Patents

Literature

82results about How to "Stability has no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

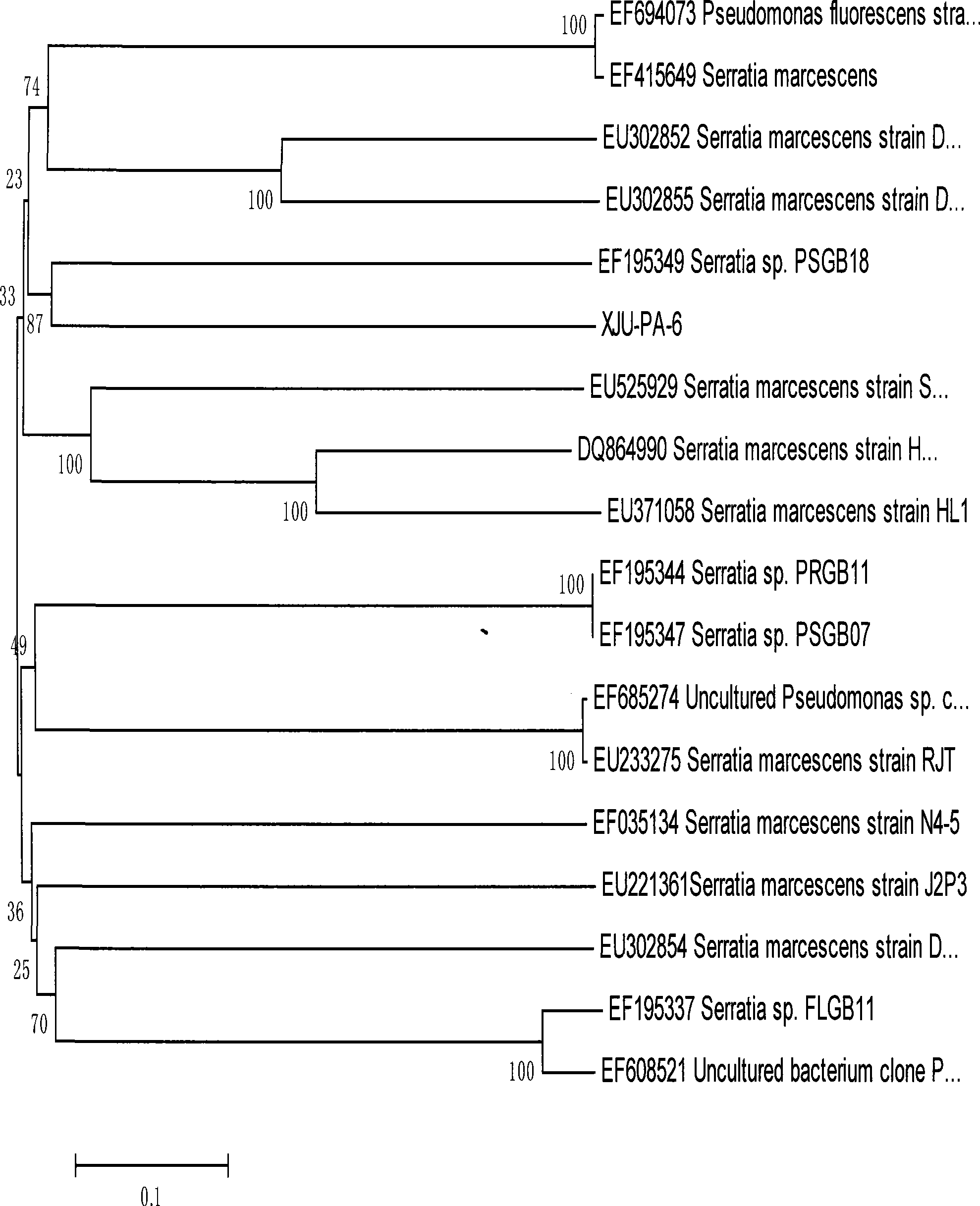

Bacillus prodigiosus and prodigiosin producted thereby

InactiveCN101392227AImprove securityStrong thermal stabilityOrganic chemistryBacteriaChemistryAnti-Tumor Drugs

The invention discloses a viscid Serratia marcescens with CGMCC.No.2593 and prodigiosin produced. The growth temperature of the strain is 28 DEG C to 38 DEG C, the pH value is 5 to 9, LB liquid medium is used for fermentation, 200mL of culture medium is filled in a 500mL triangular flask, sterilization is carried out under 1125 mutiplied by 121Pa for 20min, after being shaken for culture at temperature of 37 DEG C for 5 days, the culture medium is added with absolute ethyl alcohol and is shaken on a shaking bed for 20min, and then is placed statically for 10min, impurity removing is carried out with the centrifuge of 4000r / min for 10min, and through the extraction of absolute ethyl alcohol, prodigiosin Serratia marcescens pigment is produced with the output of 7.85g / L, the maximum absorption peak value m of the prodigiosin being 533.8nm and good heat stability. The prodigiosin obtained can be used as antineoplastic medicine, has important application prospect in the fields of foods, cosmetics and the like.

Owner:XINJIANG UNIVERSITY

Colored zirconia ceramic

ActiveCN107244914ADoes not affect the phase change toughening effectReduce dosageRare-earth elementSolid solution

The invention discloses a colored zirconia ceramic, which is composed of tetragonal phase zirconia serving as the main crystalline phase and cubic phase zirconia serving as a minor crystalline phase, or is composed of tetragonal phase zirconia serving as the main crystalline phase, cubic phase zirconia serving as a minor crystalline phase, and a transition metal oxide. The colored zirconia ceramic realizes coloring through a rare earth metal that is in a solid solution state in cubic phase zirconia crystal grains, or achieves coloring through a rare earth metal that is in a solid solution state in cubic phase zirconia crystal grains, and is assisted by the transition metal oxide provided transition metal for toning. According to the invention, coloring rare earth metal ions are in a solid solution state in cubic zirconia lattices, and have no influence to the stability of tetragonal zirconia; solid solution rare earth metal ions in cubic zirconia are mainly adopted for coloring, then the consumption of other transition metal oxide coloring materials can be reduced or even the coloring materials can be not used, thus reducing the influence of transition metal oxide coloring materials concentrated at crystal boundaries to sintering densification, and avoiding the adverse effect on material strength.

Owner:HANGZHOU ERRAN TECH

Self-adaptive ship-intercepting method

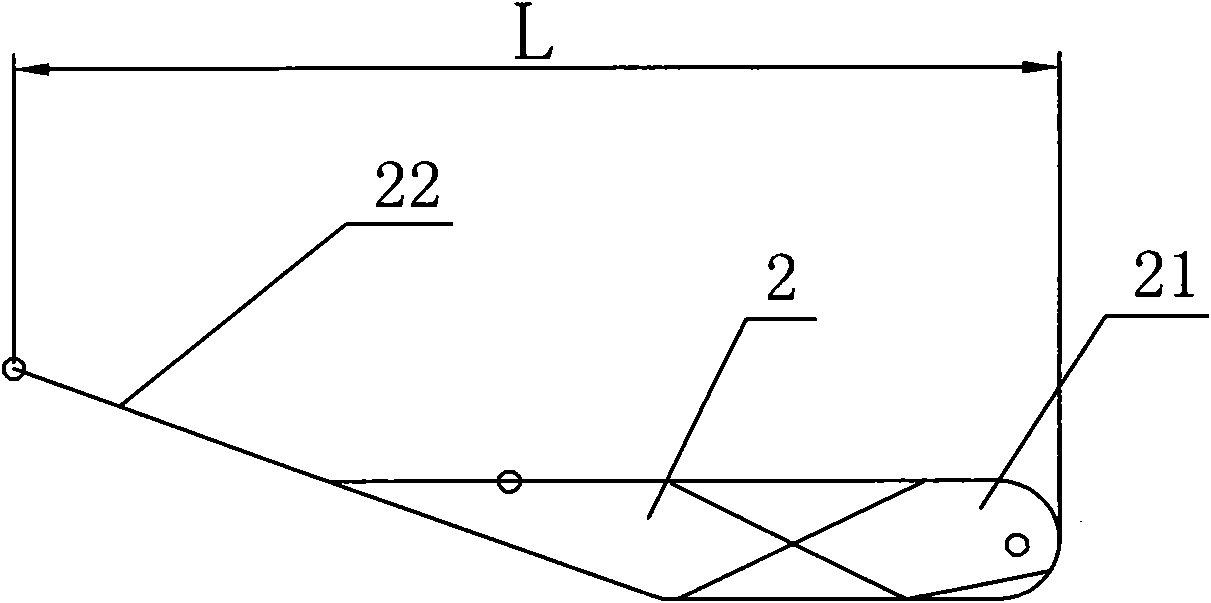

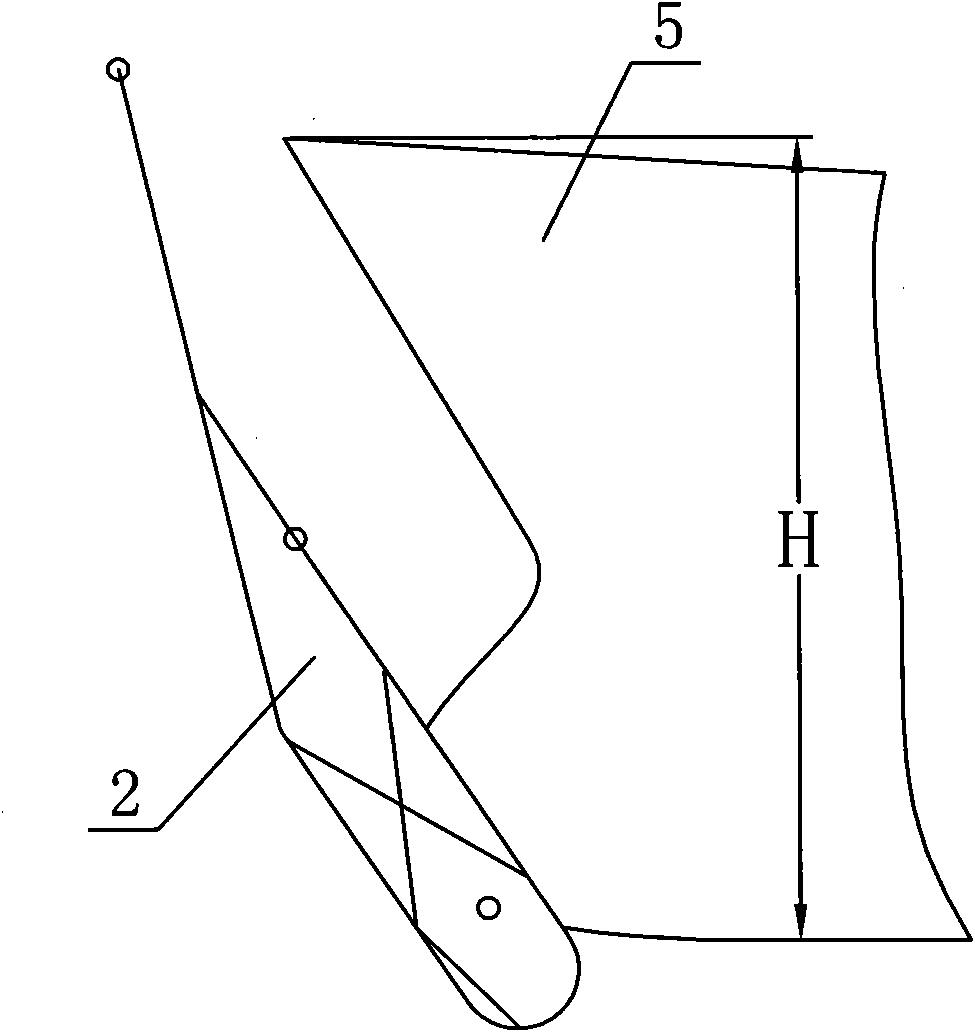

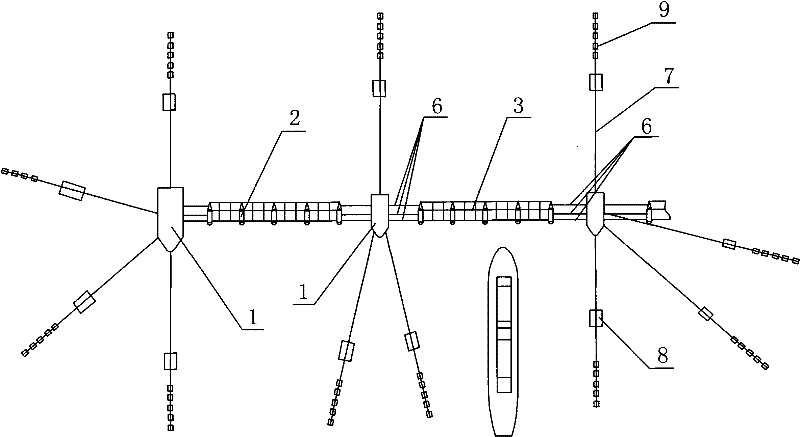

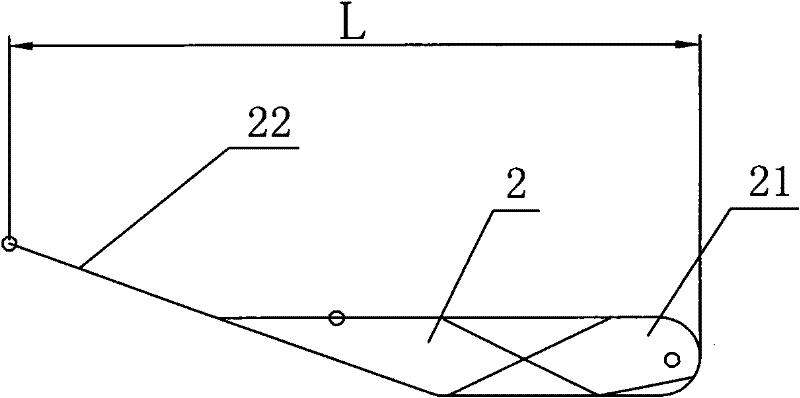

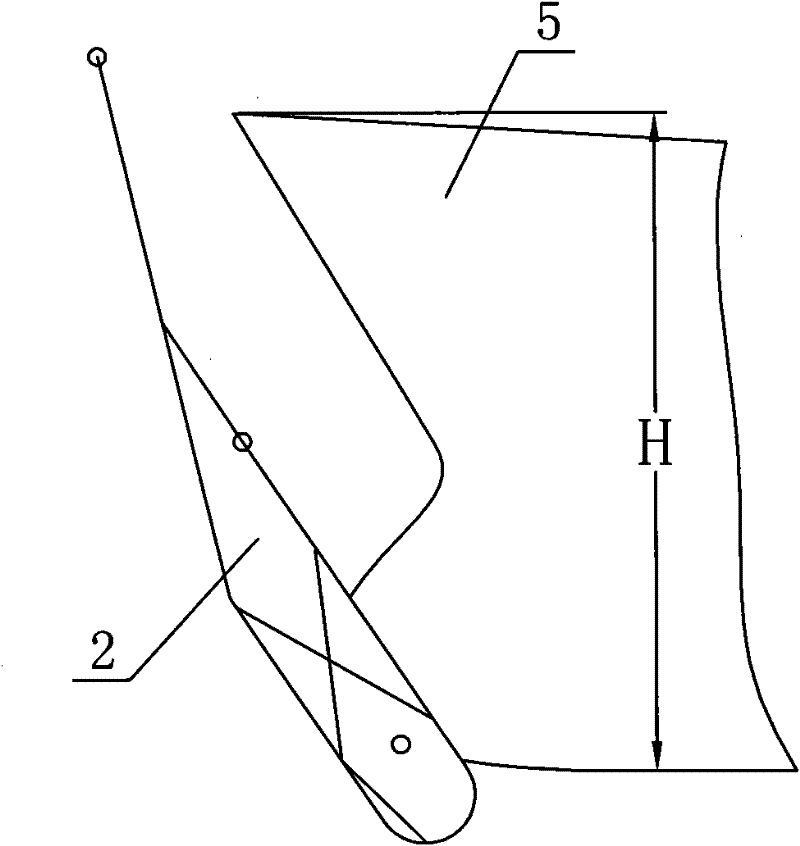

ActiveCN101793017AGuaranteed interception effectLow costClimate change adaptationShipping equipmentSelf adaptiveEngineering

The invention discloses a self-adaptive ship-intercepting method. The method has the following advantages that: the method overcomes the problem that because buoys and intercepting cables can be pressed into water by ships in the past, the anti-collision intercepting facilities can fail; moreover, because buoys and intercepting nets normally horizontally float on the water surface and the lengths of the buoys and the intercepting nets do not have affection on the stability of the whole system, the lengths of both the buoys and the intercepting nets are not limited, thereby the intercepting effect is ensured, and moreover, when the intercepting system used in the method normally horizontally floats on the water surface, sight on the sea surface cannot be affected; in addition, the intercepting system used in the method has the advantages of low construction cost, high economical efficiency, long service life and convenient replacement and maintenance; and moreover, the method can be flexibly transported to different places for use, and can change the arrangement position of the intercepting system.

Owner:NINGBO UNIV

Ink-jet printing dyestuff ink

InactiveCN101186770AIncreased reflection densityStability has no effectInksPrintingDrying timePolymer chemistry

Disclosed is pigment ink for ink-jet printing, which is composed by mixing color paste, resin, pH regulating agents and de-ionized water and is characterized in that the weight percent of the color paste is 10-50%, the weight percent of the resin is 0.1-3%, the weight percent of the pH regulating agents is 0.1-2%, and the rest is the de-ionized water. The advantages and technical effects of the invention are in that satisfied scuff resistance can be achieved by changing the added resin, fingers can smear on the surface of printed materials without leaving any marks after printing is finished, strong luster sensation is achieved together with the scuff resistance, and stability and drying time of the ink can not be influenced after the resin is added.

Owner:天津兆阳纳米科技有限公司

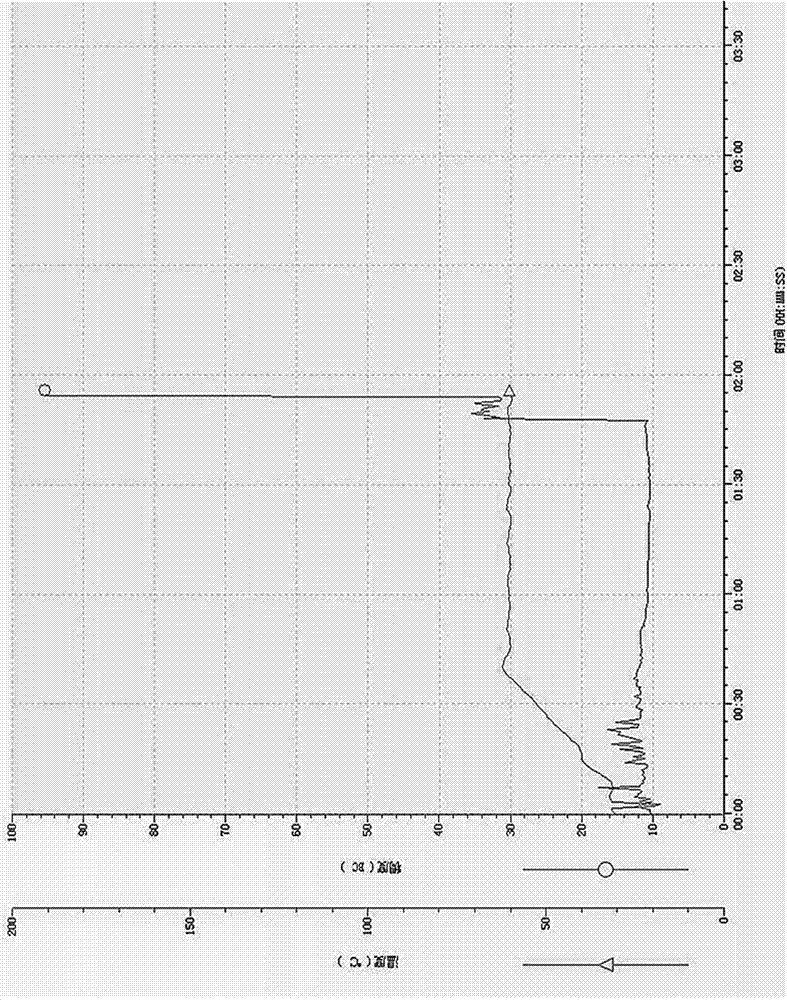

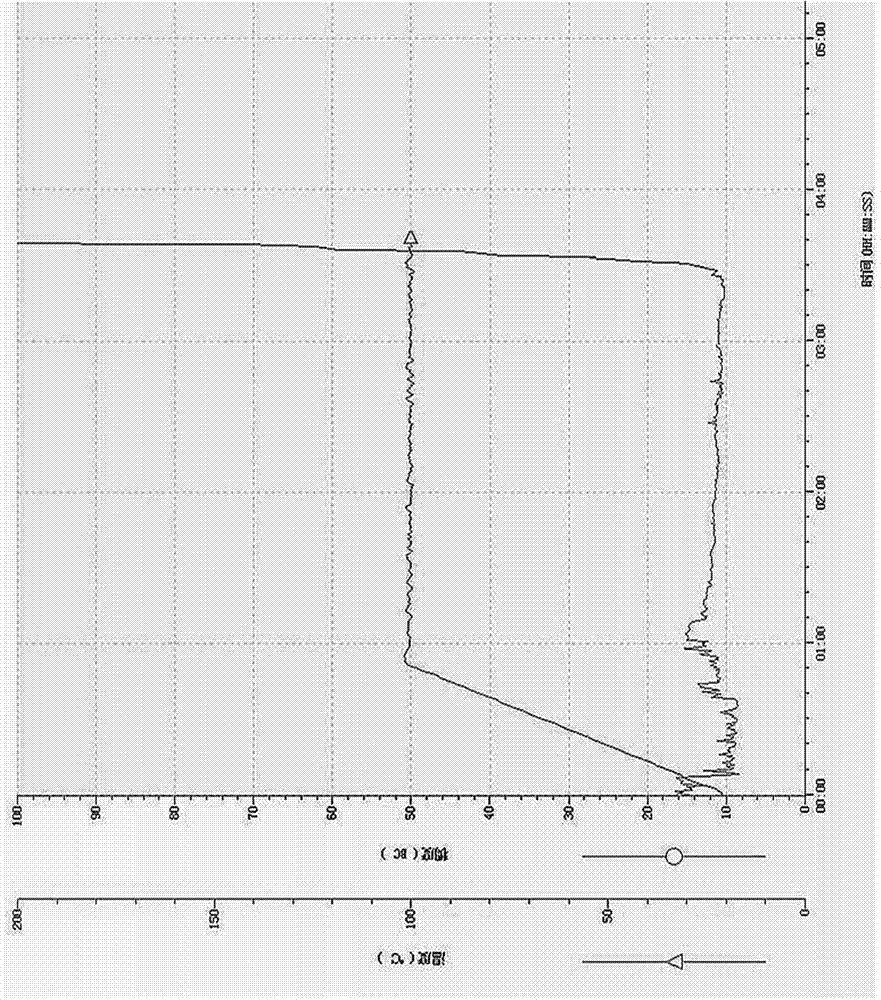

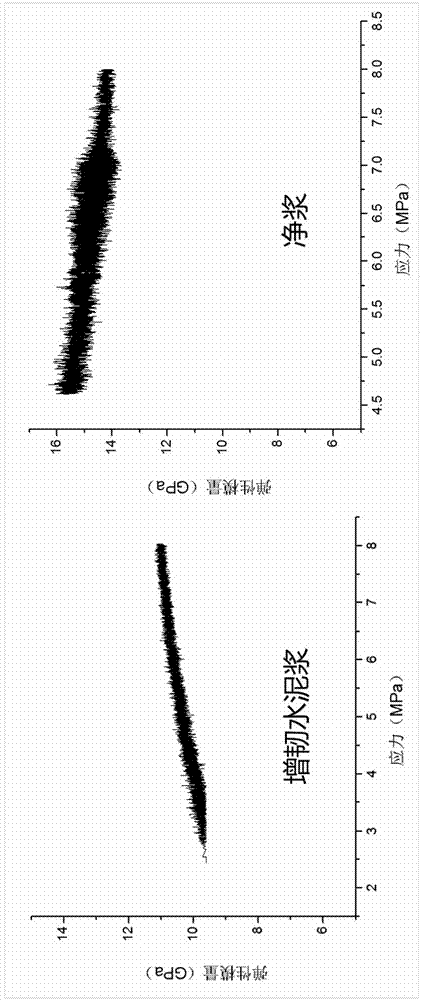

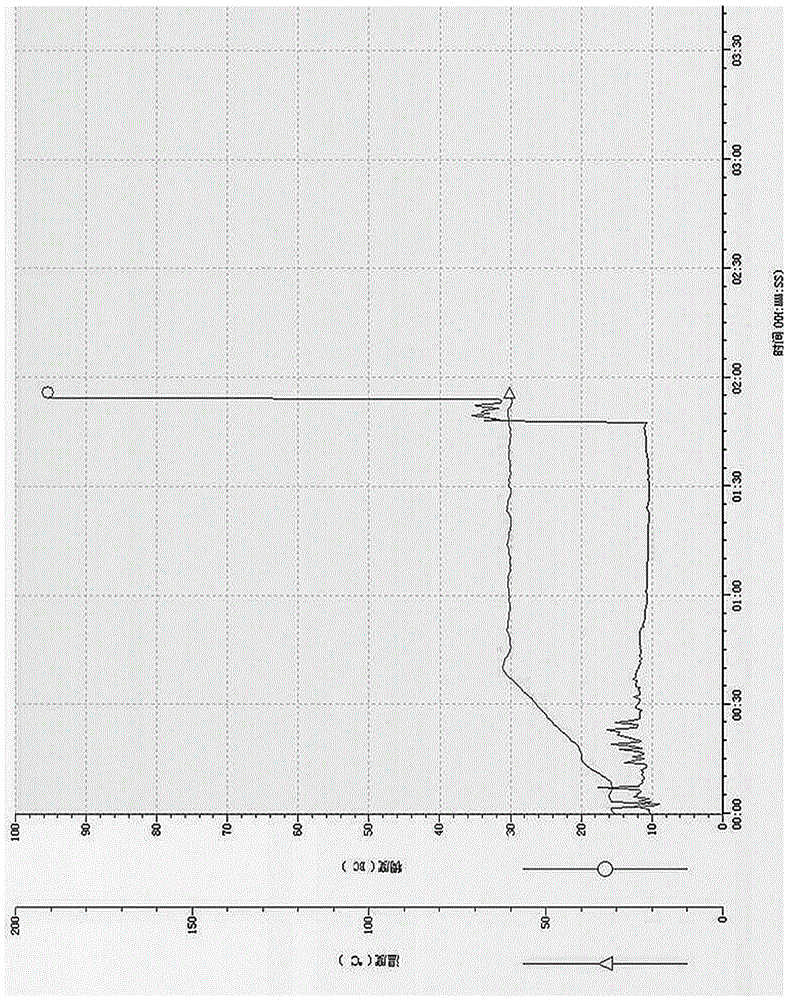

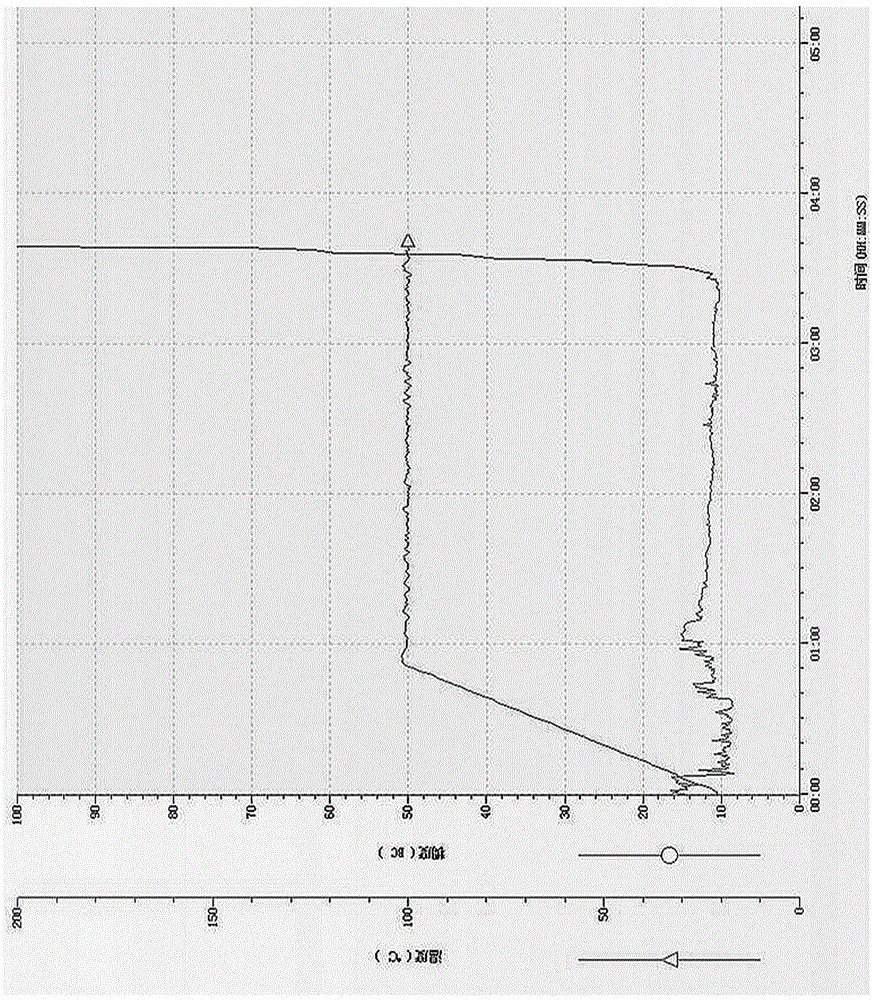

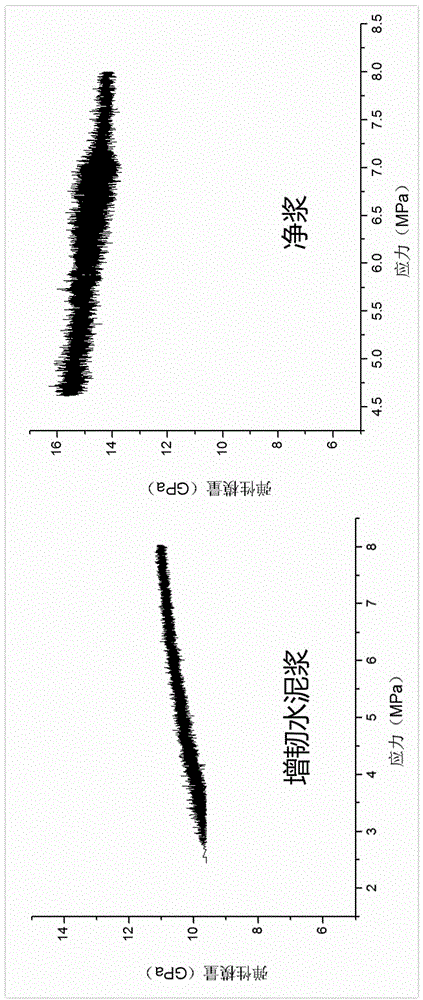

Toughened anti-channeling agent for cement and toughened cement for cementing shale gas horizontal well

ActiveCN104291733AStable performanceThickening time is easy to adjustDrilling compositionShale gasSilane coupling

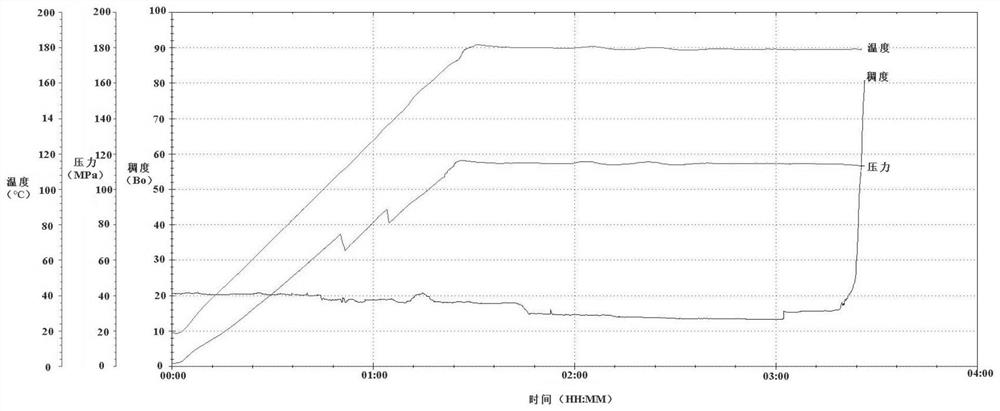

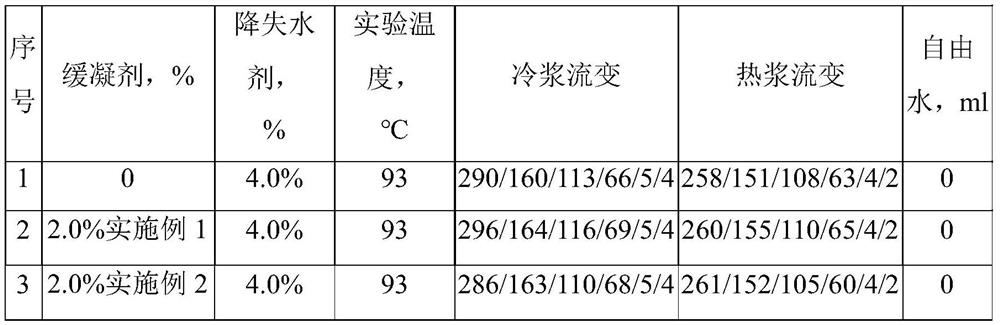

The invention relates to cement paste used when a shale gas horizontal well is cemented, and a toughened additive added to the cement paste, and belongs to the technical field of oil-gas well cement engineering. A toughened anti-channeling agent for cement is prepared from butadiene styrene rubber powder and re-dispersible rubber latex powder at the mass ratio of 2 to 1 in a mixing manner, wherein the butadiene styrene rubber powder is subjected to treatment comprising the following steps before use: firstly, preparing a silane coupling agent solution with the mss percent content being 1.5%; adding butadiene styrene rubber powder, standing for 24 hours, and then filtering; and drying in the sun, wherein the system is stable in performance after the cement paste is prepared; the thickening time is easy to adjust; the water loss is smaller than 30ml; free fluid with an inclination angle of 45 degrees and the difference of densities are 0; the compressive strength at 50 DEG C for 24 hours is greater than 30MPa; the applicable temperature range is 50-120 DEG C; the thickening time is 110-240 minutes; and the toughened anti-channeling agent for cement is added to the toughened cement for cementing the shale gas horizontal well. The cement paste system disclosed by the invention is good in stability, and low in water loss and leakage, and can meet the requirements of multistage fracturing of the shale gas horizontal well on the cement paste system.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

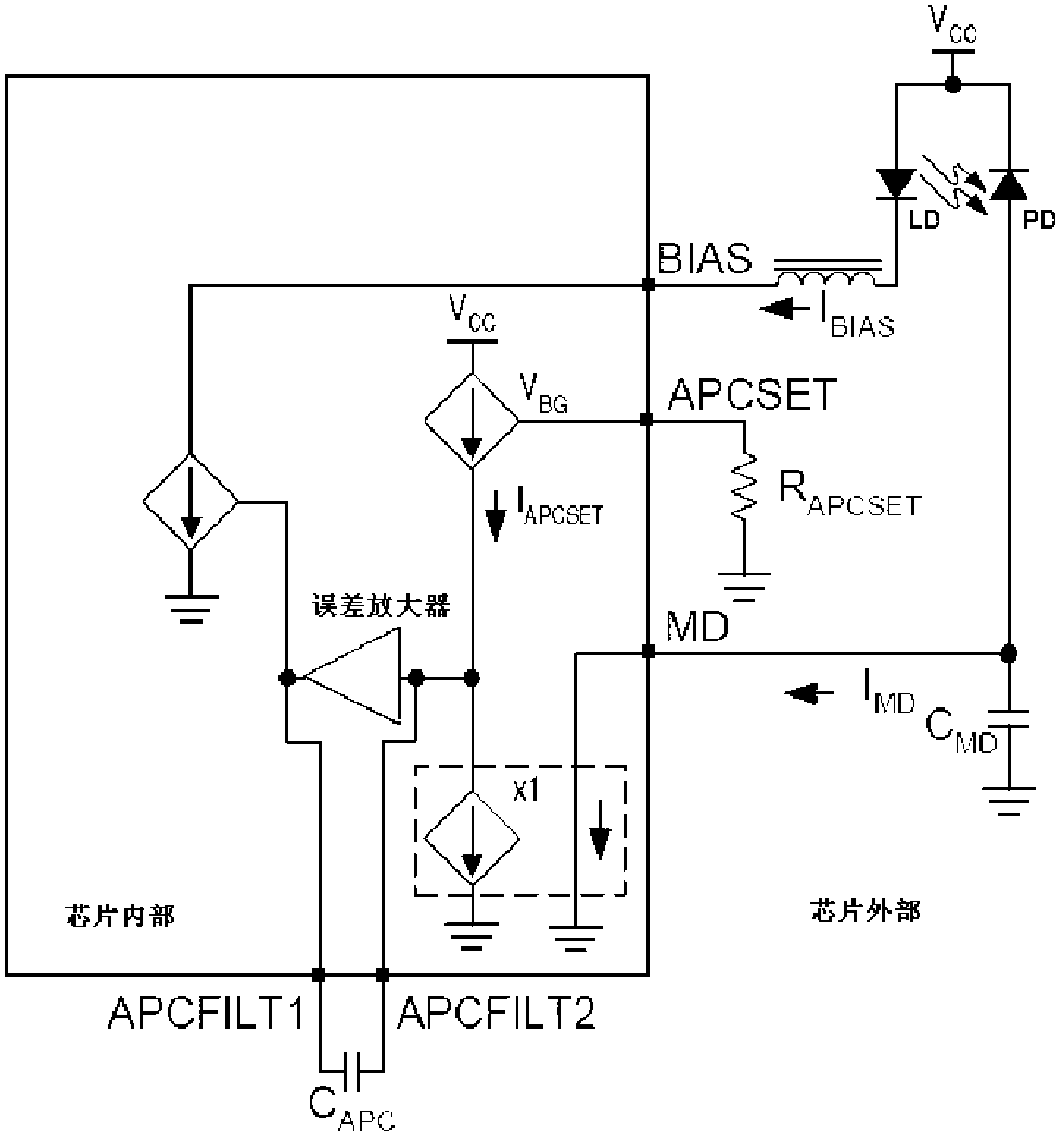

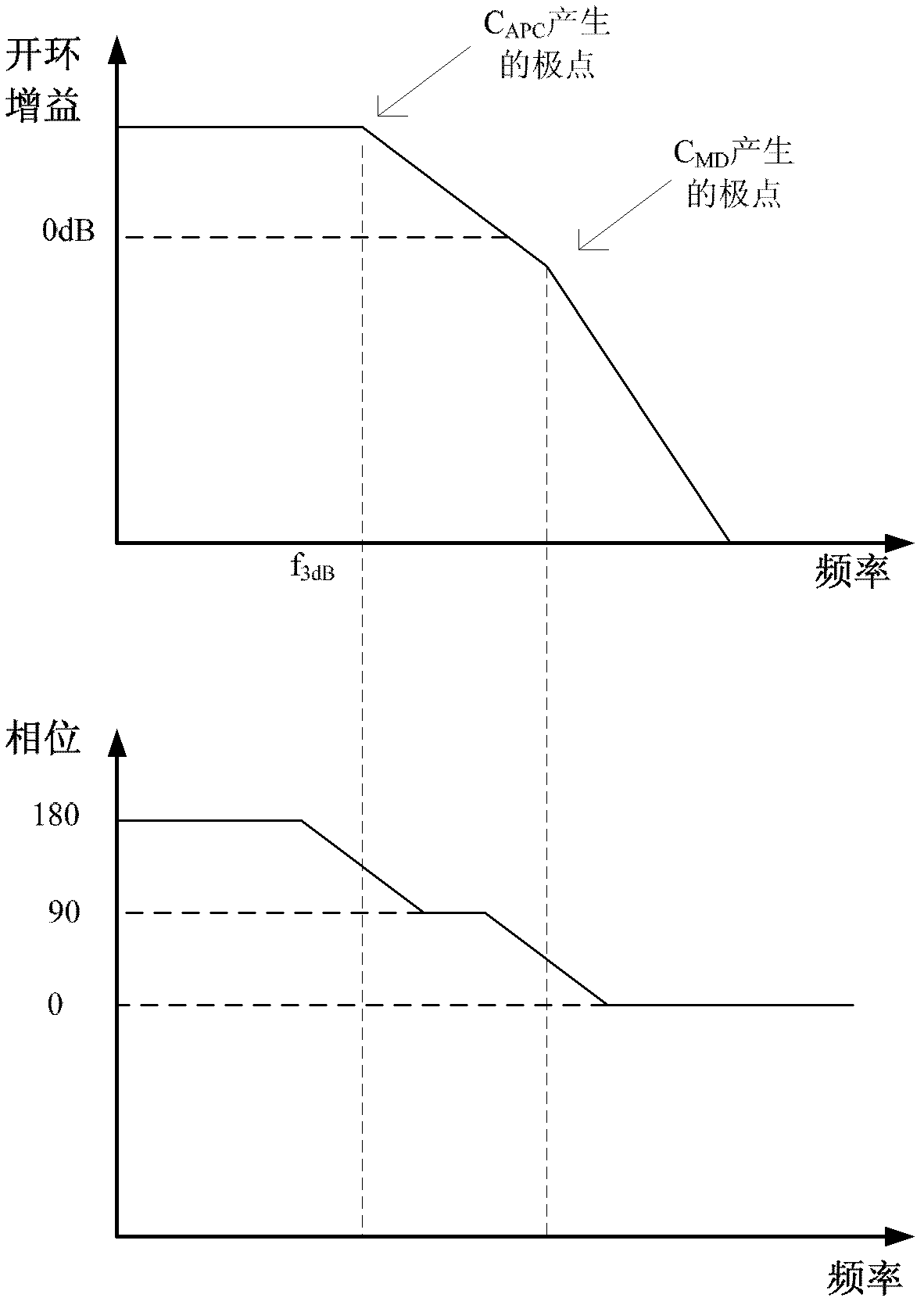

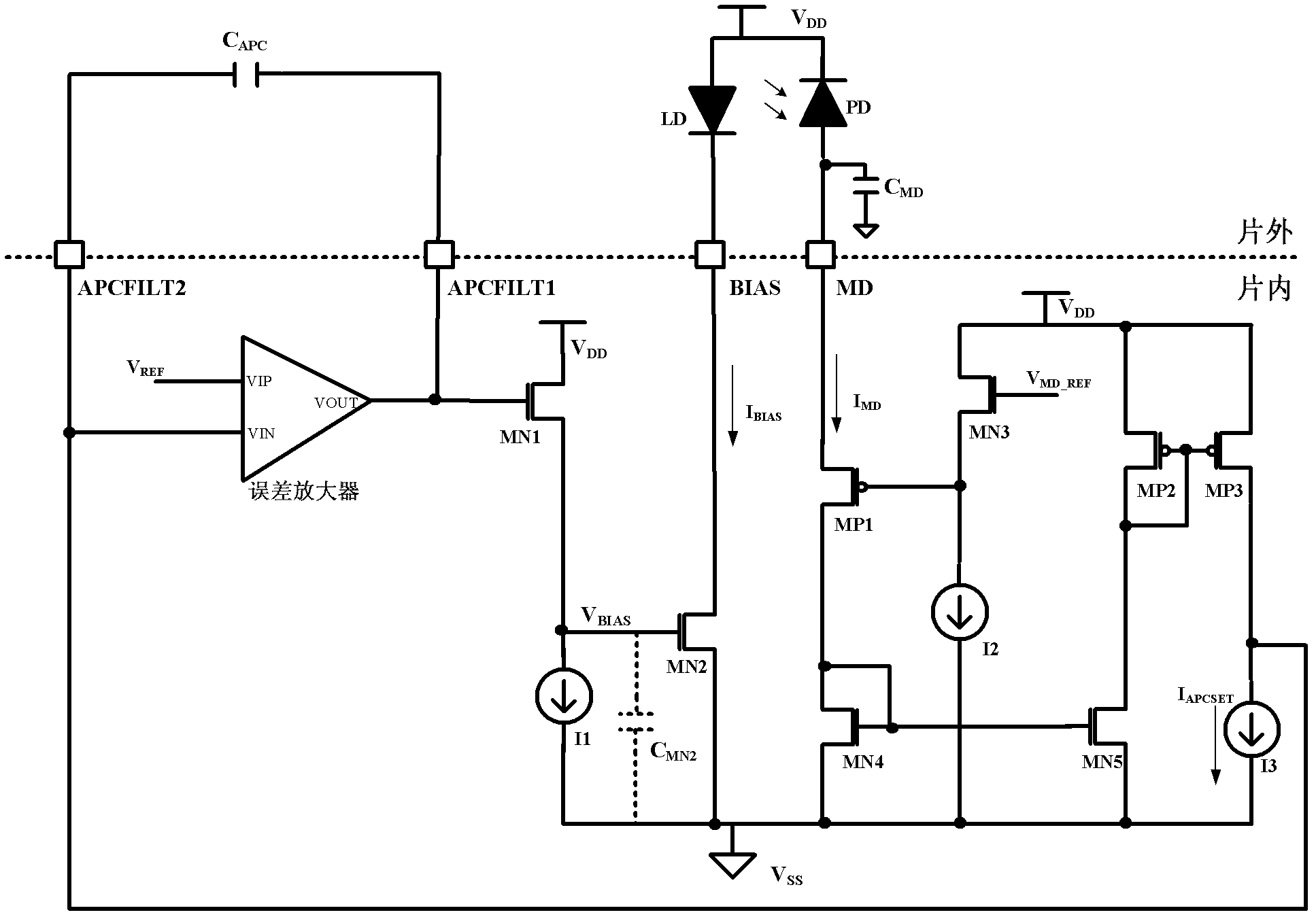

Automatic power control circuit for driving optical communication laser

ActiveCN102437507AStable DC Voltage BiasImprove work performanceLaser detailsDifferential amplifiersWork performanceEngineering

The invention relates to an automatic power control circuit for driving an optical communication laser. The circuit comprises an error amplifier, wherein the VIP end of the error amplifier is connected with a direct current reference stabilized voltage VREF, and the VIN end of the error amplifier is connected with a node APCFILT2; the VOUT end of the error amplifier is connected to a node APCFILT1; a transistor MN1 and a current source I1 form a source follower; a direct current reference stabilized voltage VMD_REF is connected to the gate of an N-channel metal oxide semiconductor (NMOS) transistor MN3; the transistor MN3 and a current source I2 form a source follower; transistors MN4 and MN5 form a pair of current mirrors; and transistors MP3 and MP2 form a pair of current mirrors. By the automatic power control circuit for the driving of the optical communication laser, the influence of other poles in the circuit on circuit stability is effectively eliminated, stable direct current voltage offset is provided for a photo diode at the same time, the working performance of the photo diode is improved, a circuit structure is simple and a small chip area is occupied.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

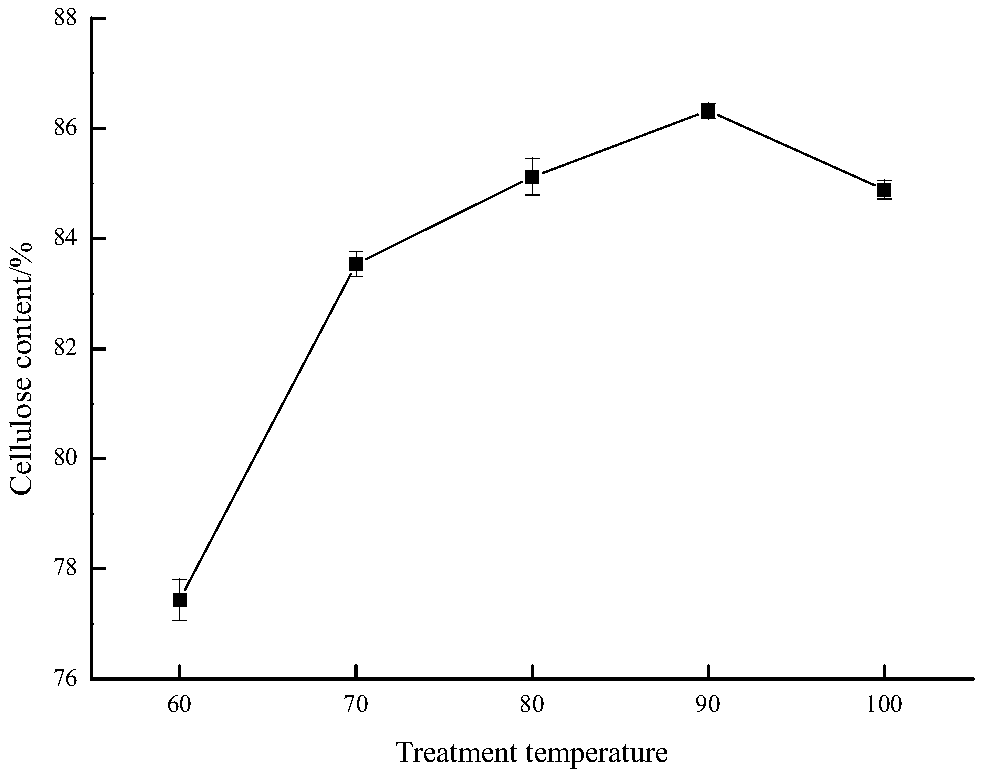

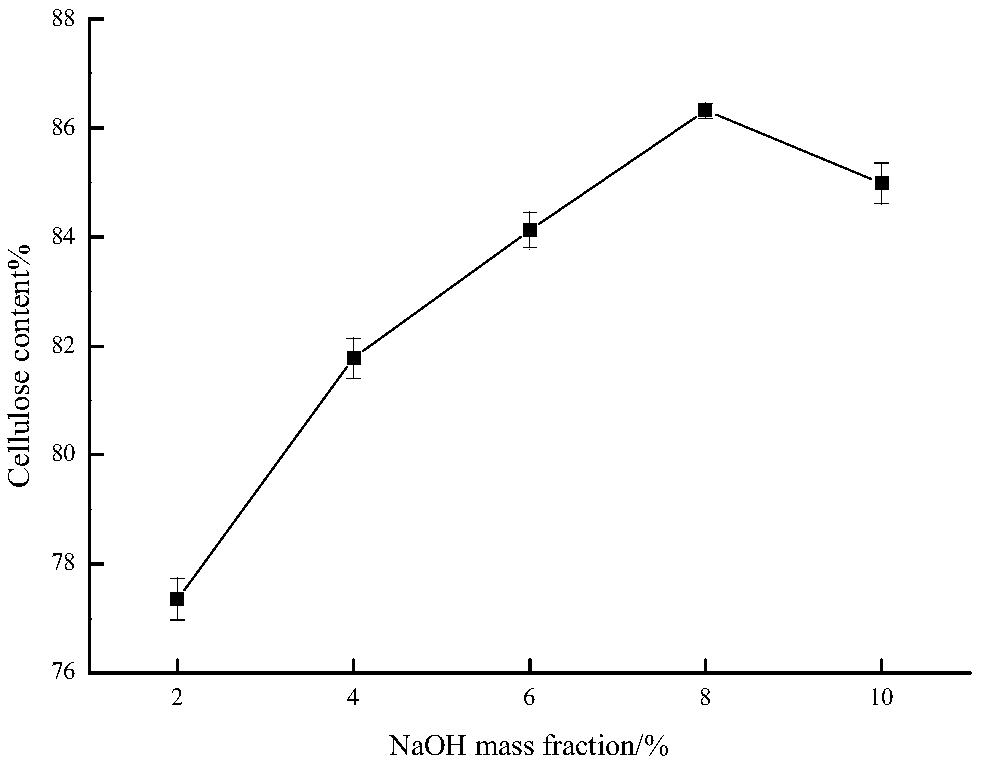

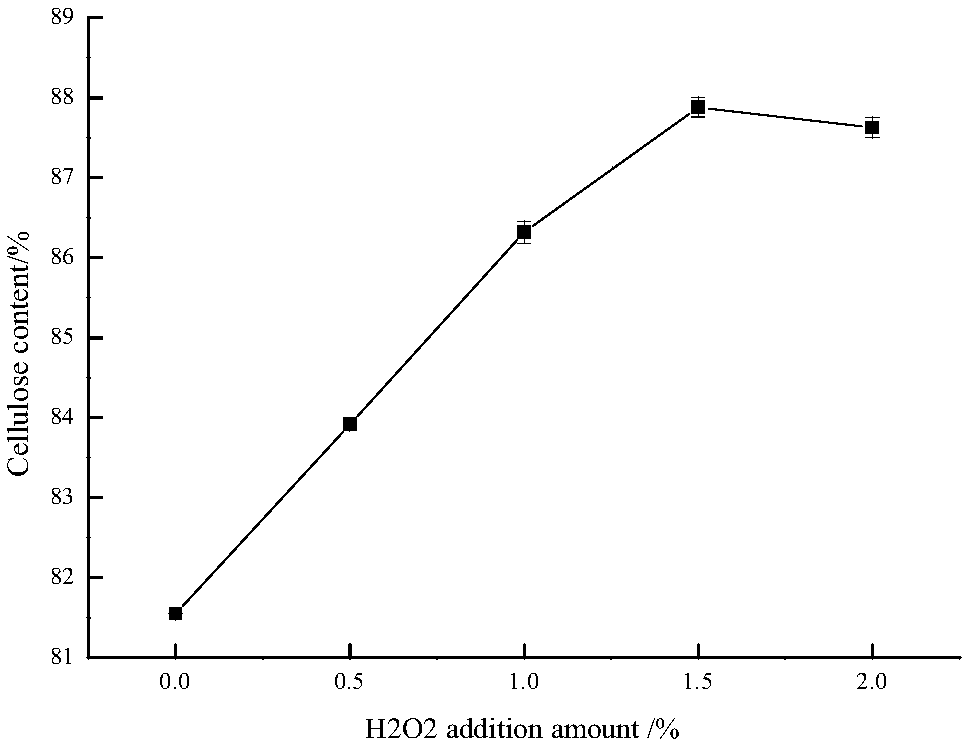

Preparing method and application of sugarcane-leaf hydrophobic modification nanocellulose

The invention discloses a preparing method of sugarcane-leaf hydrophobic modification nanocellulose. The preparing method includes the following steps that raw materials are weighed according to the weight ratio of sugarcane-leaf nanocellulose to stearic acid of (0.5-2):1, then the sugarcane-leaf nanocellulose and the stearic acid are put into an organic solvent capable of dissolving the stearic acid and mixed evenly, and a dispersion system is obtained; the dispersion system is put at the temperature of 20 DEG C to 70 DEG C, and is modified for 60 min to 100 min, filtering, washing and dryingare carried out, and then the modified nanocellulose is obtained. The invention also provides application when the sugarcane-leaf nanocellulose subjected to hydrophobic modification through the stearic acid serves as an antifoaming agent and an additive. Different hydrophobic degrees and different amounts of hydrophobic nanocellulose are added into an organic-silicon antifoaming agent, and the result shows that the antifoaming / foam inhibition performance of the organic-silicon antifoaming agent is continually increased along with increasing of the hydrophobic degrees and increasing of the additive amount; meanwhile, the hydrophobic nanocellulose is added, the stability of an emulsion antifoaming agent is not influenced, and the good stability is still achieved.

Owner:GUANGXI UNIV

Coating mildew-proof agent and preparation method thereof

InactiveCN107936659AGentle and non-irritating to the skinGood compatibilityAntifouling/underwater paintsPaints with biocidesSolventSodium Pyrithione

The invention discloses a coating mildew-proof agent and a preparation method thereof. The mildew-proof agent provided by the invention includes the following raw materials in percentages by weight: 25-50% of a pyrithione salt, 3%-10% of 4,5-dichloro-2-n-octyl-3-isothiazolone, 0.2%-0.6% of a dispersant, 0.02%-0.3% of a defoaming agent, 1%-2% of a consistence modifier, 0.2%-0.5% of an antioxidant,and 40-70% of a solvent; and the fineness of the pyrithione salt is not more than 2[mu]m. The coating mildew-proof agent provided by the invention is a safe, non-toxic high-efficiency and broad-spectrum coating mildew-proof agent with mildness and no irritating to skins, can be widely applied to a coating, and has good compatibility with the coating, and no effects on a plurality of properties such as color, viscosity, levelling performance and stability when the adding amount is proper; the mildew-proof agent provided by the invention can be directly added into the coating when being used, the general recommended usage amount is 0.2%-1%, and the mildew resistant level is 0; and the mildew-proof agent has obvious killing and resisting effects on moulds such as chaetomium globosum, mucor, penicillium, aspergillus terreus and aspergillus niger.

Owner:广州广微环境科技有限公司

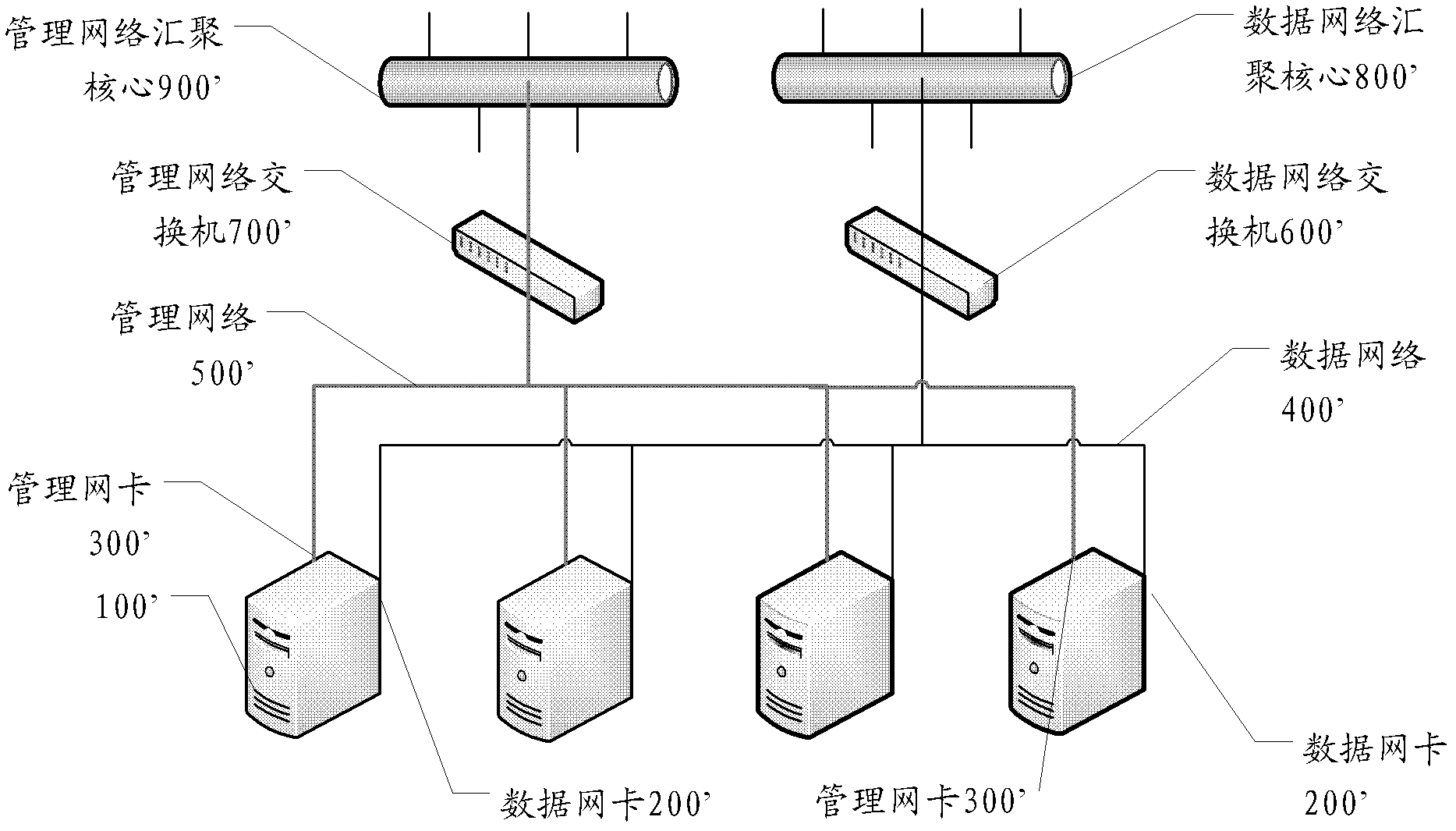

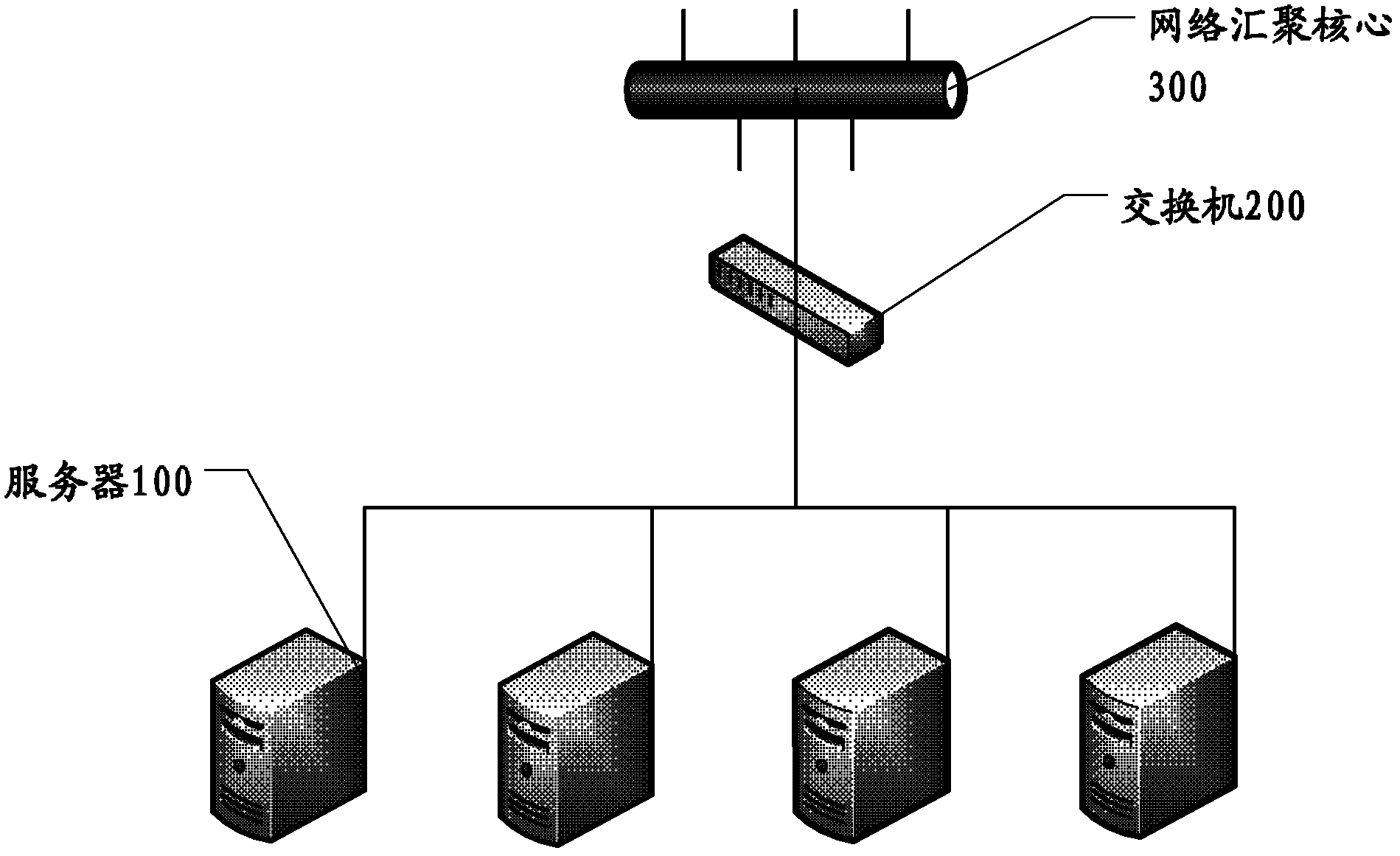

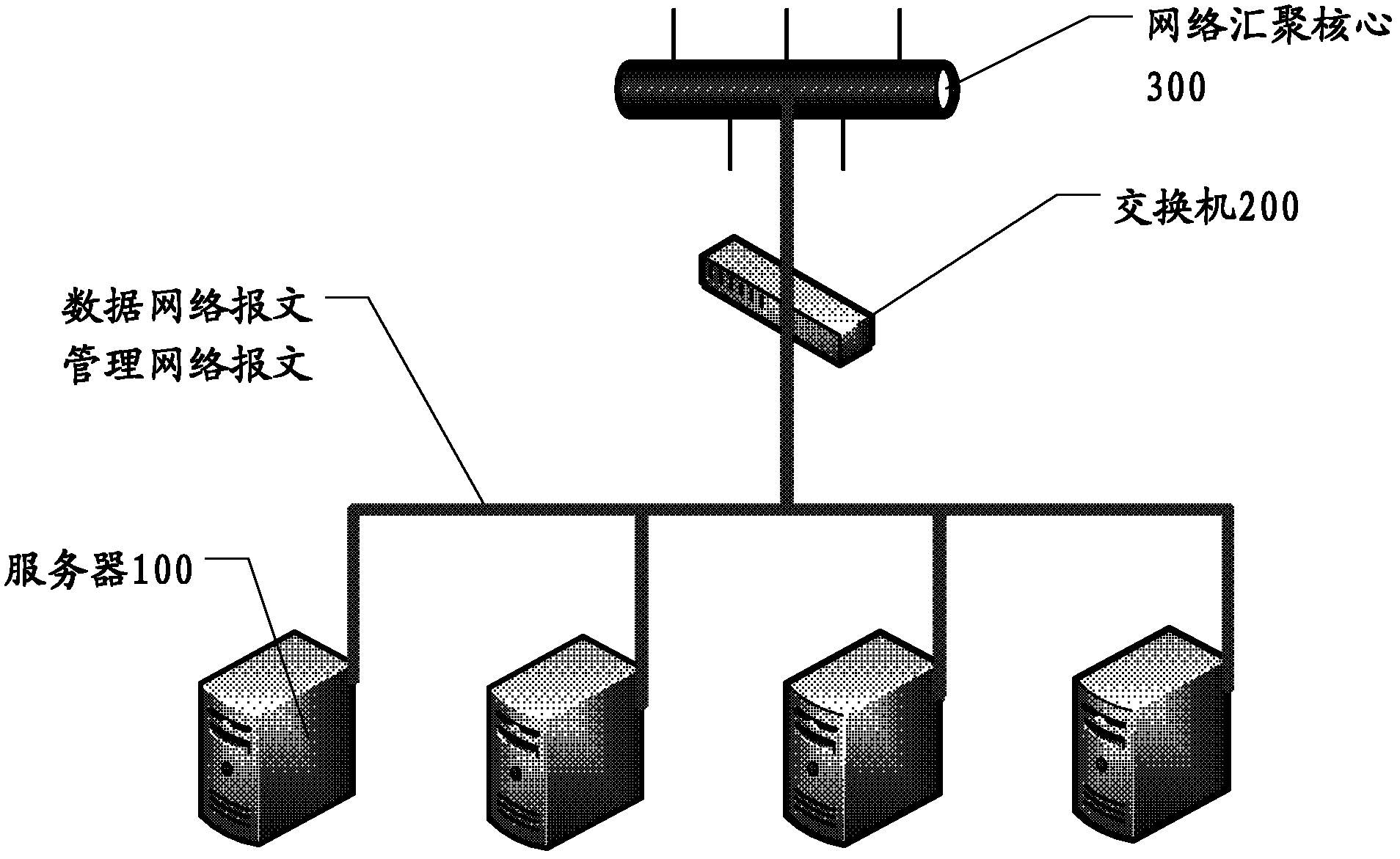

Convergence method, system and device of data network and management network

ActiveCN102281162AAvoid wastingImprove securityData switching networksNetwork managementMedia access control

The invention provides a fusion method and a fusion system of a data network and a management network and devices. The system comprises a switch, the switch comprises a first network segment and a second network segment, the first network segment corresponds to a first media access control (MAC) address, and the second network segment corresponds to a second MAC address. A server is used for receiving network message sent by the switch and judging that the network message is data network message or management network message according to the MAC address in the network message. According to the embodiment, the server is simultaneously accessed to the data network and the management network through a server network card, a switch port and a set of network gathering core, so the access cost of the server can be greatly reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Processing method for organic volatile compositions in VAE emulsion

A processing method for organic volatile compositions in a VAE emulsion comprises preparing raw materials, concretely preparing 2 wt%-3 wt% of an organic solvent, 10 wt%-13 wt% of water, 0.02 wt%-0.03 wt% of an initiator and the balance VAE emulsion; uniformly mixing the organic solvent, water and the VAE emulsion according to the percentage, heating to 85-95 DEG C for starting distillation, adding the initiator according to the percentage when distillation is performed, after distillation is performed for 4-6 h, using nitrogen to blow the container, collecting the condensed liquid, and after collection is finished, cooling and discharging. The processing method employs a high-temperature distillation means, and by adding the organic solvent, adding the initiator for cooperation when distillation is performed, and using nitrogen to blow the container after distillation is performed, the processing method helps to improve the removal rate of a residual monomer and the removal rate of benzene and other impurities, has the residual-monomer removal rate up to 99%, also has no influence on emulsion stability, particle size and molecular weight distribution, solid content and the like, and also helps to substantially shorten the processing time of the residual monomer, and benzene and other impurities, and only 8-10 hours are needed for finishing processing.

Owner:CHINA PETROCHEMICAL CORP +1

Alcohol-in-oil type emulsion comprising a multivalent metal salt

InactiveCN101355920AStability has no effectCosmetic preparationsToilet preparationsAntiperspirantsEmulsion

The present invention relates to emulsion science, especially within the area of alcohol-in-oil type emulsion, where the level of ions comprised in the alcohol-in-oil type emulsion is relatively high. In particular, the invention relates to a stable alcohol-in-oil type emulsion comprising a multivalent metal salt that may act as an antiperspirant.

Owner:RIEMANN TRADING

Overcritical Fischer-Tropsck synthesis method

InactiveCN101215213ARaw materials are cheap and easy to getImprove wear resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsGas phase

The invention discloses a method of super-critical Fischer-Tropsch synthesis, using molten-iron as catalyst to convert synthetic gas (CO+H2) into hydrocarbon in the presence of supercritical media. The process comprises as follows: mixing the synthetic gas and supercritical media, performing super-critical Fischer-Tropsch synthesis under the conditions of temperature of 180-350DEG C, pressure of 3.0-10.0MPa and synthetic gas airspeed of 1000h-1-30000h-1 and converting the synthetic gas into liquid fuel. The molten-iron catalyst has the advantages of easy obtaining of raw material, strong abrasive resistance, high space time yield, high selectivity of olefin, simple preparing process, stable catalyst property, more suitability of industrial production and the like. Under the same reaction condition, compared with gas-phase and liquid-phase Fischer-Tropsch synthesis, the super-critical Fischer-Tropsch synthesis can reduce temperature jump of beds, decrease carbon deposit on surface of the catalyst, prevent devitalization of the catalyst and prolong the service life of the catalyst. In terms of reaction property, the invention can increase conversion rate of CO, reduce selectivity of methane and increase selectivity of C5+ and olefin in products.

Owner:ZHEJIANG UNIV OF TECH

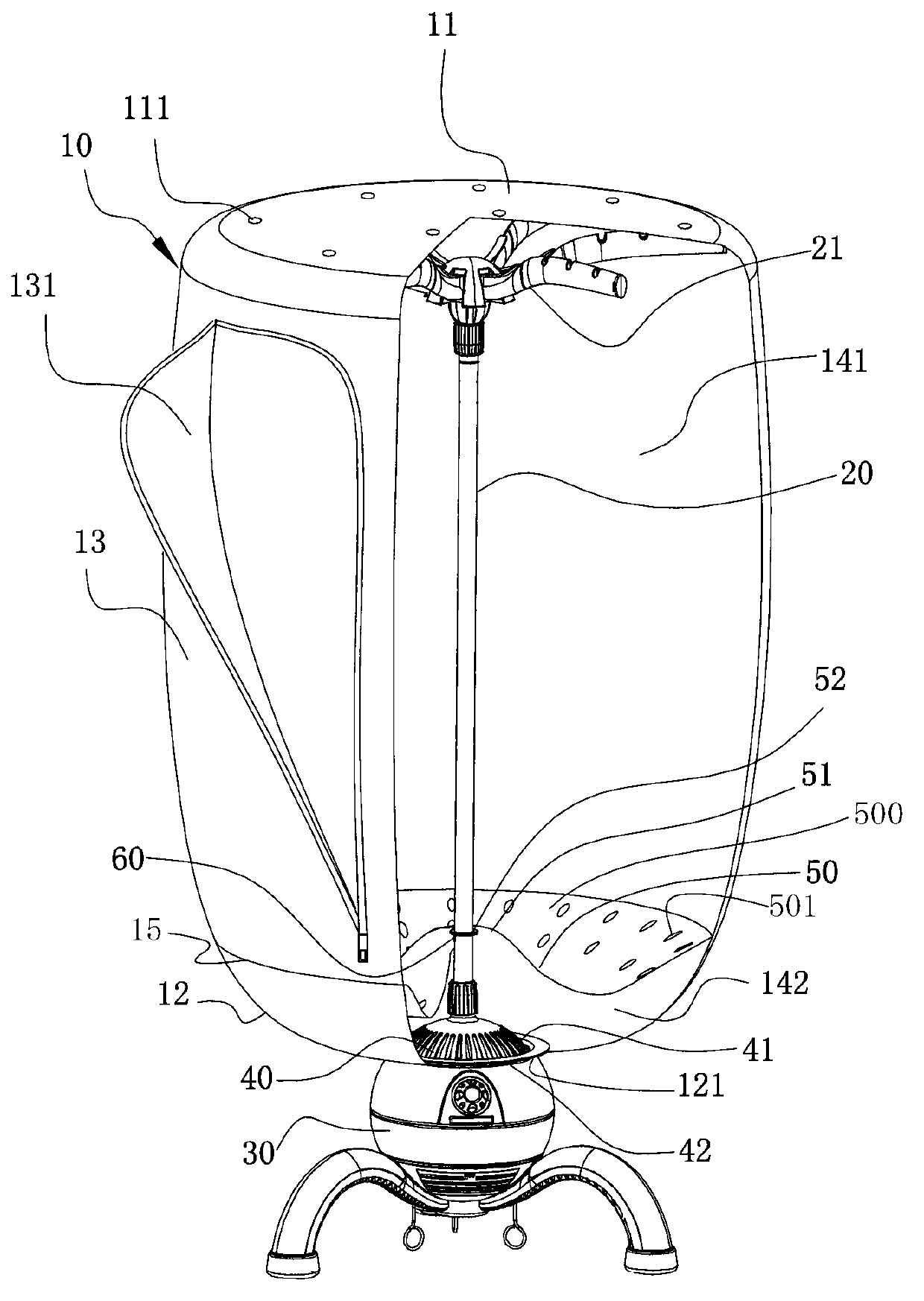

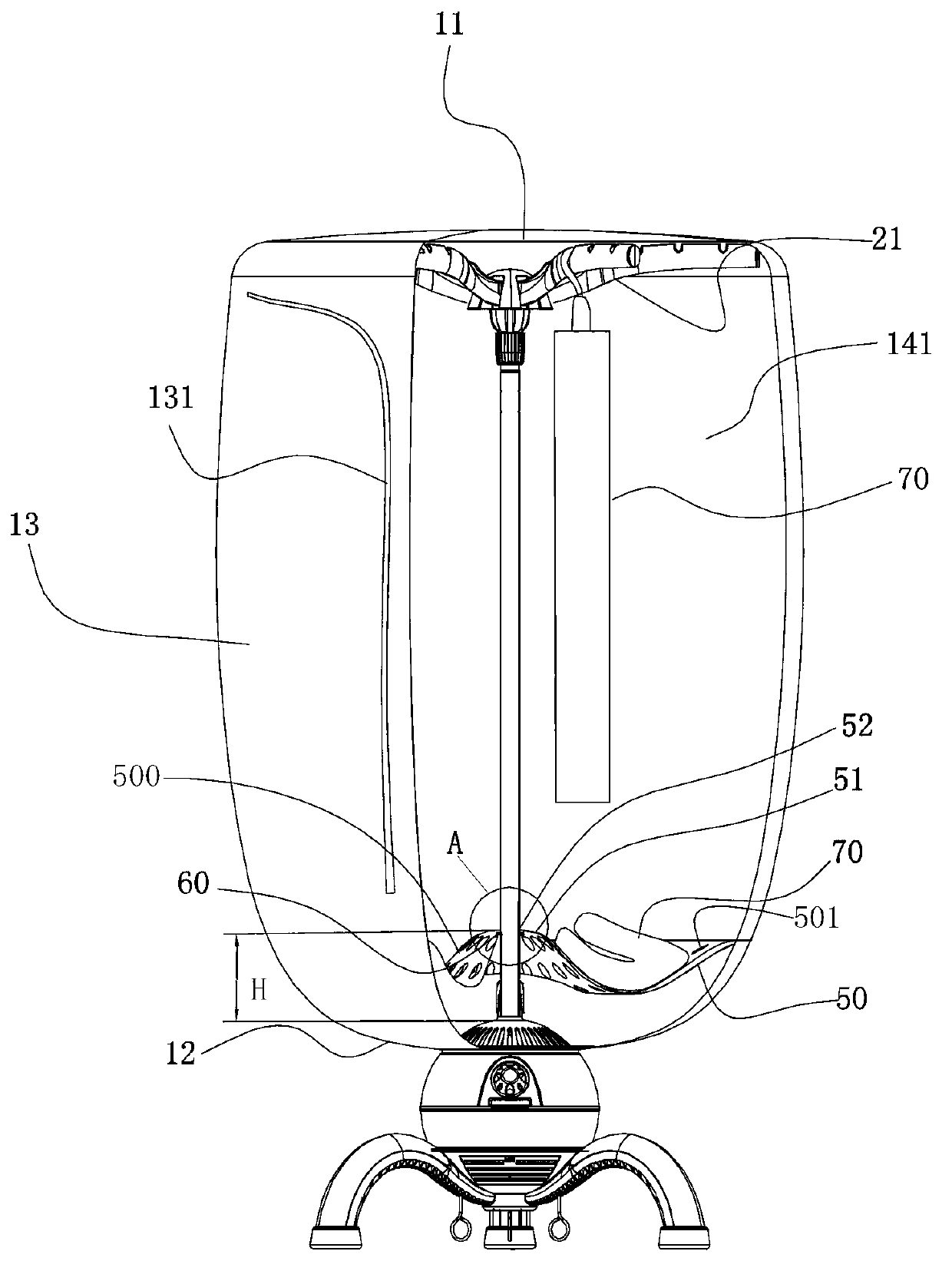

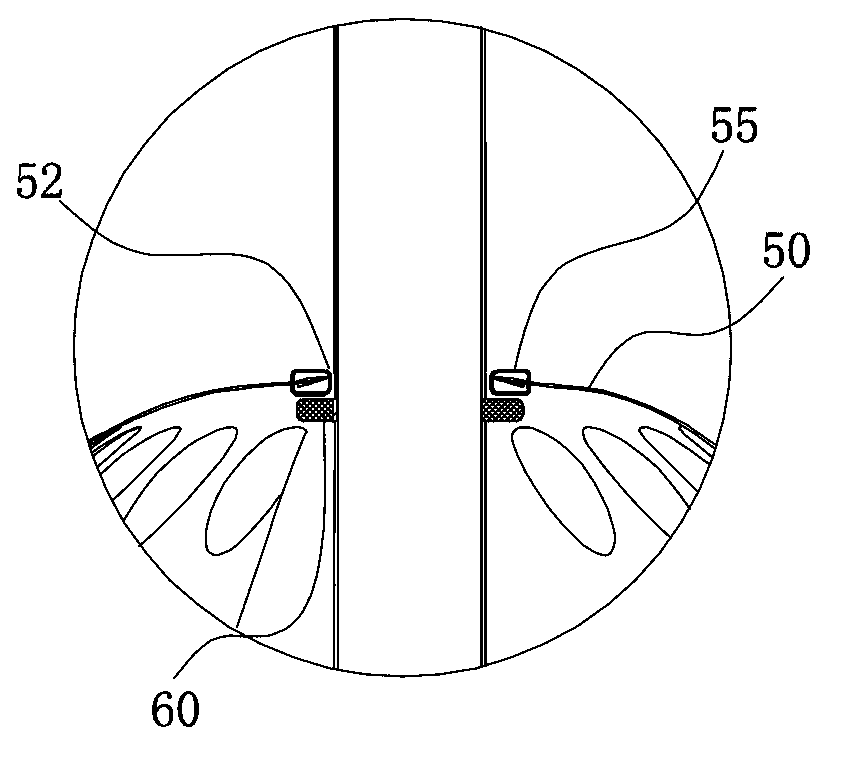

Stand column supporting fabric shade type dryer

ActiveCN103015142AStability has no effectPrecise positioningTextiles and paperLaundry driersSkin surfaceEngineering

Owner:胡杰波

Tirofiban hydrochloride freeze-dried powder injection preparation and preparation method thereof

ActiveCN101716148AImprove solubilitySimple preparation processPowder deliveryOrganic active ingredientsForeign matterSolubility

The invention relates to a tirofiban hydrochloride freeze-dried powder injection preparation and a preparation method thereof. The tirofiban hydrochloride freeze-dried powder injection preparation produced by a freeze-dried technology of the invention greatly enhances solubility of tirofiban hydrochloride; and since the pH of redissolved liquid medicine is within the range of 2.0-8.0 and visible particles and particulate matter satisfy the requirement of the pharmacopeia, the safety of medicine is greatly improved. The tirofiban hydrochloride freeze-dried powder injection preparation has simple preparation, controllable quality, stable physical and chemical properties and safe and effective use.

Owner:LUNAN PHARMA GROUP CORPORATION

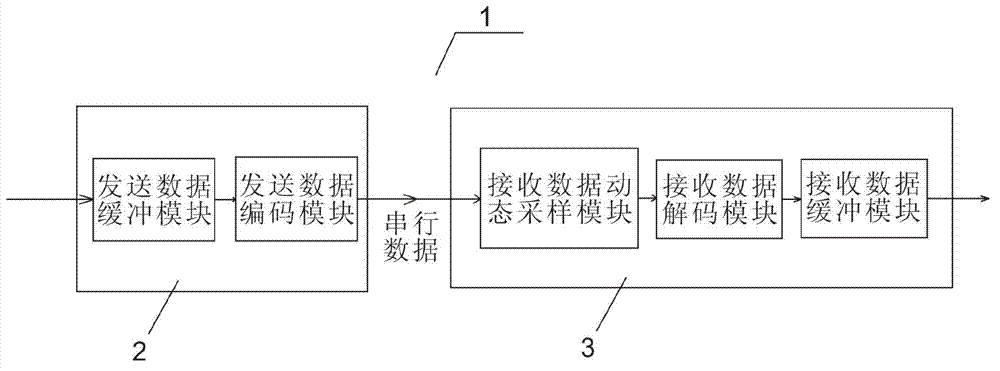

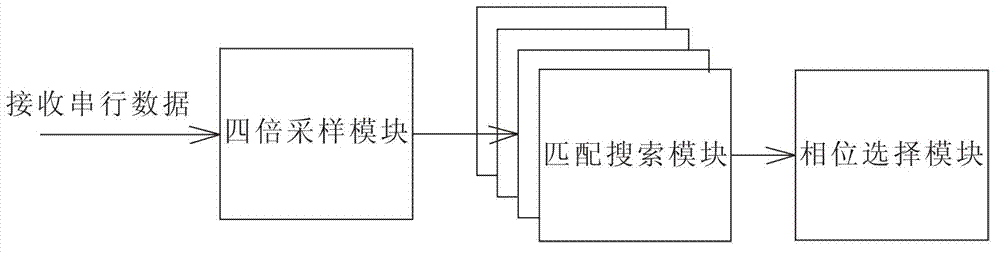

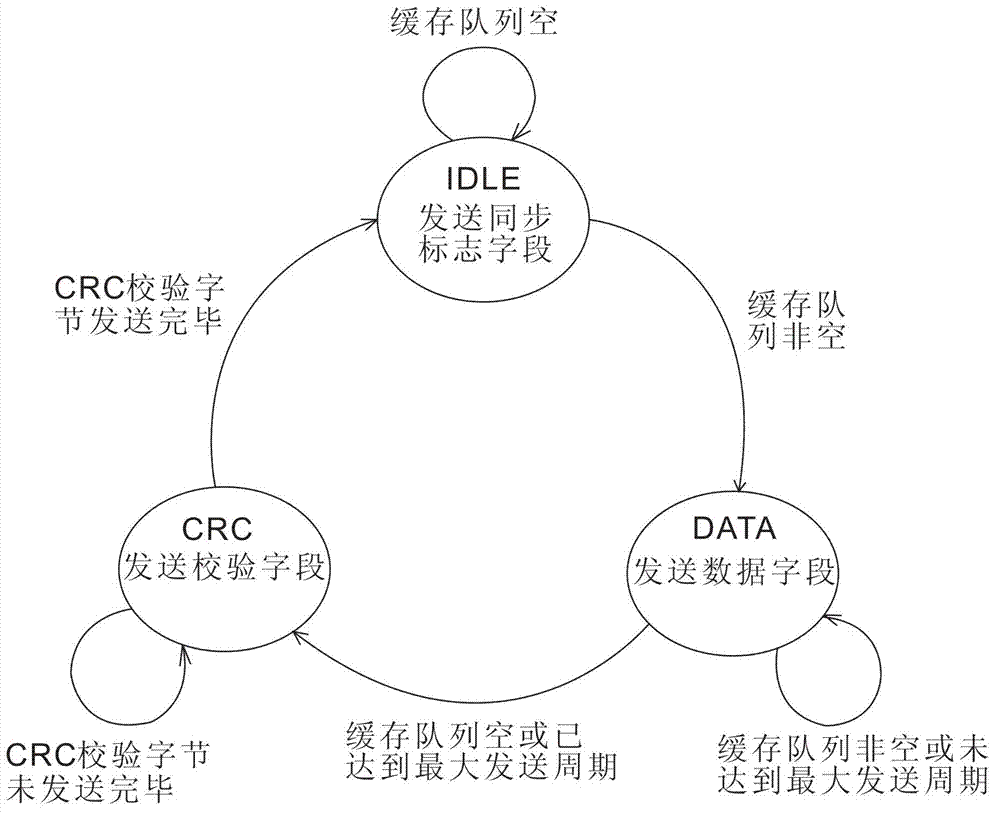

Inter-plate serial communication system and inter-plate serial communication method

ActiveCN103200127AHigh communication rateReduced physical tracesError preventionData switching networksData bufferReal-time computing

An inter-plate serial communication system comprises a transmitting module and a receiving module, wherein the transmitting module is connected with the receiving module through signals. The transmitting module comprises a transmitted data buffer module and a transmitted data encoding module, wherein the transmitted data buffer module is connected with the transmitted data encoding module through signals. The receiving module comprises a received data dynamic sampling module, a received data decoding module and a received data buffer module, wherein the received data dynamic sampling module is connected with the received data decoding module through signals, and the received data decoding module is connected with the received data buffer module through signals. The transmitted data buffer module comprises a buffer queue module and a transmission control state machine. The inter-plate serial communication system is simple in design, high in communication reliability and communication efficiency, and free of time sequence pressure.

Owner:武汉中软通科技有限公司

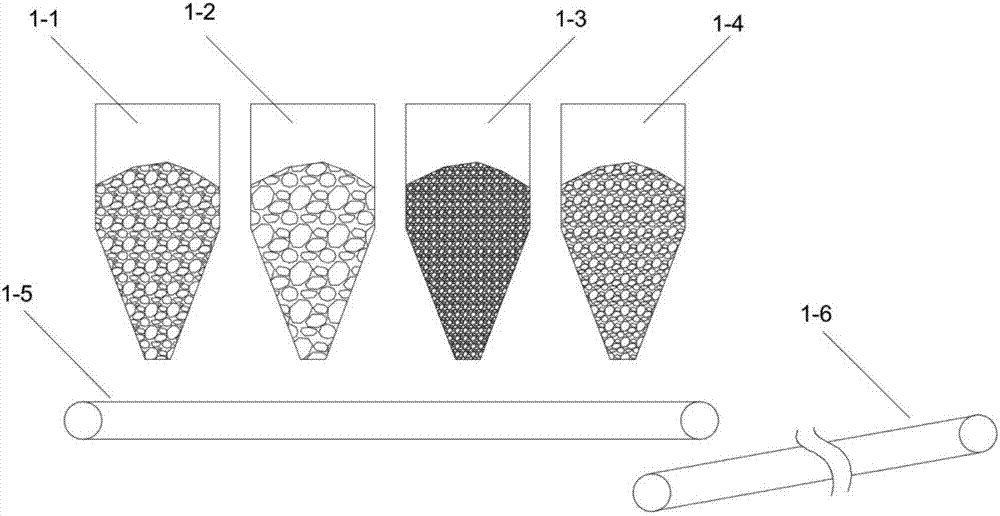

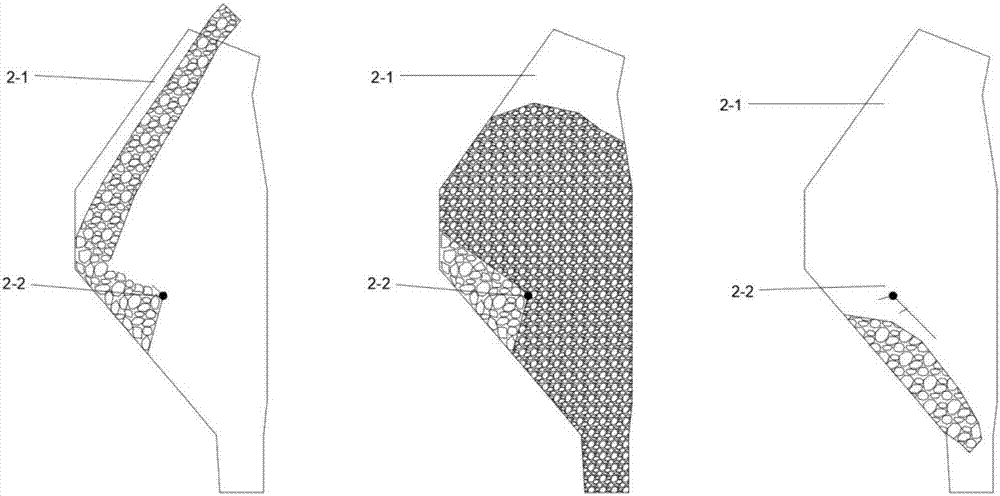

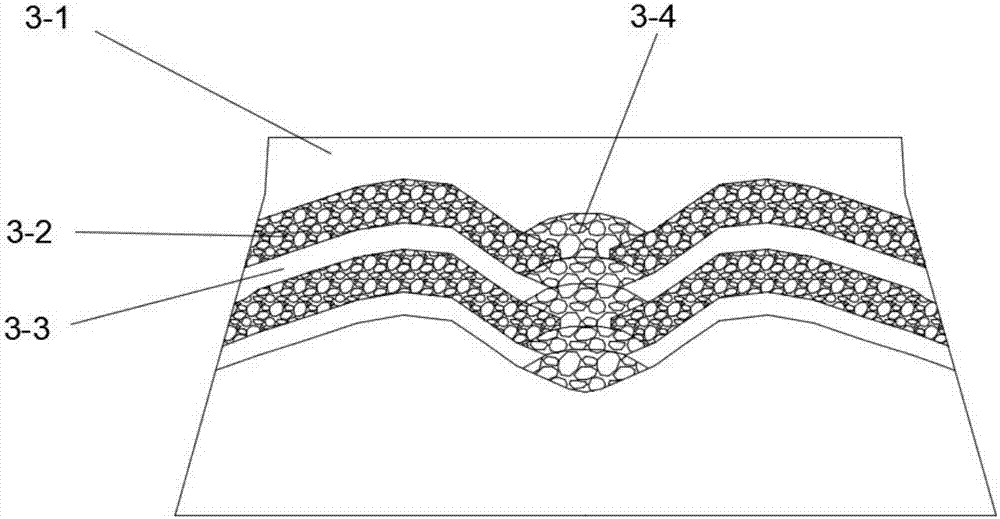

Grading and quality-dividing material distribution method in blast furnace

InactiveCN107881272AControllable processGood effectBell-and-hopper arrangementBlast furnace detailsRadial positionEngineering

Modern blast furnaces become upsized continuously, and thus, the situations that centers cannot be blown thoroughly (dead stocks are poor in air permeability), the utilization rate of coal gas is low,and the fuel ratio stays at a high level happen frequently. The primary cause is particle segregation of a paralleled pot, a large amount of small-size coke and small-size ore enter the center of a blast furnace or an annular zone near the center, and the air-permeability of the blast furnace and reduction of the ore are severely affected, which is extremely unfavorable to iron-making productionof the blast furnace. Therefore, the invention provides a grading and quality-dividing material distribution method in a blast furnace according to an existing material distribution system, crude fuelof different grades and different weights can be loaded into different radial positions of the blast furnace according to smelting requirements, and the problem is solved. The technological process is simple and controllable, the grading and quality-dividing effect is excellent, in addition, little investment and modification are applied to existing equipment, and the process that the crude fuelis loaded into the furnace in the graded and quality-divided mode is conducted effectively and continuously.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Capsule type budesonide dry powder inhalation and preparation process thereof

ActiveCN101919865AHigh yieldLessen the burden on the lungsPowder deliveryOrganic active ingredientsLarge applicationsSide effect

The invention provides a capsule type budesonide dry powder inhalation and a preparation process thereof. The budesonide dry powder inhalation comprises the following components by weight: 0.16 g-0.24 g of budesonide and 20 g-30 g of lactose. As blank lactose granules are prepared, the invention can control the loading quantity easily during split charging and improve the product yield and is beneficial for industrial production. When being used, the invention reduces the content of auxiliaries entering the lung when a patient takes medicine to ease the lunge burden of the patient, reduces the side effect during the medication and has relatively large application value.

Owner:SHANGHAI SINE PROMOD PHARMA

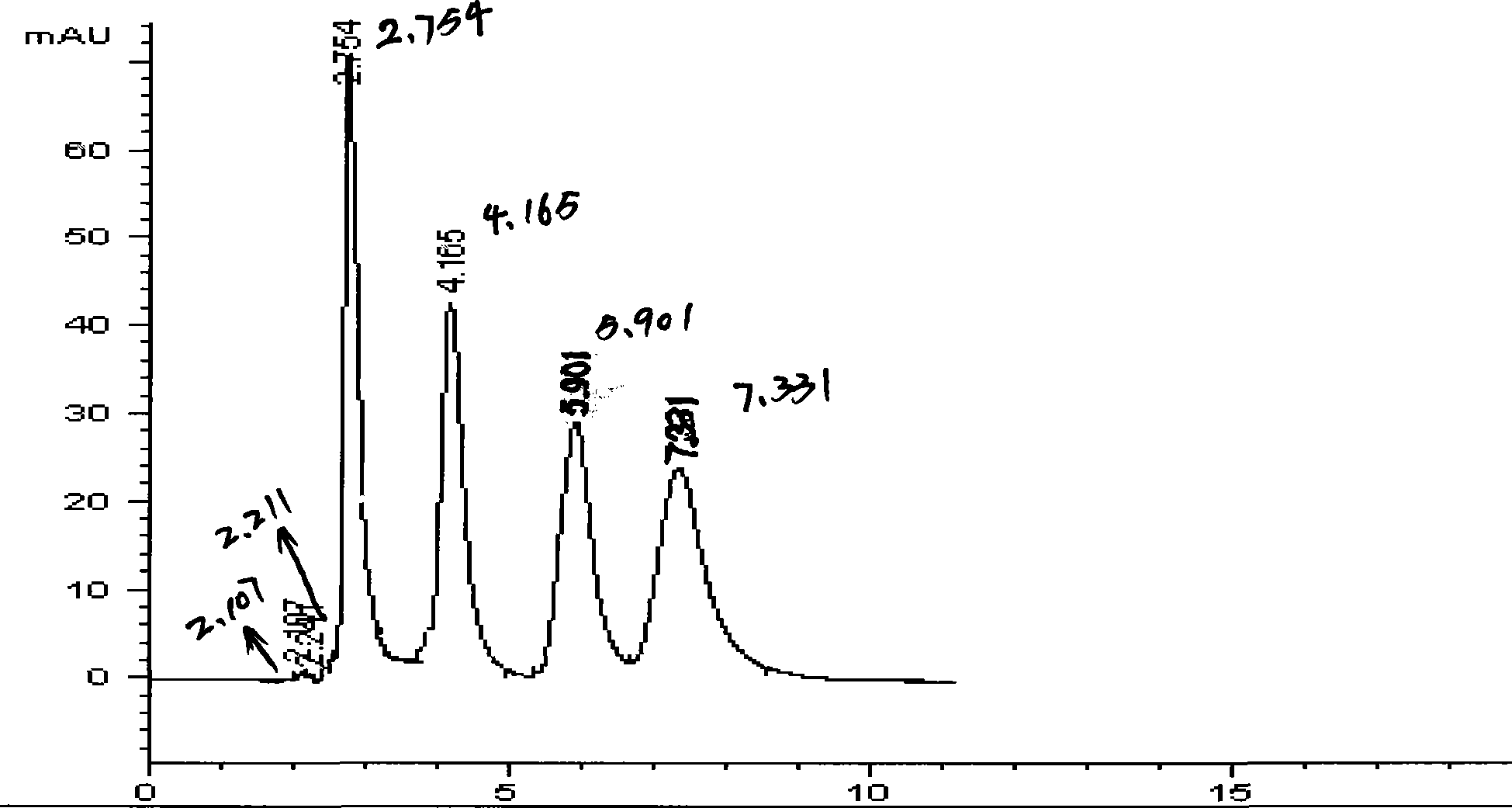

Famotidine-malic acid eutectic crystal and preparation method thereof

ActiveCN111592503AStability has no effectImprove solubilityOrganic active ingredientsOrganic chemistry methodsHigh humidityPhysical chemistry

The invention discloses a famotidine-malic acid eutectic crystal and a preparation method thereof. The molar ratio of famotidine to malic acid in the eutectic crystal is 2:1. The invention also discloses the preparation method of the eutectic crystal. The famotidine-malic acid eutectic crystal provided by the invention has a characteristic melting point, an infrared spectrum, an X-ray powder diffraction pattern and the like. The eutectic crystal improves the solubility of famotidine in water, does not change the stability of famotidine under the conditions of artificial gastric juice, high temperature and high humidity, and has the potential of improving the bioavailability of famotidine. The preparation method of the famotidine-malic acid eutectic crystal is simple in step, easy to operate and good in reproducibility, and has great commercial application value.

Owner:青岛市食品药品检验研究院

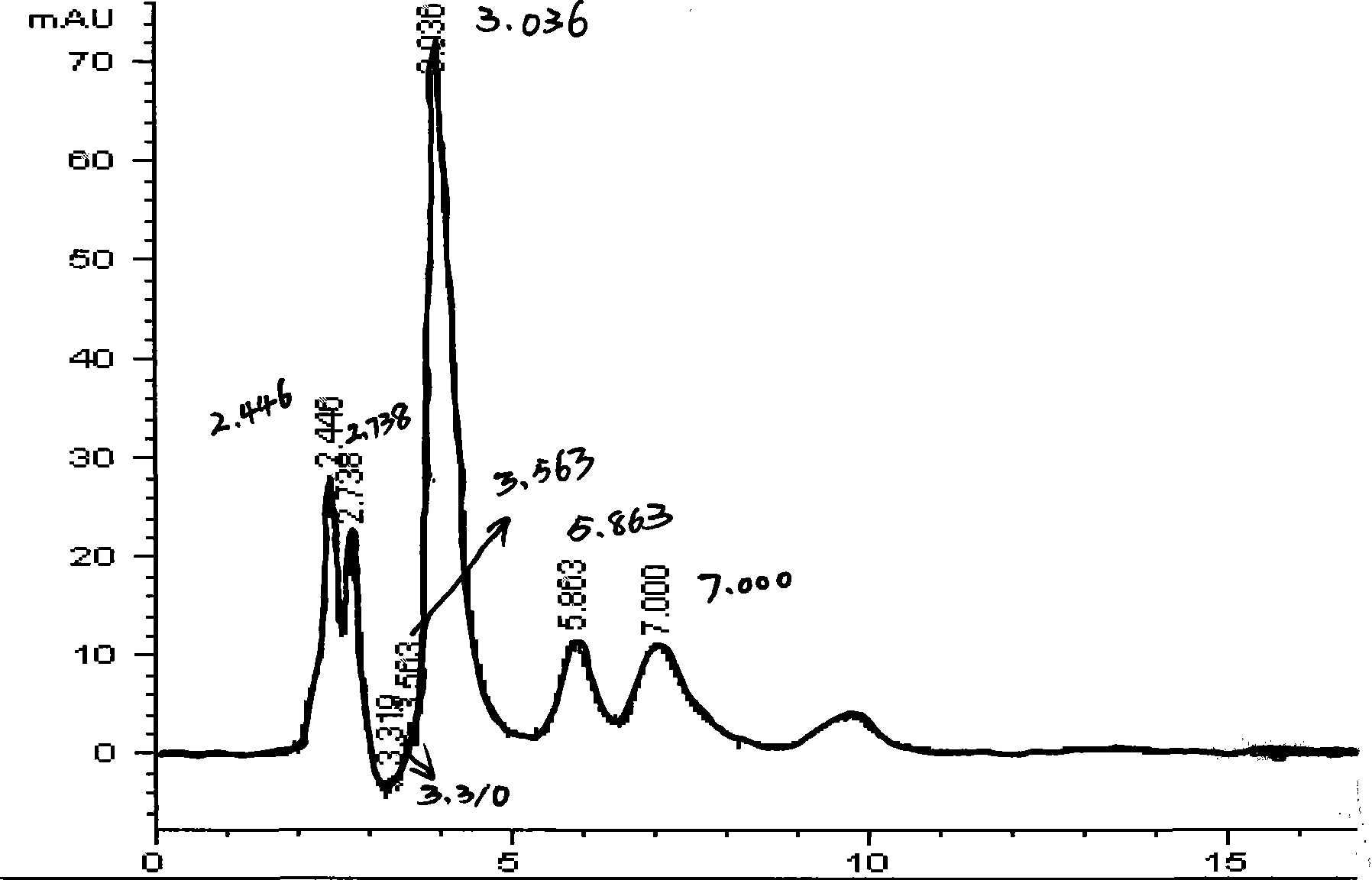

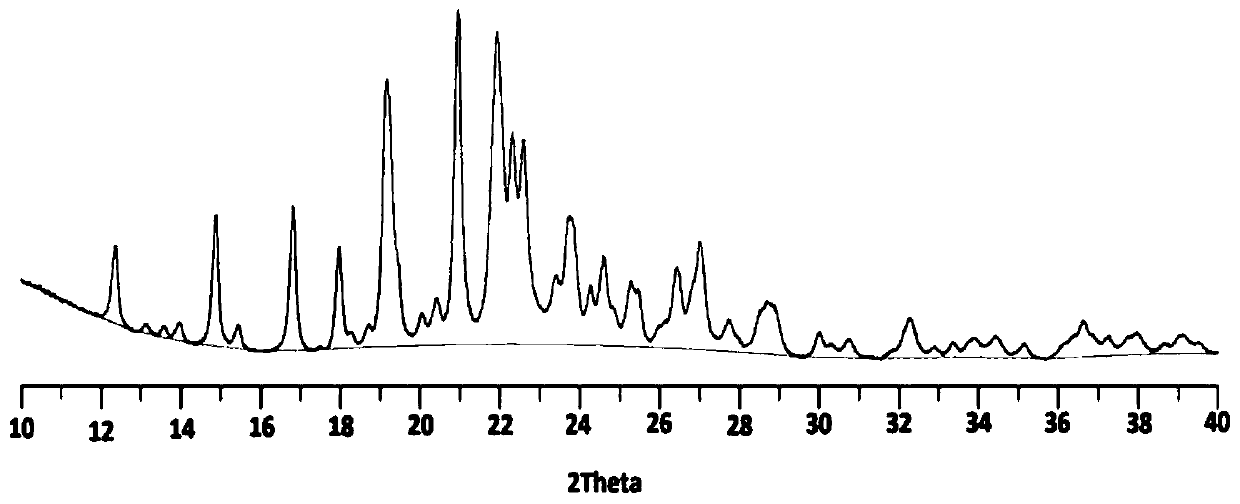

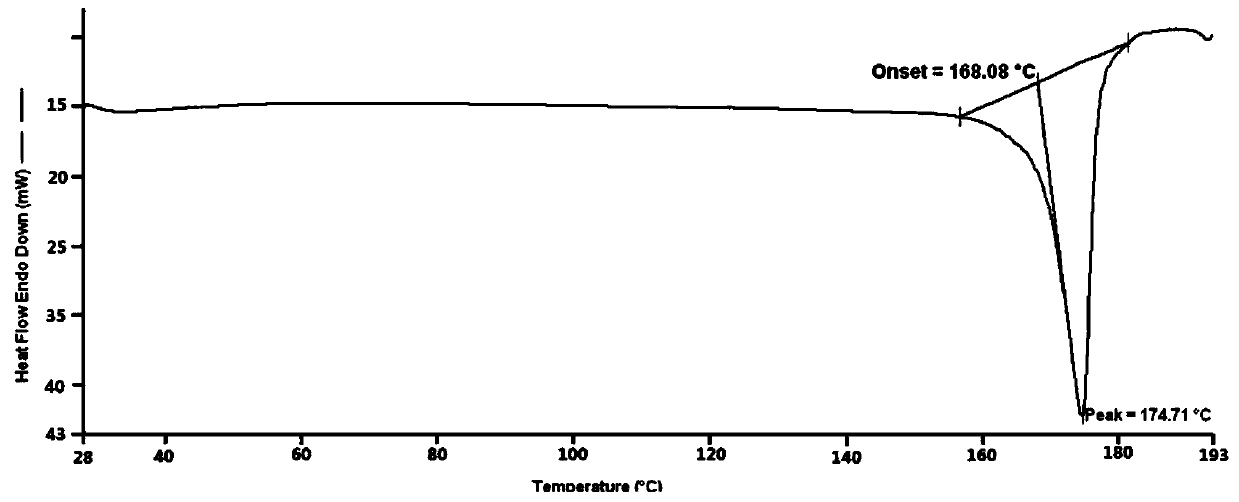

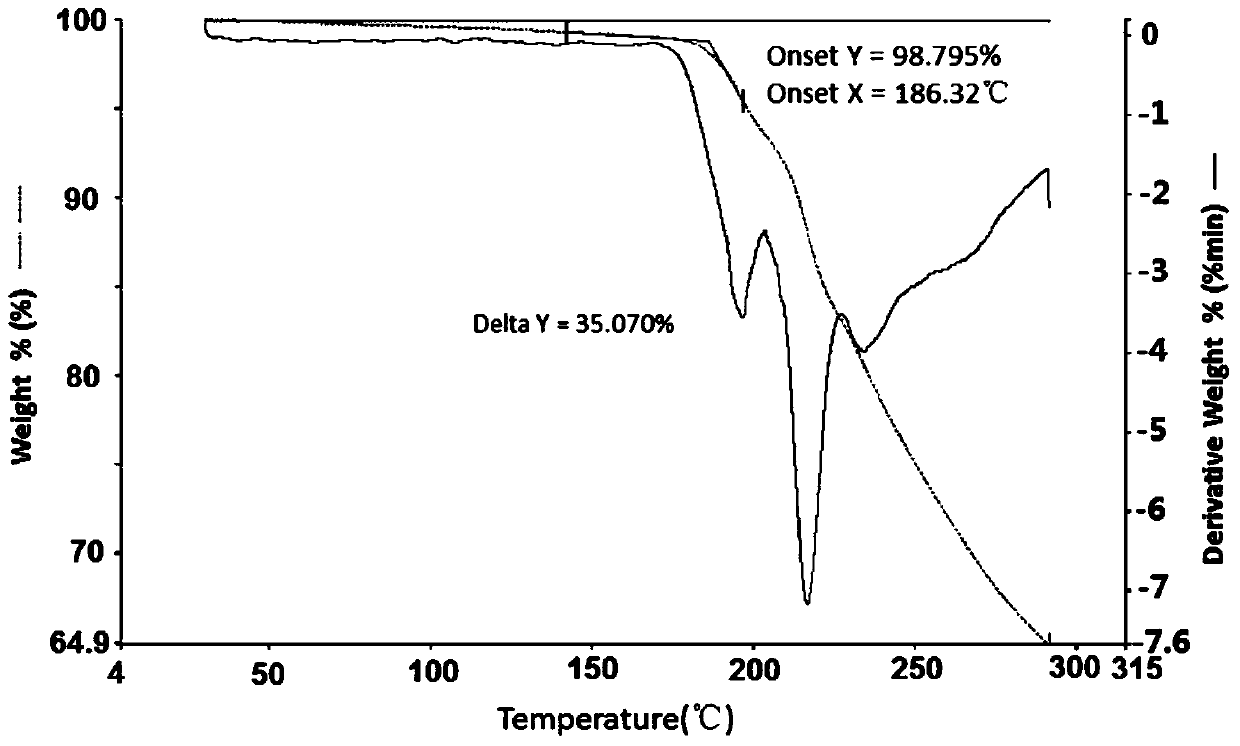

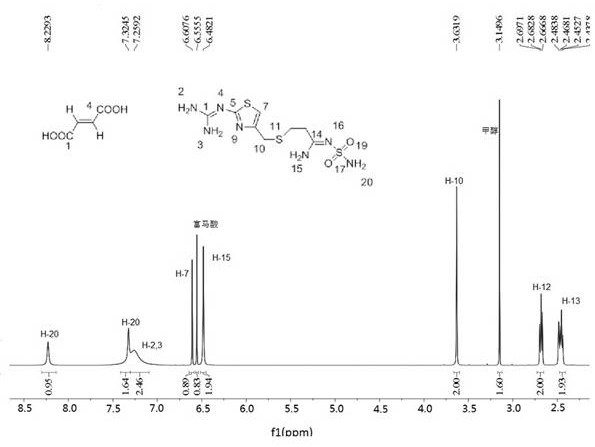

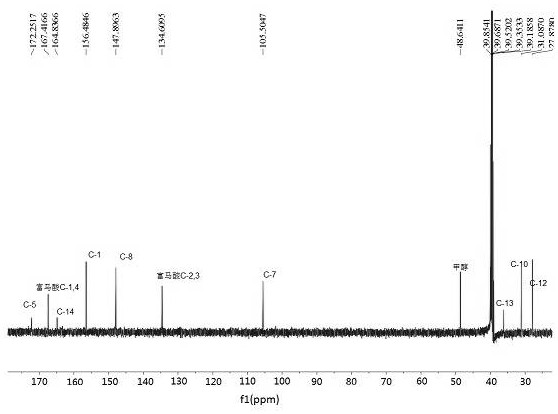

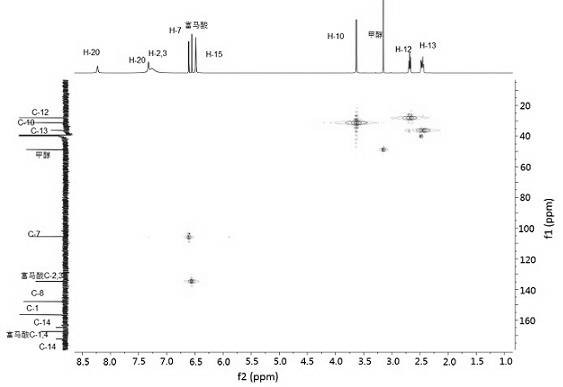

Eutectic crystal of famotidine and fumaric acid and preparation method thereof

ActiveCN111777569AImprove bioavailabilityStability has no effectOrganic active ingredientsDigestive systemMethanolPowder diffraction

The invention discloses a eutectic crystal of famotidine and fumaric acid and a preparation method thereof. The eutectic crystal is a solvate containing one molecule of methanol, and the molar ratio of famotidine to fumaric acid is 2: 1. The invention also discloses a preparation method of the eutectic crystal. The provided eutectic crystal of famotidine and fumaric acid has a characteristic melting point, an infrared spectrum, an X-ray powder diffraction pattern and the like. The solubility of famotidine in water is improved by the eutectic crystal, the stability of famotidine under high-temperature and high-humidity conditions is not changed, and the eutectic crystal has the potential of improving the bioavailability of famotidine. The preparation method of the eutectic crystal of famotidine and fumaric acid is simple in steps, easy to operate and good in reproducibility, and has a great commercial application value.

Owner:青岛市食品药品检验研究院

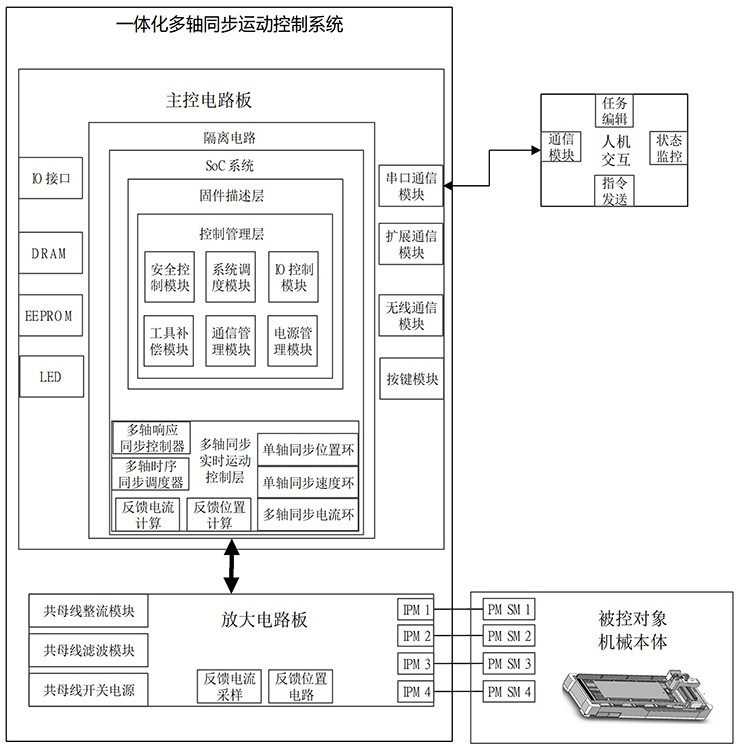

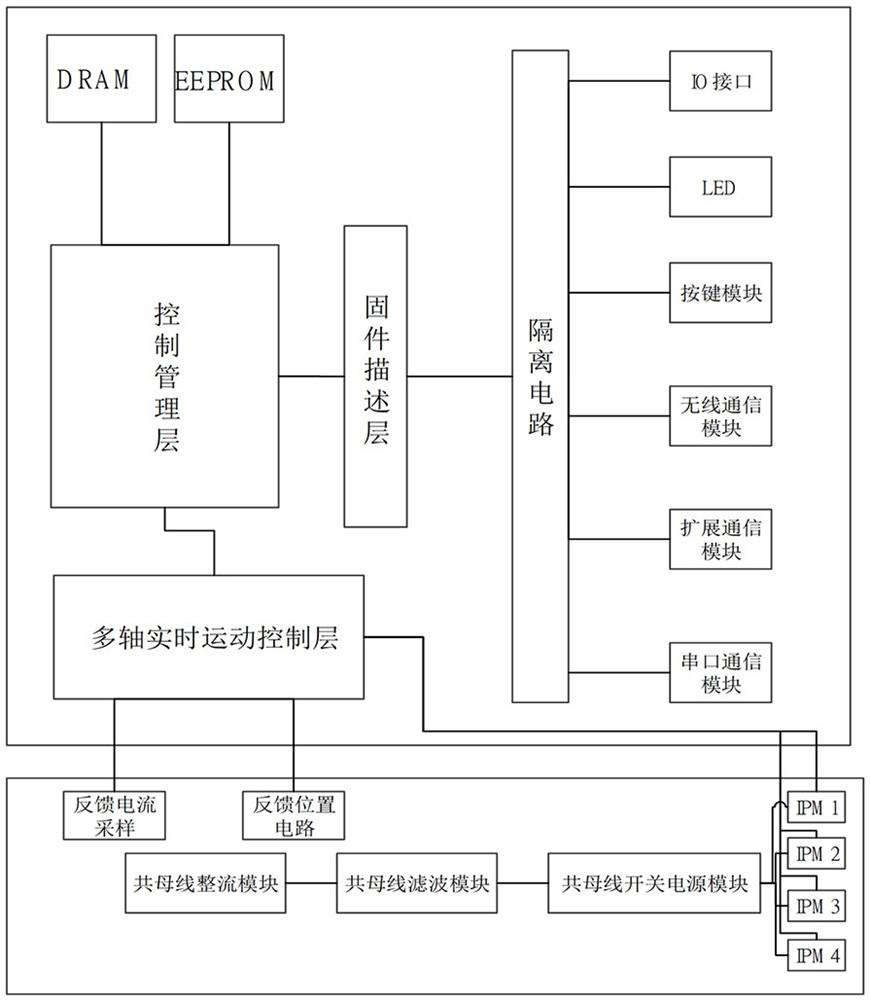

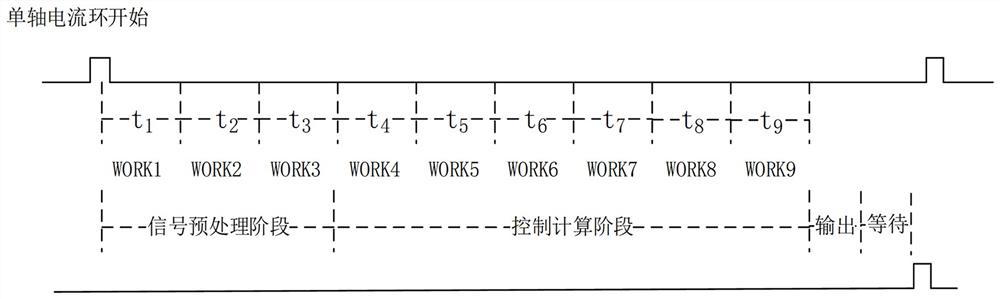

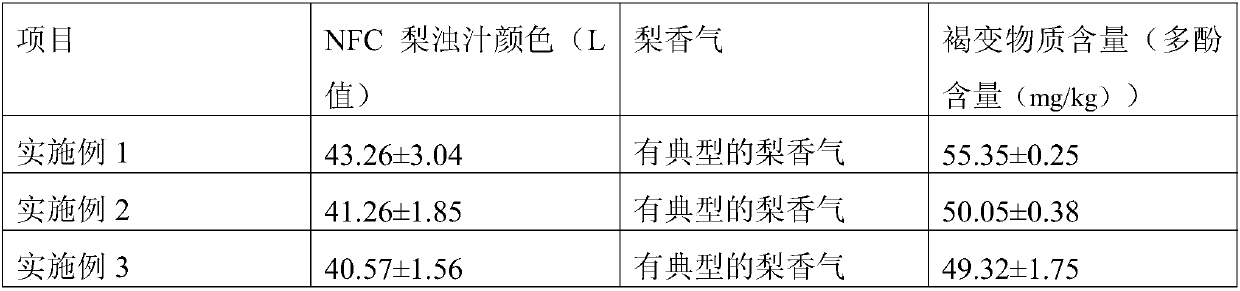

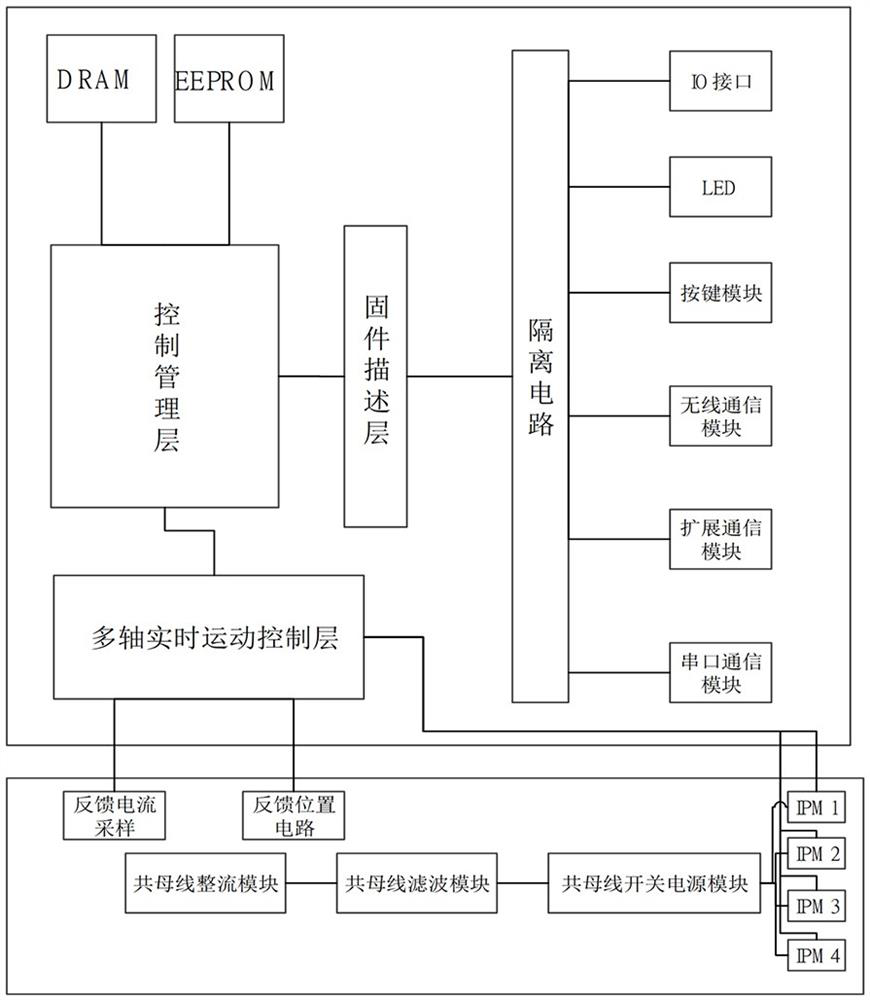

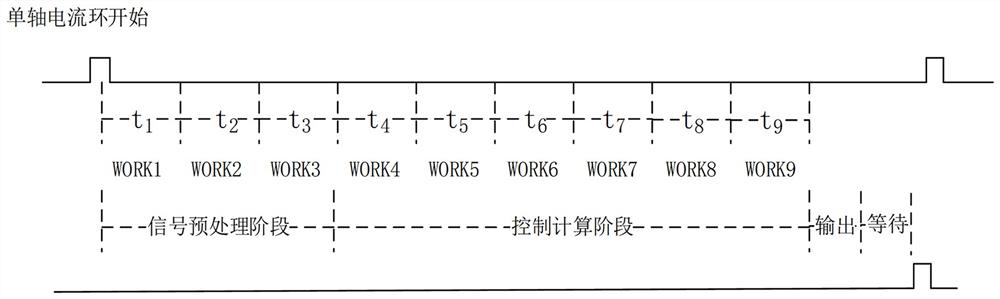

Integrated multi-axis synchronous motion control system and synchronous control method

ActiveCN112994532ALow costHigh degree of autonomyElectronic commutation motor controlElectric motor controlCurrent loop controlSynchronous control

The invention discloses an integrated multi-axis synchronous motion control system and a synchronous control method. The control system comprises a feedback sampling module and an active module; the feedback sampling module is used for sampling the running current and the running position of a multi-axis servo motor; the main control module comprises an SoC system; and the SoC system receives a sampling result of the feedback sampling module and is used for feedback position detection and calculation and feedback current detection and calculation of the multi-axis servo motor, and achieving multi-axis synchronous current loop control, multi-axis time sequence synchronous scheduling and multi-axis response synchronous control. With the integrated multi-axis synchronous motion control system and the synchronous control method of the invention, the problems that an existing multi-axis synchronous motion control method is poor in synchronization performance, high in cost, low in autonomy degree of a core technology, poor in non-whole-process time sequence-level synchronization and response-level synchronization, seriously affected in system stability, low in universality, complex in calculation and the like can be solved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for flavoring snack noodle body

The invention relates to a method for flavoring a snack noodle body. The method comprises the following steps: (1) preparing a flavoring juice; (2) conveying the flavoring juice; (3) adjusting an atomization state; (4) adjusting the spray quantity; and (5) flavoring snack noodle. According to the method provided by the invention, a principle that the noodle needs to absorb 3-4% of water during digestion is utilized, and a process of spraying the flavoring juice for flavoring before digestion is adopted to ensure that flavoring liquid sprayed to the noodle body is absorbed into the noodle body during digestion, the noodle body is fully flavored, and free water cannot be brought into a deep-frying furnace and causes no influence on the stability of furnace oil; and in addition, the method is convenient to operate, enables the snack noodle to be fully flavored and crisp in mouthfeel, and can stabilize the quality of the oil during processing.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

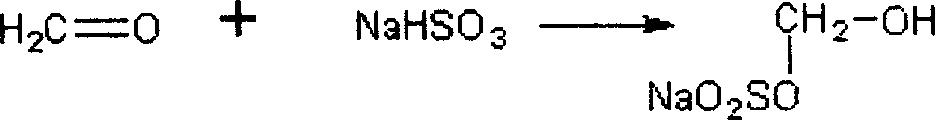

Method for removing free formaldehyde in amino resin modified by hydroxylic acrylic ester

InactiveCN1687174ABroaden the field of applicationStability has no effectWater contentSodium metabisulfite

The method for removing free formaldehyde from hydroxy acrylic acid modified amino resin includes the following steps: adding the hydroxy acrylic acid modified amino resin into reactor, regulating pH value to 6.5-7.5; drop-adding sodium bisulfite or sodium pyrosulfite saturated aqueous solution into the above-mentioned amino resin, drop-adding time is 0.5-1 hr, controlling material temperature at 60-70 deg.C; the drop-addition is completed, controlling temperature at 60-70 deg.C and making reaction for 0.5-1 hr, adding dewatering agent and antipolymerizer, heating to boiling, constant boiling distillation to remove water content; separating out affixture of sodium bisulfite and formaldehyde and unreacted sodium sulfite crystal, using precipitation filtration method to remove crystal, reduced pressure distillating filtrate to remove dewatering agent so as to obtain the hydroxy acrylic acid modified amino resin whose free formaldehyde content is less than 0.05%.

Owner:HUNAN UNIV

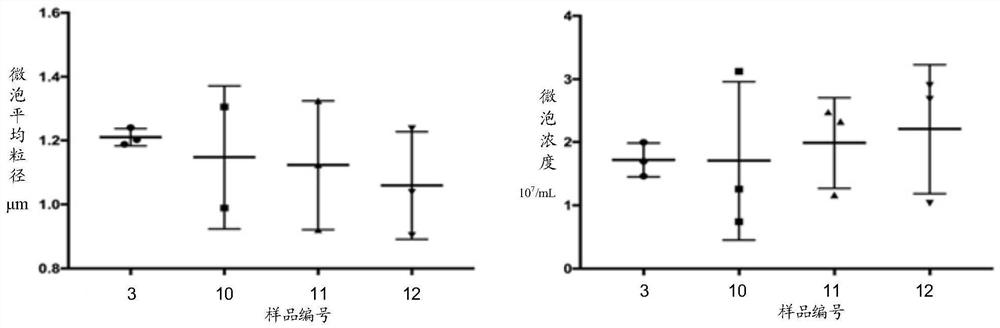

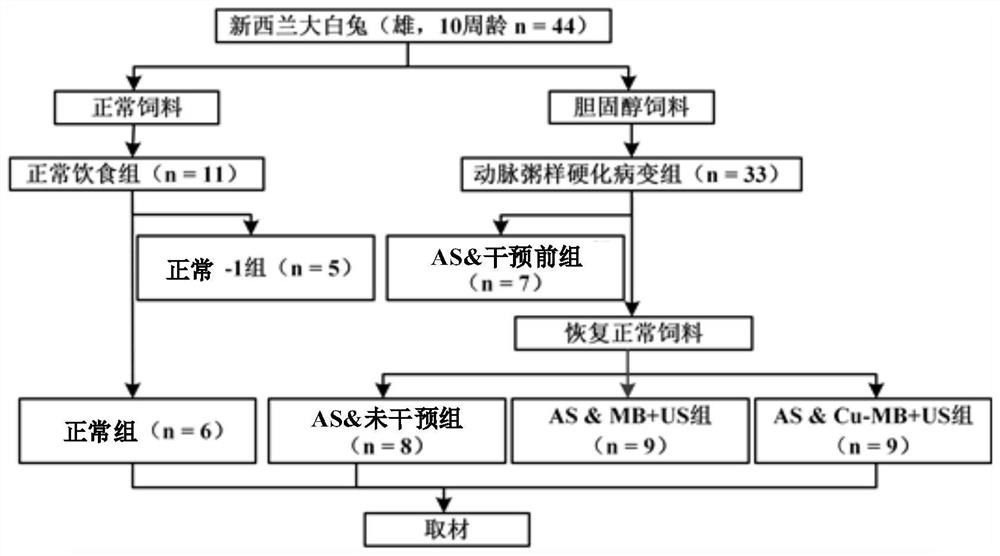

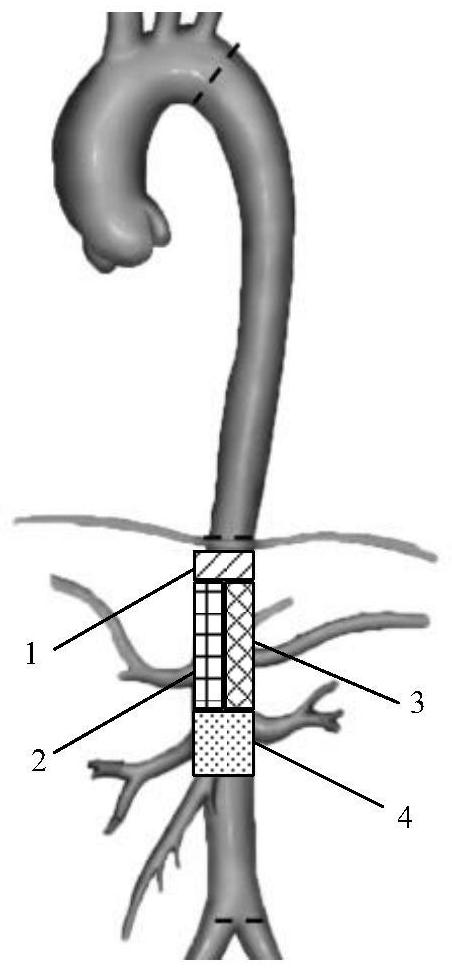

Pharmaceutical application of composition for treating atherosclerosis

PendingCN111991420AReduce areaReduce volumeInorganic active ingredientsMacromolecular non-active ingredientsCu2 ionsPlaque area

The invention discloses pharmaceutical application of a composition for treating atherosclerosis. The invention particularly relates to an application of a composition containing microbubbles and copper ions in preparation of a medicine for treating atherosclerosis. When the microbubble and copper ion composition disclosed by the invention is used for treating atherosclerosis, the plaque area is obviously reduced, but plaque fragmentation and shedding are not caused.

Owner:成都因诺科创生物科技有限公司

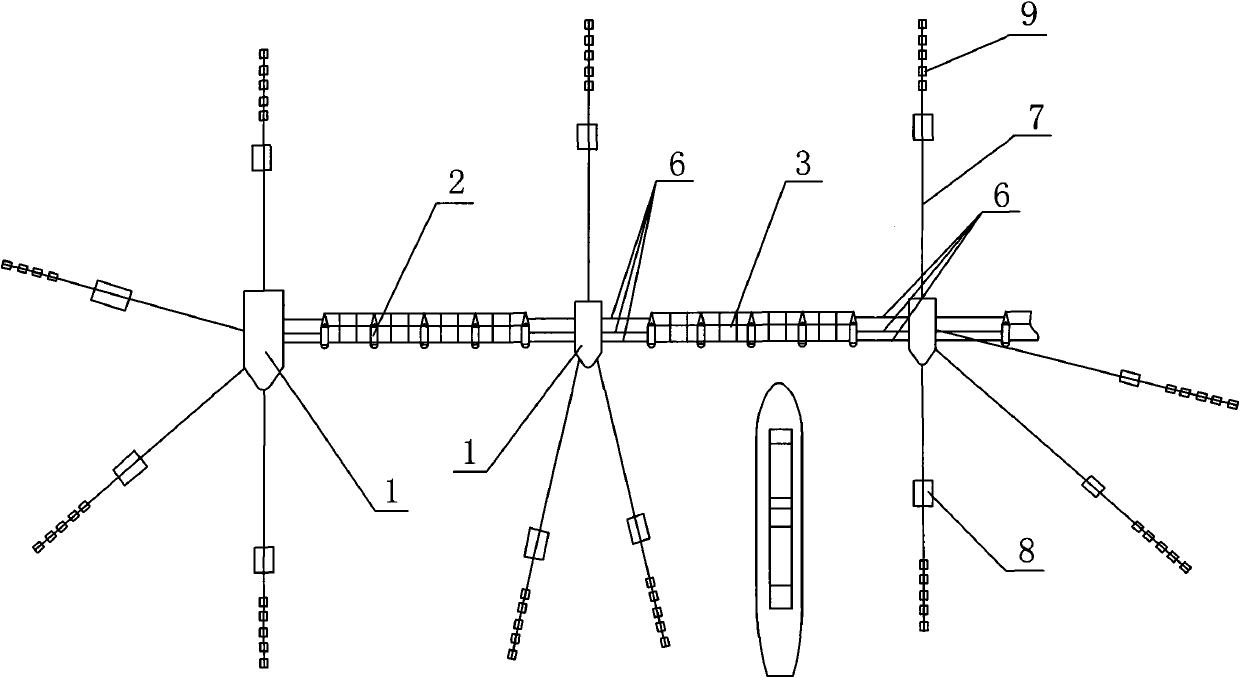

Self-adaptive ship-intercepting method

ActiveCN101793017BOvercome failureUnlimited lengthClimate change adaptationShipping equipmentBuoyEngineering

The invention discloses a self-adaptive ship-intercepting method. The method has the following advantages that: the method overcomes the problem that because buoys and intercepting cables can be pressed into water by ships in the past, the anti-collision intercepting facilities can fail; moreover, because buoys and intercepting nets normally horizontally float on the water surface and the lengthsof the buoys and the intercepting nets do not have affection on the stability of the whole system, the lengths of both the buoys and the intercepting nets are not limited, thereby the intercepting effect is ensured, and moreover, when the intercepting system used in the method normally horizontally floats on the water surface, sight on the sea surface cannot be affected; in addition, the intercepting system used in the method has the advantages of low construction cost, high economical efficiency, long service life and convenient replacement and maintenance; and moreover, the method can be flexibly transported to different places for use, and can change the arrangement position of the intercepting system.

Owner:NINGBO UNIV

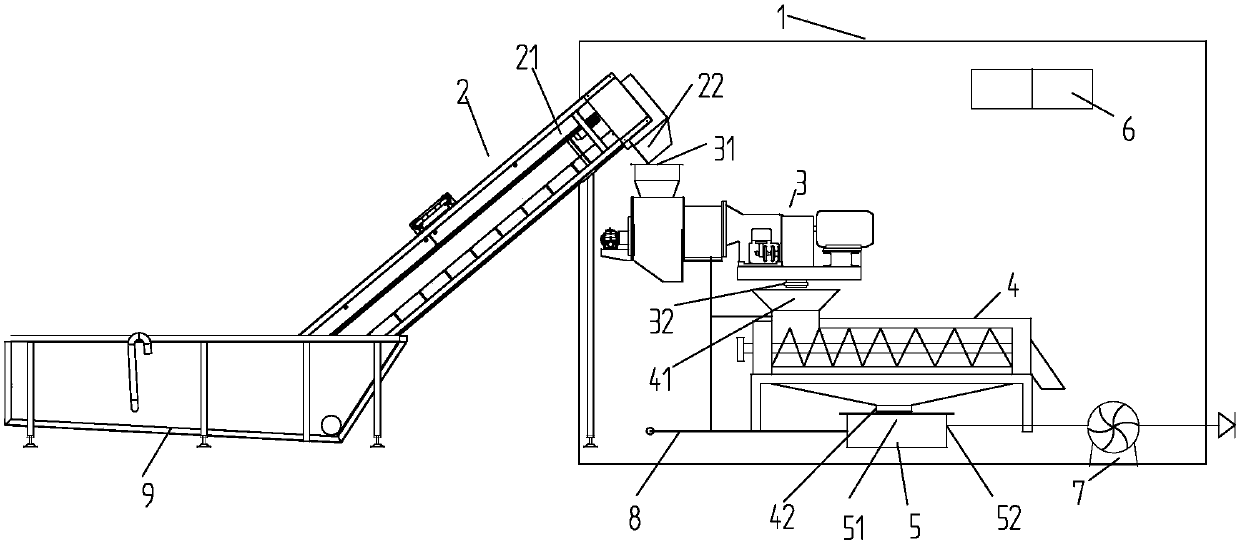

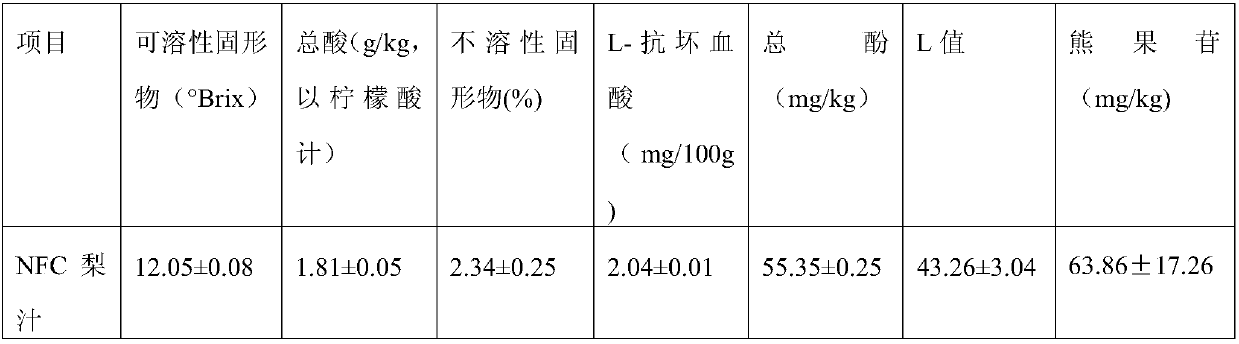

Low-temperature low-oxygen preprocessing method for making NFC pear juice

PendingCN108013297AReduce browningEnhance sensory quality and nutritional valueJuice extractionFood thermal treatmentPear juiceMashing

The invention relates to a low-temperature low-oxygen preprocessing method for making NFC (Not From Concentrate) pear juice. The method comprises the following steps of pretreating raw materials; performing low-temperature low-oxygen cold mashing; performing low-temperature low-oxygen squeezing; performing homogenizing; performing sterilization; and performing refrigeration, wherein low-temperature low-oxygen condition lies in that the temperature is controlled to be 10 DEG C or below, and the content of dissolved oxygen in materials is controlled to be 0.3-2.5mg / L. Low-temperature low-oxygencold mashing and low-temperature low-oxygen squeezing are adopted, so that polyphenol content in products can be reserved to the maximum extent, and loss caused by brown stains can be avoided. The processing technology of the pear juice is simplified, few processing courses of the NFC pear juice are realized, the method is convenient to operate and easy to control, and technique popularization andutilization are facilitated.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

Integrated multi-axis synchronous motion control system and synchronous control method

ActiveCN112994532BLow costHigh degree of autonomyElectronic commutation motor controlElectric motor controlCurrent loop controlSynchronous control

The invention discloses an integrated multi-axis synchronous motion control system and a synchronous control method. The control system includes a feedback sampling module and an active module, the feedback sampling module is used to sample the operating current and operating position of the multi-axis servo motor, the main control module includes a SoC system, and the SoC system receives the feedback The sampling results of the sampling module are used for the feedback position detection and calculation of the multi-axis servo motor, the feedback current detection and calculation, and the realization of multi-axis synchronous current loop control, multi-axis timing synchronous scheduling and multi-axis response synchronous control. The invention solves the problem of poor synchronization performance, high cost, low degree of autonomy of core technology, non-whole-process timing-level synchronization, poor response-level synchronization, serious impact on system stability, low versatility, and computational complexity of existing multi-axis synchronous motion control methods. complicated issues.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

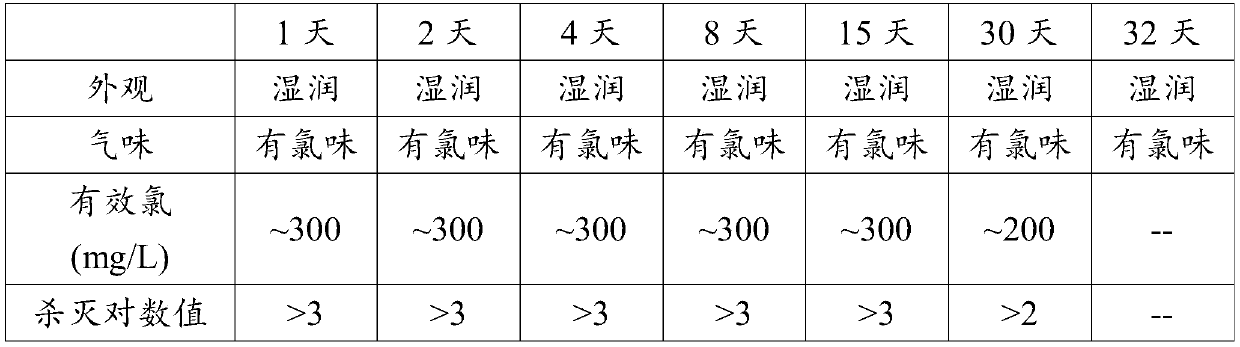

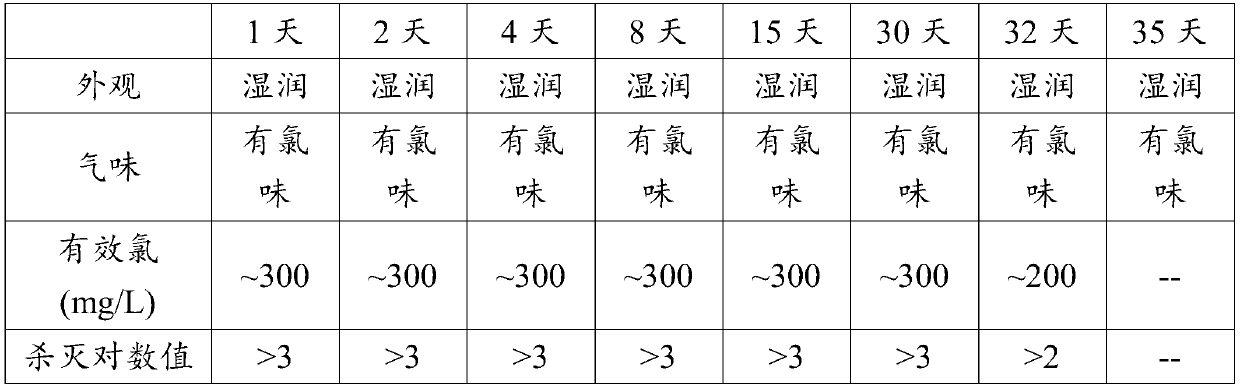

Disinfectant and preparation method and application thereof

ActiveCN111493091AStay hydratedExtended use timeBiocideGaseous substancesPolyvinyl alcoholDisinfectant

The invention provides a disinfectant and a preparation method and application thereof, the disinfectant is gel-like, water is used as a solvent, and the disinfectant comprises or is prepared from thefollowing raw materials: 10-30 wt% of sodium hypochlorite, 2-10 wt% of polyvinyl alcohol and the balance of an additive. The disinfectant provided by the invention has high stability, can realize continuous, effective and slow release of available chlorine, has a good air disinfection effect, and especially has a good disinfection effect on suspended bacteria and / or viruses in air. Moreover, thedisinfectant provided by the invention is simple and convenient to use.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Centella total glycoside cataplasm and preparation method thereof

InactiveCN103356508ALarge drug loading capacity in matrixComfortable to useMacromolecular non-active ingredientsDermatological disorderChemistryKeloid

The invention aims to disclose centella total glycoside cataplasm and a preparation method thereof. The centella total glycoside cataplasm comprises the following components in percentage by weight: 5.0%-8.0% of sodium polyacrylate, 0.5%-0.8% of gelatin, 7.0%-10.0% of sorbitol, 1.5%-2.5% of PVP (polyvinylpyrrolidone), 20.0%-40.0% of glycerinum, 0.3%-0.6% of titanium dioxide, 2.0%-4.0% of beta-cyclodextrin, 0.15%-0.4% of tartaric acid, 2.0%-5.0% of centella glycoside powder, 0.05%-0.25% of dihydroxyaluminium aminoacetate and 61.5%-28.45% of purified water. Compared with the prior art, the centella total glycoside cataplasm has the characteristics of being large in drug loading capacity, convenient to use, etc, overcomes the inconvenience caused by pollution to clothes in use, and is suitable for treating trauma, operative wound, burn, keloid and scleroderma, therefore, the aim of the invention is realized.

Owner:上海卫生材料厂有限公司

Toughening and anti-channeling agent for cement and toughening cement for shale gas horizontal well cementing

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

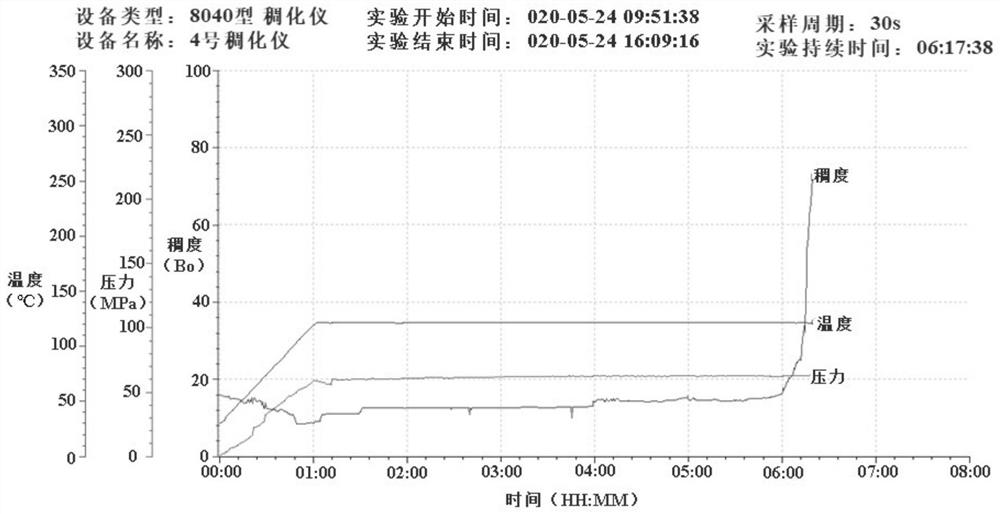

High-temperature retarder for well cementation and preparation method thereof

ActiveCN111825788AInhibition of hydrationRetarding controllableDrilling compositionPolymer scienceFunctional monomer

The invention discloses a high-temperature retarder for well cementation and a preparation method thereof. The retarder comprises a polymeric monomer, and the required retarder can be obtained throughpolymerization and hydrolysis of an aqueous solution of the polymeric monomer. The polymeric monomer comprises the following components in percentage by mass: 20-40% of a nonionic amide monomer, 20-40% of an anionic sulfonic acid monomer and 30-50% of a functional monomer; the retarder disclosed by the invention is controllable in retarding, adjustable in retarding time within the range of 90-240DEG C for 2-12 hours and excellent in temperature resistance, and the highest temperature resistance can reach 240 DEG C; the salt resistance is excellent, and the rheological property, the stability, the water loss and the strength of a well cementation cement paste system are not influenced.

Owner:北京普斯维斯石油技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com