Ink-jet printing method of bathroom product

A bathroom product, inkjet printing technology, applied in the direction of copying/marking method, printing, printing post-processing, etc., can solve the problems of insufficient printing technology, achieve excellent corrosion resistance, not easy to fade and fall off, paint film adhesion super effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

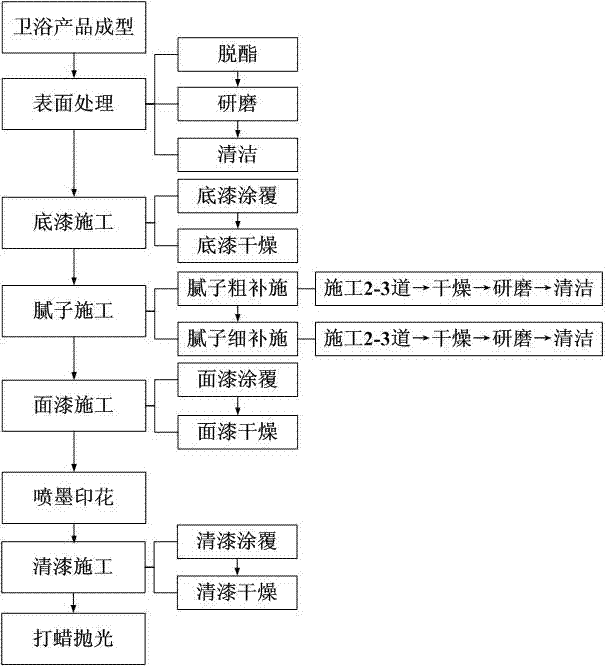

Method used

Image

Examples

Embodiment 1

[0055] Use DuPont 3920S degreasing agent to degrease the surface of the frame of the magnesium-aluminum alloy shower room that has been processed, then use 400# sandpaper to mechanically polish the degreasing surface, and then use DuPont 3920S degreasing agent to clean the surface; Within 24 hours, spray 2 coats of DuPont IC800 high-solid two-component epoxy primer on the surface of the frame of the magnesium-aluminum alloy shower room, and keep it at 20°C for 10 minutes to flash dry until the surface is semi-dry, and then spray it at temperature Keep it at 70°C for 45 minutes until the primer is completely cured, and the dry film thickness of the primer is 70 microns; after the frame of the magnesium-aluminum alloy shower room cools to room temperature, lightly polish it with 360# sandpaper on the primer, and use DuPont 749R Putty rough repair construction 3 times, dry at 20°C until solidified, then dry grind with 120# sandpaper, after dust removal, wipe clean with a clean non...

Embodiment 2

[0057] Use DuPont 3920S degreasing agent to degrease the surface of the processed stainless steel furniture door panel, then use 360# sandpaper to mechanically polish the degreasing surface, and then use DuPont 3920S degreasing agent to clean the surface; within 24 hours Inside, spray one coat of Dupont IC800 high solid two-component epoxy primer on the surface of the stainless steel furniture door panel, and keep it at 50°C for 2 minutes to flash dry until the surface is dull, and then keep it at 40°C for 10 hours Until the primer is completely cured, the dry film thickness of the primer is 50 microns; then spray 2 coats of Dupont C600 topcoat, and dry at 70°C for 5 minutes until the topcoat is not sticky, and the dry film thickness of the topcoat is 40 microns; start inkjet Printer, print the design pattern on the surface of the bathroom product through the nozzle; then spray one coat of DuPont IC720 varnish, dry it at 60°C for 30 minutes until it is completely cured, and the...

Embodiment 3

[0059] Use DuPont 3920S degreasing agent to degrease the surface of the processed magnesium aluminum alloy cabinet board, then use 600# sandpaper to mechanically polish the degreasing surface, and then use DuPont 3920S degreasing agent to clean the surface; Within 24 hours, spray one coat of DuPont IC800 high solid two-component epoxy primer on the surface of the aluminum alloy cabinet, and keep it at 40°C for 5 minutes to flash dry until the surface is semi-dry, and then spray it at a temperature of 60°C Keep it in the state for 1.5 hours until the primer is completely cured, and the dry film thickness of the primer is 60 microns; after the aluminum alloy cabinet panel cools to room temperature, lightly polish the primer with 400# sandpaper, and use Dupont 749R putty to make rough repairs 2 Dry at 40°C until solidified, then dry grind with 80# sandpaper, after dust removal, wipe clean with a clean non-woven cloth and DuPont 3920S degreasing agent; then use DuPont 749R putty to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com