A method of and a device for producing a liquid-solid metal composition

A metal composition and metal technology, applied in the field of a method device, can solve problems such as slow cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0040] The following examples will illustrate the invention and are not intended to limit the invention.

example 1

[0042] Al-7%Si Alloy Slurries Produced by Mixing Melts with Solids of Different Composition

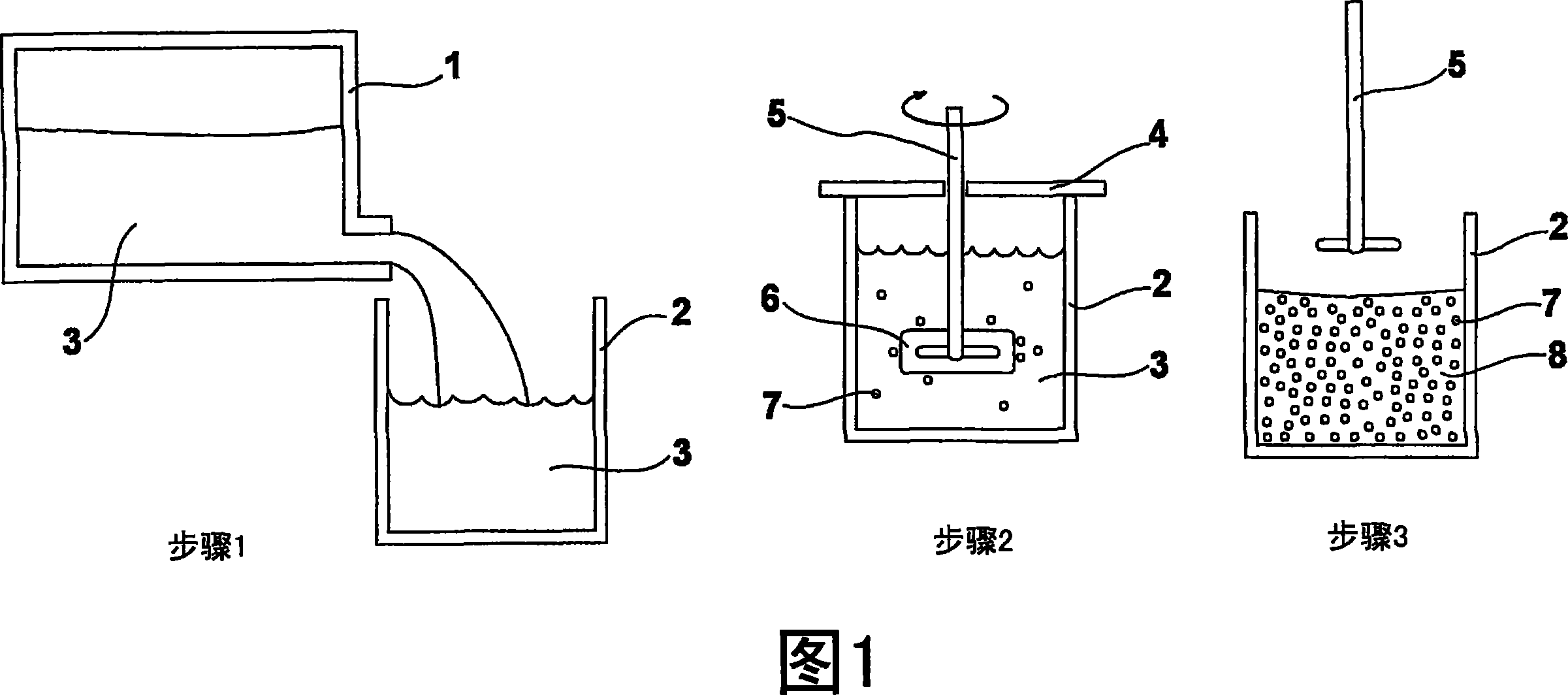

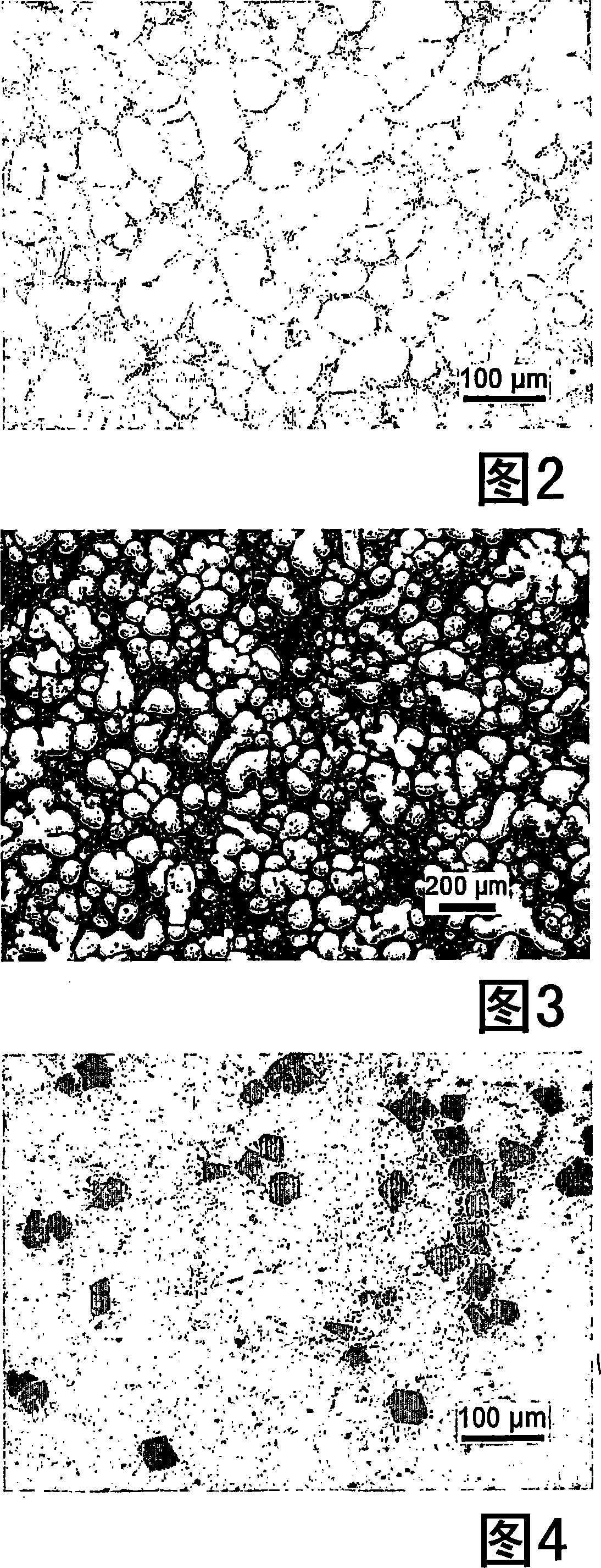

[0043] The following is a detailed description of a production method of an Al—Si alloy paste containing about 7% by weight of Si having a degenerated dendrite structure with reference to FIG. 2 .

[0044] 2013 grams of Al-Si alloy feedstock containing approximately 6.5% Si by weight was melted in a clay-graphite crucible in an electric resistance furnace. The crucible has a height of approximately 165 mm, an inner diameter of 110 mm and a wall thickness of 15 mm. When the Al-6.5%Si alloy was completely melted and reached 630°C, ie about 10°C above its liquidus temperature, the power to the furnace was shut off. 197 grams of solid Al-Si alloy containing approximately 12% Si by weight was attached to a mechanical stainless steel stirrer. Al-12% Si attached to a stirrer, both initially at room temperature, was immersed in the melt. Stirring was continued for 37 seconds. The Al-12%Si...

example 2

[0046] Mg-9%Al alloy slurry produced by mixing a melt with a solid of the same composition

[0047] The following is a detailed description of a production method of a Mg—Al alloy slurry containing 9% by weight Al having a degenerated dendrite structure with reference to FIG. 3 .

[0048] 101 grams of Mg-Al alloy feedstock containing approximately 9% by weight Al was melted in a clay-graphite crucible in an electric resistance furnace. The crucible has a height of approximately 155 mm, an inner diameter of 30 mm and a wall thickness of 1.5 mm. When the Mg-9%Al alloy was completely melted and reached 605°C, ie about 10°C above its liquidus temperature, the power to the furnace was shut off. A total of 15 grams of the room temperature solid Al-Si alloy containing 9% by weight Al was added in three separate lumps with manual stirring by a thin steel rod between each addition. The total stirring time is approximately 2 minutes. The final temperature of the Mg-9%Al alloy after s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com