Integrated multi-axis synchronous motion control system and synchronous control method

A technology of motion control and multi-axis synchronization, applied in control systems, vector control systems, motor control, etc., can solve problems such as low degree of autonomy of core technologies, poor synchronization of response levels, and influence on system stability, and achieve core technology autonomy The effect of high degree of automation, strong versatility, and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

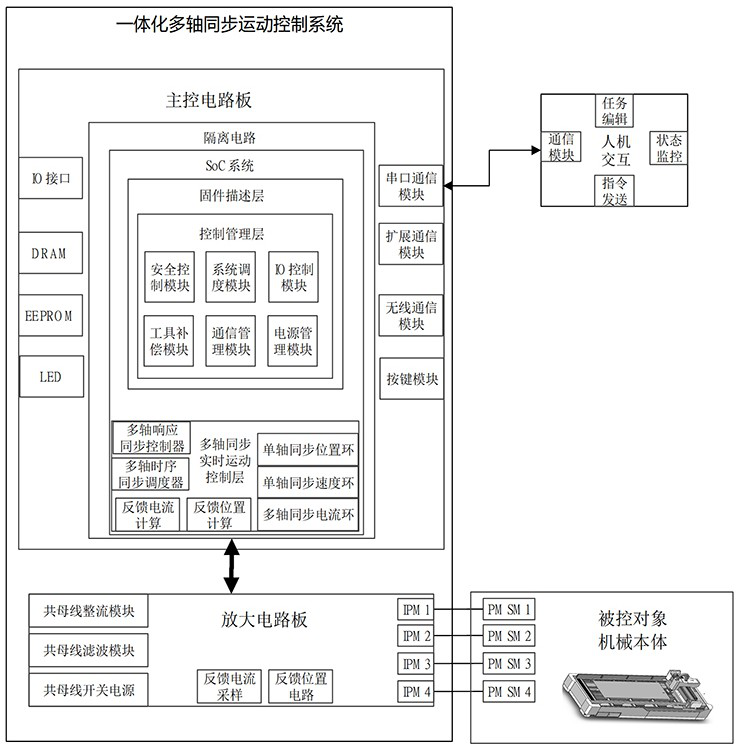

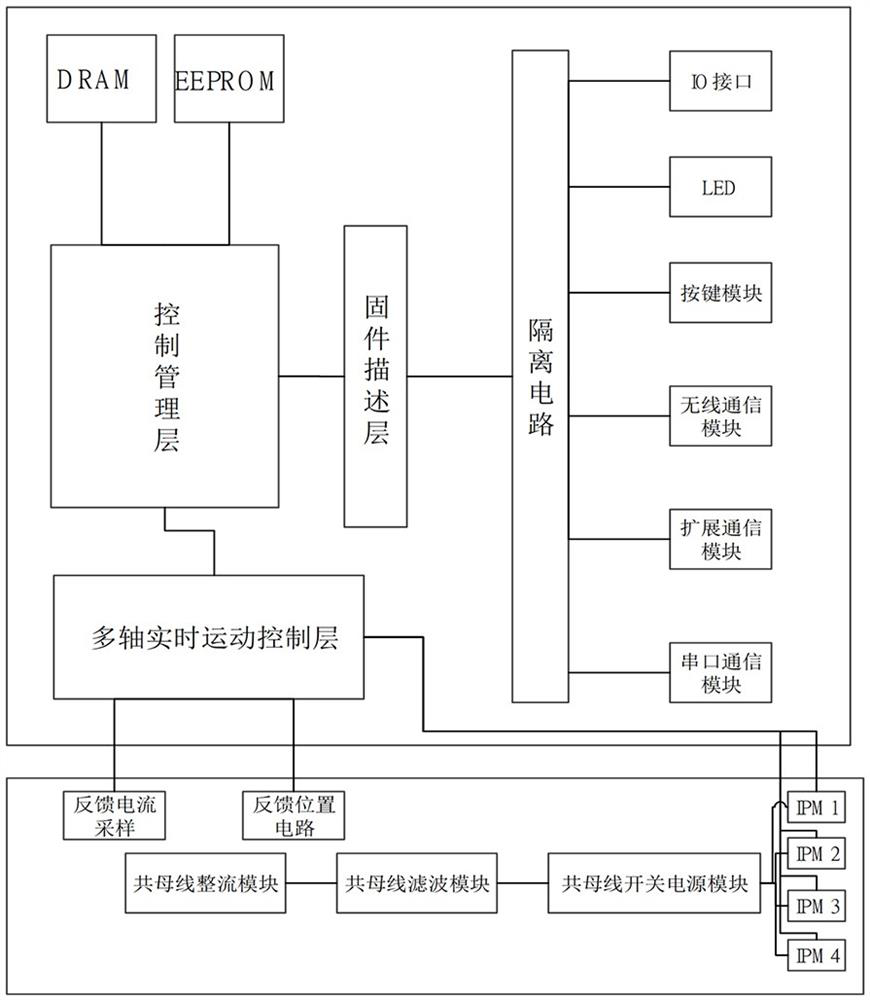

[0025] Example 1 as figure 1 As shown, an integrated multi-axis synchronous motion control system is mainly composed of a feedback sampling module and a main control module. The main control module is set on the main control circuit board, and the feedback sampling module is set on the amplification circuit board. The feedback sampling module samples the running current and running position of the multi-axis servo motor, and the sampling result is input into the main control module, which is used to realize multi-axis synchronous current loop control, multi-axis timing synchronous scheduling and multi-axis response synchronous control.

[0026] Wherein, the main control module includes IO interface circuit, DRAM memory, EEPROM memory, LED display module, serial port communication module, expansion communication module, wireless communication module, button module, isolation circuit and SoC system.

[0027] The IO interface circuit, LED display module, serial port communication...

Embodiment 2

[0031] Embodiment 2 A multi-axis synchronous motion control method includes the following steps:

[0032] Multi-axis synchronous current loop control, multi-axis timing synchronous scheduling, multi-axis response synchronous control.

[0033] Among them, multi-axis synchronous current loop control includes single-axis high-speed current loop control and multi-axis parallel pipeline synchronous current loop scheduling.

[0034] The single-axis high-speed current loop control adopts the space vector control method with PI regulator combined with parallel computing and serial computing. This method can maximize the computing speed of the controller and save computing resources, including:

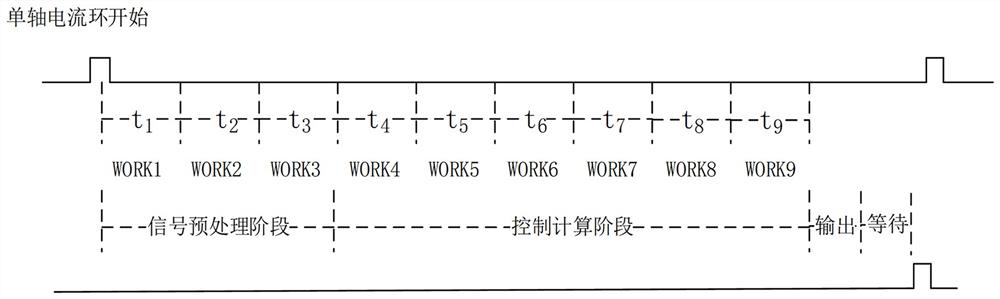

[0035] Single-axis signal preprocessing stages, such as image 3 As shown, the entire current loop control sequence occupies the first-third time period (t 1 -t 3 ), including feedforward current reading, speed loop generated current reading, feedback current sampling, encoder position samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com