Inkjet ink and inkjet recording system

An ink, inkjet technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of unable to repeatedly draw images, seepage to the back, seepage, etc., to achieve excellent ejection stability, improve the effect of printing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0016]

[0017] Hereinafter, the ink according to the first embodiment of the present invention will be described. The ink according to the first embodiment contains a pigment, first particles containing a first resin, second particles containing a second resin, and a humectant. The first resin contains repeating units derived from methyl methacrylate (hereinafter, sometimes referred to as MMA units) at a ratio of 30% by mass to 70% by mass relative to all repeating units. In the second resin, the content of MMA units is less than 30% by mass relative to all repeating units. In addition, the content ratio of the MMA unit in the second resin may be 0% by mass. That is, the second resin may not contain MMA units. The humectant contains α,ω-alkanediol.

[0018] Since the ink according to the first embodiment has the above-mentioned structure, it is possible to use the ink to increase the print density of the image formed on the recording medium while ensuring excellent ejection s...

no. 2 approach

[0072]

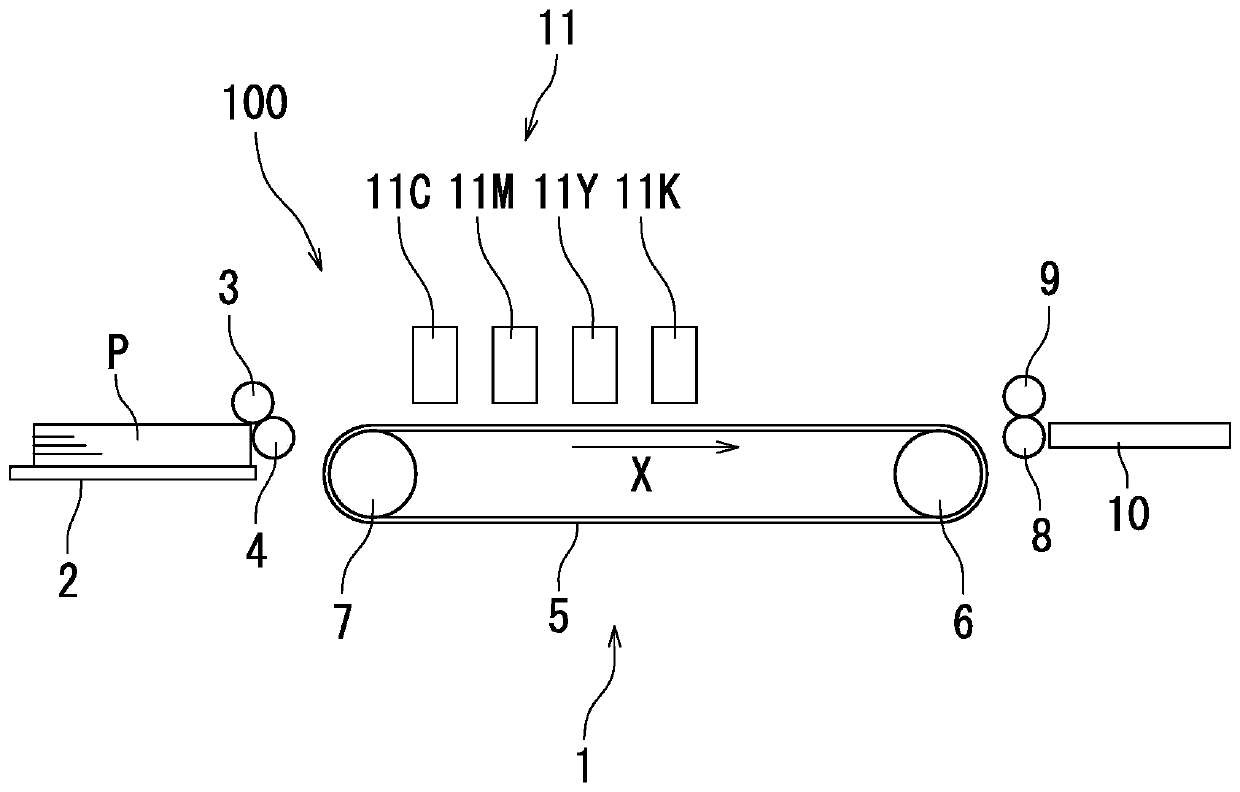

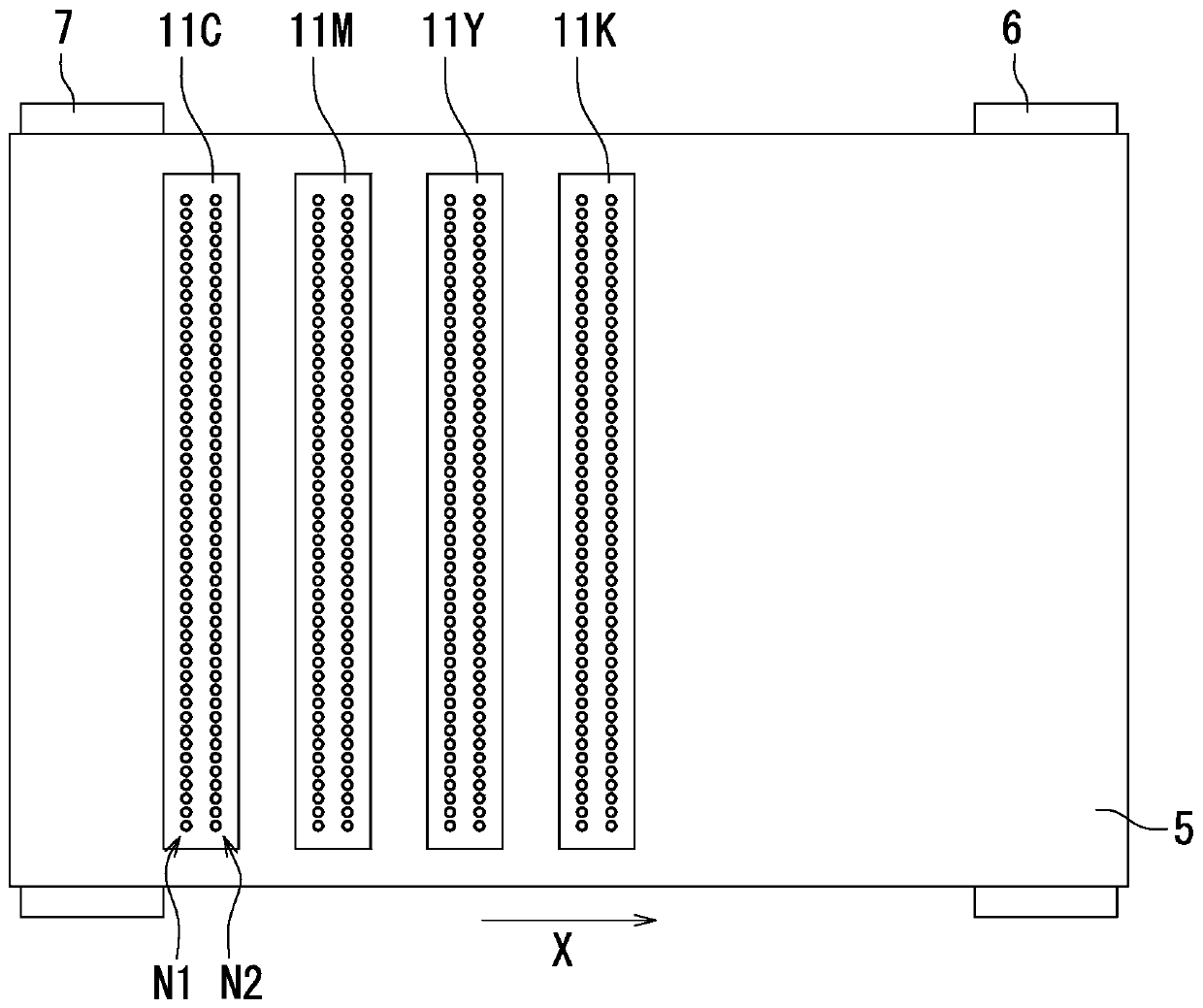

[0073] Next, the inkjet recording system according to the second embodiment of the present invention will be described. The inkjet recording system of the second embodiment includes a conveying unit and an inkjet recording head (hereinafter, sometimes referred to as a “recording head”), and the conveying unit conveys a recording medium. In the inkjet recording system of the second embodiment, the ink of the first embodiment is used. Hereinafter, the inkjet recording system of the second embodiment will be described with reference to the drawings. In addition, for ease of understanding, the drawings mainly schematically show each structural element, and for the convenience of drawing, the size, number, etc. of each structural element shown in the drawing may differ from actual ones.

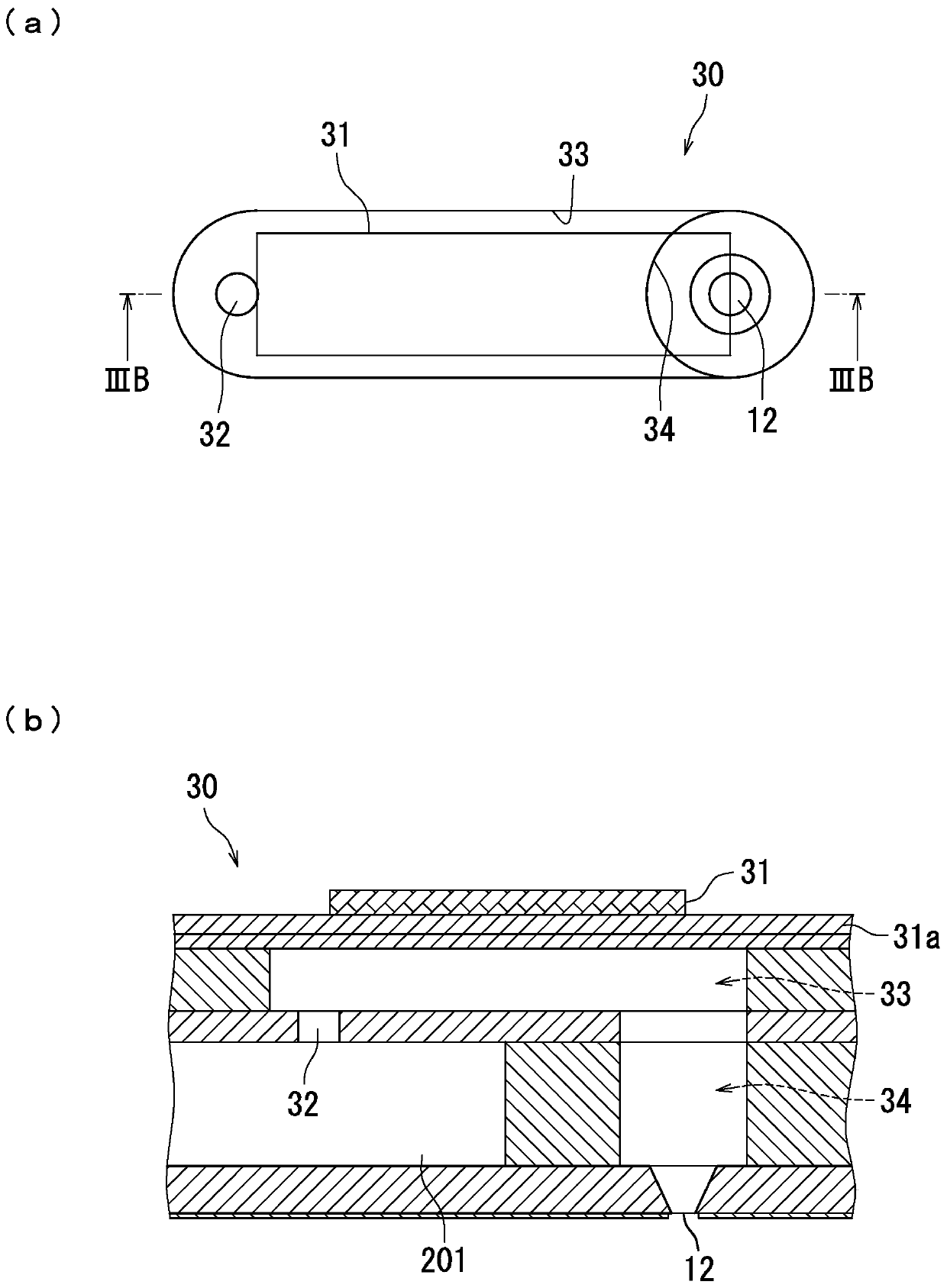

[0074] figure 1 It is a block diagram of the inkjet recording system 100. figure 2 Is viewed from above figure 1 In the inkjet recording system 100 of the conveyor belt 5 obtained diagram....

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com