Aqueous ink for inkjet recording

An inkjet recording and metal technology, applied in the direction of ink, applications, household appliances, etc., can solve the problem of insufficient printing density and achieve the effect of high printing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

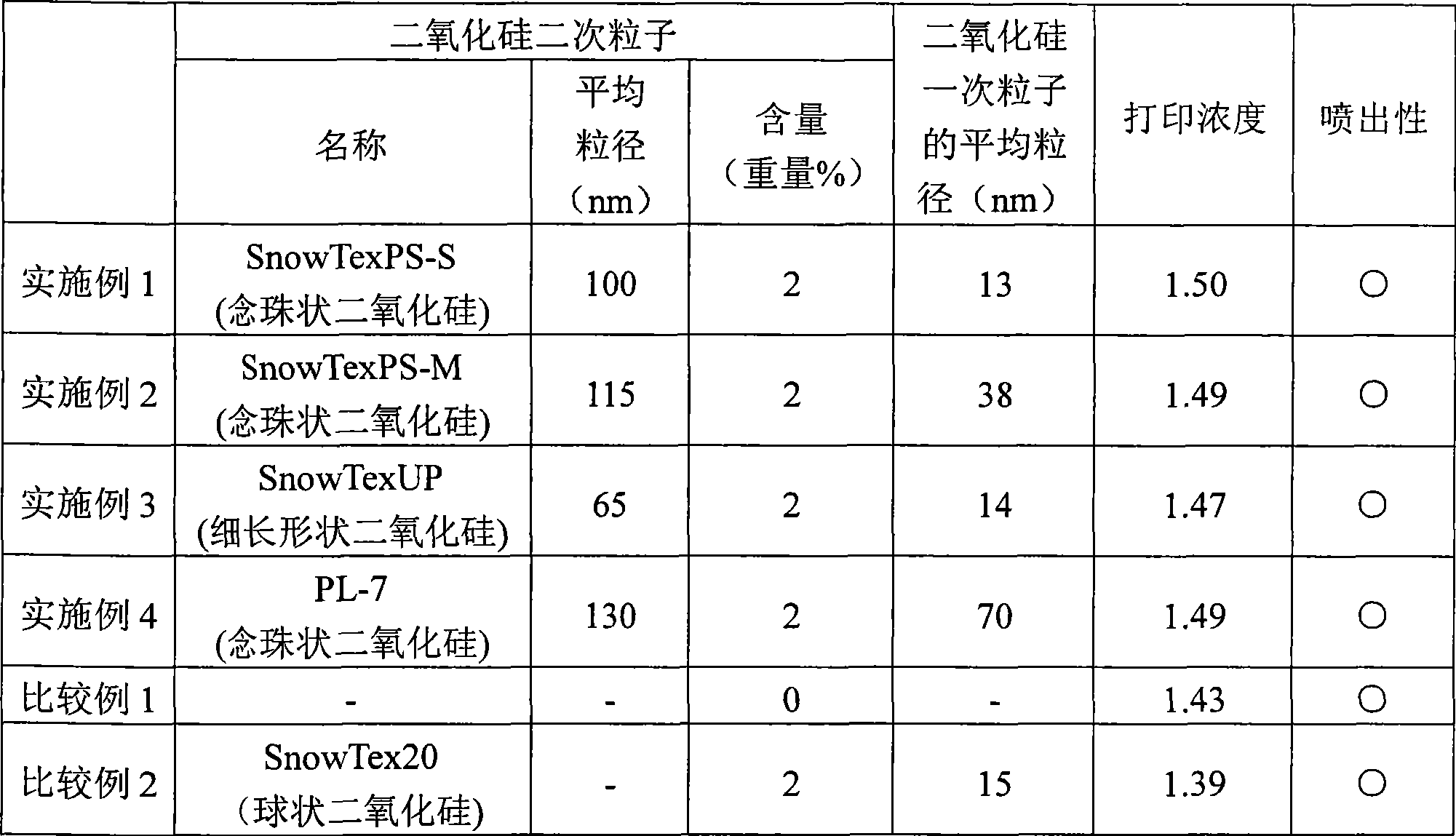

Embodiment 1~3 and comparative example 1、2

[0079] The following ink components were mixed and stirred at 25°C in an amount of 100 parts by weight as a whole to prepare a dispersion, which was filtered through a 0.8 micron filter to obtain a water-based ink.

[0080] (ink composition)

[0081] · Self-dispersing carbon black aqueous dispersion (manufactured by Orient Chemical Industries Co., Ltd.,

[0082] Product name: BONJET CW-2, solid content 15%,

[0083] Average particle diameter: 150nm) 7 parts by weight as pigment solid content

[0084] ・Silicon dioxide secondary particles (shown in Table 1) are 2 parts by weight as solid content

[0085] 5 parts by weight of glycerin

[0086] 5 parts by weight of 2-pyrrolidone

[0087] 2 parts by weight of isopropanol

[0088] ・Acetylenol EH (manufactured by Kawaken Fine Chemicals Co., Ltd.) 1 part by weight

[0089] · Water remaining

[0090] In addition, in Comparative Example 1, instead of using silica particles, water was added.

[0091] (1) Discharge property and (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com