thermal print head

A thermal printing head and printing direction technology, applied in printing and other directions, can solve the problems of weakened heat storage effect of the base layer, affect printing effect, and low printing density, and achieve the effect of increasing printing density, good printing effect, and increasing base temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

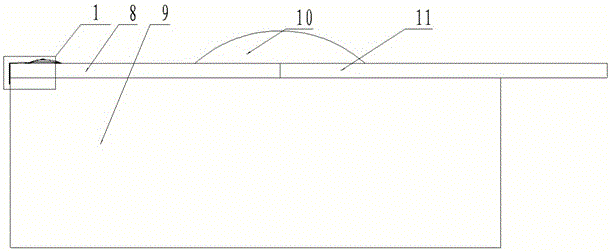

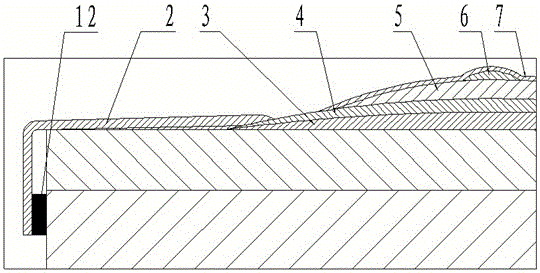

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] A thermal print head, including a substrate 8 made of insulating material, a base layer I3 is made on the base layer I3, and a layer of Al with a thermal conductivity exceeding 20W / mK is sintered on the base layer I3 by printing 2 o 3 The interlayer 4 is then the base layer Ⅱ 5, and then the wire electrodes are formed on the surface of the substrate 8 and the base layer 5. The wire electrodes are divided into individual electrodes and common electrodes. The edge formed on the wire electrodes is connected with the control IC. The secondary printing direction is connected with the heating resistor strip 6, and the other end is connected with the wire pattern. The electrical part of the thermal print head is composed of the wire electrode on the substrate 8, the heating resistor strip 6, the control IC and the PCB board 11. , the electrical part is integrally adhered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com