technology, applied in the direction of copying/marking method, ink, printing, etc., which can solve the problems of ink repellency reduction, printing density reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The present invention is described in detail below through examples, but the present invention is not limited by these examples.

[0064]

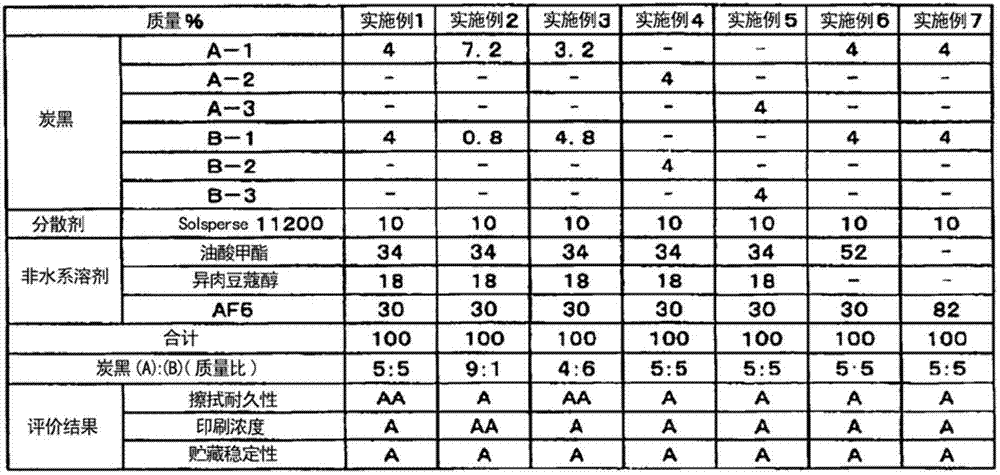

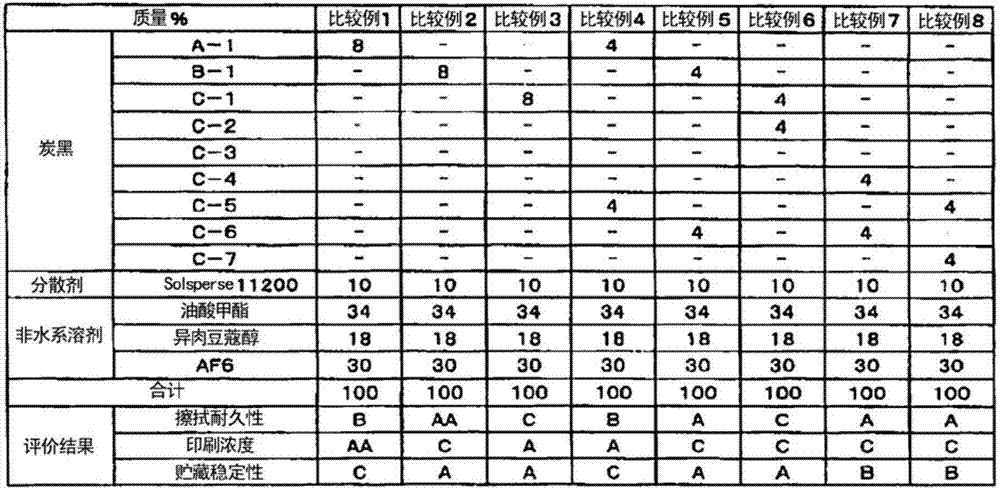

[0065] Inks were prepared according to the formulations shown in Table 1 and Table 2. According to the proportions shown in Table 1 and Table 2, each component was premixed, and 35 g of the mixed solution was put into a glass container, and 100 g of zirconia beads (diameter 0.5 mm) were put into it, and a rocking mill (Seiwa Giken Co., Ltd. .manufacturing RMO5S type), and dispersed at a frequency of 65 Hz for 2 hours to prepare an ink.

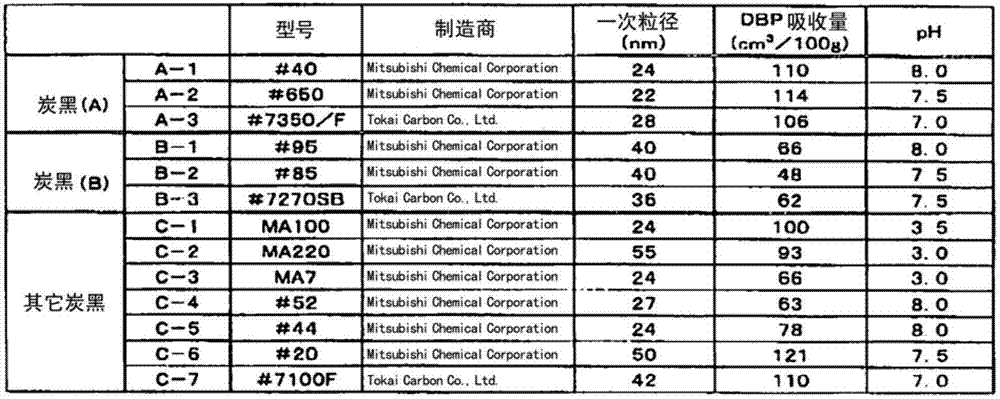

[0066] The components shown in Table 1 and Table 2 are as follows. In addition, the details of the carbon black shown in Table 1 and Table 2 are shown in Table 3.

[0067] Solsperse 11200: "Solsperse 11200" manufactured by Lubrizol Japan Ltd.

[0068] Methyl oleate: high-grade fatty acid ester solvent, Exceparl "M-OL" manufactured by Kao Corporation

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com