Rapid and energy-saving steam generator

A steam generator, fast technology, applied in the direction of steam generation, steam generation devices, lighting and heating equipment, etc., can solve the problems of reduced machine operation stability, increased cost, bulky, etc., to achieve reduced heat absorption, high thermal efficiency, and weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

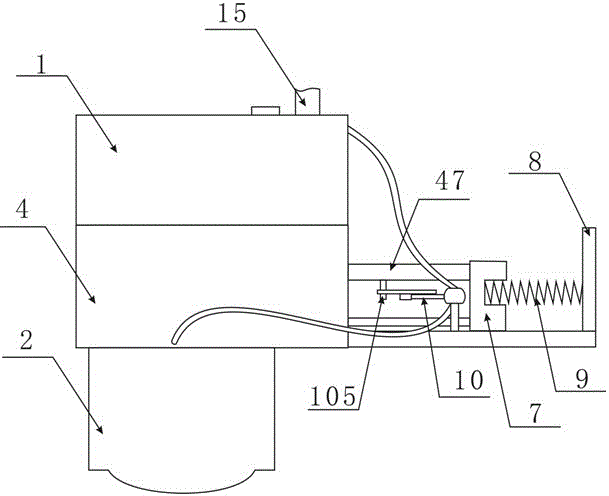

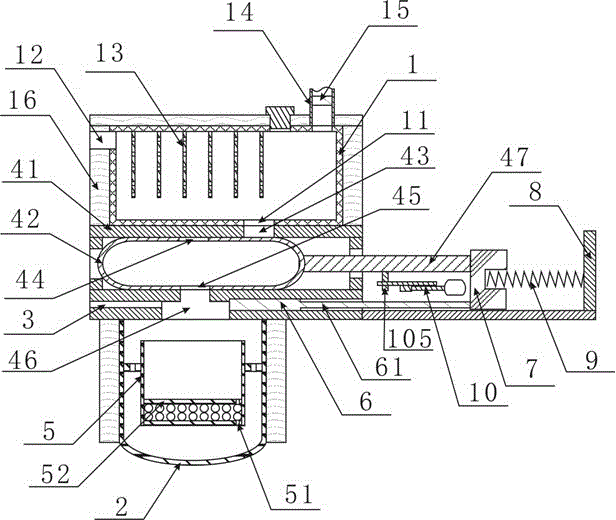

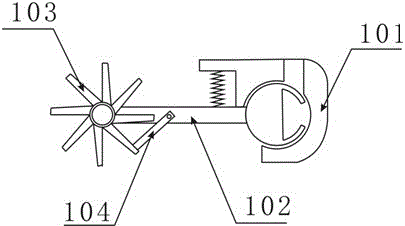

[0030] Example: see figure 1 , figure 2 and image 3 , a fast energy-saving steam generator, comprising a water tank 1, a boiler 2 below the water tank and a steam outlet channel 3 communicating with the boiler. A water adding device 4 for adding water from the water tank to the boiler is provided between the water tank and the boiler. There is an inner tank 5 for water storage in the boiler, and there is a steam passage between the inner tank and the boiler. As a preference, the inner tank is made of heat-insulating material or heat-insulating process, so as to prevent the boiler from heating the water in the inner tank to generate steam , affecting water addition. The inner tank is connected to the boiler through a connecting piece with steam vents or a supporting stand, and the two sides of the inner tank can also be closely attached and fixed to the inner wall of the boiler. The steam outlet channel is connected with the steam channel, and a heat storage block is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com