Toughening and anti-channeling agent for cement and toughening cement for shale gas horizontal well cementing

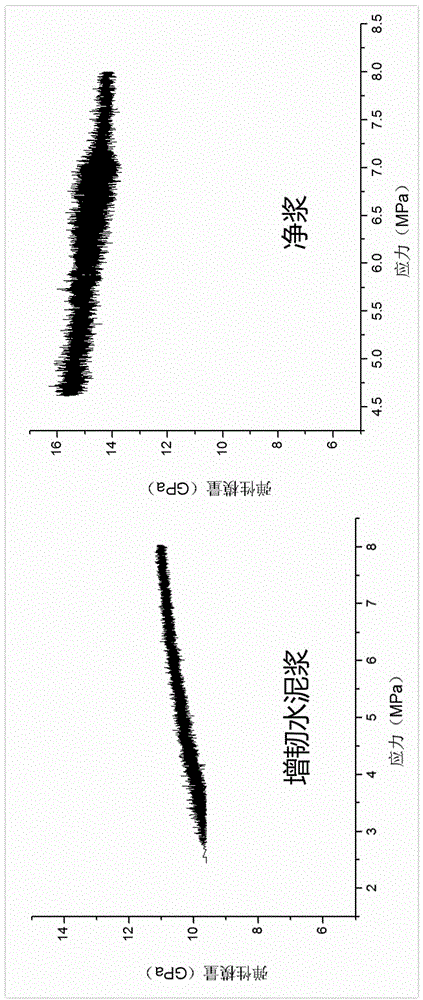

An anti-channeling agent and shale gas technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of cement slurry stability, fiber strength, and inability to significantly improve defects, etc., to achieve anti-corrosion No impact on compressive strength, good anti-channeling performance, and reduced elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Prepare a silane coupling agent aqueous solution with a mass percentage of 1.5%, add 100 mesh styrene-butadiene rubber powder to it, filter and dry after 24 hours to obtain treated styrene-butadiene rubber powder.

[0029] 2. Mix VAE emulsion and polyvinyl alcohol glue at a mass ratio of 2.5:1 and dry to obtain redispersible latex powder.

[0030] 3. Mix the above treated styrene-butadiene rubber powder with redispersible latex powder at a mass ratio of 2:1 to obtain a toughening and anti-channeling agent for cement.

Embodiment 2

[0032] Weigh 100 parts by weight of grade G high-resistance oil well cement, 0.7 parts by weight of drag reducer, and 3.0 parts by weight of toughening and anti-channeling agent for cement, and dry mix them into a dry powder mixture. Measure 37.5 parts by weight of water, 6.0 parts by weight of fluid loss reducer, 2.0 parts by weight of early strength agent, and 0.2 parts by weight of defoamer and mix them into a solution. The dry powder mixture and the solution are mixed and stirred to prepare a toughened anti-channeling low-permeability cement slurry. The applicable temperature of the cement slurry in this embodiment is 60°C.

Embodiment 3

[0034] Weigh 100 parts by weight of grade G high-resistance oil well cement, 0.7 parts by weight of drag reducer, and 3.0 parts by weight of toughening and anti-channeling agent for cement, and dry mix them into a dry powder mixture. Measure 39.4 parts by weight of water, 6.0 parts by weight of fluid loss reducer, 1.0 part by weight of early strength agent, 1.0 part by weight of retarder, and 0.2 part by weight of defoamer and mix them into a solution. The dry powder mixture and the solution are mixed and stirred to prepare a toughened anti-channeling low-permeability cement slurry. The applicable temperature of the cement slurry in this embodiment is 100°C.

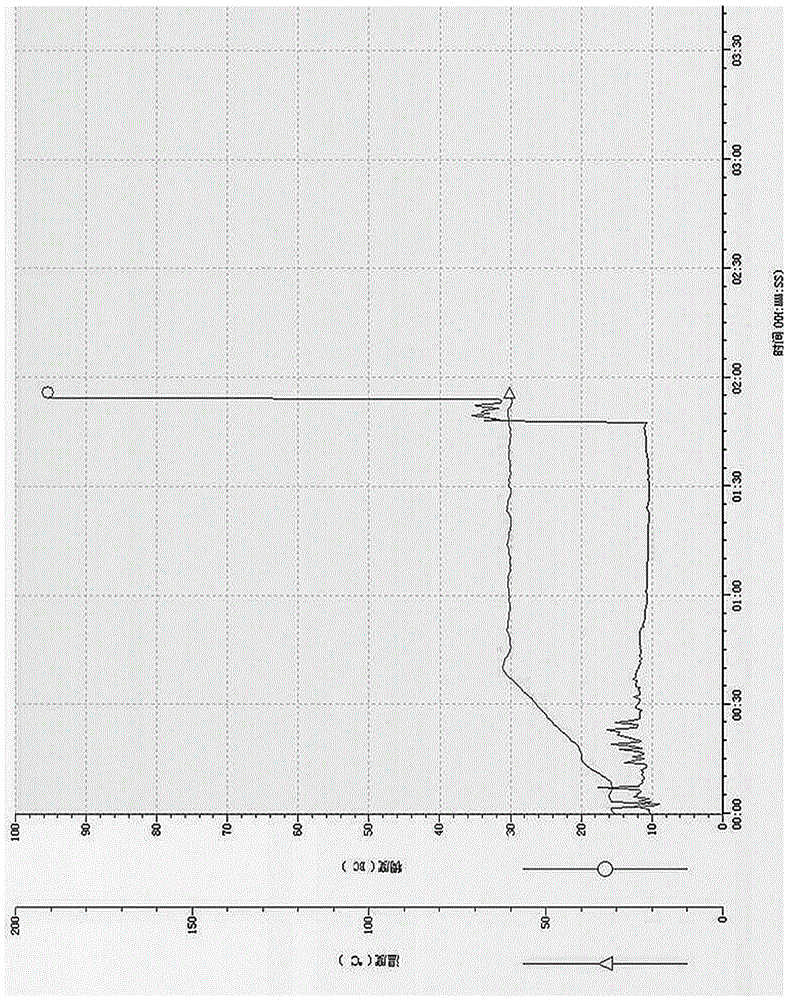

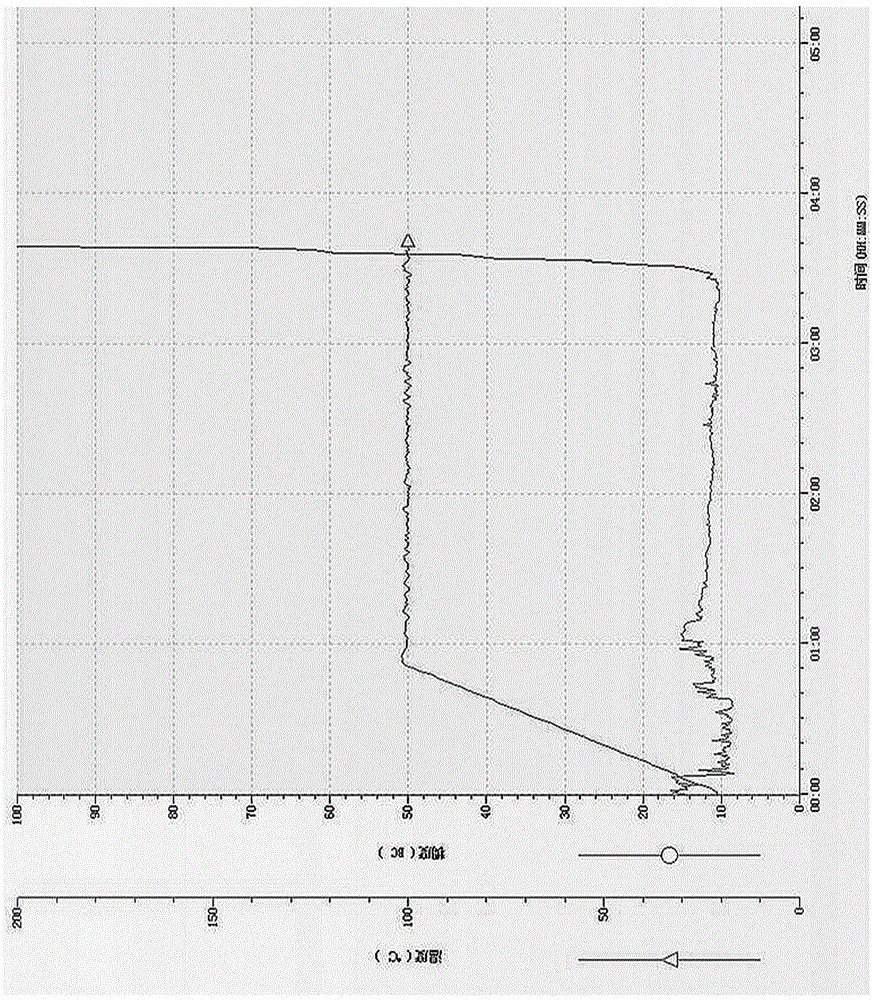

[0035] Table 1 is the comprehensive performance of above-mentioned embodiment cement slurry, figure 1 , figure 2 Be the thickening curve of embodiment. It can be seen from the table and figure that the cement slurry system has high compressive strength, good settlement stability, extremely low water loss, zero free li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com